EP0926343A2 - Schalldämpfer für einen Kältemittelkompressor - Google Patents

Schalldämpfer für einen Kältemittelkompressor Download PDFInfo

- Publication number

- EP0926343A2 EP0926343A2 EP98124260A EP98124260A EP0926343A2 EP 0926343 A2 EP0926343 A2 EP 0926343A2 EP 98124260 A EP98124260 A EP 98124260A EP 98124260 A EP98124260 A EP 98124260A EP 0926343 A2 EP0926343 A2 EP 0926343A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- channel

- damper

- outlet

- compressor according

- refrigerant compressor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/0027—Pulsation and noise damping means

- F04B39/0055—Pulsation and noise damping means with a special shape of fluid passage, e.g. bends, throttles, diameter changes, pipes

Definitions

- the invention relates to a refrigerant compressor, comprising a compressor housing, at least one in the compressor housing arranged cylinder chamber, one in the cylinder chamber oscillating piston, one of the cylinder chamber upstream suction chamber from which refrigerant in the cylinder chamber enters, one downstream of the cylinder chamber Pressure chamber in which in the cylinder chamber compressed refrigerant enters, and one of the pressure chamber downstream outlet duct.

- Such refrigerant compressors are from the prior art Technology known.

- the invention is therefore based on the object of a refrigerant compressor to improve the generic type in such a way that an effective damping of Pulsations is possible.

- This task is the beginning of a refrigerant compressor described type according to the invention solved in that compressed refrigerant through a damper duct from the Pressure chamber flows into the outlet channel that an inlet opening of the damper channel with a cross-sectional jump in the pressure chamber opens and that an outlet opening of the damper duct with a cross-sectional jump opens into the outlet channel.

- This concept according to the invention has the great advantage that a damping element to be provided in the lines is eliminated, so that additional pipe connections to install this Damping element are eliminated and that also the damper channel works optimally, since all pulsations are directly in the area their creation, namely in the pressure chamber of the refrigerant compressor dampens while a provided in the lines Damping element always has the disadvantage that even then, if it works optimally, is able to where it is arranged to dampen the pulsations as before, however, up to the damping element the undesirable Pulsations occur and unwanted noises and others Cause interference.

- the decoupling between the damper channel and the Pressure chamber also favored that the cross-sectional jump at least between the damper duct and the pressure chamber is a factor of 5, in which case a cross-sectional jump from the large cross section of the pressure chamber a cross section smaller by a factor of 5, namely the the inlet opening of the steam channel.

- the pressure chamber has a buffer volume, which pressure vibrations of the compressed refrigerant dampens and therefore ensures that the cylinder chambers relate to the pressure chamber compressed refrigerant supplied is not too large Pressure vibrations or pulsations in the pressure chamber leads.

- the buffer volume is like this is large that there are pressure vibrations so far dampens that it has a maximum amplitude of 20% have a mean outlet pressure.

- the outlet channel a buffer volume to dampen pressure vibrations or Forms pulsations.

- the outlet channel has an outlet chamber with a buffer volume.

- the outlet chamber is preferably also dimensioned in such a way that the buffer volume pressure fluctuations so far dampens that this has a maximum amplitude of 20% have a mean outlet pressure. Is particularly cheap this solution is preferred when following the outlet duct flanged to the compressor housing, a valve provided is so that the outlet channel with the outlet chamber as a whole forms a volume in which pressure vibrations could build up or in what pressure vibrations through the above buffer volume can be damped.

- damper channel itself extends over its entire length in the damper tube, so that the damper tube as an additional part in the compressor housing is inserted.

- the damper tube can be arranged, for example, that it extends into the pressure chamber.

- the outlet chamber has a volume greater than about 1.5 times, better still more than 2 times the in this lying section of the damper channel.

- a solution that is particularly favorable in terms of its effect provides that the damper channel is designed so that in essentially the entire compressed refrigerant the damper duct flows through.

- damper channel in Area of a transition of the pressure chamber into the outlet channel Closure element between the pressure chamber and the outlet channel enforced.

