EP1243441A2 - Vorrichtung und Verfahren zum binden von Druckprodukten - Google Patents

Vorrichtung und Verfahren zum binden von Druckprodukten Download PDFInfo

- Publication number

- EP1243441A2 EP1243441A2 EP02006540A EP02006540A EP1243441A2 EP 1243441 A2 EP1243441 A2 EP 1243441A2 EP 02006540 A EP02006540 A EP 02006540A EP 02006540 A EP02006540 A EP 02006540A EP 1243441 A2 EP1243441 A2 EP 1243441A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- book

- spine

- gripping device

- signature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims description 15

- 238000004519 manufacturing process Methods 0.000 claims description 2

- 239000000853 adhesive Substances 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 3

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 230000003993 interaction Effects 0.000 description 3

- 239000003292 glue Substances 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 241000208199 Buxus sempervirens Species 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 210000003746 feather Anatomy 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42C—BOOKBINDING

- B42C11/00—Casing-in

- B42C11/02—Machines or equipment for casing-in or applying covers to pamphlets, magazines, pads, or other paper-covered booklets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H39/00—Associating, collating, or gathering articles or webs

- B65H39/02—Associating,collating or gathering articles from several sources

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/30—Orientation, displacement, position of the handled material

- B65H2301/36—Positioning; Changing position

- B65H2301/361—Positioning; Changing position during displacement

- B65H2301/3613—Lateral positioning

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/43—Gathering; Associating; Assembling

- B65H2301/432—Gathering; Associating; Assembling in pockets, i.e. vertically

- B65H2301/4321—Gathering; Associating; Assembling in pockets, i.e. vertically and dropping material through bottom of the pocket

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2405/00—Parts for holding the handled material

- B65H2405/50—Gripping means

Definitions

- the present invention relates to binding in general and in particular to one Device and method for preparing a printed product or spine for binding.

- the back of the book is formed so that the bottom edges are aligned.

- the back is flat when using a book straight back should be made. If signatures and not individual sheets are gathered, the back of the book is usually sawn in so that individual sheets in every signature on the back are accessible.

- US 4,925,354 and 4,556,353 disclose methods of applying an adhesive the back of a book.

- the book is gripped from above by clamps, to expose the back of the book.

- the back of the book is flat and has one Length that is greater than the width of the back. While the back is in one Moved parallel to the length of the back, an adhesive is rolled or Applicators applied.

- U.S. Patent Application No. 09 / 570,201 addresses some of the previously known problems by proposing a construction that is perpendicular to the back in pockets transported books were clamped by two separate clamping devices. On individual sideways alignment of the signatures was not intended.

- An object of the present invention is to provide a method and an apparatus for Prepare to propose a spine, with the book perpendicular to the long edge the back is transported

- this object is achieved by a method with the features according to Claim 1 and a device with the features according to claim 8 solved.

- the present invention thus provides a method of making a spine ready, taking a variety of products from a bag to a back stop be fed.

- a single gripping device can be used to squeeze the book together.

- the gripper gives the book then free again.

- a back of the bag and the back stop will be lowered with respect to the gripping device to define an exposure of the back.

- the gripper restores the book to expose the back receive.

- the back stop is moved away from the book spine, and the gripping device is rotated to change the back angle.

- the back can then be worked on be, for example by sawing.

- Signatures as defined herein can be single sheets and / or multi-sheet signatures include.

- the rotation is preferably done by holding a lower one Section of the signatures between a rotatable clamp and the Gripping device, which are then each rotated about a corresponding pivot point.

- the spine After processing, the spine can be returned to a starting position become. After that, an upturned book cover can be added and the procedure be repeated to glue the back to the book cover for example prepare.

- the gripping device is opened, and the books can fall onto a conveyor by gravity or they can be removed from a gripper conveyor.

