EP1007461B1 - Plieuse a poches comportant deux ou trois poches de pliage - Google Patents

Plieuse a poches comportant deux ou trois poches de pliage Download PDFInfo

- Publication number

- EP1007461B1 EP1007461B1 EP98909278A EP98909278A EP1007461B1 EP 1007461 B1 EP1007461 B1 EP 1007461B1 EP 98909278 A EP98909278 A EP 98909278A EP 98909278 A EP98909278 A EP 98909278A EP 1007461 B1 EP1007461 B1 EP 1007461B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- folder

- folding

- folder block

- machine frame

- block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000008878 coupling Effects 0.000 claims description 11

- 238000010168 coupling process Methods 0.000 claims description 11

- 238000005859 coupling reaction Methods 0.000 claims description 11

- 238000009434 installation Methods 0.000 description 30

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 210000001520 comb Anatomy 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000009418 renovation Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H45/00—Folding thin material

- B65H45/12—Folding articles or webs with application of pressure to define or form crease lines

- B65H45/14—Buckling folders

- B65H45/142—Pocket-type folders

- B65H45/144—Pockets or stops therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H45/00—Folding thin material

- B65H45/12—Folding articles or webs with application of pressure to define or form crease lines

- B65H45/14—Buckling folders

- B65H45/142—Pocket-type folders

- B65H45/147—Pocket-type folders folding rollers therefor

Definitions

- the invention relates to a compression folder with two or three folding pockets, with several folding rollers, in one folding unit block detachable from the machine frame and with one outside of the folder block arranged drive, the folder block on its one side has a sheet inlet and on the opposite Side has a sheet outlet and where the sheets to the folder block over transport devices fed along an inlet plane in the direction of paper travel and along an outlet plane in the same Direction are transported away.

- the folding pockets are permanently installed in the paper running direction.

- Two fold pocket configurations are possible, namely the first fold pocket at the bottom and the second fold pocket at the top and vice versa in the direction of paper travel.

- the first folding pocket is arranged below or above, there are different folding options. If such folding units with two folding pockets are used on inserting machines or similar machines, the form must have a certain position after leaving the folding unit. If, for example, the inserting machine provides the envelope with the window on top, the form must be folded so that the address behind the folder is on the top, otherwise an additional device for turning the form would be necessary.

- an upsetting folder could be used, which has one folding pocket and one pair of folding rollers more than folds are required in the relevant form, i.e. for folding a form with two folds, an upsetting folder with three folding pockets and for folding a form with three folds , a compression folder with four folding pockets.

- One of the folding pockets can then be switched off by suitable switches and the form can be folded so that the address after the folding unit is either up or down.

- the larger number of folding pockets and folding rollers creates additional costs and sources of error as well as cycle time losses due to the lengthening of the running distance in the folding unit.

- a paper folding machine is also known (DE-PS 517 549) in which one of the folding rollers is movably mounted, so that you can choose with two different other folding rollers can work together and also have a the folding pockets from one machine side to the other is feasible. In this way, one can choose either opposite Produce directional folds, however, lies Sheet outlet depending on the position of the movable folding roller and the convertible folding pocket either on the inlet side of the bend or on the opposite side of the inlet side Page.

- the invention is therefore based on the object Compression folder with two or three folding pockets at the beginning mentioned type to create which is inexpensive is producible and so convertible with little effort is that with him the different mentioned above Folds can be made.

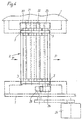

- the Inlet level and the outlet level of the transport devices arranged essentially in a common plane are that the folding rollers and folding pockets in Folding unit block are arranged so that the sheet inlet and the sheet outlet in the respective installation position of the folder in the machine frame in Area of this common level is that all folding rollers in the folder block via coupling gearwheels one end of each folding roller is arranged, are coupled in terms of drive that the Drive is arranged in the machine frame and in the area of the folder block is stored in the machine frame Has drive gear, which is in a first installation position of the folder block with one of the coupling gearwheels combs, and that one of the folding rollers on her the other end carries an output gear, which in a second installation position of the folder block, in which compared to its first installation position by one imaginary running parallel to the direction of the paper Axis rotated through 180 ° inserted into the machine frame is meshing with the drive gear.