- a closure element can in the simplest Case with a receiving the damper channel Shock tube connected collar.

- damper channel has a straight section.

- Such one straightened section of the damper duct has the great advantage that the damper tube receiving this is easy to use.

- the inventive solution that the damper channel has a curved portion.

- the curved one Section can in principle both in the outlet channel and in Pressure room.

- a particularly favorable solution provides that the curved Section of the damper channel in the cylinder head, in particular the same in the pressure chamber, since in particular the Pressure room anyway has a large volume, so that in in this case, the arrangement of the curved section therein is cheap.

- the pressure chamber in a cylinder head is arranged and such Cylinder head easy due to its removability Access to the pressure chamber and thus easy installation a damper tube with a curved section allowed.

- damper channel which the takes up the entire damper channel

- the damper channel is at least partially molded into the compressor housing.

- a particularly suitable place for this is the cylinder head of the Compressor housing in which the damper duct is easier Forms way, which on the one hand assembly is facilitated and on the other hand the possibility is created, the greatest possible length of the damper channel to accommodate.

- a particularly advantageous in terms of assembly Construction provides that the inserted in the cylinder head Damper channel arranged in a in the outlet channel Damper pipe continues.

- the inlet opening of the damper channel in point in any direction.

- the inlet opening the damper duct outlet valves arranged in the pressure chamber is. This is an advantageous inflow in particular of the compressed refrigerant into the damper tube guaranteed and thus ensured that the Pulsations of compressed refrigerant as close as possible already dampened in their place of origin by the damper tube or be compensated.

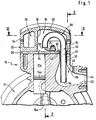

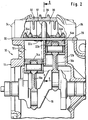

- FIGs. 1 to 3 An embodiment of a refrigeration compressor according to the invention, shown in Figs. 1 to 3, includes a as Whole with 10 designated compressor housing with a Crankcase 11, in which two cylinder chambers 12a, 12b are arranged in which pistons 14a, 14b can be moved in an oscillating manner are, the pistons 14a, 14b with connecting rods 16a, 16b a crankshaft 18 which cooperate in the crankcase 11 is stored.

- the crankshaft 18 is, for example, by a Engine not shown in the drawing, preferably a Electric motor, driven.

- the cylinder chambers 12a, b are on the head side by one on the Valve plate 20 resting on crankcase 11 is closed, which include both intake valves 22a, b and exhaust valves 24a, b.

- Valve plate 20 On a side facing away from the cylinder chambers 12a, b Valve plate 20 is located on the one hand, as shown in FIGS. 1 and 3, a suction chamber 26, which with a through the Crankcase 11 is connected through suction channel 28 and a pressure chamber 30.

- the suction chamber 26 and the pressure chamber 30 are both above the Valve plate 20 in one of the compressor housing 10 included Cylinder head 32 arranged, which the bell-like Valve plate 20 engages and with this together with the Crankcase 11, is connected, for example Screws.

- the cylinder head 32 has an outer wall 34, which total the suction chamber 26 and the pressure chamber 30 outside encloses, and a partition 36, which is between opposite areas of the outer wall 34 for separation extends from suction chamber 26 and pressure chamber 30. Both the outside wall 34 and the partition 36 extend from the Valve plate 20 to a cylinder head cover 38, the Suction chamber 26 and the pressure chamber 30 on the valve plate 20 opposite side completes.

- an opening 40 is provided so that a connection between the pressure chamber 30 and one in the compressor housing 10 provided, preferably one in the crankcase 11 molded, outlet channel 42, which in turn opens into an outlet opening 44 to which an usual line system, not shown in the drawing connects.

- the outlet channel 42 is preferably opposite each other the opening 40 widening and to the outlet opening 44 again narrowing outlet chamber 46 is formed.

- damper channel provided, which at the first Embodiment is arranged in a damper tube 51, which extends on the one hand in the pressure chamber 30, then penetrates the opening 40 and then in the outlet chamber 46 also extends.

