EP0914665B1 - Relais electromagnetique et son procede de fabrication - Google Patents

Relais electromagnetique et son procede de fabrication Download PDFInfo

- Publication number

- EP0914665B1 EP0914665B1 EP97931621A EP97931621A EP0914665B1 EP 0914665 B1 EP0914665 B1 EP 0914665B1 EP 97931621 A EP97931621 A EP 97931621A EP 97931621 A EP97931621 A EP 97931621A EP 0914665 B1 EP0914665 B1 EP 0914665B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- coil

- spring

- housing part

- contact

- armature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 13

- 230000013011 mating Effects 0.000 claims abstract description 20

- 238000005304 joining Methods 0.000 claims abstract description 18

- 238000004804 winding Methods 0.000 claims description 11

- 239000004033 plastic Substances 0.000 claims description 10

- 238000004519 manufacturing process Methods 0.000 claims description 8

- 238000003466 welding Methods 0.000 claims description 6

- 238000002604 ultrasonography Methods 0.000 claims description 4

- 238000005516 engineering process Methods 0.000 description 3

- 238000001746 injection moulding Methods 0.000 description 3

- 239000000969 carrier Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 230000003628 erosive effect Effects 0.000 description 2

- 239000011810 insulating material Substances 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 238000007765 extrusion coating Methods 0.000 description 1

- 210000003746 feather Anatomy 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000010970 precious metal Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 229910000679 solder Inorganic materials 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000012815 thermoplastic material Substances 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/02—Bases; Casings; Covers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H49/00—Apparatus or processes specially adapted to the manufacture of relays or parts thereof

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/14—Terminal arrangements

Definitions

- EP 0 531 890 A1 describes a switching relay, which basically a structure of the type mentioned having.

- the two housing parts do not form there closed housing, it is just about a base, which is preferably a printed circuit board with molded Is sidewall, and a lid part, between which too after the assembly, a large housing gap remains open.

- the relay there is preferably a multiple relay a series of magnet systems lying side by side, with a common core pole plate on the base lies and a series of vertically protruding core sections forms, on each of which a coil is attached.

- Each System also has a U-shaped anchor attached to the Core pole plate is mounted and the coil with the contact spring encloses in a frame shape.

- the cover part has slots inserted mating contact elements and spring supports, whereby these slots are also not tight. An adjustment the contacts are obviously made by the big one Housing opening in the area of the contacts.

- a relay is already known from WO 91/07770, in which the magnet system is fixed in the upper area of a housing while a contact system is from the open bottom is pushed in until the magnet system is excited Contact closes. After creating this contact system a desired overstroke by a predetermined amount inserted, it is fastened in the housing. On this way, manufacturing tolerances become apparent during assembly balanced, so that a subsequent adjustment is not more is needed.

- DE-A-2 506 626 describes a lockable with a housing, Contact carrier for switching elements made of insulating material known, anchor contacts either in a glass tube or attached in a plastic frame as a carrier are, these carriers to the outside through two housing caps be completed. All moving parts are in one and the same support part held while the housing caps no influence on the positioning of the functional elements of the relay.

- EP-A-0 251 035 also describes a relay which of two half-shell-shaped, forming a bobbin Basic body parts exist that carry the winding.

- Basic body parts In one of the basic body parts are in a common plane two pole plates embedded, the ends of which are in a contact space can be bridged within the coil by an armature contact.

- the anchor itself is in via a frame-shaped spring the parting plane between the two base parts.

- the aim of the present invention is to provide a relay of the input to create the type mentioned with a flat structure that for different sizes and applications is designed and that when using appropriate manufacturing processes in large Quantity can be produced very inexpensively. Due to the construction, a high level of accuracy is intended can already be achieved in production, so that even without Subsequent adjustment of the relay parameters with only small Scattering are observed.