- the invention is therefore based on the idea of installing one and the same folding block in the machine frame in two different installation positions rotated by 180 ° with respect to one another.

- the first folding pocket below and the second folding pocket above and in a second installation position of the folder block are arranged, so that depending on the installation position of the folder block in the machine frame, different folds of the paper sheet or form can be generated.

- the sheet infeed and sheet outfeed of the folder block are arranged in the same common plane as the entry level and the exit level, regardless of the respective installation position, it is not necessary to adjust the transport devices upstream and downstream of the upsetting folder when the folder block is 180 ° in both of them twisted installation positions in the machine frame.

- the only changeover measure is to detach the folder block from the machine frame, turn it through 180 °, reinsert it into the machine frame and screw it there.

- the drive gear mounted in the machine frame depending on the installation position of the folder block, meshes with either one of the coupling gears or with the driven gear arranged on the other side of the folder block, no further assembly work is required to connect the drive to one of the folding rollers.

- the output gear can be assigned to one of these four folds in such a way that reversing the direction of rotation of the drive motor is not necessary in order to drive the folding rollers in the correct direction of rotation regardless of the respective installation position of the folder block.

- this Machine frame positioning devices on, by means of which the folder unit in its two installation positions can be positioned in relation to the machine frame is that the sheet inlet and outlet are in the common plane and the drive gear alternately with one of the coupling gears or the output gear meshes.

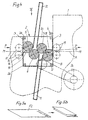

- the upsetting folder has a machine frame 1 and one of this detachable folder block 2.

- Positioning device provided in the form of guides 3, into which the folder block can be inserted from above is.

- screws 4 can be provided.

- the folder block 2 has lateral bearing plates 2a on, which are connected to each other via cross struts 2b are.

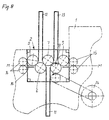

- the one shown in FIGS. 7 and 8 The embodiment is still a folding roller 9 provided.

- the one shown in Figures 1-6 Embodiment has the folder block 2 two Folding pockets 11, 12, while in the case of FIG and 8 shown embodiment, a third Folding pocket 13 is present.

- the folder block In front of the folder block is one through two transport rollers 14 for example indicated transport device provided with the the sheets of paper to be folded, e.g. printed forms F1 or F2 (see Figures 2a and 5a), the folder block are fed along an inlet plane E. Behind the folder unit 2 is a further transport device, which is indicated by rollers 15, provided with which the folded forms along one Outlet level A can be transported further.

- the entry level E and outlet level A are essentially in a common plane M-M arranged.

- the folding rollers 5 - 8 or 5 - 9 and the folding pockets 11, 12 or 11 - 13 are arranged in the folder 2 so that also its sheet inlet 16 and its sheet outlet 17 in the respective installation position of the folder block 2 in the machine frame in the area of this common level M-M lie. At sheet inlet 16 or Sheet outlet 17 are also provided baffles 18, 19.

- the direction of paper travel is indicated by the arrows P indicated.

- the folding roller 8 has an output gear at its other end 26, which is in the second installation position of the folder block 2, as shown in Figures 4 and 6 is engaged in the drive gear 25.

- the folding rollers without changing the direction of rotation of the drive motor 24 is turned over, according to Figure 4 driven in the direction indicated by arrows.

- the person skilled in the art can readily do that Find out the folding roller that he the output gear 26th must assign so that it is in both installation positions of the Folder the direction of rotation of the drive motor 24 can maintain.

- the output gear of the folding roller 6 be assigned when the drive gear 25 is arranged so that it is in the first installation position meshes with the coupling gear 22 and in the second Installation position of the folder block 2 with the then the output gear assigned to the folding roller 6.

- the folder block an imaginary one that runs across the common plane Rotate the axis by 180 ° to get it from its one installation position in its other installation position.

- the output gear would have to be another Folding roller can be assigned.

