EP1094278A2 - Dispositif d'évacuation des fumées - Google Patents

Dispositif d'évacuation des fumées Download PDFInfo

- Publication number

- EP1094278A2 EP1094278A2 EP00122081A EP00122081A EP1094278A2 EP 1094278 A2 EP1094278 A2 EP 1094278A2 EP 00122081 A EP00122081 A EP 00122081A EP 00122081 A EP00122081 A EP 00122081A EP 1094278 A2 EP1094278 A2 EP 1094278A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- supply air

- filter device

- air duct

- duct outlet

- filter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/20—Removing cooking fumes

- F24C15/2028—Removing cooking fumes using an air curtain

Definitions

- the invention relates to an extractor hood device according to the preamble of Claim 1.

- the invention relates to an extractor device containing a filter device, an exhaust duct and an exhaust fan through which haze through the filter device and then through the exhaust duct into the outside environment of a building is eligible.

- the extractor device can be a so-called extractor hood or a Eat for pulling kitchen vapors out of a kitchen. They are usually arranged over the hotplates of a stove.

- the filter device consists at least of a grease and dust filter, but can also contain an odor filter downstream of this filter Elimination of smells.

- odor filters mostly consist of activated carbon, however, can also be made from other materials for odor removal exist through adsorption or absorption or chemical reactions.

- Odor filters are normally only used in extractor hoods for "recirculation mode” used.

- “Circulating air mode” means that the haze is sucked out of the kitchen, cleaned by the filter device and then conveyed back to the kitchen becomes.

- extractor hoods for “exhaust air operation” there are normally no odor filters used, although this is also possible with them.

- “Exhaust air operation” means that the smells extracted from the kitchen after the filter device not back into the kitchen, but conveyed out of the building into the open become.

- DE utility model 1 987 333 is an extractor hood for recirculation mode known which a grease and dust filter, an odor filter with activated carbon to exude odors, and a fan in that order Blower flow direction has. Furthermore, from DE utility model 91 05 430.3 an extractor hood for air recirculation is known, in which a fan arranged in the flow path between a grease filter and an odor filter is. An extractor hood is from DE utility model 78 02 041 known with two fans, which either for recirculation mode or for exhaust air mode can be trained.

- extractor hoods are also known according to the preamble of claim 1, which are only designed for exhaust air operation.

- the extractor device can either only switchable for exhaust air operation or optionally for exhaust air operation or recirculation air operation be trained. You can use an odor filter in the exhaust air duct or in a recirculation air duct contain.

- Exhaust air operation has the advantage that no air is returned to the kitchen, which contains residues of haze particles or odors.

- Has exhaust air operation however the disadvantage that the exhaust fan constantly clean warm air from the kitchen exhausts and promotes the outdoors outside of the building, what in cold seasons results in increased heating costs.

- Recirculation mode has this disadvantage Not.

- Recirculating air operation has the disadvantage, however, that unpleasant residues of haze and smells from the extractor hood are conveyed back to the kitchen and that an odor filter is required in addition to the grease filter, if you at least partially remove unpleasant cooking smells from the haze would like to.

- the object of the invention is to be achieved in a simple manner with exhaust air operation and inexpensive way to reduce the proportion of clean kitchen air, from an exhaust fan along with the haze out of the kitchen the free is promoted outside of a building.

- an extractor device is characterized in that that an outside air supply air duct is provided, the at least one close to the suction side of the filter device in its suction area located supply air duct outlet, so that supply air from the outside environment of the building in the immediate suction area of the suction side the filter device is conductive, where they mix with rising vapor can and together with the haze from the exhaust fan through the filter device is absorbent.

- Haze (vapors) rising from a hotplate has a strong dynamic of its own (Kinetic energy), through which a deflection of the vapor flow by a Airflow is difficult unless a very strong airflow is used.

- the vapor flow is easily deflected by a mechanical element, for example also through the filter surfaces of the filter device, in particular from their grease filters. So that the vapor flow from the suction side of the grease filter is not mechanical distracted, but sucked as completely as possible through the grease filter a certain minimum suction power and minimum flow rate must be from the exhaust fan are generated in the filter device. Thereby creates a volume flow of air and haze, which is much larger than the volume flow of the haze alone. As a result, the exhaust fan will additionally a large proportion of the kitchen air surrounding the haze is also sucked into the haze and sucked through the filter device together with the haze.