- the damper channel 50 has a straight one Section 52 with which the damper channel 50 through the opening 40 into the outlet chamber 46 extends and opens into this with an outlet opening 54, due to the enlarged cross-sectional configuration the outlet chamber 46 opposite the opening 40 of the section 52 in a central region at a distance from walls 56 of the Outlet chamber 46 extends so that outlet opening 54 a cross-sectional jump from the small cross-section of the outlet opening to the large cross section of the outlet chamber 46 this point results, preferably at least one Factor 5, or even better a factor of 10.

- the straight one Section 52 also extends through the breakthrough 40 into the pressure chamber 30 and in this up to one curved section 58 of the damper channel 50, which in the Connection to the straight section 52 reversed U-shaped curved and with an inlet opening 60 of the Valve plate 20 faces. Also in the area of the inlet opening 60 is a large cross section jump of the pressure chamber 30 at this point to the small cross section the inlet opening 60 is provided, which is preferably at least a factor of 5, or even better a factor of 10.

- the damper channel 50 also has a length that results from it calculates that at the most frequently occurring pulsation frequency a reflection should occur at the open end, so that the returning wave cancels the incoming wave.

- the pressure chamber 30 is dimensioned so large that it is a Buffer volume represents the pressure pulsations through the intermittent supply of compressed refrigerant already dampens, preferably so far that a maximum Amplitude of pressure vibrations less than 20% of one average outlet pressure in the pressure chamber 30.

- the damping of pressure pulsations is further thereby improves that the outlet channel 42, preferably the outlet chamber 46, form a buffer volume that vibrates in the Decouple outlet duct 42 from damper duct 50, the Damping is preferably so large that a maximum Amplitude of pressure vibrations less than 20% of one medium outlet pressure in the outlet duct 42.

- the damper tube 51 is preferably provided with a collar 62, which is on an upper side 64 of the valve plate 20 supports, the damper tube 51 through this with respect its position relative to the valve plate 20 is fixed and also such a seal by the collar 62 of the damper tube 51 relative to the opening 40 is that in essentially all that enters the pressure chamber 30 compressed refrigerant via the damper duct 50 in the Outlet chamber 46 flows in that it is in the pressure chamber 30th enters the inlet opening 60 of the damper duct 50, this flows through and exits to the outlet opening 54 of the same and flows into the outlet chamber 46 and then from this to the outlet opening 44 in the usually connected Lines, for example as the first element of this Lines a valve is provided so that in this case the buffer volume of the outlet channel 42 a noteworthy Importance.

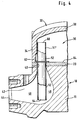

- 4 are those parts that are identical to those of the first embodiment, with provided the same reference numerals, so that with respect to the Full description of the same at first Embodiment can be referenced.

- this includes this variant used damper tube 51 'only the straight section 52 of the damper channel 50 and extends with it from the pressure chamber 30 into the outlet chamber 46, in which case the inlet opening 60 of the Valve plate 20 is arranged facing away and in the direction of Cylinder head cover 38 has.

- the damper tube 51 ′ has the damper channel 50 according to the simplified embodiment in FIG. 4 the same effect as the damper tube 51 according to the first Embodiment as long as the length of the damper channel 50th is sufficient to make the pulsations occurring satisfactory to dampen, and if necessary sufficient buffer volumes are provided.

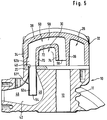

- a fifth embodiment of an inventive Refrigerant compressors shown in Fig. 5 are those Parts with those of the first embodiment are identical, provided with the same reference numerals, so that regarding the description of the same on the explanations to the first and possibly the second embodiment Reference is made.

- the damper channel 50 is in principle analogous to the first embodiment formed, with in the outlet chamber 46 a damper tube 51 '' is provided which extends from the outlet opening 54 extends to the valve plate 20 and a first straight section 52a of the damper channel 50 receives.

- the damper tube 51 ′′ is preferably in the region of the opening 40 connected to it by the valve plate 20.