Landscapes

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

Claims (2)

- Plieuse à poches, à deux ou trois poches de pliage (11, 12, 13), comprenant plusieurs cylindres de pliage, qui sont montés à palier dans un bloc de plieuse (2) pouvant être séparé du bâti de machine, et un entraínement (24) disposé à l'extérieur du bloc de plieuse, le bloc de plieuse comportant d'un premier côté une entrée de feuille (16) et du côté opposé une sortie de feuille (17) et les feuilles étant, au moyen de dispositifs de transport, acheminées au bloc de plieuse le long d'un plan d'entrée (E) suivant une direction de déplacement de papier (P) et évacuées le long d'un plan de sortie (A) suivant la même direction, caractérisée en ce que le plan d'entrée (E) et le plan de sortie (A) des dispositifs de transport (14, 15) sont disposés essentiellement dans un plan commun (M - M), en ce que les cylindres de pliage (5 - 9) et les poches de pliage (11 - 13) sont disposés dans le bloc de plieuse (2) d'une manière telle que, dans une première position de montage considérée du bloc de plieuse (2) dans le bâti de machine (1), l'entrée de feuille (16) et la sortie de feuille (17) sont également situées dans la zone de ce plan commun (M - M), en ce que tous les cylindres de pliage (5 - 9) situés dans le bloc de plieuse (2) sont accouplés entre eux, en ce qui concerne l'entraínement, au moyen de roues dentées d'accouplement (20 - 23) qui sont disposées chacune à une première extrémité donnée des cylindres de pliage (5 - 9) respectifs, en ce que l'entraínement (24) est disposé dans le bâti de machine (1) et comporte, dans la zone du bloc de plieuse (2), une roue dentée d'entraínement (25) qui est montée à palier dans le bâti de machine et qui, dans une première position de montage du bloc de plieuse (2), engrène avec l'une (22) des roues dentées d'accouplement et en ce que l'un (8) des cylindres de pliage porte, à sa seconde extrémité, une roue dentée de sortie de mouvement (26) qui engrène avec la roue dentée d'entraínement (25) dans une seconde position de montage du bloc de plieuse dans laquelle celui-ci est placé dans le bâti de machine (1) en étant retourné d'une rotation de 180° vis-à-vis de sa première position de montage autour d'un axe imaginaire s'étendant parallèlement à la direction de passage de papier.

- Plieuse à poches suivant la revendication 1, caractérisée en ce que le bâti de machine (1) comporte des dispositifs de positionnement (3) servant à maintenir et positionner le bloc de plieuse (2) dans ses deux positions de montage vis-à-vis du bâti de machine.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19709643 | 1997-03-08 | ||

| DE19709643A DE19709643C1 (de) | 1997-03-08 | 1997-03-08 | Stauchfalzwerk mit zwei oder drei Falztaschen |

| PCT/DE1998/000206 WO1998040300A1 (fr) | 1997-03-08 | 1998-01-22 | Plieuse a poches comportant deux ou trois poches de pliage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1007461A1 EP1007461A1 (fr) | 2000-06-14 |

| EP1007461B1 true EP1007461B1 (fr) | 2002-07-24 |

Family

ID=7822738

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98909278A Expired - Lifetime EP1007461B1 (fr) | 1997-03-08 | 1998-01-22 | Plieuse a poches comportant deux ou trois poches de pliage |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6224530B1 (fr) |

| EP (1) | EP1007461B1 (fr) |

| JP (1) | JP2001521477A (fr) |

| CA (1) | CA2274041A1 (fr) |

| DE (2) | DE19709643C1 (fr) |

| ES (1) | ES2179468T3 (fr) |

| WO (1) | WO1998040300A1 (fr) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6356908B1 (en) | 1999-07-30 | 2002-03-12 | International Business Machines Corporation | Automatic web page thumbnail generation |

| US6665838B1 (en) | 1999-07-30 | 2003-12-16 | International Business Machines Corporation | Web page thumbnails and user configured complementary information provided from a server |

| US6405192B1 (en) | 1999-07-30 | 2002-06-11 | International Business Machines Corporation | Navigation assistant-method and apparatus for providing user configured complementary information for data browsing in a viewer context |

| DE10132910A1 (de) * | 2001-06-28 | 2003-01-16 | Baeuerle Gmbh Mathias | Falzvorrichtung für Bogen aus Papier, Kunststoff und dergleichen |

| US20030073560A1 (en) * | 2001-10-11 | 2003-04-17 | Baldini Gerardo E. | Stops for sheet media folding apparatus |

| PL210927B1 (pl) | 2003-02-25 | 2012-03-30 | Philip Morris Products | Sposób i urządzenie do zaginania i nakładania zagiętych ulotek informacyjnych onsert na artykuły |

