EP0974532A2 - Distributeur pour bloc de sachets en film de matière thermoplastique - Google Patents

Distributeur pour bloc de sachets en film de matière thermoplastique Download PDFInfo

- Publication number

- EP0974532A2 EP0974532A2 EP99113230A EP99113230A EP0974532A2 EP 0974532 A2 EP0974532 A2 EP 0974532A2 EP 99113230 A EP99113230 A EP 99113230A EP 99113230 A EP99113230 A EP 99113230A EP 0974532 A2 EP0974532 A2 EP 0974532A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- dispenser

- bags

- bag

- pack

- folded

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/08—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession

- B65D83/0894—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession the articles being positioned relative to one another or to the container in a special way, e.g. for facilitating dispensing, without additional support

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/001—Blocks, stacks or like assemblies of bags

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/08—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession

- B65D83/0847—Containers or packages with special means for dispensing contents for dispensing thin flat articles in succession through an aperture at the junction of two walls

Definitions

- the invention relates to a dispenser with a Handle recess for the individual removal of a bag thermoplastic plastic film from a bag pack, whereby the bags in the area of an edge strip at least are blocked in areas to pack and with a perforated formed below the interlocking area Tear line to separate the bag from the blocked one Edge strips are equipped and the packing of bags parallel to the tear line to reduce the size is folded at least once and the dispenser is a flat one cuboid shape, top and narrow sides.

- Bags are often packaged in outer packaging Handle recesses made for individual removal.

- An example is DE 94 08 149.2 U1 or US-A-5655682 referred.

- the invention has for its object a donor or To create dispensers for taking bags out Packing bags, especially large format bags.

- An object of the invention is to dispense the donor to keep its format as small and handy as possible, so that if necessary, it can also be carried in a handbag or does not take up much space where it is needed.

- the large-format bag to be accommodated is the Fold bags or bag packs into smaller formats.

- Each the bag size is larger and the more folding edges are available the more difficult it is, however, to have an orderly one Removing individual bags from a package, in particular is a shifting of the bags remaining in the dispenser can hardly be prevented with multiple folded bags.

- the dispenser according to the invention with a known one Donors not only enlarged, but three-dimensional trained handle recess, which is namely over two Sides extends, namely from the top to one adjacent narrow side, an orderly removal is on small format folded bag made in the dispenser accommodated packing bags.

- a known one Donors not only enlarged, but three-dimensional trained handle recess, which is namely over two Sides extends, namely from the top to one adjacent narrow side, an orderly removal is on small format folded bag made in the dispenser accommodated packing bags.

- the dispenser according to the invention to remove Bags from packs of bags where the bags are packaged are folded several times and the bags themselves their longitudinal axis are folded during manufacture.

- a donor for long-term use that is refillable, suggested in two-part shape with floor box and lid box from one rigid material, such as cardboard, cardboard or plastic, the Handle recesses with the adjoining two-sided Columns are formed in the lid box.

- the donor or the lid box and / or the bottom box inside elastic means exerting spring pressure and / or stiff retaining cams for fixing an inner packing of bags to equip.

- the bag packs or folded bag packs even by inserting a carrier stabilize for example from cardboard or cardboard regarding the folded format. Since the packs of Bags due to the fact that the bags are made of thermoplastic film are made, none have self-supporting properties additional measure for stabilizing the packing as such usual.

- the donor has such a size and at least two Handle recesses of the same or different sizes is designed to have a corresponding number of Pick up bags of the same or different sizes can.

- the interior can be used for an orderly insertion of the bags by appropriate webs or the like, preferably the Floor box, be formed divided.

- the packaging of bags so in the Dispenser can be inserted for removal that the folded Parts of the bags are adjacent to the bottom and the first Folding edge of the bags, calculated from the tear line the same, the bottom edge of the donor with the columns are arranged adjacent.

- one for the positionally secured insert Packing bags in the dispenser suggested this Secure position at the same time via the carrier insert Stabilize the packing of bags.