- this goal is achieved with such a relay achieved in that the two housing parts as approximately trough-shaped half-shells made of plastic with their edges are sealed together that the connections for the Coil winding and for the contact elements each by the Wall of its associated housing part embedded to the outside are guided, and that the main joining planes between the two Housing parts perpendicular to the switching movement of the contact spring stand.

- the two half-shells form not just an easy-to-seal housing, but it also serve as carriers for the functional elements of the relay, these functional elements, i.e. the magnet system in one Part and the contact system in the other part already the manufacture of the respective half-shell positioned very precisely can be.

- the main joining planes are between two housing parts perpendicular to the switching movement of the Contact spring so that by joining the two housing parts the distance between the magnet system and contacts can be adjusted. Fixation is particularly easy of the functional parts in the housing and the sealing of the connections achieved in that this in the respective housing half-shell are embedded.

- the joining levels consist of Plastic, preferably thermoplastic, so that a tight connection, for example with ultrasound is easy to do.

- the magnet system from a U-shaped core yoke sheet, which is preferably as well as at least two coil connections in a plastic coil body are embedded.

- the on both ends of the Core formed pole plates then extend vertically to the coil axis in the area next to the coil, where it is from an armature lying next to the coil can be bridged.

- This Anchor can be designed more or less as a flat sheet be bent or bent at different heights at both ends to be offset accordingly in height as well Interacting pole plates. In this way, the Space in the housing for housing the contacts and the various connections can be used optimally.

- An L-shaped Contact spring which is front with a leg in front of the coil and with the other leg next to the coil Extending below or above the anchor results in a narrow space a large feather length; the anchor is preferably in the transition area between the two spring legs on the contact spring attached.

- a preferred method for producing the relay is that the first housing part is obtained by embedding the coil with the core, including the coil connections, according to the invention. that the second housing part is obtained by embedding the spring support and at least one counter-contact element, that the contact spring connected to the armature is connected to the spring support, and that the two housing parts are then placed on top of one another with their edges and connected.

- the coil former is also formed beforehand by embedding the core and the coil connections, with the first housing part being produced by a second embedding after winding the coil and after connecting the coil ends to the coil connections.

- the armature Before the two housing parts are joined together, the armature is connected to the contact spring, an electrically conductive connection by welding or the like or an insulating connection by overmolding being possible, depending on the application.

- the contact spring is then attached to the spring support anchored in the second housing part in an electrically conductive manner, for example by welding or also by means of a plug-in fastening.

- a major advantage of the invention can also be seen in the fact that that when joining the two housing parts, the contact lift can be set, for example, when joining measured the pull-through voltage of the anchor and then the joining process when reaching a predetermined electrical Characteristic value of the pull-through voltage - which is a measure of the erosion size or the overstroke of the contact is interrupted becomes.

- the two half-shells can be welded also with other technologies, for example by gluing, Clamping, casting or using a two-component injection molding process molded elostomer seal sealed become.

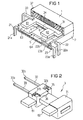

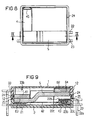

- the relay shown in Figures 1 to 5 consists of a first half-shell 1 and a second half-shell 2, the Half-shell 1 by overmolding a coil 3 and the second Half shell by overmolding a spring support 21 and two Mating contact elements 22 and 23 is formed.

- an L-shaped contact spring 4 is attached in turn carries an anchor 5.

- the almost Z-shaped curve Anchor 5 forms working air gaps with its ends with two pole faces 63 and 64 of the pole plates 61 and 62, which are part of a U-shaped core 6, but this Pole plate 62 is bent up from the core plane.

- the coil is first obtained by the middle section of the core 6 with thermoplastic material is overmolded, whereby a bobbin 31 is formed becomes.

- the pole plates 61 and 62 are kept free.

- two coil connections 32 in the coil body and 33 injected, so that not only the after externally directed pins 32a and 33a, but also the inner ones intended for contacting the winding ends Connecting surfaces 32b and 33b remain free of the embedding.

- After applying a coil winding 34 to the bobbin the ends of which are connected to the connecting surfaces 32b and 33b connected.