| US6981938B2 (en) * | 2003-08-15 | 2006-01-03 | Xerox Corporation | Booklet maker with crease rolls having a slip clutch |

| US6899664B2 (en) * | 2003-09-24 | 2005-05-31 | Gregory R. Gale | Device for returning folded paper and folding apparatus including same |

| US7217232B2 (en) * | 2004-10-26 | 2007-05-15 | Sop Services, Inc. | Automatic paper folder |

| ITBO20060291A1 (it) * | 2006-04-14 | 2007-10-15 | Tech S R L S | Apparecchiatura per la piegatura ordinata di nastri. |

| ATE462669T1 (de) * | 2006-12-08 | 2010-04-15 | Ravensburger Spieleverlag Gmbh | Vorrichtung zum erzeugen dreifach gefalteter papierstreifen in einem durchlauf |

| CN201195647Y (zh) * | 2007-12-19 | 2009-02-18 | 世庆实业股份有限公司 | 折纸机 |

| US9604493B2 (en) | 2009-11-25 | 2017-03-28 | Bell And Howell, Llc | Method and system to manufacture an integrated return mailpiece on wrapping document processing system |

| US20110192892A1 (en) | 2010-02-09 | 2011-08-11 | Bowe Bell + Howell Company | Mailpiece with personalized communication and return slip and related method utilizing wrapper system |

| IT1400065B1 (it) * | 2010-05-17 | 2013-05-17 | Bacciottini Group S R L | Macchina piegatrice |

| CN116674258A (zh) * | 2023-04-27 | 2023-09-01 | 吴江古乐包装有限公司 | 一种纸勺折叠机构 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE517549C (de) * | 1929-04-06 | 1931-02-09 | Camco Machinery Ltd | Papierfalzmaschine |

| DE730387C (de) * | 1936-04-04 | 1943-01-11 | Brehmer Geb | Stauchfalzmaschine fuer zwei- oder mehrfachen Kreuzbruch |

| DD114579A1 (fr) * | 1974-02-22 | 1975-08-12 | ||

| US4565046A (en) * | 1984-12-24 | 1986-01-21 | Simmons U.S.A. Corporation | Apparatus for manufacturing pocketed coil springs |

| DE4114105C2 (de) * | 1991-04-30 | 1994-09-15 | Baeuerle Gmbh Mathias | Stauchfalzmaschine |

| DE4123499C2 (de) * | 1991-07-16 | 1998-03-19 | Kodak Ag | Vorrichtung zur Papierführung an einem Weiterverarbeitungsgerät für Kopieblätter |

| US5514066A (en) * | 1994-09-01 | 1996-05-07 | Pitney Bowes Inc. | Buckle chute folding machine for different length sheets |

| FR2729939B1 (fr) * | 1995-01-31 | 1997-04-18 | Neopost Ind | Dispositif d'assistance au reglage de dimensions de pliage dans une machine plieuse insereuse |

| US5697880A (en) * | 1995-03-17 | 1997-12-16 | Pitney Bowes Inc. | Inserter including a pivoting conveyor module with staging capability |

| US5967963A (en) * | 1996-11-26 | 1999-10-19 | Grapha-Holding Ag | Apparatus for folding paper sheets |

-

1997

- 1997-03-08 DE DE19709643A patent/DE19709643C1/de not_active Expired - Fee Related

-

1998

- 1998-01-22 ES ES98909278T patent/ES2179468T3/es not_active Expired - Lifetime

- 1998-01-22 DE DE59804915T patent/DE59804915D1/de not_active Expired - Lifetime

- 1998-01-22 US US09/308,849 patent/US6224530B1/en not_active Expired - Fee Related