- the incoming signature is preferred kept separate from the previously collected signatures and on the side aligned. As soon as the incoming signature in the correct lateral position on Back stroke is applied, the incoming signature on the previously gathered Signatures are on.

- the present invention therefore also provides a method for collecting signatures ready at a back stop. At least one first signature of a pocket is used fed, which then on an angled shelf and on a back stop lies, further at least a second signature of the bag is supplied, the second signature is kept separate from the first signature at an upper portion and touched the first signature on the back stop.

- a vibrating device is preferably provided so that the individual incoming ones Signatures can be moved sideways. This allows different product sizes be aligned correctly in the lateral direction.

- a gripping device and a back stop are advantageously in each pocket a lower end of the pocket provided for receiving the back.

- the Back stop is movable from a first collecting position and into a second position, in which the back stop with respect to the gripping device is lower than in Collection position is arranged.

- the flat surface of the back is in the second position parallel to the flat surface of the back in the first position. In a third position the back stop can be turned away from the back.

- the gripping device works with a clamping device under the Back together.

- the gripping device holds a lower section of the products against the clamping device.

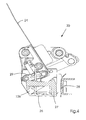

- an operating lever for performing a Gripping process and for a tighter grip when turning the spine intended.

- a locking device can be provided for the back stop, as can a Lever and a locking device for the shelf. Can also use a tension pulley and a wheel can be provided for the height of the storage surface.

- the back and the back stop form preferably an angle with the vertical plane.

- the pockets preferably each contain at least one closure element, around one keep incoming signature separate from already collected signatures.

- the closure element can then be withdrawn, for example by turning it the incoming signature can rest completely on the collected signatures.

- the Closing element therefore enables the signature to be fed on a vertically guided one Web until the lower edge of the signature is led to the back stop.

- the signature is held in a position in which its shorter lower section is angled and the longer upper section on one side of a vertical guide and on the other side is held by the closure elements. In the middle of the signature creates a curved section that provides stability along the direction of the back contributes.

- a vibrating element of the vibrating device can be just above the bend on the vertical section of the signature, initiate the signature to correct the signature to move laterally along the direction of their back.

- the Gripping device can then close against the lower ends of all signatures, and the Closure elements can be pivoted out of the vertical path, which means that Signature can rest on the previously collected signatures.

- the locking devices, levers and rollers, as well as all movements of the Parts of the bag can be operated by cams.

- book can be any type of sheet or signature composition include, in particular also printed products with cover, paper brochures and Count magazines.

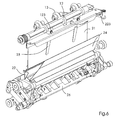

- Fig. 1 shows a side view of the device 1 for preparing a book according to the present invention.

- a signature stack 2 is located above a variety of Compilation devices 5 which move in a direction 6.

- each Compilation device 5 has a band 7 which is in a direction opposite to that Clockwise runs so that an upper section of the tape is at one speed

- the order of magnitude is that of the assembly devices 5 in the direction 6 like.

- the signature stack 2 therefore experiences a relative speed of zero and remains in the position shown in Fig. 1, while the collating devices 5 themselves move towards 6.

- Each assembly device 5 also comprises a rotatable suction device 9, for example a vacuum suction cup that can be rotated around a pivot point.

- a rotatable suction device 9 for example a vacuum suction cup that can be rotated around a pivot point.

- the pulls Suction device 9 of the compilation device 5 a lower signature of the Signature stack for performing between the compilation devices 5 after below.

- a scanning or sprung roller 13 of the assembly device 5 is opened (by rotating the shaft against the spring force) so that the front edge of the Signature between the scanning roller 13 and a drive roller 12 can enter.

- the signature goes into a pocket 20 of a plurality of pockets 20 that are put together with the assembly devices 5 moved in the direction 6.

- the signature goes into pockets 20 a vibrating device 21 with a vibrating element 22, closure elements 23 and one Back 24.

- the back 24 is attached to a rotary support 25, the one Back stop 26, which in turn carries the lower edges of the incoming signatures holds.