- Valve plate 20 On a side of the crankcase 11 opposite Valve plate 20 extends the damper channel 50 with a second straight section 52b up to the U-shaped curved section 58, which in turn with the the inlet opening 60 facing the valve plate 20 ends.

- Both the second straight section 52b and the Section U of the damper channel 50 is bent in a U-shape in contrast to the first embodiment not in that Damper tube 51, but are as channels in the cylinder head 32 molded as a whole, for which purpose the cylinder head 32 with a Channel wall 70 is provided, which is initially parallel to Outer wall 34 runs, then merges into a channel wall 72, which runs parallel to the cylinder head cover 38 and finally into a channel wall 74 which is parallel to the partition 36 runs, with the walls 70, 72 and 74 each of the outer wall 34, the cylinder head cover 38 and the partition 36 starting from the damper channel 50, for example in a U-shape enclose and in turn on the outer wall 34, the cylinder head cover 38 or the partition 36 are returned.

- the channel walls 70, 72 and 74 are preferably in one piece integrally formed the cylinder head 32 and form a unit with this, so that with placement of the cylinder head 32 on the Valve plate 20 connects to the damper tube 51 ′′ via the Breakthrough 40 is made and also that in the cylinder head 32 extending section of the damper channel 50 is present is.

- this solution allows the smallest possible size of the cylinder head 32 a section as long as possible of the damper channel 50 in this and on the other hand in terms of assembly the advantage that not on the damper tube 51 also protruding above the valve plate Must be taken into account.

- the damper tube 51 ′′ can be used, for example the assembly of the refrigerant compressor with the Connect valve plate 20 so that with the assembly of the valve plate 20 also the damper tube 51 '' in the refrigerant compressor is mounted.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Compressor (AREA)

- Applications Or Details Of Rotary Compressors (AREA)

Abstract

Description

- Fig. 1

- einen Querschnitt durch ein erstes Ausführungsbeispiel eines erfindungsgemäßen Kältemittelkompressors längs Linie 1-1 in Fig. 2 mit teilweise weggebrochener Trennwand des Kurbelgehäuses zwischen zwei aufeinanderfolgenden Zylinderkammern;

- Fig. 2

- einen Schnitt längs Linie 2-2 in Fig. 1 mit im Bereich des gesamten Druckraums im Zylinderkopf weggebrochener Außenwand desselben;

- Fig. 3

- einen Schnitt längs Linie 3-3 in Fig. 1;

- Fig. 4

- einen halbseitigen Schnitt ähnlich Fig. 1 durch ein zweites Ausführungsbeispiel eines erfindungsgemäßen Kältemittelkompressors und

- Fig. 5

- einen Schnitt ähnlich Fig. 1 durch ein drittes Ausführungsbeispiel eines erfindungsgemäßen Kältemittelkompressors.

Claims (25)

- Kältemittelkompressor, umfassend ein Kompressorgehäuse (10), mindestens eine in dem Kompressorgehäuse (10) angeordnete Zylinderkammer (12), einen in der Zylinderkammer oszillierend bewegbaren Kolben (14), einen der Zylinderkammer (12) vorgeschalteten Saugraum (26), aus welchem Kältemittel in die Zylinderkammer (12) eintritt, einen der Zylinderkammer (12) nachgeschalteten Druckraum (30), in welchen in der Zylinderkammer (12) komprimiertes Kältemittel eintritt, und einen dem Druckraum (30) nachfolgend angeordneten Auslaßkanal (42),

dadurch gekennzeichnet, daß komprimiertes Kältemittel über einen Dämpferkanal (50) von dem Druckraum (30) in den Auslaßkanal (42) strömt, daß eine Einlaßöffnung (60) des Dämpferkanals (50) mit einem Querschnittssprung in den Druckraum (30) mündet und daß eine Auslaßöffnung (54) des Dämpferkanals (50) mit einem Querschnittssprung in den Auslaßkanal (42) mündet. - Kältemittelkompressor nach Anspruch 1, dadurch gekennzeichnet, daß der Querschnittssprung zwischen dem Dämpferkanal (50) und dem Auslaßkanal (42) mindestens einen Faktor 5 beträgt.

