EP0806504B1 - Centralized control device for thread clamps of creels - Google Patents

Centralized control device for thread clamps of creels Download PDFInfo

- Publication number

- EP0806504B1 EP0806504B1 EP97107061A EP97107061A EP0806504B1 EP 0806504 B1 EP0806504 B1 EP 0806504B1 EP 97107061 A EP97107061 A EP 97107061A EP 97107061 A EP97107061 A EP 97107061A EP 0806504 B1 EP0806504 B1 EP 0806504B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- control rod

- thread

- adjusting device

- control

- central

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 claims description 3

- 238000006073 displacement reaction Methods 0.000 claims 6

- 238000013016 damping Methods 0.000 claims 1

- 238000004804 winding Methods 0.000 description 21

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 1

- 239000011358 absorbing material Substances 0.000 description 1

- ZINJLDJMHCUBIP-UHFFFAOYSA-N ethametsulfuron-methyl Chemical compound CCOC1=NC(NC)=NC(NC(=O)NS(=O)(=O)C=2C(=CC=CC=2)C(=O)OC)=N1 ZINJLDJMHCUBIP-UHFFFAOYSA-N 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000004091 panning Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02H—WARPING, BEAMING OR LEASING

- D02H1/00—Creels, i.e. apparatus for supplying a multiplicity of individual threads

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02H—WARPING, BEAMING OR LEASING

- D02H13/00—Details of machines of the preceding groups

- D02H13/22—Tensioning devices

- D02H13/24—Tensioning devices for individual threads

Definitions

- the invention relates to a central adjustment device for thread clamping of creel, with vertical movable, each assigned to a row of coils Control rods on which there is a control ramp for each thread clamp is formed with a spring-loaded, the thread clamp controlling in an open or in a clamping position Bolt is adjustable, and associated with each actuator rod vertically driven adjustment lever on the Actuating rod attacks and this in one of the open positions Thread clamp can move corresponding first position, from the control rod to one of the clamping positions of the thread clamp corresponding second position is adjustable.

- a central adjustment device with the aforementioned Features are known for example from DE 37 34 518. It is used for coil gates that have a variety of winding units. Each winding unit carries a spool, whose thread is pulled off overhead. The thread runs through a thread clamp and is deflected around a thread monitor needle and wound onto a winding machine by a winding machine. The winding takes place at high winding speeds, so that the air friction of the thread is at least a substantial one Is part of the thread tension that the winding machine has to muster. In the event of a standstill, also in Case of a sudden interruption of the winding due to thread breakage, all thread clamps of the creel are activated to all To keep threads of the entire thread taut. Do this not, the threads would get tangled. A trouble-free A restart would then not be guaranteed.

- each gate side has an electrically controlled pneumatic cylinder is assigned that above the winding units and is arranged at the end of the gate side.

- On the pneumatic cylinder are hinged rods that are horizontally above the Winding units are guided. These poles are very long and consist of several sections.

- the cylinder pressurized horizontal bars are driven by the adjustment levers connected. Due to the large number of components and the large ones Lengths of common gates are correspondingly large tolerances available, which is an ideal setting of the central adjustment not allow.

- thread clamps are generally known, their clamping force is roughly adjustable in three stages.

- the thread clamps can be individually influenced, however, due to the large number of thread clamps large adjustment effort are operated, so that this adjustment is ultimately not used.

- the task of the known object is the invention based on a central adjustment device with the entrance to improve the features mentioned so that a total Setting all thread clamps is facilitated without doing so Make individual settings on all thread clamps to have to.

- the adjusting lever on an adjusting part that acts vertically on the adjusting rod is infinitely adjustable and / or that the second position corresponding to the clamping position of the thread clamp the control rod from a stop supporting this is determined, its vertical position continuously up to the support of the bolt on the control ramp is adjustable.

- the vertical driven adjusting lever is influenced overall.

- the setting part achieved by its stepless vertical adjustment can be that the control rod is positioned higher or lower becomes. Accordingly, all inclined surfaces an adjusting rod positioned higher or lower so that all positions of the thread clamp are affected, insofar as they can be influenced by these inclined surfaces. It results there is a row-by-row adjustability, through which all Tolerances of the central adjustment device between this Setting part up to a pneumatic cylinder as an example Drive element can be switched off.

- stepless vertical adjustment between the adjustment part and the control rod can the vertical stroke of the control rod be changed so that the free passage of the thread between a jaw of the thread clamp and an abutment this jaw is adjustably kept the same.

- the central adjustment device can also do this be trained that the second, the clamping position position of the adjusting rod of the thread clamp a stop supporting this is determined, its vertical position continuously up to the support of the bolt on the Control ramp is adjustable. Due to the adjustability of the The adjusting rod has the vertical position of the supporting stop one of the setting options via the setting part independent setting option.

- the control rod can independent of the clamping positions of their thread clamps of which can be continuously adjusted, such as the open position was set via the setting part.

- the adjustment part and are in a structurally simple manner the control rod is screwed together.

- the screw connection can be easily released to the actuator stem in a relative bring another position to the adjustment part.

- the central adjustment are designed so that the Adjustment part and / or the adjusting rod have elongated holes, whose length corresponds to the vertical setting range.

- the central adjustment device can be formed so that the adjusting part is loose on the vertical driven adjustment lever that rests from the vertical Movement range of the control rod is removable and the Raise the control rod from its second position to the first can.

- the slack between the adjustment part and the vertically driven one Adjustment lever allows the control rod including of the setting part for the clamping position of the thread clamp to position.

- the drive of the adjustment lever is designed so that the control rod from this position with the adjustment lever while eliminating the slack is.

- the central adjustment device can be designed that the vertically driven adjustment lever the adjustment part is able to release, causing the control rod as a result their own weight in their second, the clamping position of the thread clamp appropriate position. It is as a result no need to provide a drive for the control rod, with which they in the the clamping position of the thread clamp appropriate position.