- the back stop 26 forms a perpendicular surface to the back 24, the preferably offset from the vertical by 30 degrees.

- the lower edges of the signatures can be between a clamping device 27 and a Gripping device 28 are clamped, as described below.

- the Clamping device 27 and gripping device 28 generally remain in one same height.

- a shelf lever 29 actuated by cams may be the rear 24 and the back stop 26 with respect to the clamping device 27 and the gripping device 28 lower.

- the back stop 26 comprises a series of Fingers that are with recesses in the lower surfaces of the clamping device 27 and interlock the gripping device 28 to exclude continuous gaps at the corners.

- the assembly devices 5 and the pockets 20 can be on one or both Sides attached to a frame moving along an endless track, for example in a loop.

- Fig. 2 shows one of the pockets 20 in the normal or initial feed position Inclusion of the signatures from the stack 2, as by the section designation A in Fig. 1 is shown.

- the back 24 is held on a pad 124 in the one Pivot 125 is mounted.

- the back stop 26 is connected to the pivot point 125 and can thereby rotate downwards when a spring locking device 126 is released 4 as shown in FIG. 4 and indicated at station E in FIG.

- the clamping device 27 and the gripping device 28 are in the frame of the pocket 20 held.

- the clamping device 27 has a first position, which is shown in FIG. 2 and in FIG. 3 and a second position in which it is rotated downward, as in FIG. 4 is shown and indicated at station E in FIG. 1.

- the gripping device 28 has one open position for receiving signatures, as indicated at station A in FIG. 1, a closed position for pressing signatures onto the clamping device 27, as shown at station B in FIG. 1 and a rotated position as at station E in FIG. 1 and shown in Fig. 4.

- a vibrating device 21 can also be used an element 22 on each incoming signature while the gripping device 28 is open, the closure elements 23 holding the upper edge of the signature, so that the top edge maintains a generally vertical position.

- Element 22 can hit the signature just above the bend on the vertical top section, to move the signature sideways.

- the gripper 28 may close, as shown in section B in FIG Get alignment.

- the closure elements 23 by means of a cam working on a cam roller 223 about a pivot point 123 be rotated.

- the upper portion of the incoming signature with the already collected signatures so that a book with forms correct alignment.

- the back will be used to prepare the Further processing exposed by lowering the storage area.

- the gripping device 28 opens, and the rear 24 and the Back stop 26 are with respect to the frame and the clamping device 27 and Gripping device 28 lowered down to a portion of the back below the Expose gripping device 27 and the clamping device 28.

- the lowering takes place by releasing a shelf locking device by a Lock lever 128 as shown in FIGS. 2 and 3.

- the scope of the Exposure can be changed by adjusting a cam that interacts with the Roll 129 stands (Fig. 2 and Fig. 3), the shelf lever 29 and thereby the height of the Back 24 and the back stop 26 checked.

- the gripper 28 is then closed on the book to expose it and the back stop 26 is released by loosening the one shown in FIG Backstop locking device 126 rotated downwards.

- the back 24 is in their lower or lowest position lowered.

- the clamping device 28 is made by rolling 131 (Fig. 6) rotated, which are in interaction with a cam track to the Align the bottom section of the book vertically and your back horizontally Present cutting.

- the cams interact against the force of one Tension torsion spring 134.

- rollers of the gripping device are in Interaction with opposing cams that compress springs 132 on the gripping device assemblies, which is why the gripping device 27 a can exert greater holding force for holding the book against the clamping device 28.

- An operating lever 130 of the gripping device as shown in FIG. 5 becomes to be operated the gripping device when the lever is depressed (as shown), and compresses the springs when it is raised. By using the interaction Between the spring and the cam, great reaction forces on the pocket seem to be avoided become. Then, as shown at section E in Fig. 1, the spine of the book is closed Further processing ready in this embodiment for sawing the back. The height The back 24 (and therefore the book) and the saws can cut the position determine.

