EP1024186A2 - Teleskoprohr für eine Austragseinrichtung an einem Beschickungswagen für Koksöfen - Google Patents

Teleskoprohr für eine Austragseinrichtung an einem Beschickungswagen für Koksöfen Download PDFInfo

- Publication number

- EP1024186A2 EP1024186A2 EP99122466A EP99122466A EP1024186A2 EP 1024186 A2 EP1024186 A2 EP 1024186A2 EP 99122466 A EP99122466 A EP 99122466A EP 99122466 A EP99122466 A EP 99122466A EP 1024186 A2 EP1024186 A2 EP 1024186A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- seal

- tensioning

- filling

- tube

- outer tube

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B31/00—Charging devices

- C10B31/02—Charging devices for charging vertically

- C10B31/04—Charging devices for charging vertically coke ovens with horizontal chambers

Definitions

- the invention relates to a telescopic tube for a discharge device on a loading cart for coke ovens with a filling pipe, a vertical one enclosing the filling pipe adjustable outer tube and a sealing arrangement for Sealing the annular gap between the filling pipe and the Outer tube during the loading of a coke oven Coal.

- the Telescopic tube is formed in several parts and at least has a filling pipe connected to the discharge device and a liftable and lowerable outer tube. Special value is in the execution of the telescopic tube on a tight Execution laid so that during the coal filling in the coke oven chamber no fill emissions through the telescopic tube get into the environment.

- known telescopic tube has the fixed to the discharge device connected filling pipe at its lower end a ring-shaped collar filled with sand.

- the known design allows it not, height differences between the lower edge of the lowered Compensate outer tube and the Greochrahmen.

- the cuff usually made of steel or one Special fabric made, has only a limited stretch, which are directly related to their overall length stands and neither by the constructive execution nor is significantly influenced by the choice of material.

- the Distance between the lower edge of the telescopic tube when raised Condition and the top edge of the Medoch frame often greater than the allowable expansion of the compensator, so that Entire furnace ceiling areas with the Grep frame in complex and raised actions associated with significant costs and in the range of the allowable expansion joints have to be brought.

- the invention has for its object a telescopic tube of the intended purpose described at the beginning, that any distance between in a large work area the lower edge of the telescopic tube and the upper edge of the fill hole frame of a coke oven bridged and the leakage of Filling emissions effectively prevented.

- the task is with a telescopic tube of the entrance described construction according to the invention solved in that the sealing arrangement encloses the filling pipe, elastically deformable seal as well as a seal has acting clamping device and that the clamping device with a drive for operational clamping and release is equipped.

- the elastic seal is by clamping the clamping device against the filling pipe and can be pressed against a flange surface connected to the outer tube. By loosening the clamping device, the seal comes of the filling pipe wall again free, so that the outer pipe without Wear of the seal is vertically adjustable.

- the seal can consist of several sealing rings arranged one above the other consist.

- Pneumatic or hydraulic cylinders are used as the drive, electromechanical actuators as well as manual actuatable mechanical drives can be used.

- the drive has at least one hydraulic cylinder / Piston arrangement on.

- a first embodiment is the seal in one of two Flange rings limited and connected to the outer tube annular housing arranged radially from one in the tensioned strap is inserted into the housing.

- the seal is expediently divided in the longitudinal direction and forms together a clamping ring with the strap.

- clamping device released the inner diameter of the clamping ring is slightly larger than that Outside diameter of the filling pipe, so that when lowering and Lifting the outer tube no direct contact between There is a clamping ring and filling tube and a mechanical output the seal is excluded.

- the drive has a contracting on the ends of the strap Traction device, e.g. a linear drive with a Cylinder / piston arrangement.

- the seal pressurized in the radial direction during the clamping process.

- Another embodiment of the invention provides that the seal in one of a flange ring and one Pipe section limited annular space and arranged by a vertically adjustable connected to the drive Clamping ring is acted on in the axial direction.