- the carrier insert is preferably in the first fold of the Packing bags, counting from the tear line of the same, inserted.

- Such a carrier insert can with a tab Push through in the blocked edge strip of the Pack trained slot to fix the location of the Packing both in terms of the carrier insert and in be trained in relation to the donor. The tab can then further be fixed within the donor.

- the inventive design of handle recesses two adjoining pages in three-dimensional form such that a large handle opening on a large one Surface of the dispenser in connection with a slit-shaped handle opening that is essentially the width the pack of bags to be placed in the dispenser, can not only stiffen on dispensers self-supporting materials, but also based on them soft wrapping materials can be used.

- the Dispenser made of a non-self-supporting wrapping material in Shape of a closed envelope, like a plastic film, be made, the handle recess and the adjacent Gap by means of perforated characteristics in the envelope material are formed and then for later opening along the Characteristic curves of the handle recess by tearing them open is trainable.

- the donor be stationary for example in the kitchen or next to a cash register or on should be at least temporarily attachable to a counter, it is suggested at least on the back of the donor one covered with a removable protective film Attach the pressure sensitive area.

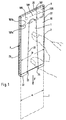

- FIG. 1 schematically shows a dispenser or dispenser 2 shown having a flat cuboid shape Top 20, narrow long sides 26, 27 of a head edge 25 and opposite lower edge 22 and one Bottom.

- the dispenser 2 there is a pack P with bags 1 inserted, the bag in an edge region R, the runs parallel to the top edge of the dispenser, in at least an area 105 are interlocked and preferred a slot 108 running through the edge strip R in the middle can be formed by stamping.

- the individual bags are each via a perforated tear line 107 with the Edge strips R connected.

- the handle recess 21 educated.

- the handle recess 21 extends to the lower edge 22 of the donor and, for example, has a slight conical shape.

- the handle recess 21 is like this great that it can be reached comfortably with one finger can to by pressing the bag and at the same time Trigger movement in the direction of arrow F, i.e. towards the lower edge a bag 1 from the edge strip R at the tear line 107 can be separated and pulled out.

- the handle recess 21 takes up, for example, in the area of the lower edge Third of the width B of the dispenser.

- the handle recess 21 is in the area of the lower edge 22 in Direction of the two narrow long sides 26, 27 through on the Lower edge, preferably running on the lower narrow side trained column 23, 24 widened. To this Way is following on the lower edge 22 of the dispenser 2 the handle recess 21 is a pull-out slot with a length corresponding approximately to the width m of a bag 1 formed.

- the Handle recess 21 and that formed by the gaps 23, 24 Pull-out slits run on successive sides of the Dispensers 2.

- Handle recess 21 allows the topmost to be gripped Bag 21 for pulling the same from the edge strip R over tear line 107, during the subsequent one Pull-out slit on the lower edge, formed by the gaps 23, 24 in connection with the handle recess 21, the light Pull out the gripped bag 1 over its entire Allow width m from dispenser 2 in direction of arrow F.

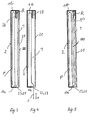

- a dispenser 2 in two parts with a Floor box 2b and a lid box 2a shown, the Donors, for example, by injection molding from one thermoplastic can be made.

- the bag pack P is preferably in the floor box 2b inserted and the dispenser by placing the lid box 2a closed.

- the lid box has the all-round Narrow sides 26, 27, 25 and 22 on and the top 20, in of the handle recess 21, which to the bottom edge designated narrow side goes through.

- On the lower edge 22 is in the area of the adjacent narrow side to the top 20 a gap 23 and 24 respectively on the side of the handle recess continued laterally towards the side edges, whereby an extension slot is formed on the narrow side.

- the length this pull-out slot corresponds essentially to the width m of packing bags into the dispenser for removal is inserted.

- the height d of the floor box 2b is preferably smaller than that Height c + a of the lid box 2a of the dispenser, see Fig. 2, where a is the depth of the gaps 23, 24. D of the bottom box is equal to c of the top box. In this way the pull-out gap can easily be formed in the area "a" become. If the floor box has a greater height, is not only on the lower edge - narrow side - of the lid box the pull-out slot by means of the additional gaps 23, 24 train, but also at the appropriate a corresponding narrow side of the floor box slot-like recess to form a continuous Pull slot.