- step F becomes firmer by one set Cam returned to its starting position.

- the back stop 26 will closed and raised with the back 24 until the back stop 26 den Spine touches.

- the gripping device 27 is opened, and the rear 24 and the Back stop 26 are in the starting position or in the fully raised position, in the respective locking devices 128 and 126 the rear 24 and the stop 26 lock.

- An envelope can then be added to the book at station F of FIG.

- the Lowering the counter surface is repeated to the cropped back and the Expose the uncut envelope at the bottom of the book as shown in step G. is.

- Glue can then be applied to the back surface using an adhesive roller which turns under the pockets and at coordinated speeds tangentially.

- the book with the cover turned over is released by the Gripping device 28 and the clamping device 27 returned parallel to the rear 24 and the gripper cam is opened. This allows the book, as in Step H shown, passed on from the gripping device to a conveyor a gripper conveyor or a belt.

- the components of the bag are then turned by turning the back stop and Raise the back and back stop to the raised position returned in which they are found.

- a gripping device as defined herein can be any device that starts at bow. All movements of the different parts the pockets can be triggered by fixed cams.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Collation Of Sheets And Webs (AREA)

- Pile Receivers (AREA)

- Basic Packing Technique (AREA)

- Feeding Of Articles By Means Other Than Belts Or Rollers (AREA)

Abstract

Description

- 1

- Vorrichtung zum Vorbereiten eines Buchrückens

- 2

- Signaturenstapel

- 5

- Zusammenstell-Einrichtungen

- 6

- Richtung

- 7

- Band

- 9

- Ansaugvorrichtung

- 12

- Antriebswalze

- 13

- Abtastwalze

- 20

- Taschen

- 21

- Rüttelvorrichtung

- 22

- Rüttelelement

- 23

- Verschlusselement

- 24

- Rückseite

- 25

- Drehauflage

- 26

- Rückenanschlag

- 27

- Klemmvorrichtung

- 28

- Greifvorrichtung

- 29

- Ablagefläche-Hebel

- 123

- Drehpunkt

- 124

- Auflage

- 125

- Drehpunkt

- 126

- Rückenanschlag-Feststellvorrichtung

- 128

- Feststellvorrichtungshebel

- 129

- Rolle

- 130

- Bedienungshebel

- 131

- Rollen

- 132

- Federn

- 134

- Spann-Torsionsfeder

- 223

- Kurvenrolle

Claims (14)

- Verfahren zum Herstellen eines Buchrückens, wobei eine Vielzahl von Produkten einer Tasche (20) bis an einen Rückenanschlag (26) zugeführt wird, um ein Buch mit einem Rücken zu formen;

gekennzeichnet durch

folgende Schritte:Transportieren des Buchs in einer Richtung 6 senkrecht zum Rücken;Greifen des Buchs mit einer Greifvorrichtung (28);Lösen der Greifvorrichtung (28) von dem Buch; undAbsenken des Rückenanschlags (26) relativ zur Greifvorrichtung (28), um den Rücken zugänglich zu machen. - Verfahren nach Anspruch 1,

dadurch gekennzeichnet, dass die Greifvorrichtung (28) nochmals an das Buch angestellt wird, um die Zugänglichkeit des Rückens zu fixieren. - Verfahren nach Anspruch 1,

dadurch gekennzeichnet, dass der Rückenanschlag (26) vom Rücken wegbewegt wird, und die Greifvorrichtung (28) zum Drehen eines unteren Endes des Buchs gedreht wird. - Verfahren nach Anspruch 1,

dadurch gekennzeichnet, dass nach dem Zugänglichmachen des Rückens der Rücken bearbeitet, insbesondere gesägt wird. - Verfahren nach Anspruch 4,

dadurch gekennzeichnet, dass der Buchrücken nach dem Bearbeiten in eine Ausgangsposition zurückgeführt wird. - Verfahren nach Anspruch 1,