- the winding ends are protected guided behind ribs 35 in channels 36 of the bobbin.

- the entire coil is overmolded again, so to win the first half-shell according to FIG. 3.

- the pole faces 63 and 64 of the pole plates 61 and 62 also remain from this Overmolding free, while the rest of the parts, in particular also the coil winding 34, in the plastic 11 of the first Half shell 1 can be embedded.

- the coil connector pins 32a and 33a are close to the outside in this new embedding performed where it is angled downwards according to FIG. 1 or FIG. 3 or in a manner not shown, also for education from SMT connections in a horizontal plane can.

- the second half-shell 2 is, as already mentioned, by injection molding the spring support 21 and the mating contact elements 22 and 23 won, with a cavity for the coil and for the movable armature contact spring unit is free.

- the Mating contact elements each have a close to Outside guided pin 22a or 23a, while in Inside each a fixed contact section 32b or 33b with a Precious metal contact layer 32c or 33c is provided.

- the contact material in the The present example is the contact material as an inlay plated in the surface of the respective contact element, so that a cover when overmoulding easily possible is. Otherwise, other technologies would also apply of the contact material conceivable.

- the two mating contact elements 22 and 23 could of course only be a mating contact element to form an opener or a closer be provided.

- the L-shaped contact spring 4 has a first Spring leg 41, which extends in front of the coil, and a second spring leg 42, which is laterally extends next to the coil below the armature and one movable contact 43 carries.

- the first spring leg 41 is via an upwardly angled fastening tab 44 the spring support 21 via a welded connection 46 according to FIG 4 or attached via a clamping claw 45 according to FIG. 8. Thanks to this connection technology, the mounting height is Contact spring 4 on the spring support 21 variable, which also the position of the second spring leg 42 relative to the mating contact elements can be adjusted. In this way the anchor restoring force or the rest contact force during the assembly process to compensate for tolerances become.

- the contact spring Before attaching the contact spring to the spring carrier 21 it is connected to the anchor 5, which, for example, according to 6 done electrically conductive via a welded joint 51 can. Should be insulation between the contact spring and the magnet system can be reached, so the connection made by an insulating material sheath 52 according to FIG. 7 become. For certain cases of use, it is also possible to conduct the current to the contact spring via a wire. For example, higher tax levels can be achieved through such Low-resistance wire to the contact point to to avoid excessive heating of the spring.

- FIG. 10 shows a variant of the relay from FIG. 1.

- the two half-shells 101 and 102 are not in a single joining plane, but with mutually graduated Joining planes 103 and 104 connected.

- the interior structure of the Relay is the same as in the previous example, except that a mating contact element, namely a normally open mating contact plate 105 with its pin 105a in the first half-shell is injected with the magnet system.

- a mating contact element namely a normally open mating contact plate 105 with its pin 105a in the first half-shell is injected with the magnet system.

- the distance between the two half-shells can be added the counter contacts are influenced.

- the construction of the relay allowed by the application of the relative parts also plan other embodiments of the connection geometry, so that the connections also on only one relay side can emerge from the housing.

- Such an opportunity is shown in Figure 11, with a first half-shell 110 the contact elements with pins 111, 112 and 113 and a second half shell 120 the magnet system with coil pins 121 and 122 carries.

- Such a relay is required only a small footprint for plugging or soldering.

- flat plugs can also be provided.

- the connector pins can of course also designed as surface-mountable SMT connections his.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Electromagnets (AREA)

- Financial Or Insurance-Related Operations Such As Payment And Settlement (AREA)

- General Factory Administration (AREA)

- Manufacturing Of Electric Cables (AREA)

Claims (20)