- the one that drives the control rod or its setting part Control lever has to transmit a corresponding actuating force, which is usually from a pneumatic cylinder as usual Drive part of the central adjustment device exercised becomes.

- the actuation force is transmitted above of the winding units horizontally, so that a deflection of movement from the horizontal to the vertical is necessary.

- the central adjustment device is therefore designed so that the vertically driven adjustment lever a two-armed swivel lever one arm of which can be acted upon by a drive and on the other arm the adjustment part lies loosely.

- the coil gate 10 shown in FIGS. 1, 2 is a so-called V-gate, from the two sides of the gate 10 'threads F run to a winding device, namely a slip machine 11, of which the sheet of threads F on one Winding tree 21 is wound.

- the winding tree 21 has Winding disks 21 ', between which a pressure roller 22 which are constantly increasing in diameter during winding Presses.

- the winding process is carried out by a control panel 23 the winding device controlled from where also a shutdown can take place if there is a breakage of a thread F.

- the coil gate 10 has a larger number of gate fields 20, in which coils 24 line in a conventional manner and are arranged in columns.

- To accommodate the coils 24 2 shows schematically in each coil field 20 with dash-dotted lines Turning circles illustrated rotary gates 25 that can be loaded from the interior 26 of the creel 10 can, while on the outer sides of the gate sides 10 ' Threads F are withdrawn.

- each thread guide device has a thread clamp 14, which a gate strut 26 attached in a manner not shown is.

- the gate strut 26 is part of the rest Gate frame, not shown, from its spindles the coils 24 are also worn.

- the thread clamp 14 has a tubular housing 27 with an external Abutment 29.

- the jaw 30 is held by a bolt 31, the is guided in the housing 27 such that the jaw 30 can only move according to this guidance.

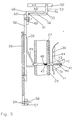

- the bolt 31 in the holes shown in Fig.3.4 guided in the directions of its longitudinal axis.

- the End 40 of the bolt 31 on the jaw side has one to the plane of representation vertical guide pin 41, both ends of which are guided in slots 42 which are parallel to the bolts Holding tab 43 of the jaw 30 are located.

- the floor 44 the jaw has a hole through which the bolt 31 passes is so that it is always arranged perpendicular to the bolt 31.

- a compression spring 45 from which the jaw 30 in its clamping position tries to press.

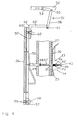

- the adjusting rod 50 is held up by an adjusting lever 51, which is designed as a two-armed angle lever. He is driven by a rod 52 which is articulated on the angle arm 53 is and is adjusted horizontally, for example as a result Actuation by a pneumatic cylinder 54, the acts on the lever arm 53 via the rod 52. A panning around the frame-fixed pivot point 55 in the counterclockwise direction causes the lever arm 56 to lower and thus the transition of the control rod 50 from that shown in Figure 3 Position in the low position shown in Figure 4. For this the adjustment lever 51 is quickly folded away so that the Bar 50 falls down. Your case will be answered by someone else Gate strut 26 adjustable stop 57 limited which is made of sound-absorbing material.

- the stop 57 is provided with an elongated hole 59, so that it goes up and down in the circumference of this elongated hole can be adjusted.

- the stop 57 is, for example completely adjusted downwards if the bolt 31 is not yet in illustrated manner supported in the inclined area of the control ramp 49 is and should be ensured that the thread clamp 14 clamps with full force of the spring 45.

- a position of Adjusting rod 50 is set, in which the bolt 31st is supported on the slope of the control ramp 49. With that a exact material-related clamping force can be set continuously. The setting is made in that part of the control ramp 49, with respect to which the bolt 31 within the Slot 42 is freely movable without the thread clamp 14th opens.

- the rod 50 must also be raised can be set, expediently independently from their subscript.

- the adjusting rod 50 provided with an adjusting part 60, namely with an angle, whose one angle leg 60 'is arranged approximately horizontally is and on a support pin 61 of the angle arm 56 of the adjusting lever 51 is loose.

- the other angle arm is 60 '' attached to the upper end 50 'of the actuating rod 50 and is for this purpose provided with an elongated hole 62 so that it is vertically adjustable is.

- upper end 50 'of the adjusting rod 50 as far as possible attached to the angle arm 60 'is attached. That is for example advisable if the full open position shown in Fig.3 the thread clamp 14 is to be reached, the bolt 31 but still in a manner not shown on the Inclined surface of the control ramp 49 is supported.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Warping, Beaming, Or Leasing (AREA)

- Unwinding Of Filamentary Materials (AREA)

- Moulding By Coating Moulds (AREA)

- Particle Accelerators (AREA)

Description

Die Erfindung bezieht sich auf eine Zentralverstelleinrichtung für Fadenklemmen von Spulengattern, mit vertikal verschieblichen, jeweils einer Spulenreihe zugeordneten Stellstangen, an denen für jede Fadenklemme eine Steuerrampe ausgebildet ist, mit der ein federbeaufschlagter, die Fadenklemme in eine Offen- oder in eine Klemmstellung steuernder Bolzen verstellbar ist, und mit einem jeder Stellstange zugeordneten vertikal angetriebenen Verstellhebel, der an der Stellstange angreift und diese in eine der Offenstellung der Fadenklemme entsprechende erste Stellung zu bewegen vermag, aus der die Stellstange in eine der Klemmstellung der Fadenklemme entsprechende zweite Stellung verstellbar ist.The invention relates to a central adjustment device for thread clamping of creel, with vertical movable, each assigned to a row of coils Control rods on which there is a control ramp for each thread clamp is formed with a spring-loaded, the thread clamp controlling in an open or in a clamping position Bolt is adjustable, and associated with each actuator rod vertically driven adjustment lever on the Actuating rod attacks and this in one of the open positions Thread clamp can move corresponding first position, from the control rod to one of the clamping positions of the thread clamp corresponding second position is adjustable.