dadurch gekennzeichnet,

ein in die Tasche (20) einlaufendes Produkt von den bereits in der Tasche (20) befindlichen Blättern getrennt gehalten wird. - Verfahren nach Anspruch 6,

welches ferner ein seitliches Ausrichten der einlaufenden Signatur umfasst. - Vorrichtung zum Bearbeiten eines Buchrückens insbesondere zum Vorbereiten für das Klebebinden mit einer Vielzahl bewegbarer Taschen (20), einer Greifvorrichtung (28) und einem Rückenanschlag (26) an einem unteren Ende der Tasche (20),

dadurch gekennzeichnet, dass jede der Taschen (20) eine abgewinkelte Rückseite (24) aufweist und der Rückenanschlag von einer Sammelposition in eine Freigabeposition bewegbar ist. - Vorrichtung nach Anspruch 8,

dadurch gekennzeichnet, dass jede Tasche (20) eine Klemmvorrichtung (27) unter der Rückseite (24) aufweist, wobei die Greifvorrichtung (28) einen unteren Abschnitt der Produkte an die Klemmvorrichtung (27) halten kann. - Vorrichtung nach Anspruch 8 oder 9,

dadurch gekennzeichnet, dass jede Tasche (20) ferner einen Bedienungshebel 130 für die Greifvorrichtung (28) zur Vornahme eines Greifvorgangs umfasst. - Vorrichtung nach einem der Ansprüche 8 bis 10,

dadurch gekennzeichnet, dass jede Tasche (20) ferner ein Ablagehöhe-Rädchen zum Einstellen einer Höhe der Rückseite (24) umfasst. - Vorrichtung nach einem der Ansprüche 8 bis 11,

dadurch gekennzeichnet, dass jede Tasche (20) mindestens ein einziehbares Verschlusselement (23) umfasst, um eine einlaufende Signatur von bereits gesammelten Signaturen getrennt zu halten. - Vorrichtung nach einem der Ansprüche 8 bis 12,

dadurch gekennzeichnet, dass eine Rüttelvorrichtung (21) zum seitlichen Ausrichten einer einlaufenden Signatur vorgesehen ist. - Eine Tasche zum Sammeln von Signaturen mit einem Rückenanschlag (26) gekennzeichnet durch,

eine abgewinkelten Rückseite (24), mindestens ein Verschlusselement (23), um eine obere Kante einer einlaufenden Signatur von Signaturen getrennt zu halten, die auf der abgewinkelten Rückseite (24) liegen und eine Rüttelvorrichtung (21) zum seitlichen Ausrichten der einlaufenden Signatur.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US814635 | 1992-10-14 | ||

| US09/814,635 US6547501B2 (en) | 2001-03-22 | 2001-03-22 | Device and method for binding printed products |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1243441A2 true EP1243441A2 (de) | 2002-09-25 |

| EP1243441A3 EP1243441A3 (de) | 2004-04-14 |

Family

ID=25215594

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02006540A Withdrawn EP1243441A3 (de) | 2001-03-22 | 2002-03-20 | Vorrichtung und Verfahren zum binden von Druckprodukten |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US6547501B2 (de) |

| EP (1) | EP1243441A3 (de) |

| JP (1) | JP4280454B2 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5356554A (en) * | 1991-11-20 | 1994-10-18 | Lever Brothers Company, Division Of Conopco, Inc. | Bleach catalyst composition, manufacture and use thereof in detergent and/or bleach compositions |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20090269166A1 (en) * | 2008-04-24 | 2009-10-29 | Xerox Corporation. | Method and system for mechanically binding a book spine |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4556353A (en) | 1982-11-10 | 1985-12-03 | Ehlermann Hans Dieter | Process and apparatus for binding books |

| US4925354A (en) | 1989-10-10 | 1990-05-15 | Am International Incorporated | Apparatus and method for applying adhesive to books |