- An essential idea of the invention then is the additional air, which for the extraction of the vapor through the filter device is required, not from the Provide kitchen, but from the outside air surrounding the kitchen building.

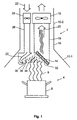

- the extractor device 2 shown schematically in vertical section in FIG. 1 is arranged above a hotplate 4, which is schematic is represented by a saucepan 6 and vapor 8 (vapors) rising from it.

- the extractor device 2 has a housing 10, which in the upper area Shaft 10-2 and in the lower area a funnel-like widening Screen 10-1 forms.

- a filter device 14 is in the flow path of the rising vapor 8 Form of a grease filter arranged obliquely, for. B. at about 45 ° like a kind Half of a saddle roof over the right half of the stream ascending Haze 8.

- the filter device 14 is located at the lower end of an exhaust air duct 16, in which an exhaust fan 18 is arranged to exhaust 20 into the outside environment or to promote the freedom of a building in which the extractor device 2 is arranged in a kitchen.

- the exhaust air 20 consists of vapor 8 (vapors) and added fresh air, hereinafter Air called 22, from the outside of the building.

- Air vapor

- the Shaft 10-2 extends parallel to the exhaust air duct 16, an inlet air duct 26 vertically downward, in which there is a supply air blower 28.

- the supply air fan 28 sucks fresh air or supply air from the outside of the building 22 and blows it from a supply air duct outlet 30, which in Fig. 1 to the left of Haze 8 is arranged over the rising haze 8 against the intake side 32 of the grease filter 14.

- the supply air 22 flows in the form of an air curtain 34 between the rising vapor 8 and the grease filter 14 against its suction side 32.

- the air curtain 34 forms a kind of left half of a gable roof, the right half is formed by the fat filter 14 above the rising haze 8.

- the supply air flow 34 flowing out of the supply air duct outlet 30 is on it Top through a diagonally upwards from the supply air duct outlet towards The upper end of the filter device 14 defines a baffle 36.

- the rising vapor stream 8 penetrates just before the intake side 32 and also on this intake side 32 into the air curtain 34 of the supply air and then together with this as exhaust air 20 from the exhaust fan 18 through the exhaust duct 16 sucked through and conveyed into the outside atmosphere of the building.

- the large kinetic energy of the vapor stream 8 can penetrate it into the Supply air close to the upstream side of the fat filter 14 also as an injection in this additional air 22, 34 are referred to.

- the supply air duct outlet 30 can be in the form of a slot nozzle or in the form of a nozzle tube with a variety be formed by nozzle bores and the supply air 22 in the form of an air curtain 34 or one extending over the entire cross section of the grease filter 14 Dispense spray onto this grease filter 14.

- This turns the haze 8 (Vapors), which is automatically by convection from the hotplate or Cooking pot 6 rises, injected into the air flow 34 of the supply air 22 and into this entrained the grease filter 14.

- the exhaust fan 18 sucks about 20% more (depending on the embodiment the extractor device and the performance of the exhaust fan 18) volume flow through the filter device 14 as supply air 22 through the supply air blower 28 is supplied, and blows the exhaust air 20 out into the outside atmosphere of the building.

- the volume of the exhaust air flow 20 is a multiple of the volume flow of the Steam is 8, this means that the flow of exhaust air 20 is almost 80% Supply air 22, and about 20% from haze 8 and little or no air from the kitchen consists.

- the exhaust air duct 16 and the supply air duct 26 can together as a heat exchanger be trained, e.g. B. separated from each other only by a heat-permeable wall be so that cold supply air 22 in the supply air duct 26 of warm exhaust air 20 in the exhaust air duct 16 is heated.

- the supply air duct outlet 30 can have an annular shape be and the path of the rising steam 8 partially or completely surround.

- the supply air blower 28 is omitted and the supply air 22 is the suction of the exhaust fan 18 on the Suction side of the filter device 14 from the outside environment of the building sucked through the supply air duct 26.

- This suction effect is then special effective if there is a lack of fresh air in the kitchen, e.g. B. all windows and doors are tightly closed.