- Kältemittelkompressor nach Anspruch 2, dadurch gekennzeichnet, daß der Querschnittssprung zwischen dem Dämpferkanal (50) und dem Auslaßkanal (42) mindestens einen Faktor 10 beträgt.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Querschnittssprung zwischen dem Dämpferkanal (50) und dem Druckraum (30) mindestens einen Faktor 5 beträgt.

- Kältemittelkompressor nach Anspruch 4, dadurch gekennzeichnet, daß der Querschnittssprung zwischen dem Dämpferkanal (50) und dem Druckraum (30) mindestens einen Faktor 10 beträgt.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Druckraum (30) ein Puffervolumen aufweist, welches Druckschwingungen des komprimierten Kältemittels dämpft.

- Kältemittelkompressor nach Anspruch 6, dadurch gekennzeichnet, daß das Puffervolumen Druckschwingungen soweit dämpft, daß diese höchstens eine maximale Amplitude von 20 % eines mittleren Auslaßdrucks aufweisen.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Auslaßkanal (42) eine Auslaßkammer (46) mit einem Puffervolumen bildet.

- Kältemittelkompressor nach Anspruch 8, dadurch gekennzeichnet, daß die Auslaßkammer (46) ein Puffervolumen aufweist, welches Druckschwingungen soweit dämpft, daß diese höchstens eine maximale Amplitude von 20 % eines mittleren Auslaßdrucks aufweisen.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Dämpferkanal (50) sich zumindest teilweise in einem Dämpferrohr (51, 51') erstreckt.

- Kältemittelkompressor nach Anspruch 10, dadurch gekennzeichnet, daß der Dämpferkanal (50) sich über seine gesamte Länge in dem Dämpferrohr (51, 51') erstreckt.

- Kältemittelkompressor nach Anspruch 10 oder 11, dadurch gekennzeichnet, daß sich das Dämpferrohr (51, 51') in dem Druckraum (30) erstreckt.

- Kältemittelkompressor nach einem der Ansprüche 10 bis 12, dadurch gekennzeichnet, daß sich das Dämpferrohr (51, 51', 51'') in dem Auslaßkanal (42) erstreckt.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß die Auslaßöffnung (54) des Dämpferkanals (50) in einer Auslaßkammer (46) des Auslaßkanals (42) liegt.

- Kältemittelkompressor nach Anspruch 14, dadurch gekennzeichnet, daß die Auslaßöffnung (54) des Dämpferkanals (50) in einem mittigen Bereich der Auslaßkammer (46) liegt.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Dämpferkanal (50) so eingesetzt ist, daß im wesentlichen das gesamte verdichtete Kältemittel das Dämpferrohr (51) durchströmt.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Dämpferkanal (50) im Bereich eines Übergangs des Druckraums (30) in den Auslaßkanal (42) ein Verschlußelement (62) zwischen dem Druckraum (30) und dem Auslaßkanal (42) durchsetzt.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Dämpferkanal (50) einen geradegerichteten Abschnitt (52) aufweist.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Dämpferkanal (50) einen gekrümmten Abschnitt (58) aufweist.

- Kältemittelkompressor nach Anspruch 19, dadurch gekennzeichnet, daß der gekrümmte Abschnitt (58) des Dämpferkanals (50) in dem Druckraum (30) angeordnet ist.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß der Dämpferkanal (50) zumindest teilweise in das Kompressorgehäuse (10) eingeformt ist.

- Kältemittelkompressor nach Anspruch 21, dadurch gekennzeichnet, daß der Dämpferkanal (50) in einen Zylinderkopf (32) des Kompressorgehäuses (10) eingeformt ist.

- Kältemittelkompressor nach Anspruch 22, dadurch gekennzeichnet, daß der Dämpferkanal (50) längs eines Zylinderkopfdeckels (38) und mindestens einer Wand (34) des Zylinderkopfs (32) verläuft.