| US4988086A (en) | 1989-01-26 | 1991-01-29 | Am International Incorporated | Apparatus and method for forming sheet material assemblages |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1528349A (en) * | 1922-03-30 | 1925-03-03 | Joseph C Theberath | Signature-stuffing machine |

| US2461573A (en) * | 1945-04-02 | 1949-02-15 | Tw & Cb Sheridan Co | Machine for stuffing newspapers or similar sheet material assemblages |

| US2634971A (en) * | 1949-08-06 | 1953-04-14 | Tw & Cb Sheridan Co | Machine for stuffing newspapers or similar sheet material assemblages |

| US3580563A (en) * | 1969-01-30 | 1971-05-25 | Ernest D Bassett | Collating machine feeding into or out of racks |

| CH594553A5 (de) * | 1976-02-19 | 1978-01-13 | Grapha Holding Ag | |

| CH594552A5 (de) * | 1976-02-19 | 1978-01-13 | Grapha Holding Ag | |

| US4477067A (en) * | 1982-05-10 | 1984-10-16 | Harris Graphics Corporation | Method and apparatus for assembling sheet material assemblages |

| US5082256A (en) * | 1987-12-17 | 1992-01-21 | Am International Incorporated | Method and apparatus for forming sheet material assemblages |

| US5269504A (en) * | 1989-06-10 | 1993-12-14 | Idab Wamac Ab | Insertion of supplements into newspapers |

| CH681448A5 (de) * | 1990-09-12 | 1993-03-31 | Grapha Holding Ag | |

| US5213318A (en) * | 1992-01-02 | 1993-05-25 | Am International Incorporated | Signature gatherer with light detector misfeed sensors |

| EP0712736B1 (de) * | 1994-11-18 | 1999-02-10 | Grapha-Holding Ag | Verfahren zur Herstellung von klebegebundenen Büchern, Broschuren oder dgl. Produkten |

| US6082724A (en) * | 1997-08-01 | 2000-07-04 | Heidelberger Druckmaschinen Ag | Variable speed signature collating apparatus |

| US5921538A (en) * | 1997-10-07 | 1999-07-13 | Heidelberger Druckmaschinen Ag | Apparatus and method for combined gathering and binding of sheet like articles |

| EP0911289B2 (de) * | 1997-10-27 | 2007-03-21 | Grapha-Holding Ag | Verfahren und Herstellung von Druckerzeugnissen durch Einstecken von Teilprodukten und/oder Beilagen in ein Hauptprodukt sowie Vorrichtung zu dessen Durchführung. |

| US6170638B1 (en) * | 1999-05-07 | 2001-01-09 | Graphic Management Associates, Inc. | Stream aligner |

| US6447229B1 (en) * | 2000-05-12 | 2002-09-10 | Heidelberger Druckmaschinen Ag | Device and method for preparing a book spine for binding |

-

2001

- 2001-03-22 US US09/814,635 patent/US6547501B2/en not_active Expired - Fee Related

-

2002

- 2002-03-20 EP EP02006540A patent/EP1243441A3/de not_active Withdrawn

- 2002-03-22 JP JP2002081014A patent/JP4280454B2/ja not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4556353A (en) | 1982-11-10 | 1985-12-03 | Ehlermann Hans Dieter | Process and apparatus for binding books |

| US4988086A (en) | 1989-01-26 | 1991-01-29 | Am International Incorporated | Apparatus and method for forming sheet material assemblages |

| US4925354A (en) | 1989-10-10 | 1990-05-15 | Am International Incorporated | Apparatus and method for applying adhesive to books |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5356554A (en) * | 1991-11-20 | 1994-10-18 | Lever Brothers Company, Division Of Conopco, Inc. | Bleach catalyst composition, manufacture and use thereof in detergent and/or bleach compositions |