- the floor box 2b is with a Bag pack P, see Fig.

- this Bag packs can have a slightly greater thickness than that Height d of the floor box corresponds, so that the bag pack can protrude above the top of the floor box. It can additional elastic inserts 29, as schematically indicated on the back of the lid box 2a, either in the floor box or in the lid box, so that the pack of bags between the elastic cushions 29 and the top 20 of the lid box 2a out of position is, if necessary under a slight spring pressure.

- elastic cushions 29 are preferred in the floor box 2b in the corner areas adjacent to the later pull-out opening arranged.

- a holding cam 28 may be formed.

- the holding cam 28 if it extends parallel to the top 20, such Leave space that the blocked edge strip of the Bag packs, see Fig. 1, insertable in between and light can be clamped.

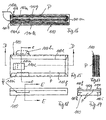

- the individual bags 1 in this way are manufactured so that they are manufactured in in Folding edges lying in the longitudinal direction of the bag with respect to them Width can be folded in, for example in FIG. 10 shown in perspective, here an M-fold of Bag 1 is provided around folded edges 120.

- the pouch 10 are at their lower end, like shown, before folding in longitudinal extension with a Provide weld seam 101. But it is also possible to use the pouch 1 to be welded in this area after the M-fold, whereby then a weld seam welds the bag in the M-fold.

- the bag 1 according to FIG blocked other bags, not shown, see Fig. 1, so that a pack of, for example, 50 bags is produced, wherein after the production of the blocked sachet pack the Pack by punching with the slot 108, see Fig. 1, and the perforated tear line 107 is provided.

- a perforated tear line in shape is preferred of about half waves or sickle-like incisions, the Incisions 107a are continuously punched and only in the transition to the next incision 107a Connecting web 107b remains, which holds the bag with the Edge strips connects and when the bag is subsequently pulled off is severed by the edge strip.

- FIG. 11 shows how the bag 1 according to FIG. 10 is separated from the edge strip R at the tear line 107, the bag only after tearing and pulling out from the dispenser 2 is unfolded again, see Fig. 11, and then opened in the area of the tear line.

- Bags and bag packs with bags according to FIG. 10 can now with regard to the bag width according to the number of their Folds around longitudinal axes are narrowed and can further through further foldings transverse to its longitudinal axis as packs can be reduced in size again.

- U folds, Z folds and folded Z folds can be used can be used with advantage for the bag packs.

- FIG. 3 is a schematic cross section through a Cuboid shaped dispenser, as shown in Fig. 2, for example a two-part dispenser box according to section AA, shown.

- the schematic representation of the donor 2 shows the handle recess 21 on the top 20 of the dispenser with that formed by the gaps 23, 24 on the lower edge Pull-out slit, creating a three-dimensional opening for the A bag is removed.

- the pack of bags inside of the dispenser 2, of which schematically only one bag 1 is shown, is folded in a Z-shape, so that three layers with two folds 1a, 1b arise.

- the bag pack is included the bags folded so that the folds to the bottom of the donor are directed so that the first folding 1a to lie adjacent to the pull-out slot of the columns 23, 24 comes and the second fold near the top edge of the dispenser is arranged.

- Fig. 4 it is shown how the bag 1 through Removal, as shown in FIG. 1, from the dispenser 2 through the pull-out slot formed on the lower edge 22 by means of the column 23, 24 and the handle recess in The direction of the arrow F is pulled out, starting with the upper one One third of the folded bag is pulled out until Folding edge 1a and then the next part of the Bag connects and then the end, being an orderly Removing and pulling a bag out of the dispenser 2 is enabled and the remaining bags of the bag pack that are still blocked with the edge area, not from theirs folded orderly position are moved.

- a rigid stabilizing Carrier insert 110 can be provided, for example between the first and second folding of the bag pack is inserted, see FIG. 5.