Eine Zentralverstelleinrichtung mit den vorgenannten Merkmalen ist beispielsweise aus der DE 37 34 518 bekannt. Sie kommt bei Spulengattern zum Einsatz, die eine Vielzahl von Spulstellen aufweisen. Jede Spulstelle trägt eine Spule, deren Faden über Kopf abgezogen wird. Der Faden durchläuft eine Fadenklemme und wird um eine Fadenwächternadel umgelenkt und von einer Wickelmaschine auf deren Wickelbaum aufgewikkelt. Das Aufwickeln erfolgt mit hohen Wickelgeschwindigkeiten, so daß die Luftreibung des Fadens zumindest einen wesentlichen Teil der Fadenzugkraft ausmacht, welche die Wikkelmaschine aufzubringen hat. Im Stillstandsfall, auch im Fall einer plötzlichen Wickelunterbrechung wegen Fadenbruchs, werden alle Fadenklemmen des Spulengatters aktiviert, um alle Fäden der gesamten Fadenschar stramm zu halten. Geschähe dies nicht, würden sich die Fäden verheddern. Ein störungsfreier Wiederanlauf wäre dann nicht gewährleistet.A central adjustment device with the aforementioned Features are known for example from DE 37 34 518. It is used for coil gates that have a variety of winding units. Each winding unit carries a spool, whose thread is pulled off overhead. The thread runs through a thread clamp and is deflected around a thread monitor needle and wound onto a winding machine by a winding machine. The winding takes place at high winding speeds, so that the air friction of the thread is at least a substantial one Is part of the thread tension that the winding machine has to muster. In the event of a standstill, also in Case of a sudden interruption of the winding due to thread breakage, all thread clamps of the creel are activated to all To keep threads of the entire thread taut. Do this not, the threads would get tangled. A trouble-free A restart would then not be guaranteed.

Es ist erforderlich, daß alle Fäden der gesamten Fadenschar von den Fadenklemmen gleichzeitig und in gleichem Maße geklemmt werden. Darüber hinaus ist es erforderlich, daß alle Fadenklemmen in gleichem Maße geöffnet sind, um einen reibungsfreien bzw. um einen störungsfreien Fadendurchlauf zu gewährleisten. Es ist also erforderlich, daß alle Klemmbacken der Fadenklemmen zu den zugehörigen Widerlagern gleichmäßig großen Abstand aufweisen. Das trägt auch dazu bei, daß sich wenig Abrieb und Flusenflug in den Fadenklemmen absetzen kann, was zu losen Fäden im Klemmfall führen würde.It is necessary that all threads of the entire family of threads from the thread clamps simultaneously and to the same extent be clamped. In addition, it is required that everyone Thread clamps are open to the same extent to ensure a smooth or to ensure that the thread runs smoothly guarantee. So it is necessary that all jaws the thread clamps to the associated abutments evenly have a large distance. This also contributes to the fact that little abrasion and fluff in the thread clamps can, which would lead to loose threads in the event of a pinch.

Die bekannte Zentralverstelleinrichtung ist so ausgebildet, daß jeder Gatterseite ein elektrisch gesteuerter Pneumatikzylinder zugeordnet ist, der oberhalb der Spulstellen und am Ende der Gatterseite angeordnet ist. An dem Pneumatikzylinder sind Stangen angelenkt, die waagerecht oberhalb der Spulstellen geführt sind. Diese Stangen sind sehr lang und bestehen aus mehreren Teilstücken. Die zylinderbeaufschlagten waagerechten Stangen sind antriebsmäßig mit den Verstellhebeln verbunden. Durch die Vielzahl der Bauteile und die grossen Längen üblicher Gatter sind entsprechend große Toleranzen vorhanden, die eine ideale Einstellung der Zentralverstelleinrichtung nicht zulassen. Es ist allgemein bekannt, über eine Hubveränderung an den Pneumatikzylindern die Klemmkräfte der Fadenklemmen gesamthaft zu verändern. Durch die vorgenannten Toleranzen ist jedoch die infolgedessen vorhandene Ungleichmäßigkeit der Klemmkräfte nicht auszugleichen. Auch eine Vergleichmäßigung der Öffnung der Fadenklemmen in deren Offenstellung ist nicht gesamthaft möglich.The known central adjustment device is designed that each gate side has an electrically controlled pneumatic cylinder is assigned that above the winding units and is arranged at the end of the gate side. On the pneumatic cylinder are hinged rods that are horizontally above the Winding units are guided. These poles are very long and consist of several sections. The cylinder pressurized horizontal bars are driven by the adjustment levers connected. Due to the large number of components and the large ones Lengths of common gates are correspondingly large tolerances available, which is an ideal setting of the central adjustment not allow. It is well known about a change in stroke on the pneumatic cylinders the clamping forces to change the thread clamps in their entirety. By the aforementioned However, tolerances are the resultant Uneven clamping forces cannot be compensated. Also an equalization of the opening of the thread clamps in their Open positions are not possible as a whole.

Ferner sind Fadenklemmen allgemein bekannt, deren Klemmkraft in drei Stufen grob einstellbar ist. In diesem Fall ist zwar eine individuelle Beeinflussung der Fadenklemmen möglich, jedoch muß wegen der Vielzahl der Fadenklemmen ein großer Verstellaufwand betrieben werden, so daß diese Einstellmöglichkeit letztlich nicht genutzt wird. Furthermore, thread clamps are generally known, their clamping force is roughly adjustable in three stages. In this case the thread clamps can be individually influenced, however, due to the large number of thread clamps large adjustment effort are operated, so that this adjustment is ultimately not used.

Dem Bekannten gegenüber liegt der Erfindung die Aufgabe zugrunde, eine Zentralverstelleinrichtung mit den eingangs genannten Merkmalen so zu verbessern, daß eine gesamthafte Einstellung aller Fadenklemmen erleichtert wird, ohne dabei an allen Fadenklemmen jeweils einzeln Einstellungen vornehmen zu müssen.The task of the known object is the invention based on a central adjustment device with the entrance to improve the features mentioned so that a total Setting all thread clamps is facilitated without doing so Make individual settings on all thread clamps to have to.