- Relais électromagnétique comportantcaractérisé par le faitune première partie de boítier (1) qui porte une bobine (3) et un noyau (6) traversant la bobine et formant des tôles polaires (61, 62) en dehors de la bobine à ses deux extrémités,une deuxième partie de boítier (2) dans laquelle au moins un support de ressort (21) et au moins un élément de contre-contact (22, 23) sont ancrés, le support de ressort (21) portant un ressort de contact (4) coopérant avec l'élément de contre-contact (22, 23), etun induit (5) qui est relié au ressort de contact (4) et qui ponte les tôles polaires (61, 62) en formant des entrefers de travail,

que les deux parties de boítier (1, 2) en tant que demi-coques en matière plastique approximativement en forme de cuve sont assemblées de manière étanche par leurs bords, que les bornes (21a, 22a, 23a, 32a, 33a) destinées à l'enroulement de bobine (34) et aux éléments de contact (21, 22, 23) sont toutes guidées vers l'extérieur enrobées à travers la paroi de leur partie de boítier (1, 2) associée et que les plans de jointure principaux entre deux parties de boítier (1, 2) sont perpendiculaires au mouvement de commutation du ressort de contact (4). - Relais selon la revendication 1, caractérisé par le fait que la bobine (3) formée du corps de bobine (31) avec l'enroulement (34) est enrobée avec le noyau (6) dans la matière plastique de la première partie de boítier (1) - en laissant libre les surfaces polaires (63, 64) dans la zone des entrefers - tandis que le support de ressort (21) et le ou les éléments de contre-contact (22, 23) sont enrobés dans la matière plastique de la deuxième partie de boítier (2).

- Relais selon la revendication 2, caractérisé par le fait que le noyau (6) est enrobé dans la matière plastique du corps de bobine (31).

- Relais selon la revendication 3, caractérisé par le fait que des éléments de connexion (32, 33) pour l'enroulement de bobine (34) sont enrobés aussi bien dans le corps de bobine (31) que dans la matière plastique de la première partie de boítier (1).

- Relais selon l'une des revendications 1 à 4, caractérisé par le fait que le noyau (6) est en forme de U, un tronçon central portant la bobine (3) et deux tôles polaires (61, 62) étant à une certaine distance globalement perpendiculairement à l'axe de bobine et que l'induit (5) s'étend globalement parallèlement à l'axe de bobine à côté de la bobine (3) et forme les entrefers avec les deux tôles polaires (61, 62).

- Relais selon la revendication 5, caractérisé par le fait que le ressort de contact (4) est coupé en forme de L de telle sorte qu'il a deux branches (41, 42) qui s'étendent globalement dans un plan, dont la première s'étend frontalement devant la bobine et dont la deuxième s'étend latéralement à côté de la bobine, cette deuxième branche (42) et l'induit (5) se trouvant parallèlement l'un au-dessus de l'autre et étant reliés dans la zone de l'angle entre les deux branches du ressort de contact.

- Relais selon la revendication 6, caractérisé par le fait que l'induit (5) est assemblé au ressort de contact (4) de façon métallique, c'est-à-dire par soudure (51), par rivetage ou par un autre moyen analogue.

- Relais selon la revendication 6, caractérisé par le fait que l'induit (5) est assemblé au ressort de contact (4) par l'intermédiaire d'une enveloppe en matière isolante (52) commune.

- Relais selon l'une des revendications 1 à 8, caractérisé par le fait que deux éléments de contre-contact (22, 23) qui forment un contact de commutation avec le ressort de contact (4) sont ancrés dans la deuxième partie de boítier (2).

- Relais selon l'une des revendications 1 à 8, caractérisé par le fait qu'un deuxième élément de contre-contact (105) est ancré dans la première partie de boítier (101) et forme un contact de commutation avec l'élément de contre-contact (23) ancré dans la deuxième partie de boítier (102) et avec le ressort de contact (4).

- Relais selon l'une des revendications 1 à 10, caractérisé par le fait que les deux parties de boítier (1, 2) avec des bords conçus étagés (103, 104) comportent au moins deux plans de séparation décalés parallèlement l'un par rapport à l'autre.