- Kältemittelkompressor nach Anspruch 22 oder 23, dadurch gekennzeichnet, daß der in den Zylinderkopf (32) eingeformte Dämpferkanal (50) sich in einem im Auslaßkanal (42) angeordneten Dämpferrohr (51'') fortsetzt.

- Kältemittelkompressor nach einem der voranstehenden Ansprüche, dadurch gekennzeichnet, daß die Einlaßöffnung (60) des Dämpferkanals (50) der Ventilplatte (20) zugewandt angeordnet ist.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19757829 | 1997-12-24 | ||

| DE1997157829 DE19757829A1 (de) | 1997-12-24 | 1997-12-24 | Kältemittelkompressor |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0926343A2 true EP0926343A2 (de) | 1999-06-30 |

| EP0926343A3 EP0926343A3 (de) | 2000-05-10 |

| EP0926343B1 EP0926343B1 (de) | 2015-08-19 |

Family

ID=7853355

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98124260.5A Expired - Lifetime EP0926343B1 (de) | 1997-12-24 | 1998-12-18 | Schalldämpfer für einen Kältemittelkompressor |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0926343B1 (de) |

| DE (1) | DE19757829A1 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2001055594A1 (de) | 2000-01-29 | 2001-08-02 | Bitzer Kühlmaschinenbau Gmbh | Kältemittelkompressor |

| WO2022243201A1 (de) * | 2021-05-18 | 2022-11-24 | thyssenkrupp Presta Ilsenburg GmbH | Kolbenverdichter, insbesondere radialkolbenverdichter |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10242139A1 (de) * | 2002-09-03 | 2004-03-18 | Bitzer Kühlmaschinenbau Gmbh | Schraubenverdichter |

| DE102014010018A1 (de) * | 2014-07-08 | 2016-01-14 | Gea Bock Gmbh | Verdichter |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3785453A (en) * | 1970-12-10 | 1974-01-15 | Carrier Corp | Compressor discharge muffling means |

| DE2134181A1 (de) * | 1971-03-03 | 1973-11-15 | Monsator Haushaltsgrossgeraete | Daempfer fuer verdichter, insbesondere fuer hermetische kaeltemittelverdichter |

| DE3213476C1 (de) * | 1982-04-10 | 1983-06-01 | Danfoss A/S, 6430 Nordborg | Kaeltemaschine mit gekapseltem Motorverdichter |

| DE3332259A1 (de) * | 1983-09-07 | 1985-03-28 | Danfoss A/S, Nordborg | Kaeltemaschinenverdichter |

| JPS60152077U (ja) * | 1984-03-21 | 1985-10-09 | 株式会社豊田自動織機製作所 | 斜板式圧縮機 |

| JPH0717827Y2 (ja) * | 1987-03-11 | 1995-04-26 | 株式会社豊田自動織機製作所 | 圧縮機のマフラー機構 |

| US4842492A (en) * | 1988-01-25 | 1989-06-27 | Tecumseh Products Company | Compressor discharge muffler having cover plate |

| JPH02161178A (ja) * | 1988-12-13 | 1990-06-21 | Sanyo Electric Co Ltd | 圧縮機 |

| US4988269A (en) * | 1990-02-08 | 1991-01-29 | Copeland Corporation | Compressor discharge gas sound attenuation |

| US5101931A (en) * | 1990-05-23 | 1992-04-07 | Copeland Corporation | Discharge muffler and method |

| US5173034A (en) * | 1991-07-18 | 1992-12-22 | White Consolidated Industries, Inc. | Discharge muffler for refrigeration compressor |

| US5236312A (en) * | 1991-12-23 | 1993-08-17 | Ford Motor Company | Swash-plate-type air conditioning pump |

| KR940003845Y1 (ko) * | 1991-12-28 | 1994-06-15 | 주식회사 금성사 | 밀폐형 전동압축기 |

| JP2763734B2 (ja) * | 1993-05-20 | 1998-06-11 | 松下冷機株式会社 | 密閉型圧縮機 |

-

1997

- 1997-12-24 DE DE1997157829 patent/DE19757829A1/de not_active Ceased

-

1998

- 1998-12-18 EP EP98124260.5A patent/EP0926343B1/de not_active Expired - Lifetime