- Fig. 6 is shown schematically how the Bag packs P also in the folded Z-fold with two Refoldings 1a, 1b can be accommodated in the dispenser and to stabilize the packing between the first and second Folding a flat carrier insert 110, for example, is inserted from cardboard.

- the dispenser according to the invention as a box, such as in 2 is particularly suitable for the individual Removing bags from a pack of bags, the Packing bags is folded several times to make it little To take up space.

- a bag packing is shown for example in Fig. 7a, 7b.

- Fig. 7a, 7b As from the Side view of Fig. 7b emerges, is from a Variety of superimposed and in the edge area R blocked bags 1 existing packs P across

- the longitudinal extension of the bags is folded twice and in a Z shape folded so that the packs to a third of its length is shortened.

- the bag pack P is made in such a way that the individual Bags 1 are stacked and in the edge area, the the bottom weld of the bag is opposite to each other blocked, see here the two blocking areas 105 Detach the bag 1 from the blocked edge strip R.

- a perforated tear line 107 is provided. Is preferred this tear line 107 of half waves or arches 107a, as from 7a can be seen, formed as punch cuts are executed, with small between each half wave Connecting webs 107b remain when the bags are torn off be severed from the edge strip. With the help of it is arcuate tear line 107 according to FIG. 7a possible to clean the bag 1 from the edge strip R.

- the bags made of thermoplastic plastic film are not are self-supporting, but very soft and handy as they are made of thin film, it is for an orderly removal and Securing the position of the pack, as described in FIGS. 7a, b is, conveniently, the folded bag pack by means of a rigid support insert 110, preferably between the first and second fold of the pack is insertable to stabilize.

- 8a and 8b is a possible form of such Carrier insert 110 shown from cardboard.

- the carrier insert 110 an additional securing device for the packing within the Equip donors.

- a Type closure can be produced.

- a as in Fig. 7a, b Equipped packs shown is in Fig. 5 in Cross section shown inserted in a dispenser 2, wherein this dispenser 2 is designed as a box and schematically is shown.

- the carrier insert With the help of the carrier insert, the Securing the position of the packing, in particular the edge strip for orderly tearing of bags inside the dispenser be made possible.

- Dispenser with multiple handle openings, for example three Handle recesses 21, as shown in Fig. 9, manufacture.

- the dispenser 2 is again in two parts, as in FIG. 2 explains, forms and has, for example, two large ones Handle recesses 21 and a smaller handle recess 21, the floor box is divided by webs 121 for three Pack and another intermediate web 122 for smaller packs are provided for a smaller compartment or but also in this area, for example, an insert can be provided to suit the space for one to shrink smaller packs.

- a further carrier insert 110 for the inclusion of a folded bag pack to secure the folded state of the bag packing also for the later Removal and tearing of individual bags from the packs shown.

- the carrier insert 110 folded slightly box-shaped with a bottom area 110k, at the Foldable folding areas connect to the side edges.

- the small bottom face 110m is provided, to both On the long sides, the double folding areas 110e and 110f, so that by folding these areas 110f and 110e an open one Box with a side guide to be inserted Bag packaging is formed.

- a double fold area over the web 110b is formed with a large cover flap 110g, wherein in the cover flap a recess 110c with a bendable Tab 110a is formed.

- the cover flap has 110g side guide tabs 110i and 110h, which, as from the Fig. 13 can be seen by double folding a sub-chamber 110b for the first folded over on the bottom of the Form the carrier insert of the folded part of the bag pack, see also Fig. 19.

- Figs. 13 and 14 show the to Box folded carrier insert for the admission of a Bag packing.

- the top layer 110g is between the top layer of the Bag packing and the first folding of the bag packing inserted. This way the folded bag packing is in the folded in as shown in Figs. 13 and 14 Carrier insert securely fixed in position and against slipping secured even when individual bags are torn off.

- FIG. 15 is the top view of the folded Carrier insert 110 with inlaid schematically indicated Bag pack P, see also the cross sections as in Fig. 16 and 17 shown.