Also Published As

| Publication number | Publication date |

|---|---|

| US6547501B2 (en) | 2003-04-15 |

| EP1243441A3 (de) | 2004-04-14 |

| JP4280454B2 (ja) | 2009-06-17 |

| JP2002331771A (ja) | 2002-11-19 |

| US20020136618A1 (en) | 2002-09-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2702738C2 (de) | Einsteckmaschine | |

| EP0883566B1 (de) | Schwertfalzwerk | |

| DE69607132T2 (de) | Vorrichtung zum Zuführen von Papier für eine Buchbindemaschine | |

| CH651525A5 (de) | Vorrichtung zum buendeln von papierblaettern, z.b. papiergeld. | |

| DE2827540B1 (de) | Stapelvorrichtung fuer Faltschachteln | |

| CH403811A (de) | Verfahren und Vorrichtung zum Einbringen von Einlagen in gefalzte Umschlagbogen | |

| EP1690696A1 (de) | Verfahren sowie Vorrichtung zum Abpressen von Druckerzeugnissen | |

| EP1153872B1 (de) | Vorrichtung und Verfahren zur Vorbereitung eines Buchrückens zum Binden | |

| EP0908408B1 (de) | Vorrichtung und Verfahren für das kombinierte Zusammentragen und Binden von bogenförmigen Produkten | |

| DE2921383A1 (de) | Papierfalzmaschine fuer eine rotationspresse | |

| EP0675005A1 (de) | Einrichtung zum Klebebinden von Druckereiprodukten | |

| DE2209566A1 (de) | Verfahren und Vorrichtung zur Her stellung aus einer Vielzahl von Papierbogen zusammengefugter Bucher, Broschüren oder Hefte | |

| EP0712736B1 (de) | Verfahren zur Herstellung von klebegebundenen Büchern, Broschuren oder dgl. Produkten | |

| DE60306402T2 (de) | Verfahren und apparat zum falzen von blättern | |

| DE2508745A1 (de) | Vorrichtung zum aufstauen vereinzelt vorgeschobener papierboegen zu stapeln und zum weitertransportieren dieser stapel | |

| DE3244422A1 (de) | Schneidevorrichtung fuer bogen sowie hefte mit mindestens einem rotierenden schneidmesser und einer foerdervorrichtung | |

| EP0418529A2 (de) | Vorrichtung für den dreiseitigen Beschnitt von Druckexemplaren | |

| EP1140517B1 (de) | Sammelheftmaschine und verfahren zum herstellen eines aufschlagregisters an mittels einer sammelheftmaschine zu heftenden druck- oder papierwerken | |

| DE938697C (de) | Maschine zum Schneiden, Nuten, Praegen od. dgl. | |

| EP1394088A2 (de) | Vorrichtung zum Trennen von Vorfalz und Nachfalz in Bogenaufnahmetaschen und Verfahren zum Trennen von Vorfalz und Nachfalz in Bogenaufnahmeverfahren | |

| EP1254857A2 (de) | Vorrichtung zum Zusammentragen flacher Gegenstände zu Stapeln und zur Weiterverarbeitung des Stapel | |

| EP1475339A1 (de) | Verfahren und Vorrichtung zur Weiterverarbeitung gedruckter Bogen | |

| EP1243441A2 (de) | Vorrichtung und Verfahren zum binden von Druckprodukten | |

| DE2514838A1 (de) | Vorrichtung zum abheben und weiterfoerdern eines auf einem keilfoermigen sattel zugefuehrten heftes | |

| DE2926387C2 (de) | Sammelzylinder zum Bilden von Stapeln aus flachen Werkstücken |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7B 65H 39/02 B Ipc: 7B 42C 11/02 A |

|

| 17P | Request for examination filed |

Effective date: 20040308 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: GOSS INTERNATIONAL AMERICAS, INC. |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17Q | First examination report despatched |

Effective date: 20060113 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20070219 |