Non-Patent Citations (1)

| Title |

|---|

| None |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2001055594A1 (de) | 2000-01-29 | 2001-08-02 | Bitzer Kühlmaschinenbau Gmbh | Kältemittelkompressor |

| DE10003882A1 (de) * | 2000-01-29 | 2001-08-16 | Bitzer Kuehlmaschinenbau Gmbh | Kältemittelkompressor |

| US6568921B2 (en) | 2000-01-29 | 2003-05-27 | Bitzer Kuehlmaschinenbau Gmbh | Refrigerant compressor |

| DE10003882C2 (de) * | 2000-01-29 | 2003-10-02 | Bitzer Kuehlmaschinenbau Gmbh | Kältemittelkompressor |

| WO2022243201A1 (de) * | 2021-05-18 | 2022-11-24 | thyssenkrupp Presta Ilsenburg GmbH | Kolbenverdichter, insbesondere radialkolbenverdichter |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19757829A1 (de) | 1999-07-01 |

| EP0926343B1 (de) | 2015-08-19 |

| EP0926343A3 (de) | 2000-05-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69731674T2 (de) | Silencieux d'aspiration pour compresseur | |

| DE19943246B4 (de) | Schalldämpfer zur Herabminderung der Luftgeräusche im Ansaugstrang von Brennkraftmaschinen | |

| DE69709304T2 (de) | Saugschalldämpfer für einen hermetischen verdichter | |

| EP1702163B1 (de) | Schraubenverdichter mit einem schalldämpfer | |

| DE102012111324B4 (de) | Schalldämpfer eines Fahrzeuges | |

| DE69202692T2 (de) | Auspuffschalldämpfer für einen Kühlverdichter. | |

| DE69918633T2 (de) | Ansauggeräuschdämpfer für Kraftfahrzeuge | |

| DE102005041692A1 (de) | Schalldämpfer für eine Abgasanlage | |

| DE10003882C2 (de) | Kältemittelkompressor | |

| DE3215586A1 (de) | Kuehlkompressor mit einem schalldaempfersystem | |

| DE112006003265T5 (de) | Auspufftopfeinheit mit schalldämpfendem Element | |

| EP2828528B1 (de) | Kältemittelverdichter | |

| DE102010015756B4 (de) | Integrale Rotorgeräuschdämpfer | |

| DE202005005328U1 (de) | Zweitaktmotor | |

| DE69832764T2 (de) | Schalldämpfer | |

| DE60114880T2 (de) | Geschlossener kompressor | |

| EP1396640B1 (de) | Schraubenverdichter | |

| DE20314134U1 (de) | Pneumatischer Abblas-Schalldämpfer | |

| DE102010022780B4 (de) | Breitbanddämpfer | |

| EP0753666B1 (de) | Zahnradpumpe | |

| DE2545364A1 (de) | Brennkraftmaschinen-abgasschalldaempfer | |

| DE2951463C2 (de) | ||

| EP0926343B1 (de) | Schalldämpfer für einen Kältemittelkompressor | |

| DE8021214U1 (de) | Verbrennungsmotor-Ansauganordnung | |

| DE69723687T3 (de) | Ansauganordnung für einen hermetischen verdrängerverdichter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT DE DK ES FR GB IT PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20001026 |

|

| AKX | Designation fees paid |

Free format text: AT DE DK ES FR GB IT PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20041216 |

|

| 17Q | First examination report despatched |

Effective date: 20041216 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150304 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BITZER KUEHLMASCHINENBAU GMBH |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE DK ES FR GB IT PT SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 744030 Country of ref document: AT Kind code of ref document: T Effective date: 20150915 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 59814555 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150819 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150819 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150819 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 59814555 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160520 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 744030 Country of ref document: AT Kind code of ref document: T Effective date: 20151218 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151218 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20171229 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20171228 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180228 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20171220 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59814555 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20181217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20181217 |