- 1998-01-22 JP JP53904398A patent/JP2001521477A/ja active Pending

- 1998-01-22 WO PCT/DE1998/000206 patent/WO1998040300A1/fr not_active Ceased

- 1998-01-22 CA CA002274041A patent/CA2274041A1/fr not_active Abandoned

- 1998-01-22 EP EP98909278A patent/EP1007461B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| US6224530B1 (en) | 2001-05-01 |

| EP1007461A1 (fr) | 2000-06-14 |

| DE19709643C1 (de) | 1998-07-16 |

| CA2274041A1 (fr) | 1998-09-17 |

| ES2179468T3 (es) | 2003-01-16 |

| WO1998040300A1 (fr) | 1998-09-17 |

| DE59804915D1 (de) | 2002-08-29 |

| JP2001521477A (ja) | 2001-11-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1007461B1 (fr) | Plieuse a poches comportant deux ou trois poches de pliage | |

| EP0741020B1 (fr) | Machine d'impression rotative comprenant un appareil de pliage à assemblage libre | |

| EP0085751B1 (fr) | Machine rotative d'impression offset de feuilles | |

| EP0481172B1 (fr) | Rotative d'impression pour l'impression de livres et de calandriers, avec deux dispositifs de pliage longitudinal | |

| EP0107126A1 (fr) | Dispositif de guidage de la bande de papier dans une rotative d'impression | |

| DE29501537U1 (de) | Bogenleiteinrichtung mit Luftversorgungskästen | |

| DE19516443A1 (de) | Einzeln angetriebener Falzapparat für eine Rotationsdruckmaschine | |

| EP1634832B1 (fr) | Machine à imprimer comprenant au moins un groupe d'impression, un appareil de pliage avec un cône plieur et au moins un niveau de retournement et de mélange. | |

| EP0054326A2 (fr) | Dispositif d'alimentation en formulaires en continu vers le rouleau d'impression et à partir de celui-ci | |

| DE19610900A1 (de) | Falzapparat mit einem heftebildenden Zusatzmodul | |

| EP1498353B1 (fr) | Machine pour l'emballage | |

| EP1456107A1 (fr) | Dispositif de production de produits plies | |

| EP1762527A2 (fr) | Partie supérieure d'une groupe de pliage | |

| EP0303556B1 (fr) | Dispositif de guidage de papier pour machines de bureau, notamment pour imprimantes à matrice | |

| DE4329688C1 (de) | Falzschwertanordnung für Schwertfalzwerke | |

| DE9312170U1 (de) | Falzapparat für Rollenrotationsdruckmaschinen | |

| DE1761377A1 (de) | Papierbogenfalzmaschine | |

| EP0351480B1 (fr) | Station d'impression avec dispositif de sortie pour feuilles individuelles | |

| DE29704263U1 (de) | Stauchfalzwerk mit zwei oder drei Falztaschen | |

| DE10163211C2 (de) | Vorrichtung zur Herstellung von Falzprodukten | |

| DE2408351C3 (de) | Kombinierte Vierbruchfalzmaschine | |

| EP0153668B1 (fr) | Machine à plier | |

| EP0170251B1 (fr) | Plieuse | |

| EP1348665A2 (fr) | Plieuse avec un module pour plier des feuilles en direction perpendiculaire au pli transversal | |

| DE315587C (fr) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19990812 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI NL SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010711 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: JOERG, HELMUT Inventor name: OKELMANN, WALTER |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI NL SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020724 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: LUCHS & PARTNER PATENTANWAELTE |

|

| REF | Corresponds to: |

Ref document number: 59804915 Country of ref document: DE Date of ref document: 20020829 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20021024 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2179468 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030425 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20031231 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050801 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20050801 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20100125 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20100126 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: BOEWE SYSTEC GMBH Free format text: BOEWE SYSTEC AG#WERNER-VON-SIEMENS-STRASSE 1#86159 AUGSBURG (DE) -TRANSFER TO- BOEWE SYSTEC GMBH#WERNER-VON-SIEMENS-STR. 1#86159 AUGSBURG (DE) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20110202 Year of fee payment: 14 Ref country code: DE Payment date: 20110121 Year of fee payment: 14 Ref country code: CH Payment date: 20110124 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20110519 AND 20110525 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 59804915 Country of ref document: DE Owner name: BOEWE SYSTEC GMBH, DE Free format text: FORMER OWNER: BOEWE SYSTEC AG, 86159 AUGSBURG, DE Effective date: 20110429 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110120 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: BOWE SYSTEC GMBH, DE Effective date: 20110831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110122 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20120220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110123 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120122 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120122 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120801 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59804915 Country of ref document: DE Effective date: 20120801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 |