- Procédé de fabrication d'un relais selon la revendication 1, dans lequelcaractérisé par le faitdans une première partie de boítier (1), on ancre une bobine (3) et un noyau (6) traversant la bobine et formant des tôles polaires (61, 62) en dehors de la bobiné à ses deux extrémités,dans une deuxième partie de boítier (2), on ancre au moins un support de ressort (21) et au moins un élément de contre-contact (22, 23), le support de ressort (21) portant un ressort de contact (4) coopérant avec l'élément de contre-contact (22, 23), etun induit (5) est relié au ressort de contact (4) et ponte les tôles polaires (61, 62) en formant des entrefers,les deux parties de boítier (1, 2) étant conçues chacune en forme de cuve de telle sorte que leurs bords forment au moins un plan de jointure principal qui est perpendiculaire à la direction du mouvement de l'induit,qu'on obtient la première partie de boítier (1) en enrobant la bobine (3) avec le noyau (6), y compris les bornes de bobine (32, 33),on obtient la deuxième partie de boítier (2) en enrobant le support de ressort (21) et au moins un élément de contre-contact (22, 23),on assemble le ressort de contact (4) relié à l'induit (5) avec le support de ressort (21), eton place l'une sur l'autre et on assemble les deux parties de boítier (1, 2) par leurs bords.

- Procédé selon la revendication 12, caractérisé par le fait qu'on forme d'abord un corps de bobine (31) en enrobant le noyau (6) et les bornes de bobine (32, 33), qu'on munit ce corps de bobine (31) d'un enroulement de bobine (34) et qu'on l'enrobe ensuite une nouvelle fois pour former la première partie de boítier (1).

- Procédé selon la revendication 12 ou 13, caractérisé par le fait qu'on assemble l'induit (5) au ressort de contact (4) par soudure et qu'on assemble ensuite ce dernier au support de ressort (21).

- Procédé selon la revendication 12 ou 13, caractérisé par le fait qu'on assemble l'induit (5) au ressort de contact (4) au moyen d'un enrobage dans une matière isolante (52).

- Procédé selon l'une des revendications 12 à 15, caractérisé par le fait qu'on assemble le ressort de contact (4) au support de ressort (21) par soudure.

- Procédé selon l'une des revendications 12 à 15, caractérisé par le fait qu'on assemble le ressort de contact (4) au support de ressort (21) au moyen d'une fixation par enfichage.

- Procédé selon l'une des revendications 12 à 17, caractérisé par le fait que, lors de l'assemblage des deux parties de boítier (1, 2), on mesure indirectement (par l'intermédiaire de la tension d'attraction) le jeu d'induit et/ou le surjeu et on arrête l'opération d'assemblage lorsqu'une valeur prescrite est atteinte.

- Procédé selon la revendication 18, caractérisé par le fait que, lors de l'assemblage, on déforme la zone du bord (25) au moins de l'une des deux demi-coques (1) jusqu'à atteindre le surjeu prescrite.

- Procédé selon la revendication 19, caractérisé par le fait que, lors de l'assemblage, on déforme par ultrasons le bord ou une nervure (25), formée sur le bord, de l'une des deux demi-coques (1).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19627844A DE19627844C1 (de) | 1996-07-10 | 1996-07-10 | Elektromagnetisches Relais und Verfahren zu dessen Herstellung |

| DE19627844 | 1996-07-10 | ||

| PCT/DE1997/001230 WO1998001880A1 (fr) | 1996-07-10 | 1997-06-17 | Relais electromagnetique et son procede de fabrication |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0914665A1 EP0914665A1 (fr) | 1999-05-12 |

| EP0914665B1 true EP0914665B1 (fr) | 2000-01-26 |

Family

ID=7799471

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97931621A Expired - Lifetime EP0914665B1 (fr) | 1996-07-10 | 1997-06-17 | Relais electromagnetique et son procede de fabrication |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6252479B1 (fr) |

| EP (1) | EP0914665B1 (fr) |

| JP (1) | JP2000514235A (fr) |

| KR (1) | KR20000023651A (fr) |

| AT (1) | ATE189334T1 (fr) |

| DE (2) | DE19627844C1 (fr) |

| WO (1) | WO1998001880A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2155383A1 (es) * | 1998-05-07 | 2001-05-01 | Siemens Electromech Components | Sistema magnetico para un rele electromagnetico. |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1101233B1 (fr) * | 1998-07-27 | 2002-02-20 | Siemens Aktiengesellschaft | Appareil de commutation comportant une partie inferieure de boitier comme element constitutif, et procede de production correspondant |

| DE10209810B4 (de) * | 2001-03-09 | 2006-11-16 | Omron Corporation | Relais |

| GB0110948D0 (en) * | 2001-05-04 | 2001-06-27 | Tyco Electronics Amp Gmbh | Bus controlled relays |

| JP4022440B2 (ja) * | 2002-07-01 | 2007-12-19 | 株式会社オートネットワーク技術研究所 | 回路ユニット |

| WO2004047136A1 (fr) * | 2002-11-15 | 2004-06-03 | Tyco Electronics Amp Gmbh | Revetement par extrusion de systeme d'aimant destine a un relais |

| JP4673217B2 (ja) * | 2003-04-23 | 2011-04-20 | 由紀夫 佐藤 | メチル化CpGポリヌクレオチド |

| DE102012003236A1 (de) | 2012-02-20 | 2013-08-22 | Clariant Produkte (Deutschland) Gmbh | Vorvergoldung von Pd-Au-gecoateten Schalenkatalysatoren |

| CN110473743B (zh) * | 2019-04-25 | 2024-06-18 | 厦门宏发汽车电子有限公司 | 一种可保证衔铁或动簧片正常动作的继电器 |

| EP4002414A1 (fr) * | 2020-11-13 | 2022-05-25 | Tyco Electronics Austria GmbH | Dispositif électrique comprenant un boîtier étanche ayant une partie inférieure et une partie supérieure de boîtier |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1598789A (fr) * | 1968-12-27 | 1970-07-06 | ||

| BE786042A (fr) * | 1970-12-02 | 1973-01-10 | Int Standard Electric Corp | Equipement de contact multipolaire place sous enveloppe scellee |

| DE2506626A1 (de) | 1975-02-17 | 1976-08-26 | Hans Sauer | Mit einem gehaeuse abschliessbarer, aus isolierstoff bestehender kontakttraeger fuer schaltelemente |

| DE2622133A1 (de) * | 1976-05-18 | 1977-12-08 | Siemens Ag | Elektrisches bauelement, insbesondere elektromagnetisches relais |

| DE2723430C2 (de) * | 1977-05-24 | 1984-04-26 | Siemens AG, 1000 Berlin und 8000 München | Elektromagnetisches Relais |

| DE3378805D1 (en) * | 1982-07-06 | 1989-02-02 | Nec Corp | Transfer-type electromagnetic relay |

| US4827234A (en) * | 1986-06-23 | 1989-05-02 | Siemens Aktiengesellschaft | Electromagnetic relay |

| US4975666A (en) * | 1989-03-28 | 1990-12-04 | Matsushita Electric Works, Ltd. | Polarized electromagnetic relay |

| WO1991007769A1 (fr) | 1989-11-16 | 1991-05-30 | Siemens Aktiengesellschaft | Relais electromagnetique |

| WO1991007770A1 (fr) * | 1989-11-16 | 1991-05-30 | Siemens Aktiengesellschaft | Relais electromagnetique |

| US5038123A (en) * | 1989-12-14 | 1991-08-06 | General Motors Corporation | Flat electromagnetic relay |

| US5191306A (en) * | 1990-09-14 | 1993-03-02 | Matsushita Electric Works, Ltd. | Miniature electromagnetic assembly and relay with the miniature electromagnet assembly |

| US5148136A (en) * | 1991-08-19 | 1992-09-15 | General Motors Corporation | Flat electromagnetic relay |

| US5216396A (en) * | 1991-09-13 | 1993-06-01 | Eaton Corporation | Switching relay |

-

1996

- 1996-07-10 DE DE19627844A patent/DE19627844C1/de not_active Expired - Fee Related

-

1997

- 1997-06-17 JP JP10504638A patent/JP2000514235A/ja active Pending

- 1997-06-17 DE DE59701074T patent/DE59701074D1/de not_active Expired - Lifetime

- 1997-06-17 WO PCT/DE1997/001230 patent/WO1998001880A1/fr not_active Application Discontinuation

- 1997-06-17 EP EP97931621A patent/EP0914665B1/fr not_active Expired - Lifetime

- 1997-06-17 US US09/214,731 patent/US6252479B1/en not_active Expired - Fee Related

- 1997-06-17 AT AT97931621T patent/ATE189334T1/de not_active IP Right Cessation

-

1999

- 1999-01-08 KR KR1019997000104A patent/KR20000023651A/ko not_active Application Discontinuation

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2155383A1 (es) * | 1998-05-07 | 2001-05-01 | Siemens Electromech Components | Sistema magnetico para un rele electromagnetico. |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19627844C1 (de) | 1997-08-28 |

| WO1998001880A1 (fr) | 1998-01-15 |

| KR20000023651A (ko) | 2000-04-25 |

| DE59701074D1 (de) | 2000-03-02 |

| ATE189334T1 (de) | 2000-02-15 |

| JP2000514235A (ja) | 2000-10-24 |

| US6252479B1 (en) | 2001-06-26 |

| EP0914665A1 (fr) | 1999-05-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60018502T2 (de) | Elektromagnetisches Relais | |

| DE19747167C1 (de) | Elektromagnetisches Relais | |

| DE4406682A1 (de) | Magnetspule, Magnetschütz mit Magnetspule, und Herstellungsverfahren für eine Magnetspule | |

| DE3829035C2 (fr) | ||

| EP0914665B1 (fr) | Relais electromagnetique et son procede de fabrication | |

| EP1025573B1 (fr) | Procede de production d'un relais | |

| EP0017129B2 (fr) | Relais polarisé à lames de contact | |

| EP0758484B1 (fr) | Relais modulaire | |

| DE69735239T2 (de) | Hochfrequenzschalter | |

| EP0713233A2 (fr) | Agencement d'un relais avec un adaptateur à fiches et procédé pour la fabrication de cet agencement | |

| DE2353444A1 (de) | In isolierstoff eingebettetes elektromatnetisches relais | |

| DE4310369A1 (de) | Adapter | |

| EP0308819B1 (fr) | Relais électromagnétique | |

| EP0910861B1 (fr) | Procede de fabrication d'un relais electromagnetique | |

| EP0056085B1 (fr) | Relais électromagnétique polarisé | |

| EP0858670A2 (fr) | Interrupteur de contact electrique | |

| DE3435823C2 (de) | Verfahren zur Herstellung von Klinkensteckerbuchsen | |

| EP0846330B1 (fr) | Relais electromagnetique et son utilisation sur une carte de circuits imprimes | |

| DE3025814A1 (de) | Elektromagnetisches relais | |

| DE10304445A1 (de) | Anschlussaufbau eines Hochfrequenzübertragungsteils | |

| EP0410984B1 (fr) | Corps de bobine et son procede de fabrication | |

| EP0502842B1 (fr) | Relais electromagnetique | |

| EP0056840B1 (fr) | Relais électromagnétique | |

| DE19511877A1 (de) | Kontakteinheit, insbesondere für elektrische Schalter | |

| DE19820458C1 (de) | Magnetsystem für ein elektromagnetisches Relais |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19990105 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE FR GB IT LI |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19990623 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 189334 Country of ref document: AT Date of ref document: 20000215 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59701074 Country of ref document: DE Date of ref document: 20000302 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000617 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20010502 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20010531 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010630 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020617 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20020617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050617 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140627 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59701074 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160101 |