Diese Aufgabe wird dadurch gelöst, daß der Verstellhebel an einem Einstellteil angreift, das an der Stellstange vertikal stufenlos einstellbar befestigt ist und/oder daß die zweite, der Klemmstellung der Fadenklemme entsprechende Stellung der Stellstange von einem diese abstützenden Anschlag bestimmt ist, dessen Vertikalstellung stufenlos bis zur Abstützung des Bolzens auf der Steuerrampe einstellbar ist.This object is achieved in that the adjusting lever on an adjusting part that acts vertically on the adjusting rod is infinitely adjustable and / or that the second position corresponding to the clamping position of the thread clamp the control rod from a stop supporting this is determined, its vertical position continuously up to the support of the bolt on the control ramp is adjustable.

Für die Erfindung ist von Bedeutung, daß der vertikal angetriebene Verstellhebel gesamthaft beeinflußt wird. Für diese Beeinflussung ist zum einen das Einstellteil vorgesehen, durch dessen stufenlose vertikale Einstellung erreicht werden kann, daß die Stellstange höher oder tiefer positioniert wird. Dementsprechend werden auch sämtliche Schrägflächen einer Stellstange höher oder tiefer positioniert, so daß alle Stellungen der Fadenklemme beeinflußt werden, soweit sie durch diese Schrägflächen beeinflußt werden können. Es ergibt sich eine spulenreihenweise Justierbarkeit, durch die sämtliche Toleranzen der Zentralverstelleinrichtung zwischen diesem Einstellteil bis zu einem Pneumatikzylinder als beispielsweisem Antriebselement ausgeschaltet werden können. Infolge der stufenlosen vertikalen Einstellung zwischen dem Einstellteil und der Stellstange kann der senkrechte Hub der Stellstange so verändert werden, daß der freie Durchgang des Fadens zwischen einer Klemmbacke der Fadenklemme und einem Widerlager dieser Klemmbacke einstellbar gleich gehalten wird.It is important for the invention that the vertical driven adjusting lever is influenced overall. For this influence is provided on the one hand by the setting part, achieved by its stepless vertical adjustment can be that the control rod is positioned higher or lower becomes. Accordingly, all inclined surfaces an adjusting rod positioned higher or lower so that all positions of the thread clamp are affected, insofar as they can be influenced by these inclined surfaces. It results there is a row-by-row adjustability, through which all Tolerances of the central adjustment device between this Setting part up to a pneumatic cylinder as an example Drive element can be switched off. As a result of stepless vertical adjustment between the adjustment part and the control rod can the vertical stroke of the control rod be changed so that the free passage of the thread between a jaw of the thread clamp and an abutment this jaw is adjustably kept the same.

Die Zentralverstelleinrichtung kann zum anderen dahingehend ausgebildet werden, daß die zweite, der Klemmstellung der Fadenklemme entsprechende Stellung der Stellstange von einem diese abstützenden Anschlag bestimmt ist, dessen Vertikalstellung stufenlos bis zur Abstützung des Bolzens auf der Steuerrampe einstellbar ist. Infolge der Einstellbarkeit der Vertikalstellung des abstützenden Anschlags hat die Stellstange eine von der Einstellmöglichkeit über das Einstellteil unabhängige Einstellmöglichkeit. Die Stellstange kann also bezüglich der Klemmstellungen ihrer Fadenklemmen unabhängig davon stufenlos eingestellt werden, wie die Offenstellung über das Einstellteil eingestellt wurde. Durch die stufenlose Verstellung des Anschlags, bedarfsweise bis in den Bereich hinein, in dem sich der Bolzen auf der Steuerrampe abstützt, kann eine genaue materialbezogene Klemmkraft eingestellt werden.The central adjustment device can also do this be trained that the second, the clamping position position of the adjusting rod of the thread clamp a stop supporting this is determined, its vertical position continuously up to the support of the bolt on the Control ramp is adjustable. Due to the adjustability of the The adjusting rod has the vertical position of the supporting stop one of the setting options via the setting part independent setting option. The control rod can independent of the clamping positions of their thread clamps of which can be continuously adjusted, such as the open position was set via the setting part. By the stepless Adjustment of the stop, if necessary up to the area into which the bolt is supported on the control ramp, an exact material-related clamping force can be set.

Es ist insbesondere vorteilhaft, die Zentralverstelleinrichtung so auszubilden, daß das Einstellteil zwischen dem oberen Ende der Stellstange und dem Verstellhebel angeordnet ist. Es ergibt sich eine kompakte Bauform am oberen Ende der Stellstange im Hinblick auf die von dem Pneumatikzylinder angetriebenen Stangen und Verstellhebel.It is particularly advantageous to use the central adjustment device so that the adjusting part between the arranged upper end of the adjusting rod and the adjusting lever is. The result is a compact design at the top of the Control rod with regard to those driven by the pneumatic cylinder Rods and adjustment levers.

In konstruktiv einfacher Weise sind das Einstellteil und die Stellstange miteinander verschraubt. Die Verschraubung kann leicht gelöst werden, um die Stellstange in eine relativ andere Lage zum Einstellteil zu bringen.The adjustment part and are in a structurally simple manner the control rod is screwed together. The screw connection can be easily released to the actuator stem in a relative bring another position to the adjustment part.

Will man eine stufenlose Verstellung erreichen, so kann die Zentralverstelleinrichtung so ausgebildet werden, daß das Einstellteil und/oder die Stellstange Langlöcher aufweisen, deren Länge dem vertikalen Einstellbereich entspricht.If you want to achieve a continuous adjustment, you can the central adjustment are designed so that the Adjustment part and / or the adjusting rod have elongated holes, whose length corresponds to the vertical setting range.

Es ist möglich, die für eine derartige Einstellung zweckmäßigen Einstellelemente einzusetzen. Sofern nur geringe Einstellhübe nötig sind, ist es vorteilhaft, wenn das Einstellteil und die Stellstange über einen Einstellexzenter miteinander verbunden sind. In diesem Fall ist es nicht nötig, das Einstellteil und die Stellstange über eine Verschraubung zu betätigen, wenn der Einstellexzenter selbsthemmend ausgebildet ist.It is possible for such a setting use appropriate setting elements. If only minor Adjustment strokes are necessary, it is advantageous if the adjustment part and the control rod via an adjustment eccentric are interconnected. In this case it is not necessary the adjusting part and the adjusting rod via a screw connection to be operated when the adjustment cam is self-locking is trained.

Es muß dafür gesorgt werden, daß die beiden Einstellmöglichkeiten an der Stellstange unabhängig voneinander möglich sind. Zu diesem Zweck kann die Zentralverstelleinrichtung so ausgebildet werden, daß das Einstellteil lose auf dem vertikal angetriebenen Verstellhebel aufliegt, der aus dem vertikalen Bewegungsbereich der Stellstange entfernbar ist und die Stellstange aus ihrer zweiten Stellung in die erste anheben kann. Die Lose zwischen dem Einstellteil und dem vertikal angetriebenen Verstellhebel ermöglicht es, die Stellstange einschließlich des Einstellteils für die Klemmstellung der Fadenklemme zu positionieren. Der Antrieb des Verstellhebels ist so ausgebildet, daß die Stellstange aus dieser Stellung mit dem Verstellhebel unter Beseitigung der Lose anzuheben ist.It must be ensured that the two setting options possible independently on the control rod are. For this purpose, the central adjustment device can be formed so that the adjusting part is loose on the vertical driven adjustment lever that rests from the vertical Movement range of the control rod is removable and the Raise the control rod from its second position to the first can. The slack between the adjustment part and the vertically driven one Adjustment lever allows the control rod including of the setting part for the clamping position of the thread clamp to position. The drive of the adjustment lever is designed so that the control rod from this position with the adjustment lever while eliminating the slack is.

Die Zentralverstelleinrichtung kann so ausgebildet werden, daß der vertikal angetriebene Verstellhebel das Einstellteil freizugeben vermag, wodurch die Stellstange infolge ihres Eigengewichts in ihre zweite, der Klemmstellung der Fadenklemme entsprechende Stellung gelangt. Es ist infolgedessen nicht nötig, für die Stellstange einen Antrieb vorzusehen, mit dem sie in die der Klemmstellung der Fadenklemme entsprechende Stellung gelangt.The central adjustment device can be designed that the vertically driven adjustment lever the adjustment part is able to release, causing the control rod as a result their own weight in their second, the clamping position of the thread clamp appropriate position. It is as a result no need to provide a drive for the control rod, with which they in the the clamping position of the thread clamp appropriate position.

Der die Stellstange bzw. dessen Einstellteil antreibende Stellhebel hat eine entsprechende Betätigungskraft zu übertragen, die üblicherweise von einem Pneumatikzylinder als üblichem Antriebsteil der Zentralverstelleinrichtung ausgeübt wird. Die Weiterleitung der Betätigungskraft erfolgt oberhalb der Spulstellen horizontal, so daß eine Bewegungsumlenkung aus der Horizontalen in die Vertikale notwendig ist. Die Zentralverstelleinrichtung wird daher so ausgebildet, daß der vertikal angetriebene Verstellhebel ein zweiarmiger Schwenkhebel ist, dessen einer Arm von einem Antrieb beaufschlagbar ist und auf dessen anderem Arm das Einstellteil lose aufliegt.The one that drives the control rod or its setting part Control lever has to transmit a corresponding actuating force, which is usually from a pneumatic cylinder as usual Drive part of the central adjustment device exercised becomes. The actuation force is transmitted above of the winding units horizontally, so that a deflection of movement from the horizontal to the vertical is necessary. The central adjustment device is therefore designed so that the vertically driven adjustment lever a two-armed swivel lever one arm of which can be acted upon by a drive and on the other arm the adjustment part lies loosely.

Die Erfindung wird anhand eines in der Zeichnung dargestellten Ausführungsbeispiels erläutert. Es zeigt:

- Fig.1

- eine schematische Seitenansicht eines Spulengatters mit einer fädenabziehenden Wickelvorrichtung,

- Fig.2

- eine Aufsicht auf die Anordnung der Fig.1 in Richtung A,

- Fig.3

- eine schematische Seitenansicht auf eine Fadenklemme in ihrer Offenstellung, und

- Fig.4

- eine der Fig.3 entsprechende Seitenansicht auf die Fadenklemme in ihrer Klemmstellung.

- Fig. 1

- 1 shows a schematic side view of a creel with a thread-pulling winding device,

- Fig. 2

- 1 is a top view of the arrangement of FIG. 1 in direction A,

- Fig. 3

- is a schematic side view of a thread clamp in its open position, and

- Fig. 4

- a side view corresponding to the 3 on the thread clamp in its clamping position.

Das in den Fig.1,2 dargestellte Spulengatter 10 ist ein

sogenanntes V-Gatter, von dessen beiden Gatterseiten 10' Fäden

F einer Wickelvorrichtung zulaufen, nämlich einer Zettelmaschine

11, von der die Fadenschar der Fäden F auf einen

Wickelbaum 21 aufgewickelt wird. Der Wickelbaum 21 besitzt

Wickelscheiben 21', zwischen denen eine Anpreßwalze 22 auf

den sich beim Wickeln ständig im Durchmesser vergrößernden

Wickel drückt. Der Wickelvorgang wird von einem Steuerpult 23

der Wickelvorrichtung gesteuert, von wo aus auch eine Abschaltung

erfolgen kann, falls ein Bruch eines Fadens F vorliegt.The

Das Spulengatter 10 hat eine größere Anzahl von Gatterfeldern

20, in denen Spulen 24 in herkömmlicher Weise zeilen-

und spaltenförmig angeordnet sind. Zur Aufnahme der Spulen 24

in jedem Spulenfeld 20 zeigt Fig.2 schematisch mit strichpunktierten

Drehkreisen veranschaulichte Drehgatter 25, die

vom Innenraum 26 des Spulengatters 10 aus bestückt werden

können, während auf den Außenseiten der Gatterseiten 10' die

Fäden F abgezogen werden.The

Zur Aufnahme der Spulen 24 im Spulengatter 10 dienen

Spulstellen 12' mit nicht dargestellten Spulendornen, auf die

die Spulen 24 aufgesteckt werden. Von diesen Spulen 24 wird

der Faden F über Kopf abgezogen, durchläuft eine nicht dargestellte

Fadenführungseinrichtung und wird in Richtung zur

Wickelvorrichtung 11 umgelenkt. Damit alle Fäden F der Gesamtfadenschar

F-F im Falle eines Stillstands der Wickelvorrichtung

11 in gleicher Weise geordnet zum Stillstand kommen,

hat jede Fadenführungsvorrichtung eine Fadenklemme 14, die an

einer Gatterstrebe 26 in nicht dargestellter Weise angebracht

ist. Die Gatterstrebe 26 ist ein Bestandteil des im übrigen

nicht näher dargestellten Gattergestells, von dessen Spulendornen

auch die Spulen 24 getragen sind. Die Fadenklemme 14

hat ein rohrstückartiges Gehäuse 27 mit einem außenliegenden

Widerlager 29. Dieses wirkt mit einer in der Darstellungsebene

verstellbaren Klemmbacke 30 zusammen. Zwischen der Klemmbacke

30 und dem Widerlager 29 läuft der Faden F senkrecht

zur Darstellungsebene. Der Fadenverlauf ist idealerweise so,

daß der Faden weder die Klemmbacke 30, noch das Widerlager 29

berührt. Für eine derartige Führung des Fadens sorgen beispielsweise

im Raum zwischen der Fadenklemme 14 und der zugehörigen

Spule angeordnete Vorumschlingungsstangen, die an

sich bekannt und daher hier nicht dargestellt sind.Serve to accommodate the

Die Klemmbacke 30 ist von einem Bolzen 31 gehalten, der

im Gehäuse 27 derart geführt ist, daß sich die Klemmbacke 30

lediglich entsprechend dieser Führung bewegen kann. Hierzu

ist der Bolzen 31 in den aus den Fig.3,4 ersichtlichen Bohrungen

in den Richtungen seiner Längsachse geführt. Das

klemmbackenseitige Ende 40 des Bolzens 31 hat einen zur Darstellungsebene

vertikalen Führungsstift 41, dessen beide Enden

in Schlitzen 42 geführt sind, die sich in bolzenparallelen

Haltelappen 43 der Klemmbacke 30 befinden. Der Boden 44

der Klemmbacke hat ein Loch, der vom Bolzen 31 durchsetzt

ist, so daß er stets senkrecht zum Bolzen 31 angeordnet ist.

Zwischen dem Boden 44 und einem Abstützstift 46 stützt sich

eine Druckfeder 45 ab, die die Klemmbacke 30 in ihre Klemmstellung

zu drücken sucht. Des weiteren ist eine Druckfeder

47 vorgesehen, die sich mit einem Ende am Gehäuse 27 und mit

dem anderen Ende am Kragen 48 des Bolzens 31 abstützt, so daß

sie die Klemmbacke 30 in die Klemmstellung zu drücken sucht.The

Die Steuerung des Bolzens 31 in die eine Stellung, nämlich

in Fig.3 dargestellte Offenstellung der Fadenklemme 14,

oder in die andere Stellung, nämlich die in Fig.4 dargestellte

Klemmstellung der Fadenklemme 14, erfolgt mit einer Steuerrampe

49. Diese Steuerrampe 49 ist ein an einer Stellstange

50 befestigtes Blechteil. Befindet sich dieses in der in Fig.

3 dargestellten Hochstellung, wird der Bolzen 31 entgegen der

Kraft der Feder 47 nach rechts verschoben. Der durch die

Steuerrampe 49 zu erzielende Hub ist so groß, daß der volle

Durchlaufspalt zwischen der Klemmbacke 30 und dem Widerlager

29 freigegeben wird. Das kann auch bereits dann der Fall

sein, wenn der Bolzen 31 noch nicht die in Fig.3 dargestellte

Stellung erreicht hat, sondern sich noch auf der Steuerrampe

49 abstützt. Befindet sich die Stellstange 50 hingegen in ihrer

Tiefstellung gemäß Fig.4, so vermag die Feder 47 den Bolzen

31 entgegen der Wirkung der Feder 45 nach links zu verschieben,

so daß die Klemme 14 schließt.The control of the

Beim Lösen der Fadenklemme 14 wird der Auflagedruck der

Klemmbacke 30 auf das Widerlager 29 in dem Maß verringert,

wie sich die Feder 45 entspannen kann. Der Auflagedruck der

Klemmbacke 30 auf dem Faden wird demgemäß nicht sprunghaft

von maximalen Klemmdruck auf Null verringert, sondern entsprechend

der stetigen Verringerung des von Feder 45 verursachten

Anpreßdrucks.When the

Die Stellstange 50 wird von einem Verstellhebel 51 hochgehalten,

der als zweiarmiger Winkelhebel ausgebildet ist. Er

ist von einer Stange 52 angetrieben, die am Winkelarm 53 angelenkt

ist und horizontal verstellt wird, beispielsweise infolge

Beaufschlagung durch einen Pneumatikzylinder 54, der

über die Stange 52 auf den Hebelarm 53 einwirkt. Ein Verschwenken

um den gattergestellfesten Drehpunkt 55 im Gegenuhrzeigersinn

bewirkt ein Absenken des Hebelarms 56 und damit

den Übergang der Stellstange 50 aus der in Fig.3 dargestellten

Stellung in die in Fig.4 dargestellte Tiefstellung. Hierzu

wird der Verstellhebel 51 schnell weggeklappt, so daß die

Stange 50 nach unten fällt. Ihr Fall wird durch einen an der

Gatterstrebe 26 einstellbar befestigten Anschlag 57 begrenzt,

der aus schalldämmendem Werkstoff besteht. Dessen Befestigung

erfolgt beispielsweise mittels einer Befestigungsschraube 58.