- the Z-folded bag pack P lies with its lowest folding part on the bottom surface 110k Carrier insert on, while the top layer 110g in the others Folding the bag pack is inserted. 15, 18 and 19 the pack of bags is not shown in detail.

- the Tab 110a of the cover layer can then be cut through the punching slot 108 of the bag packing, see explanations for Fig. 7a, be inserted and by bending in the direction of the arrow, 16, are fixed in position so that when the folded bag pack P according to FIG. 16 with carrier insert in a donor the flawless removal of the individual bags is possible.

- the two folding areas 110f and 110e end the top of the bag pack, so that there is enough space for Grasp the bag is given.

- the carrier insert 110 folded into a box enables inserting the folded pack of bags, each Fold the bag pack on all sides through the folded carrier insert is guided.

- the one on the top layer 110g trained side flaps 110h, i that face down are folded around a folded position of the bag pack P are preferably in the region of the tear-off edge to be located here the bag arranged and secure with their leading edge H the perfect tearing off and orderly pulling out the Bag.

- Carrier insert 110 with inserted bag packs P are shown as a unit in an outer packaging packed and can be removed in one after removing the outer packaging Donors, see Fig. 2, are inserted for consumption.

- the present invention enables among improved Conditions, the removal of plastic bags from a Dispenser, the dispenser being cuboid-shaped a rigid material, such as plastic or cardboard, can be made or from a softer Wrapping material in one piece.

- the donor is characterized by that he's one in the middle of the top of the dispenser Has trained handle recess that up to one Bottom edge goes through and in the area of this bottom edge or the adjoining side edge of the dispenser towards the sides is widened like a slit, which in addition to the Handle recess on the top of an extension slot on the adjoining page, which enables the Bags in full width as in the dispenser is housed, ordered by the pull-out slot deduct.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Bag Frames (AREA)

- Laminated Bodies (AREA)

- Making Paper Articles (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29812819U | 1998-07-18 | ||

| DE29812819U DE29812819U1 (de) | 1998-07-18 | 1998-07-18 | Beutelpacken von Beuteln aus thermoplastischer Kunststoffolie |

| DE29812818U | 1998-07-18 | ||

| DE29812818U DE29812818U1 (de) | 1998-07-18 | 1998-07-18 | Spender für Packen von Beuteln aus thermoplastischer Kunststoffolie |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0974532A2 true EP0974532A2 (fr) | 2000-01-26 |

| EP0974532A3 EP0974532A3 (fr) | 2000-08-16 |

Family

ID=26061683

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98122423A Expired - Lifetime EP0974526B1 (fr) | 1998-07-18 | 1998-11-26 | Blocs de sachets en film de matière thermoplastique et procédé pour leur fabrication |

| EP99113230A Withdrawn EP0974532A3 (fr) | 1998-07-18 | 1999-07-08 | Distributeur pour bloc de sachets en film de matière thermoplastique |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98122423A Expired - Lifetime EP0974526B1 (fr) | 1998-07-18 | 1998-11-26 | Blocs de sachets en film de matière thermoplastique et procédé pour leur fabrication |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6286680B1 (fr) |

| EP (2) | EP0974526B1 (fr) |

| AT (1) | ATE246125T1 (fr) |

| DE (1) | DE59809160D1 (fr) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050261119A1 (en) * | 2004-05-18 | 2005-11-24 | Sabrina Pichee Chen | Tri-fold plastic bag roll, method and apparatus for making same |

| US8834335B2 (en) * | 2004-05-18 | 2014-09-16 | Sabrina Pichee Chen | Tri-fold plastic bag roll, method and apparatus for making same |

| DE202005012851U1 (de) * | 2005-08-16 | 2005-12-08 | Papier-Mettler Inhaber Michael Mettler | Beutelstrang, insbesondere Knotenbeutelstrang, sowie Beutelspender, insbesondere Knotenbeutelspender |

| US7775717B2 (en) * | 2005-10-12 | 2010-08-17 | Sealed Air Corporation (Us) | Compacted bag configuration and method for making the same |