- the supply of supply air 22 is preferably switched off, for. B. by switching off the Supply air blower 28 and / or by a closure flap for closing the supply air duct 26.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Ventilation (AREA)

- Filtering Of Dispersed Particles In Gases (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19950817 | 1999-10-21 | ||

| DE1999150817 DE19950817A1 (de) | 1999-10-21 | 1999-10-21 | Dunstabzugsvorrichtung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1094278A2 true EP1094278A2 (fr) | 2001-04-25 |

| EP1094278A3 EP1094278A3 (fr) | 2002-10-09 |

Family

ID=7926469

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00122081A Withdrawn EP1094278A3 (fr) | 1999-10-21 | 2000-10-11 | Dispositif d'évacuation des fumées |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1094278A3 (fr) |

| DE (1) | DE19950817A1 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005033224A1 (de) * | 2005-07-15 | 2007-01-18 | BSH Bosch und Siemens Hausgeräte GmbH | Dunstabzugshaube und Dunstabzugsvorrichtung |

| WO2010149328A1 (fr) * | 2009-06-23 | 2010-12-29 | Udo Berling | Hotte aspirante |

| CN103017225A (zh) * | 2012-12-30 | 2013-04-03 | 宁波市鄞州云帆工程咨询有限公司 | 正压涡流式免拆洗抽油烟机 |

| WO2014154384A1 (fr) * | 2013-03-27 | 2014-10-02 | Rentschler Reven Gmbh | Hotte aspirante |

| JP2014238256A (ja) * | 2014-07-23 | 2014-12-18 | 三菱電機株式会社 | 加熱調理器 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006040303A1 (de) * | 2006-08-29 | 2008-03-20 | Thilo Horber | Kochmodul zum Zubereiten von Speisen |

| DE202012104696U1 (de) | 2012-12-03 | 2013-01-31 | Herbert Ott | Dunstabzugshaube |

| DE102015119865B4 (de) | 2015-11-17 | 2023-12-21 | RobArt GmbH | Robotergestützte Bearbeitung einer Oberfläche mittels eines Roboters |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1987333U (de) | 1968-06-12 | Collo Rheincollodium Köln G.m.b.H. Werk Hersei, 5304 Hersei | Dunstabzugshaube | |

| DE7802041U1 (de) | 1978-01-24 | 1978-05-03 | G. Bauknecht Gmbh, Elektrotechnische Fabriken, 7000 Stuttgart | Dunstabzugshaube |

| DE9105430U1 (de) | 1991-05-02 | 1992-09-03 | Bosch-Siemens Hausgeräte GmbH, 8000 München | Dunstabzugseinrichtung |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3457850A (en) * | 1967-12-11 | 1969-07-29 | Elster S Air Conditioning | Air curtain ventilator |

| US4047519A (en) * | 1975-02-24 | 1977-09-13 | Nett Louis A | Ventilating apparatus |

| DE8510615U1 (de) * | 1985-04-11 | 1985-06-05 | Maimer GmbH, 7301 Deizisau | Dunstabzugshaube |

| DE8534455U1 (de) * | 1985-12-07 | 1986-01-23 | Rentschler Reven Lüftungssysteme GmbH, 7126 Sersheim | Dunstabzugshaube |

| DE3622744A1 (de) * | 1986-07-07 | 1988-01-21 | Wimboeck Gmbh Lufttechnik | Verfahren zum abziehen von dunst, fett- oder oelhaltiger luft oder dergl., sowie dunstabzugshaube zur durchfuehrung des verfahrens |

| DE8903530U1 (de) * | 1989-03-21 | 1989-05-03 | Rentschler Reven-Lüftungssysteme GmbH, 7126 Sersheim | Dunstabzugshaube |