Außerdem ist der Anschlag 57 mit einem Langloch 59 versehen,

so daß er im Umfang dieses Langlochs nach oben und nach unten

verstellt werden kann. Der Anschlag 57 wird beispielsweise

völlig nach unten verstellt, wenn der Bolzen 31 noch in nicht

dargestellter Weise im Schrägbereich der Steuerrampe 49 abgestützt

ist und gewährleistet werden soll, daß die Fadenklemme

14 mit voller Kraft der Feder 45 klemmt. Andererseits kann es

durchaus sein, daß mit dem Anschlag 57 eine Stellung der

Stellstange 50 eingestellt wird, bei der sich der Bolzen 31

auf der Schräge der Steuerrampe 49 abstützt. Damit kann eine

genaue materialbezogene Klemmkraft stufenlos eingestellt werden.

Die Einstellung erfolgt in demjenigen Teil der Steuerrampe

49, bezüglich dessen der Bolzen 31 innerhalb des

Schlitzes 42 frei beweglich ist, ohne daß die Fadenklemme 14

öffnet.The adjusting

Andererseits muß auch die Hochstellung der Stange 50

eingestellt werden können, und zwar zweckmäßigerweise unabhängig

von ihrer Tiefstellung. Hierzu ist die Stellstange 50

mit einem Einstellteil 60 versehen, nämlich mit einem Winkel,

dessen einer Winkelschenkel 60' etwa horizontal angeordnet

ist und auf einem Tragstift 61 des Winkelarms 56 des Verstellhebels

51 lose aufliegt. Der andere Winkelarm 60'' ist

am oberen Ende 50' der Stellstange 50 befestigt und ist hierzu

mit einem Langloch 62 versehen, so daß er vertikal einstellbar

ist. Es kann infolgedessen erreicht werden, daß das

obere Ende 50' der Stellstange 50 soweit wie möglich nach

oben verschoben am Winkelarm 60' befestigt wird. Das ist beispielsweise

ratsam, wenn die in Fig.3 dargestellte volle Offenstellung

der Fadenklemme 14 erreicht werden soll, der Bolzen

31 jedoch noch in nicht dargestellter Weise auf der

Schrägfläche der Steuerrampe 49 abgestützt ist.On the other hand, the

Claims (9)

- Central adjusting device for thread grippers (14) of bobbin creels (10), having vertically displaceable control rods (50) allocated to a respective row of bobbins (63), on which control rods a control ramp (49) is formed for each thread gripper (14), by means of which ramp a spring-biassed pin (31) moving the thread gripper (14) into an open position or a gripping position can be displaced, and having a vertically driven displacement lever (51) allocated to each control rod (50), engaging the control rod (50) and able to move this control rod into a first position corresponding to the open position of the thread gripper (14), from which first position the control rod (50) can be displaced into a second position corresponding to the gripping position of the thread gripper (14), characterised in that the displacement lever (51) engages an adjusting part (60) which is fixed to the control rod (50) in such a way as to be vertically adjustable in a non-stepped manner, and/or that the second position of the control rod (50) corresponding to the gripping position of the thread gripper (14) is determined by a stop (57) bearing against this control rod and whose vertical position can be adjusted in a non-stepped manner until the pin (31) comes to bear on the control ramp (49).

- Central adjusting device according to claim 1, characterised in that the adjusting part (60) is disposed between the upper end (50') of the control rod (50) and the displacement lever (51).

- Central adjusting device according to claim 1 or 2, characterised in that the adjusting part (60) and the control rod (50) are screwed together.

- Central adjusting device according to claim 1 or 2, characterised in that the adjusting part (60) and/or the control rod (50) comprise elongate holes (62), of which the length corresponds to the vertical adjusting range.

- Central adjusting device according to one of claims 1 to 4, characterised in that the adjusting part (60) and the control rod (50) are connected to each other by an adjusting eccentric.

- Central adjusting device according to one of claims 1 to 5, characterised in that the adjusting part (60) lies freely against the vertically driven displacement lever (51) which can be moved out of the vertical movement range of the control rod (50) and can lift the control rod (50) from its second position into the first.

- Central adjusting device according to one of claims 1 to 6, characterised in that the vertically driven displacement lever (51) can release the adjusting part (60), whereby the control rod (50) moves into its second position corresponding to the gripping position of the thread gripper (14) under the effect of its own weight.

- Central adjusting device according to claims 6 or 7, characterised in that the vertically driven displacement lever (51) is a two-arm pivot lever, of which one arm (53) can be acted upon by a drive and the other arm (56) has the adjusting part (60) lying freely against it.