| US7963898B2 (en) | 2007-07-26 | 2011-06-21 | Greg Tan | Tri-fold side seamed plastic produce bag, method and apparatus for making same |

| EP2244621A4 (fr) * | 2007-12-19 | 2016-03-23 | Sca Hygiene Prod Ab | Toile perforée et repliée |

| US9296547B2 (en) | 2012-02-27 | 2016-03-29 | All In One Bag Aps | Assembly assembled of a recipient and a retainer, a method for producing the assembly, and a use of the assembly |

| US9517605B2 (en) | 2012-08-08 | 2016-12-13 | Greg Tan | Tri-fold plastic bag roll, method and apparatus for making same |

| US10308426B2 (en) * | 2015-11-05 | 2019-06-04 | Deja S. Castro | Trash bag apparatus |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1255139A (en) * | 1970-02-23 | 1971-11-24 | Smith & Nephew | Dispenser for first-aid dressings and like flat articles |

| US4175673A (en) * | 1977-11-21 | 1979-11-27 | Union Carbide Corporation | Dispensing carton for corrugated plastic bags |

| US4527693A (en) * | 1984-03-12 | 1985-07-09 | Hercules Membrino | Box dispenser for pad of plastic bags |

| DE9408149U1 (de) * | 1994-05-18 | 1994-08-04 | Hofrichter, Karl Heinz, Sao Paulo | Hüllbeutel aus Kunststoffolie für einen Packen von verblockten Beuteln aus Kunststoffolie |

| US5655682A (en) * | 1994-08-26 | 1997-08-12 | Phimaplan Industria E Comercio De Materiais Plasticos Ltda | Container that dispenses articles made of thin and flexible plastic sheets |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3242510A1 (de) * | 1982-11-18 | 1984-05-24 | Karl-Heinz Dr. 4802 Halle Sengewald | Abreissbeutel aus kunststoffolie |

| GB2131392B (en) * | 1982-11-18 | 1986-09-24 | Sengewald Karl H | Bag |

| DE3420620C1 (de) * | 1984-06-02 | 1985-11-07 | LEMO M. Lehmacher & Sohn GmbH Maschinenfabrik, 5216 Niederkassel | Stapel aus Tragetaschen |

| US4854451A (en) * | 1986-12-17 | 1989-08-08 | Jensen Harold A | Apparatus for the manufacture of block-sealed side-gussetted bags |

| ES2050652T3 (es) * | 1986-07-23 | 1994-06-01 | Pathold Investments Co | Bolsas. |

| US5226858A (en) * | 1992-02-27 | 1993-07-13 | Equitable Bag Co., Inc. | Method and apparatus for producing bags interconnected at their open ends |

| US5469969A (en) * | 1992-06-25 | 1995-11-28 | Durabag, Inc., A California Corporation | Self-opening plastic bag pack system |

| US5348399A (en) * | 1992-12-23 | 1994-09-20 | Dematteis Robert B | Plastic bags with waveform edge configurations |

| CA2164485A1 (fr) * | 1994-12-08 | 1996-06-09 | Robert Dematteis | Sacs de type "t-shirt" et ratelier |

| US5924573A (en) * | 1997-01-20 | 1999-07-20 | Orange Plastics, Inc. | Easy dispense plastic bag dispensing system |

-

1998

- 1998-11-26 AT AT98122423T patent/ATE246125T1/de not_active IP Right Cessation

- 1998-11-26 DE DE59809160T patent/DE59809160D1/de not_active Expired - Fee Related

- 1998-11-26 EP EP98122423A patent/EP0974526B1/fr not_active Expired - Lifetime

-

1999

- 1999-02-19 US US09/252,766 patent/US6286680B1/en not_active Expired - Fee Related