- the seal is moved by a vertical movement of the clamping ring pressed together and to the filling pipe as well as on the corresponding contact surfaces of the outer tube pressed. After loosening the clamping device, it deforms the seal back so that the outer tube is adjusted vertically can be without the seal wear is exposed.

- the telescopic tube 1 shown in Fig. 1 is to the Discharge device 2 of a loading trolley, not shown connected on the furnace ceiling 3 a coke oven is movable.

- the telescopic tube 1 has a filling pipe firmly connected to the discharge device 2 4 and a vertically adjustable one enclosing the filling pipe 4 Outer tube 5 on.

- Via a support ring 6 and Articulated rods 7 is the outer tube 5 with a lifting beam 8 connected.

- a sealing arrangement 10 which the annular gap between the filling tube 4 and the outer tube 5 during the loading sealing the coke oven chamber with coal prevents during coal filling filling emissions through the telescopic tube get into the environment.

- FIGS. 2 to 4 show the structure of the sealing arrangement 10. It has an elastic surrounding the filling tube 4 deformable seal 11 and a seal 11 acting clamping device 12.

- the jig 12 is with a drive 13 for operational clamping and Solve equipped.

- tensioning the jig 12 is the elastically deformable seal 11 against that Filling tube 4 and against one connected to the outer tube 5 Flange surface can be pressed.

- the seal 11 comes free from the filling pipe wall, so that the outer tube 5 is raised without wear of the seal 11 or can be lowered.

- the seal 11 can, like indicated in FIGS. 2 and 4, from several one above the other arranged sealing rings exist.

- the seal 11 in one of two flange rings 14 limited and connected to the outer tube 5 annular housing 15 arranged and radially from one tensioned in the housing 15 inserted strap 16.

- the seal 11 is advantageously divided in the longitudinal direction and forms a clamping ring with the strap 16, which by the the ends of the tensioning band contracting drive 13 can be clamped against the wall surface of the filling tube 4 (Fig. 3).

- the drive 13 is in the embodiment with a hydraulic cylinder / piston arrangement as pulling device educated. Pneumatic cylinders, electromechanical, are also suitable Actuators or manually operated Actuators.

- FIG. 4 10 is the seal 11 in one of one Flange ring 14 and a tubular section limited annulus arranged and connected by a drive 13 vertically adjustable clamping ring 18 in the axial direction acted upon.

- the left representation of FIG. 4 that is Lowered outer tube 5 for a filling process and the Clamping device 12 cocked.

- the from several sealing rings existing seal 11 is by an actuating movement of the upper clamping ring 18 pressed and is under pressure both on the filling pipe 4 and on the corresponding Contact surfaces of the outer tube 5.

- the right half of the 4 shows the sealing arrangement 10 with the tensioning device released 12.

- the drive 13 is relieved, and the upper one Clamping ring 18 rests on the seal 11 without pressure.

- the elastic sealing rings have deformed back, whereby between the seal 11 and the outer surface of the filling tube 4 a gap s can be seen.

- the outer tube 5 is vertically adjustable without wearing the seal 11.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Sealing Devices (AREA)

- Coke Industry (AREA)

- Joints Allowing Movement (AREA)

Abstract

Description

- Fig. 1

- ein Teleskoprohr an einer Austragseinrichtung eines Beschickungswagens für Koksöfen,

- Fig. 2

- einen Ausschnitt aus der in Fig. 1 dargestellten Vorrichtung in vergrößerter Darstellung,

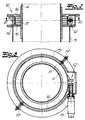

- Fig. 3

- den Schnitt A-A aus Fig. 2,

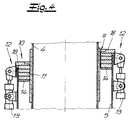

- Fig. 4

- eine weitere Ausführung der in Fig. 2 dargestellten Vorrichtung.

Claims (7)

- Teleskoprohr für eine Austragseinrichtung an einem Beschickungswagen für Koksöfen mitdadurch gekennzeichnet, daß die Dichtungsanordnung (10) eine das Füllrohr (4) umschließende, elastisch verformbare Dichtung (11) sowie eine auf die Dichtung (11) wirkende Spannvorrichtung (12) aufweist und daß die Spannvorrichtung (12) mit einem Antrieb (13) zum betriebsmäßigen Spannen und Lösen ausgerüstet ist, wobei die Dichtung (11) durch Spannen der Spannvorrichtung (12) gegen das Füllrohr (4) und gegen eine mit dem Außenrohr (5) verbundene Flanschfläche preßbar ist und wobei die Dichtung (11) durch Lösen der Spannvorrichtung (12) von der Füllrohrwand wieder freikommt, so daß das Außenrohr (5) ohne Verschleiß der Dichtung (11) vertikal verstellbar ist.einem Füllrohr (4),einem das Füllrohr (4) umschließenden, vertikal verstellbaren Außenrohr (5) undeiner Dichtungsanordnung (10) zur Abdichtung des Ringspaltes zwischen dem Füllrohr (4) und dem Außenrohr (5) während der Beschickung eines Koksofens mit Kohle,

- Teleskoprohr nach Anspruch 1, dadurch gekennzeichnet, daß die Dichtung (11) in einem von zwei Flanschringen (14) begrenzten und mit dem Außenrohr (5) verbundenen ringförmigen Gehäuse (15) angeordnet sowie radial von einem in das Gehäuse (15) eingelegten Spannband (16) beaufschlagt ist.

- Teleskoprohr nach Anspruch 2, dadurch gekennzeichnet, daß der Antrieb (13) eine die Enden des Spannbandes (16) zusammenziehende Zugeinrichtung aufweist und daß am Umfang des Spannbandes (16) federbeweglich am Gehäuse (15) abgestützte Rückstellelemente (17) angeordnet sind, die nach Lösen der Spannvorrichtung (12) das Spannband (16) zentrieren und die Dichtungsanordnung (10) mit einem Ringspalt zum Füllrohr (4) halten.

- Teleskoprohr nach Anspruch 2 oder 3, dadurch gekennzeichnet, daß die Dichtung (11) in Längsrichtung geteilt ist.

- Teleskoprohr nach Anspruch 1, dadurch gekennzeichnet, daß die Dichtung (11) in einem von einem Flanschring (14) und einem Rohrabschnitt begrenzten Ringraum angeordnet und von einem an den Antrieb (13) angeschlossenen, vertikal verstellbaren Spannring (18) in axialer Richtung beaufschlagt ist.

- Teleskoprohr nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß der Antrieb (13) mindestens eine hydraulische Zylinder/Kolbenanordnung aufweist.

- Teleskoprohr nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, daß die Dichtung (11) aus mehreren übereinander angeordneten Dichtungsringen besteht.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19902968 | 1999-01-26 | ||

| DE1999102968 DE19902968B4 (de) | 1999-01-26 | 1999-01-26 | Teleskoprohr für eine Austragseinrichtung an einem Beschickungswagen für Koksöfen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1024186A2 true EP1024186A2 (de) | 2000-08-02 |

| EP1024186A3 EP1024186A3 (de) | 2001-10-24 |

| EP1024186B1 EP1024186B1 (de) | 2004-01-28 |

Family

ID=7895397

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99122466A Expired - Lifetime EP1024186B1 (de) | 1999-01-26 | 1999-11-11 | Teleskoprohr für eine Austragseinrichtung an einem Beschickungswagen für Koksöfen |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1024186B1 (de) |

| AT (1) | ATE258584T1 (de) |

| DE (2) | DE19964274B4 (de) |

| ES (1) | ES2214798T3 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008131933A3 (de) * | 2007-04-25 | 2009-03-05 | Ruhrpumpen Gmbh | Anordnung zum führen einer bohrstange eines decoking-werkzeugs |

| CN116164181A (zh) * | 2022-12-16 | 2023-05-26 | 诸暨市沣泽动力机械有限公司 | 一种烟囱伸缩膨胀节 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007044181B4 (de) | 2007-09-15 | 2009-05-28 | Uhde Gmbh | Füllteleskop zum Befüllen von Koksöfen |

| CN111747028B (zh) * | 2020-07-03 | 2024-09-03 | 中冶焦耐(大连)工程技术有限公司 | 一种移动给料机通廊的封闭及开启机构 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3941410A (en) * | 1974-10-10 | 1976-03-02 | Tadashi Miyaoka | Pipe joint construction |

| DE2922571C2 (de) * | 1979-06-02 | 1985-08-01 | Dr. C. Otto & Co Gmbh, 4630 Bochum | Füllwagen für Verkokungsöfen |

| DE3930871A1 (de) * | 1988-09-19 | 1990-03-22 | Still Otto Gmbh | Verfahren und vorrichtung zur abdichtung von auf die fuellochrahmen von verkokungsoefen absenkbaren ueberleiteinrichtungen |

| DE3913320C1 (de) * | 1989-04-22 | 1990-07-05 | Hartung Kuhn & Co Maschf | Füllwagen für eine Koksofenbatterie |

| DE59406110D1 (de) * | 1993-06-29 | 1998-07-09 | Hartung Kuhn & Co Maschf | Verfahren und Vorrichtung zum Füllen von Kohle in die Ofenkammern einer Koksofenbatterie |

| DE4333999A1 (de) * | 1993-10-06 | 1995-04-13 | Manibs Spezialarmaturen | Vorrichtung zum mediendichten Anschluß eines Rohres |

-

1999

- 1999-01-26 DE DE19964274A patent/DE19964274B4/de not_active Expired - Lifetime

- 1999-11-11 AT AT99122466T patent/ATE258584T1/de active

- 1999-11-11 ES ES99122466T patent/ES2214798T3/es not_active Expired - Lifetime

- 1999-11-11 DE DE59908416T patent/DE59908416D1/de not_active Expired - Lifetime

- 1999-11-11 EP EP99122466A patent/EP1024186B1/de not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008131933A3 (de) * | 2007-04-25 | 2009-03-05 | Ruhrpumpen Gmbh | Anordnung zum führen einer bohrstange eines decoking-werkzeugs |

| US8382960B2 (en) | 2007-04-25 | 2013-02-26 | Ruhrpumpen Gmbh | Arrangement for guiding a drill stem of a decoking tool |

| CN116164181A (zh) * | 2022-12-16 | 2023-05-26 | 诸暨市沣泽动力机械有限公司 | 一种烟囱伸缩膨胀节 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1024186B1 (de) | 2004-01-28 |

| DE19964274B4 (de) | 2005-11-17 |

| ES2214798T3 (es) | 2004-09-16 |

| DE59908416D1 (de) | 2004-03-04 |

| ATE258584T1 (de) | 2004-02-15 |

| EP1024186A3 (de) | 2001-10-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102007044181B4 (de) | Füllteleskop zum Befüllen von Koksöfen | |

| DE102007018021A1 (de) | Hydraulikstempel mit dünnwandigen Außen- und Innenrohren | |

| DE3217169C2 (de) | Falzmesserzylinder | |

| DE1259816B (de) | Kolben fuer hydraulische Grubenstempel od. dgl. | |

| DE29612637U1 (de) | Vorrichtung zum Ziehen eines im Erdreich verlegten oder zu verlegenden Rohres | |

| EP1024186A2 (de) | Teleskoprohr für eine Austragseinrichtung an einem Beschickungswagen für Koksöfen | |

| EP0640764B1 (de) | Kolbenkompressor | |

| DE2319295A1 (de) | Heizpressen-system | |

| DE1946581C2 (de) | Brillenschieber | |

| DE19902968B4 (de) | Teleskoprohr für eine Austragseinrichtung an einem Beschickungswagen für Koksöfen | |

| DE4141275A1 (de) | Vorrichtung zum automatischen waagerechten montieren und/oder demontieren eines grossen und schweren kolbens in und/oder aus einem zylinderrohr | |