- Central adjusting device according to one of claims 1 to 8, characterised in that the stop (57) consists of a noise-damping material.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29608167U DE29608167U1 (en) | 1996-05-06 | 1996-05-06 | Central adjustment device for thread clamping of creel |

| DE29608167U | 1996-05-06 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0806504A1 EP0806504A1 (en) | 1997-11-12 |

| EP0806504B1 true EP0806504B1 (en) | 2000-11-02 |

Family

ID=8023583

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97107061A Expired - Lifetime EP0806504B1 (en) | 1996-05-06 | 1997-04-29 | Centralized control device for thread clamps of creels |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0806504B1 (en) |

| DE (2) | DE29608167U1 (en) |

| ES (1) | ES2151203T3 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7086111B2 (en) | 2001-03-16 | 2006-08-08 | Braun Gmbh | Electric dental cleaning device |

| PT1367958E (en) | 2001-03-14 | 2008-01-24 | Braun Gmbh | Device for cleaning teeth |

| DE10159395B4 (en) | 2001-12-04 | 2010-11-11 | Braun Gmbh | Device for cleaning teeth |

| US8443476B2 (en) | 2001-12-04 | 2013-05-21 | Braun Gmbh | Dental cleaning device |

| DE102004062150A1 (en) | 2004-12-23 | 2006-07-13 | Braun Gmbh | Interchangeable accessory for a small electrical appliance and method for determining the service life of the accessory |

| ES2764825T3 (en) | 2010-08-19 | 2020-06-04 | Braun Gmbh | Resonant motor unit and electrical device with resonant motor unit |

| EP2550937B1 (en) | 2011-07-25 | 2014-02-26 | Braun GmbH | Magnetic connection between a toothbrush handle and a brush head |

| WO2013014632A1 (en) | 2011-07-25 | 2013-01-31 | Braun Gmbh | Linear electro-polymer motors and devices having the same |

| PL2550938T3 (en) | 2011-07-25 | 2015-06-30 | Braun Gmbh | Oral hygiene device |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2853662C2 (en) * | 1978-12-13 | 1986-07-03 | Hacoba Textilmaschinen Gmbh & Co Kg, 5600 Wuppertal | Warping or warping system |

| DE3436714A1 (en) * | 1984-10-06 | 1986-04-17 | Hacoba Textilmaschinen Gmbh & Co Kg, 5600 Wuppertal | SPOOL GATE FOR PAPER OR SHARPENING MACHINE AND METHOD FOR CONTROLLING THE THREAD CLAMP OF A SPOOL GATE |

| US4598184A (en) * | 1985-04-16 | 1986-07-01 | West Point Foundry And Machine Co. | Thread tension monitoring and clamping apparatus |

| CH675598A5 (en) * | 1986-04-02 | 1990-10-15 | Benninger Ag Maschf | |

| DE3734518A1 (en) * | 1987-10-13 | 1989-04-27 | Hacoba Textilmaschinen | DEVICE FOR START-UP CONTROL OF COILS |

| CH674512A5 (en) * | 1987-12-03 | 1990-06-15 | Benninger Ag Maschf | |

| CH683193A5 (en) * | 1991-04-24 | 1994-01-31 | Benninger Ag Maschf | Device for monitoring the thread run on a bobbin creel. |

-

1996

- 1996-05-06 DE DE29608167U patent/DE29608167U1/en not_active Expired - Lifetime

-

1997

- 1997-04-29 ES ES97107061T patent/ES2151203T3/en not_active Expired - Lifetime

- 1997-04-29 EP EP97107061A patent/EP0806504B1/en not_active Expired - Lifetime

- 1997-04-29 DE DE59702550T patent/DE59702550D1/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ES2151203T3 (en) | 2000-12-16 |

| EP0806504A1 (en) | 1997-11-12 |

| DE59702550D1 (en) | 2000-12-07 |

| DE29608167U1 (en) | 1997-09-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0546150B1 (en) | Spooling assembly with a device for controlling the contact pressure between the spool and its drive roller | |

| DE4114012A1 (en) | Warp knitting machine with individually movable thread guides attached to a laying bar | |

| DE2841210C2 (en) | Device to limit the balloon on a creel | |

| DE102010005720B3 (en) | Reel for receiving coil for delivery to downstream processing machine, has belt receiver that is rotatable around central rotating axis, where belt receiver carries radial guides and guide body | |

| EP0806504B1 (en) | Centralized control device for thread clamps of creels | |

| DE69607301T2 (en) | Thread guide eyelet for spinning machines | |

| DE2534364C2 (en) | ||

| DE4115059C2 (en) | Device for delimiting the thread balloons on a creel | |

| EP0141258B1 (en) | Winding apparatus for forming a cotton wool package | |

| EP0080568B1 (en) | Support for a group of drawing rollers | |

| DE19703002C2 (en) | Device for warping a group of threads on a warp beam | |

| EP1130151B1 (en) | Embroidery machine, especially shuttle embroidery machine | |

| EP0441178A1 (en) | Apron drafting machine and spinning machine with a plurality of such apron drafting machines | |

| DE4344348C2 (en) | Thread change with compressed air transport | |

| DE3100880C2 (en) | Bobbin creels for warping or warping machines | |

| DE3137346A1 (en) | Spinning machine with drafting units | |

| EP0511160B2 (en) | Device for monitoring the run of the thread on a creel | |

| WO1997042364A1 (en) | Winding device for threads from creels | |

| DE2735760A1 (en) | Yarn braking device having a pair of rollers - whose nip pressure is controlled by pivotal level supporting one roller and acted upon by fluid pressure | |

| DE19823613A1 (en) | Thread brake device | |

| DE2255554C3 (en) | Device and method for automatically attaching bobbins or bobbin tubes to a spinning or twisting machine | |

| DE102007051526B3 (en) | Device for removing the web on a loom and loom with such a device | |

| EP0529429A1 (en) | Disc brake for textile yarns | |

| DE2163161A1 (en) | Automatic maintenance device for spinning machines or the like | |

| DE2749797A1 (en) | Creel braking system - has pressure source and pressure store with brake sections with defined force lines to prevent flutter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES IT LI |

|

| 17P | Request for examination filed |

Effective date: 19971111 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20000131 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES IT LI |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: E. BLUM & CO. PATENTANWAELTE Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59702550 Country of ref document: DE Date of ref document: 20001207 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2151203 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010528 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010528 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20020514 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050429 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090421 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101103 |