- 1999-07-08 EP EP99113230A patent/EP0974532A3/fr not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1255139A (en) * | 1970-02-23 | 1971-11-24 | Smith & Nephew | Dispenser for first-aid dressings and like flat articles |

| US4175673A (en) * | 1977-11-21 | 1979-11-27 | Union Carbide Corporation | Dispensing carton for corrugated plastic bags |

| US4527693A (en) * | 1984-03-12 | 1985-07-09 | Hercules Membrino | Box dispenser for pad of plastic bags |

| DE9408149U1 (de) * | 1994-05-18 | 1994-08-04 | Hofrichter, Karl Heinz, Sao Paulo | Hüllbeutel aus Kunststoffolie für einen Packen von verblockten Beuteln aus Kunststoffolie |

| US5655682A (en) * | 1994-08-26 | 1997-08-12 | Phimaplan Industria E Comercio De Materiais Plasticos Ltda | Container that dispenses articles made of thin and flexible plastic sheets |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE246125T1 (de) | 2003-08-15 |

| EP0974526A2 (fr) | 2000-01-26 |

| DE59809160D1 (de) | 2003-09-04 |

| EP0974526B1 (fr) | 2003-07-30 |

| EP0974526A3 (fr) | 2000-08-16 |

| US6286680B1 (en) | 2001-09-11 |

| EP0974532A3 (fr) | 2000-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0030601B1 (fr) | Emballage souple formé à partir d'une feuille de matière plastique, en particulier pour des mouchoirs en papier | |

| EP0544156B1 (fr) | Emballage pour feuilles en papier, en particulier pour mouchoirs en papier | |

| EP0401621B1 (fr) | Emballage flexible, en particulier pour mouchoirs en papier | |

| DE69404102T2 (de) | Wiederverschliessbare Packung und Verfahren zur Herstellung eines Zuschnitts für eine solche Packung | |

| DE69830080T2 (de) | Spender für vorgeformte beutel sowie beutel dafür | |

| DE4139924A1 (de) | Weichpackung fuer papiertaschentuecher | |

| DE2654867C3 (de) | Verpackter Aufgußbeutel, insbe-, sondere für Tee | |

| DE69203232T2 (de) | Vorrichtung zum öffnen eines beutels aus flexiblem material für pressbare produkte. | |

| DE1918248A1 (de) | Blattspender,insbesondere fuer Zellstofftuecher | |

| DE7833822U1 (de) | Beutelvorratspackung | |

| DE3410217A1 (de) | Zuschnitt fuer parallelepipedische verpackungen oder verpackungselemente | |

| DE29618895U1 (de) | Faltschachtel, insbesondere zur Aufbewahrung von Hygieneartikeln | |

| EP0974532A2 (fr) | Distributeur pour bloc de sachets en film de matière thermoplastique | |

| EP0046518B1 (fr) | Emballage pour fil de suture chirurgical | |

| DE29502062U1 (de) | Zigarettenpapierbüchel | |

| DE19946257A1 (de) | Verpackung zur Aufnahme von zwei Brötchenhälften mit dazwischenliegendem Belagbeutel und einer Vorrichtung zu seinem Entleeren | |

| EP0360925B1 (fr) | Emballage pour mouchoirs en papier | |

| DE3618765A1 (de) | Schlauchbeutelverpackung fuer tafel- oder riegelfoermiges gut, beispielsweise schokoladeprodukte | |

| DE2614235A1 (de) | Filtertuetensatz | |

| DE60121740T2 (de) | Steife verpackung für eine mehrzahl von zigarettenpackungen | |

| DE3246162C1 (de) | Packung fuer chirurgisches Nahtmaterial | |

| DE4006224A1 (de) | Faltschachtel, insbesondere zur verpackung von hygiene-produktion | |

| DE60004774T2 (de) | Schachtel mit zwei zu einander versetzten Ausgabeöffnungen | |

| DE60004472T3 (de) | Spenderpackung zur Einzelentnahme bahnförmiger Gebrauchsartikel | |

| DE29812818U1 (de) | Spender für Packen von Beuteln aus thermoplastischer Kunststoffolie |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 7B 65D 33/00 A, 7B 65D 83/08 B |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| AKX | Designation fees paid | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20010217 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |