EP0806504B1 - Dispositif de réglage centralisé pour des pinces-fil de cantres - Google Patents

Dispositif de réglage centralisé pour des pinces-fil de cantres Download PDFInfo

- Publication number

- EP0806504B1 EP0806504B1 EP97107061A EP97107061A EP0806504B1 EP 0806504 B1 EP0806504 B1 EP 0806504B1 EP 97107061 A EP97107061 A EP 97107061A EP 97107061 A EP97107061 A EP 97107061A EP 0806504 B1 EP0806504 B1 EP 0806504B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- control rod

- thread

- adjusting device

- control

- central

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 claims description 3

- 238000006073 displacement reaction Methods 0.000 claims 6

- 238000013016 damping Methods 0.000 claims 1

- 238000004804 winding Methods 0.000 description 21

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 1

- 239000011358 absorbing material Substances 0.000 description 1

- ZINJLDJMHCUBIP-UHFFFAOYSA-N ethametsulfuron-methyl Chemical compound CCOC1=NC(NC)=NC(NC(=O)NS(=O)(=O)C=2C(=CC=CC=2)C(=O)OC)=N1 ZINJLDJMHCUBIP-UHFFFAOYSA-N 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000004091 panning Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02H—WARPING, BEAMING OR LEASING

- D02H1/00—Creels, i.e. apparatus for supplying a multiplicity of individual threads

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02H—WARPING, BEAMING OR LEASING

- D02H13/00—Details of machines of the preceding groups

- D02H13/22—Tensioning devices

- D02H13/24—Tensioning devices for individual threads

Definitions

- the invention relates to a central adjustment device for thread clamping of creel, with vertical movable, each assigned to a row of coils Control rods on which there is a control ramp for each thread clamp is formed with a spring-loaded, the thread clamp controlling in an open or in a clamping position Bolt is adjustable, and associated with each actuator rod vertically driven adjustment lever on the Actuating rod attacks and this in one of the open positions Thread clamp can move corresponding first position, from the control rod to one of the clamping positions of the thread clamp corresponding second position is adjustable.

- a central adjustment device with the aforementioned Features are known for example from DE 37 34 518. It is used for coil gates that have a variety of winding units. Each winding unit carries a spool, whose thread is pulled off overhead. The thread runs through a thread clamp and is deflected around a thread monitor needle and wound onto a winding machine by a winding machine. The winding takes place at high winding speeds, so that the air friction of the thread is at least a substantial one Is part of the thread tension that the winding machine has to muster. In the event of a standstill, also in Case of a sudden interruption of the winding due to thread breakage, all thread clamps of the creel are activated to all To keep threads of the entire thread taut. Do this not, the threads would get tangled. A trouble-free A restart would then not be guaranteed.

- each gate side has an electrically controlled pneumatic cylinder is assigned that above the winding units and is arranged at the end of the gate side.

- On the pneumatic cylinder are hinged rods that are horizontally above the Winding units are guided. These poles are very long and consist of several sections.

- the cylinder pressurized horizontal bars are driven by the adjustment levers connected. Due to the large number of components and the large ones Lengths of common gates are correspondingly large tolerances available, which is an ideal setting of the central adjustment not allow.

- thread clamps are generally known, their clamping force is roughly adjustable in three stages.

- the thread clamps can be individually influenced, however, due to the large number of thread clamps large adjustment effort are operated, so that this adjustment is ultimately not used.

- the task of the known object is the invention based on a central adjustment device with the entrance to improve the features mentioned so that a total Setting all thread clamps is facilitated without doing so Make individual settings on all thread clamps to have to.

- the adjusting lever on an adjusting part that acts vertically on the adjusting rod is infinitely adjustable and / or that the second position corresponding to the clamping position of the thread clamp the control rod from a stop supporting this is determined, its vertical position continuously up to the support of the bolt on the control ramp is adjustable.

- the vertical driven adjusting lever is influenced overall.

- the setting part achieved by its stepless vertical adjustment can be that the control rod is positioned higher or lower becomes. Accordingly, all inclined surfaces an adjusting rod positioned higher or lower so that all positions of the thread clamp are affected, insofar as they can be influenced by these inclined surfaces. It results there is a row-by-row adjustability, through which all Tolerances of the central adjustment device between this Setting part up to a pneumatic cylinder as an example Drive element can be switched off.

- stepless vertical adjustment between the adjustment part and the control rod can the vertical stroke of the control rod be changed so that the free passage of the thread between a jaw of the thread clamp and an abutment this jaw is adjustably kept the same.

- the central adjustment device can also do this be trained that the second, the clamping position position of the adjusting rod of the thread clamp a stop supporting this is determined, its vertical position continuously up to the support of the bolt on the Control ramp is adjustable. Due to the adjustability of the The adjusting rod has the vertical position of the supporting stop one of the setting options via the setting part independent setting option.

- the control rod can independent of the clamping positions of their thread clamps of which can be continuously adjusted, such as the open position was set via the setting part.

- the adjustment part and are in a structurally simple manner the control rod is screwed together.

- the screw connection can be easily released to the actuator stem in a relative bring another position to the adjustment part.

- the central adjustment are designed so that the Adjustment part and / or the adjusting rod have elongated holes, whose length corresponds to the vertical setting range.

- the central adjustment device can be formed so that the adjusting part is loose on the vertical driven adjustment lever that rests from the vertical Movement range of the control rod is removable and the Raise the control rod from its second position to the first can.

- the slack between the adjustment part and the vertically driven one Adjustment lever allows the control rod including of the setting part for the clamping position of the thread clamp to position.

- the drive of the adjustment lever is designed so that the control rod from this position with the adjustment lever while eliminating the slack is.

- the central adjustment device can be designed that the vertically driven adjustment lever the adjustment part is able to release, causing the control rod as a result their own weight in their second, the clamping position of the thread clamp appropriate position. It is as a result no need to provide a drive for the control rod, with which they in the the clamping position of the thread clamp appropriate position.

- the one that drives the control rod or its setting part Control lever has to transmit a corresponding actuating force, which is usually from a pneumatic cylinder as usual Drive part of the central adjustment device exercised becomes.

- the actuation force is transmitted above of the winding units horizontally, so that a deflection of movement from the horizontal to the vertical is necessary.

- the central adjustment device is therefore designed so that the vertically driven adjustment lever a two-armed swivel lever one arm of which can be acted upon by a drive and on the other arm the adjustment part lies loosely.

- the coil gate 10 shown in FIGS. 1, 2 is a so-called V-gate, from the two sides of the gate 10 'threads F run to a winding device, namely a slip machine 11, of which the sheet of threads F on one Winding tree 21 is wound.

- the winding tree 21 has Winding disks 21 ', between which a pressure roller 22 which are constantly increasing in diameter during winding Presses.

- the winding process is carried out by a control panel 23 the winding device controlled from where also a shutdown can take place if there is a breakage of a thread F.

- the coil gate 10 has a larger number of gate fields 20, in which coils 24 line in a conventional manner and are arranged in columns.

- To accommodate the coils 24 2 shows schematically in each coil field 20 with dash-dotted lines Turning circles illustrated rotary gates 25 that can be loaded from the interior 26 of the creel 10 can, while on the outer sides of the gate sides 10 ' Threads F are withdrawn.

- each thread guide device has a thread clamp 14, which a gate strut 26 attached in a manner not shown is.

- the gate strut 26 is part of the rest Gate frame, not shown, from its spindles the coils 24 are also worn.

- the thread clamp 14 has a tubular housing 27 with an external Abutment 29.

- the jaw 30 is held by a bolt 31, the is guided in the housing 27 such that the jaw 30 can only move according to this guidance.

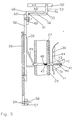

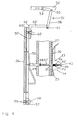

- the bolt 31 in the holes shown in Fig.3.4 guided in the directions of its longitudinal axis.

- the End 40 of the bolt 31 on the jaw side has one to the plane of representation vertical guide pin 41, both ends of which are guided in slots 42 which are parallel to the bolts Holding tab 43 of the jaw 30 are located.

- the floor 44 the jaw has a hole through which the bolt 31 passes is so that it is always arranged perpendicular to the bolt 31.

- a compression spring 45 from which the jaw 30 in its clamping position tries to press.

- the adjusting rod 50 is held up by an adjusting lever 51, which is designed as a two-armed angle lever. He is driven by a rod 52 which is articulated on the angle arm 53 is and is adjusted horizontally, for example as a result Actuation by a pneumatic cylinder 54, the acts on the lever arm 53 via the rod 52. A panning around the frame-fixed pivot point 55 in the counterclockwise direction causes the lever arm 56 to lower and thus the transition of the control rod 50 from that shown in Figure 3 Position in the low position shown in Figure 4. For this the adjustment lever 51 is quickly folded away so that the Bar 50 falls down. Your case will be answered by someone else Gate strut 26 adjustable stop 57 limited which is made of sound-absorbing material.

- the stop 57 is provided with an elongated hole 59, so that it goes up and down in the circumference of this elongated hole can be adjusted.

- the stop 57 is, for example completely adjusted downwards if the bolt 31 is not yet in illustrated manner supported in the inclined area of the control ramp 49 is and should be ensured that the thread clamp 14 clamps with full force of the spring 45.

- a position of Adjusting rod 50 is set, in which the bolt 31st is supported on the slope of the control ramp 49. With that a exact material-related clamping force can be set continuously. The setting is made in that part of the control ramp 49, with respect to which the bolt 31 within the Slot 42 is freely movable without the thread clamp 14th opens.

- the rod 50 must also be raised can be set, expediently independently from their subscript.

- the adjusting rod 50 provided with an adjusting part 60, namely with an angle, whose one angle leg 60 'is arranged approximately horizontally is and on a support pin 61 of the angle arm 56 of the adjusting lever 51 is loose.

- the other angle arm is 60 '' attached to the upper end 50 'of the actuating rod 50 and is for this purpose provided with an elongated hole 62 so that it is vertically adjustable is.

- upper end 50 'of the adjusting rod 50 as far as possible attached to the angle arm 60 'is attached. That is for example advisable if the full open position shown in Fig.3 the thread clamp 14 is to be reached, the bolt 31 but still in a manner not shown on the Inclined surface of the control ramp 49 is supported.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Warping, Beaming, Or Leasing (AREA)

- Moulding By Coating Moulds (AREA)

- Unwinding Of Filamentary Materials (AREA)

- Particle Accelerators (AREA)

Claims (9)

- Dispositif de manoeuvre centralisée pour des pince-fil (14) de cantres (10), comportant des tringles de manoeuvre (50) mobiles verticalement qui sont associées chacune à une rangée de bobines (63) et sur lesquelles est formée pour chaque pince-fil (14) une rampe de commande (49) qui permet de déplacer un axe (31) contraint par ressort et amenant le pince-fil (14) dans une position ouverte ou dans une position de pincement, et un levier de manoeuvre (51) entraíné verticalement qui est associé à chaque tringle de manoeuvre (50), qui agit sur celle-ci et qui peut l'amener dans une première position qui correspond à la position ouverte du pince-fil (14) et à partir de laquelle ladite tringle de manoeuvre (50) peut être amenée dans une seconde position correspondant à la position de pincement du pince-fil (14), caractérisé en ce que le levier de manoeuvre (51) agit sur un élément de réglage (60) qui est fixé à la tringle de manoeuvre (50) pour être réglable progressivement, à la verticale, et/ou en ce que la seconde position de la tringle de manoeuvre (50) correspondant à la position de pincement du pince-fil (14) est définie par une butée (57) qui supporte ladite tringle (50) et dont la position verticale est réglable progressivement jusqu'à ce que l'axe (31) soit en appui sur la rampe de commande (49).

- Dispositif de manoeuvre centralisée selon la revendication 1, caractérisé en ce que l'élément de réglage (60) est disposé entre l'extrémité supérieure (50') de la tringle de manoeuvre (50) et le levier de manoeuvre (51).

- Dispositif de manoeuvre centralisée selon la revendication 1 ou 2, caractérisé en ce que l'élément de réglage (60) et la tringle de manoeuvre (50) sont vissés ensemble.

- Dispositif de manoeuvre centralisée selon la revendication 1 ou 2, caractérisé en ce que l'élément de réglage (60) et/ou la tringle de manoeuvre (50) présentent des trous oblongs (62) dont la longueur correspond à la plage de réglage vertical.

- Dispositif de manoeuvre centralisée selon l'une des revendications 1 à 4, caractérisé en ce que l'élément de réglage (60) et la tringle de manoeuvre (50) sont reliés par l'intermédiaire d'un excentrique de réglage.

- Dispositif de manoeuvre centralisée selon l'une des revendications 1 à 5, caractérisé en ce que l'élément de réglage (60) est posé de manière lâche sur le levier de manoeuvre (51) entraíné verticalement qui peut être éloigné de la zone de mouvement vertical de la tringle de manoeuvre (50) et qui peut soulever celle-ci pour la faire passer de la seconde position à la première.

- Dispositif de manoeuvre centralisée selon l'une des revendications 1 à 6, caractérisé en ce que le levier de manoeuvre (51) entraíné verticalement peut libérer l'élément de réglage (60), moyennant quoi la tringle de manoeuvre (50) arrive, de par son poids propre, dans sa seconde position correspondant à la position de pincement du pince-fil (14).

- Dispositif de manoeuvre centralisée selon la revendication 6 ou 7, caractérisé en ce que le levier de manoeuvre (51) entraíné verticalement est constitué par un levier pivotant à deux bras dont un bras (53) est apte à être sollicité par un mécanisme d'entraínement, tandis que l'élément de réglage (60) est posé de manière lâche sur le second bras (56).

- Dispositif de manoeuvre centralisée selon l'une des revendications 1 à 8, caractérisé en ce que la butée (57) se compose d'un matériau insonorisant.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29608167U DE29608167U1 (de) | 1996-05-06 | 1996-05-06 | Zentralverstelleinrichtung für Fadenklemmen von Spulengattern |

| DE29608167U | 1996-05-06 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0806504A1 EP0806504A1 (fr) | 1997-11-12 |

| EP0806504B1 true EP0806504B1 (fr) | 2000-11-02 |

Family

ID=8023583

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97107061A Expired - Lifetime EP0806504B1 (fr) | 1996-05-06 | 1997-04-29 | Dispositif de réglage centralisé pour des pinces-fil de cantres |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0806504B1 (fr) |

| DE (2) | DE29608167U1 (fr) |

| ES (1) | ES2151203T3 (fr) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7086111B2 (en) | 2001-03-16 | 2006-08-08 | Braun Gmbh | Electric dental cleaning device |

| ATE377394T1 (de) | 2001-03-14 | 2007-11-15 | Braun Gmbh | Vorrichtung zur zahnreinigung |

| DE10159395B4 (de) | 2001-12-04 | 2010-11-11 | Braun Gmbh | Vorrichtung zur Zahnreinigung |

| US8443476B2 (en) | 2001-12-04 | 2013-05-21 | Braun Gmbh | Dental cleaning device |

| DE102004062150A1 (de) | 2004-12-23 | 2006-07-13 | Braun Gmbh | Auswechselbares Zubehörteil für ein Elektrokleingerät und Verfahren zum Bestimmen der Benutzungsdauer des Zubehörteils |

| WO2012023121A2 (fr) | 2010-08-19 | 2012-02-23 | Braun Gmbh | Procédé de fonctionnement d'un appareil électrique et appareil électrique |

| EP2550937B1 (fr) | 2011-07-25 | 2014-02-26 | Braun GmbH | Connexion magnétique entre la manche d'une brosse à dents et la tête de brosse |

| PL2550938T3 (pl) | 2011-07-25 | 2015-06-30 | Braun Gmbh | Urządzenie do higieny jamy ustnej |

| CN103703668B (zh) | 2011-07-25 | 2016-12-07 | 博朗有限公司 | 线性电动聚合物马达和具有所述线性电动聚合物马达的装置 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2853662C2 (de) * | 1978-12-13 | 1986-07-03 | Hacoba Textilmaschinen Gmbh & Co Kg, 5600 Wuppertal | Schär- oder Zettelanlage |

| DE3436714A1 (de) * | 1984-10-06 | 1986-04-17 | Hacoba Textilmaschinen Gmbh & Co Kg, 5600 Wuppertal | Spulengatter fuer zettel- oder schaermaschine und verfahren zur steuerung der fadenklemmen eines spulengatters |

| US4598184A (en) * | 1985-04-16 | 1986-07-01 | West Point Foundry And Machine Co. | Thread tension monitoring and clamping apparatus |

| CH675598A5 (fr) * | 1986-04-02 | 1990-10-15 | Benninger Ag Maschf | |

| DE3734518A1 (de) * | 1987-10-13 | 1989-04-27 | Hacoba Textilmaschinen | Vorrichtung fuer die anlaufsteuerung von spulengattern |

| CH674512A5 (fr) * | 1987-12-03 | 1990-06-15 | Benninger Ag Maschf | |

| CH683193A5 (de) * | 1991-04-24 | 1994-01-31 | Benninger Ag Maschf | Vorrichtung zur Ueberwachung des Fadenlaufs an einem Spulengatter. |

-

1996

- 1996-05-06 DE DE29608167U patent/DE29608167U1/de not_active Expired - Lifetime

-

1997

- 1997-04-29 EP EP97107061A patent/EP0806504B1/fr not_active Expired - Lifetime

- 1997-04-29 DE DE59702550T patent/DE59702550D1/de not_active Expired - Fee Related

- 1997-04-29 ES ES97107061T patent/ES2151203T3/es not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE59702550D1 (de) | 2000-12-07 |

| DE29608167U1 (de) | 1997-09-18 |

| EP0806504A1 (fr) | 1997-11-12 |

| ES2151203T3 (es) | 2000-12-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0546150B1 (fr) | Dispositif de bobinage muni d'une unite de commande pour la regulation de la pression d'appui d'une bobine sur un cylindre entraineur | |

| DE4114012A1 (de) | Kettenwirkmaschine mit auf einer legebarre angebrachten individuell bewegbaren fadenfuehrer | |

| DE102010005720B3 (de) | Haspel zur Aufnahme eines Coils aus Draht oder einem rohrförmigen oder einem bandförmigen Material zur Abgabe an eine nachgeschaltete Verarbeitungsmaschine | |

| DE2841210C2 (de) | Einrichtung zur Ballonbegrenzung an einem Spulengatter | |

| EP0806504B1 (fr) | Dispositif de réglage centralisé pour des pinces-fil de cantres | |

| DE69607301T2 (de) | Fadenleitöse für Spinnereimaschinen | |

| DE2534364C2 (fr) | ||

| DE4115059C2 (de) | Vorrichtung zum Begrenzen der Fadenballons an einem Spulengatter | |

| EP0141258B1 (fr) | Dispositif de bobinage pour la formation d'enroulement d'ouate | |

| EP0080568B1 (fr) | Support pour ensemble de rouleaux d'étirage | |

| DE19703002C2 (de) | Vorrichtung zum Schären einer Fadenschar auf einem Kettbaum | |

| EP1130151B1 (fr) | Machine à broder, en particulier machine à broder à navette | |

| EP0441178A1 (fr) | Banc à étirer à courroies et continu à filer avec une pluralité de telles bancs à étirer à courroies | |

| DE4344348C2 (de) | Fadenwechsel mit Drucklufttransport | |

| DE3100880C2 (de) | Spulengatter für Zettel- oder Schärmaschinen | |

| DE3137346A1 (de) | Spinnereimaschine mit streckwerken | |

| EP0511160B2 (fr) | Dispositif de contrÔle de la course du fil sur un cantre | |

| WO1997042364A1 (fr) | Dispositif d'enroulement pour fils de cantres | |

| DE2735760A1 (de) | Vorrichtung zum abnehmen von faeden, insbesondere von garnen | |

| DE19823613A1 (de) | Fadenbremsvorrichtung | |

| DE102007051526B3 (de) | Einrichtung zum Abziehen der Warenbahn an einer Webmaschine und Webmaschine mit einer derartigen Einrichtung | |

| DE2255554C3 (de) | Vorrichtung und Verfahren zum automatischen Aufstecken von Spulen bzw. Spulenhülsen an einer Spinn- oder Zwirnmaschine | |

| EP0529429A1 (fr) | Frein à disques pour fils textiles | |

| DE2749797A1 (de) | Vorrichtung zum abnehmen von faeden | |

| DE2146989C3 (de) | Spulenhaltevorrichtung, insbesondere für Spul-, Zwirn- oder Aufwickelmaschinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES IT LI |

|

| 17P | Request for examination filed |

Effective date: 19971111 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20000131 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES IT LI |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: E. BLUM & CO. PATENTANWAELTE Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59702550 Country of ref document: DE Date of ref document: 20001207 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2151203 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010528 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010528 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20020514 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050429 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090421 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101103 |