-

1999

- 1999-10-21 DE DE1999150817 patent/DE19950817A1/de not_active Ceased

-

2000

- 2000-10-11 EP EP00122081A patent/EP1094278A3/fr not_active Withdrawn

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1987333U (de) | 1968-06-12 | Collo Rheincollodium Köln G.m.b.H. Werk Hersei, 5304 Hersei | Dunstabzugshaube | |

| DE7802041U1 (de) | 1978-01-24 | 1978-05-03 | G. Bauknecht Gmbh, Elektrotechnische Fabriken, 7000 Stuttgart | Dunstabzugshaube |

| DE9105430U1 (de) | 1991-05-02 | 1992-09-03 | Bosch-Siemens Hausgeräte GmbH, 8000 München | Dunstabzugseinrichtung |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005033224A1 (de) * | 2005-07-15 | 2007-01-18 | BSH Bosch und Siemens Hausgeräte GmbH | Dunstabzugshaube und Dunstabzugsvorrichtung |

| WO2010149328A1 (fr) * | 2009-06-23 | 2010-12-29 | Udo Berling | Hotte aspirante |

| CN102483240A (zh) * | 2009-06-23 | 2012-05-30 | 贝尔林有限公司 | 抽烟机 |

| CN103017225A (zh) * | 2012-12-30 | 2013-04-03 | 宁波市鄞州云帆工程咨询有限公司 | 正压涡流式免拆洗抽油烟机 |

| CN103017225B (zh) * | 2012-12-30 | 2015-03-04 | 佘玲 | 正压涡流式免拆洗抽油烟机 |

| WO2014154384A1 (fr) * | 2013-03-27 | 2014-10-02 | Rentschler Reven Gmbh | Hotte aspirante |

| CN105102895A (zh) * | 2013-03-27 | 2015-11-25 | 瑞文通风系统有限公司 | 收集罩 |

| US10132506B2 (en) | 2013-03-27 | 2018-11-20 | Rentschler Reven Gmbh | Collecting hood |

| JP2014238256A (ja) * | 2014-07-23 | 2014-12-18 | 三菱電機株式会社 | 加熱調理器 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19950817A1 (de) | 2001-04-26 |

| EP1094278A3 (fr) | 2002-10-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1194721B1 (fr) | Dispositif d'aspiration d'air pour poste de travail | |

| EP3045824B1 (fr) | Dispositif d'aspiration d'air d'une cuisiniere | |

| CH682512A5 (de) | Dampfabzugeinrichtung. | |

| DE10325007A1 (de) | Abzugshaube für einen Küchenherd | |

| DE4114329A1 (de) | Dunstabzugshaube mit luftschleier | |

| EP1134501A1 (fr) | Hotte aspirante de buée | |

| DE202016003254U1 (de) | Abzugsvorrichtung | |

| EP3701192A1 (fr) | Appareil combiné comprenant un dispositif d'aspiration des fumées et une table de cuisson | |

| EP2210048B1 (fr) | Dispositif d'aspiration de vapeurs | |

| EP1094278A2 (fr) | Dispositif d'évacuation des fumées | |

| DE102019135258B4 (de) | Kombidämpfer mit wenigstens zwei Gareinheiten und einer Dunstabzugshaube | |

| DE3718686A1 (de) | Dunstabzugshaube, insbesondere fuer kuechen | |

| EP1128132B1 (fr) | Hotte aspirant la buée | |

| EP2829808B1 (fr) | Hotte aspirante | |

| EP2677242A1 (fr) | Dispositif de déviation d'air | |

| EP0886112A2 (fr) | Hotte combinée pour l'évacuation de fumée et le conditionnement d'air | |

| DE2615604B2 (de) | Backofen, insbesondere mit Mitteln zur pyrolytischen Reinigung mit einem Kühlluftgebläse | |

| EP1111311A2 (fr) | Dispositif d'évacuation des fumées | |

| CH680947A5 (fr) | ||

| EP0942235A1 (fr) | Feu de boulanger avec boíte d'aspiration | |

| DE102020104387B4 (de) | Kochfeld mit Kochstelle und Absaugvorrichtung für Kochdünste | |

| WO2009106548A2 (fr) | Système de hotte aspirante et procédé pour purifier l'air d'une cuisine | |

| DE3913076C2 (fr) | ||

| DE9416271U1 (de) | Dunstabzugsvorrichtung | |

| DE20100535U1 (de) | Kochvorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHMID, DIETRICH, DIPL.-ING. Inventor name: REIFF, UDO, DIPL.-ING. |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20030409 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BSH BOSCH UND SIEMENS HAUSGERAETE GMBH |

|

| 17Q | First examination report despatched |

Effective date: 20041004 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Effective date: 20050204 |