| DE1756858A1 (de) | Gaskissen-Lasttrageeinrichtung | |

| EP2182259A1 (de) | Verfahren zum Sperren einer Rohrleitung und Rohrsperrgerät | |

| DE2055366A1 (de) | Hydraulisch betatigbare Hubeinrichtung fur den Ein und Ausbau von Konverterboden in bzw aus Konvertern, bzw fur den Ein und Aufbau von Konvertern in bzw aus deren Tragringen | |

| DE1299259B (de) | Einrichtung zum Anziehen stark belasteter Muttern fuer Schraubbolzen | |

| DE1800025C (de) | Hydraulische Spannpresse fur Spann drahte von Spannbetonkonstruktionen | |

| DE2814080C2 (de) | ||

| DE2517026B2 (de) | Stützvorrichtung zur Halterung einer Heißwindleitung eines Hochofens | |

| DE2447445A1 (de) | Schutzvorrichtung fuer kolbenstangen von hydraulischen oder pneumatischen arbeitszylindern | |

| DE1027159B (de) | Zweiteiliges Stuetzelement fuer den Strebausbau | |

| DE3020027A1 (de) | Vorrichtungen zum teleskopieren und zu anwendungen bei hubwerken | |

| DE2506000C3 (de) | Einbauteil bei einem Tiefofenkran, Stripperkran oder einem Universalstripperkran | |

| DE1434800A1 (de) | Silo | |

| DE1123639B (de) | Wandernder Strebausbau | |

| DE7433390U (de) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 7C 10B 31/04 A, 7B 65G 69/18 B |

|

| 17P | Request for examination filed |

Effective date: 20011023 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20020830 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040128 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040128 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 59908416 Country of ref document: DE Date of ref document: 20040304 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040428 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040428 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040512 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2214798 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041130 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20041029 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| NLS | Nl: assignments of ep-patents |

Owner name: UHDE GMBH Effective date: 20060222 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040628 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59908416 Country of ref document: DE Representative=s name: RAINER ALBRECHT, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59908416 Country of ref document: DE Representative=s name: ALBRECHT, RAINER, DIPL.-ING. DR.-ING., DE Effective date: 20120627 Ref country code: DE Ref legal event code: R081 Ref document number: 59908416 Country of ref document: DE Owner name: THYSSENKRUPP INDUSTRIAL SOLUTIONS AG, DE Free format text: FORMER OWNER: UHDE GMBH, 44141 DORTMUND, DE Effective date: 20120627 Ref country code: DE Ref legal event code: R081 Ref document number: 59908416 Country of ref document: DE Owner name: THYSSENKRUPP UHDE GMBH, DE Free format text: FORMER OWNER: UHDE GMBH, 44141 DORTMUND, DE Effective date: 20120627 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20131121 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20131113 Year of fee payment: 15 Ref country code: LU Payment date: 20131202 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141111 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141112 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141111 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59908416 Country of ref document: DE Representative=s name: ALBRECHT, RAINER, DIPL.-ING. DR.-ING., DE Ref country code: DE Ref legal event code: R081 Ref document number: 59908416 Country of ref document: DE Owner name: THYSSENKRUPP INDUSTRIAL SOLUTIONS AG, DE Free format text: FORMER OWNER: THYSSENKRUPP UHDE GMBH, 44141 DORTMUND, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20161118 Year of fee payment: 18 Ref country code: GB Payment date: 20161122 Year of fee payment: 18 Ref country code: NL Payment date: 20161118 Year of fee payment: 18 Ref country code: DE Payment date: 20161121 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20161118 Year of fee payment: 18 Ref country code: AT Payment date: 20161121 Year of fee payment: 18 Ref country code: ES Payment date: 20161114 Year of fee payment: 18 Ref country code: IT Payment date: 20161123 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59908416 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20171201 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 258584 Country of ref document: AT Kind code of ref document: T Effective date: 20171111 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20171111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171111 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180731 Ref country code: BE Ref legal event code: MM Effective date: 20171130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171201 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171130 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180602 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171130 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171111 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20181226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171112 |