EP0780552B1 - Auspuffanlage für Kraftfahrzeuge - Google Patents

Auspuffanlage für Kraftfahrzeuge Download PDFInfo

- Publication number

- EP0780552B1 EP0780552B1 EP96402533A EP96402533A EP0780552B1 EP 0780552 B1 EP0780552 B1 EP 0780552B1 EP 96402533 A EP96402533 A EP 96402533A EP 96402533 A EP96402533 A EP 96402533A EP 0780552 B1 EP0780552 B1 EP 0780552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steel

- central part

- compris entre

- degrees celsius

- exhaust

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N1/00—Silencing apparatus characterised by method of silencing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features

- F01N13/16—Selection of particular materials

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0226—Hot rolling

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2510/00—Surface coverings

- F01N2510/08—Surface coverings for corrosion prevention

Definitions

- the present invention relates to an exhaust pipe motor vehicle.

- a motor vehicle exhaust pipe is made up an outer shell, an inner shell and a central part made up of perforated pipes and assembled transverse partitions between them to form a chicane, called tripaille.

- the central part of the exhaust pipes, as well as their inner shell must withstand very acidic and very basics of condensates that form during use when expansion therein of the burnt gases from the vehicle combustion engine automobile.

- European Patent No. 007,131 describes such a particular type of enamel, the manufacturing and implementation of which complex and therefore entail an additional cost compared to the use of standard enamels.

- the present invention provides an exhaust for motor vehicle, resistant to severe attack by condensates which are formed in its central part, and which is of a low cost.

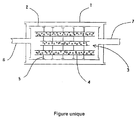

- an exhaust pipe motor vehicle consists of an outer casing 1, a inner casing 2 and a central part 3.

- the central part 3 consists of perforated tubing 4 and transverse partitions 5 assembled together to form a baffle allowing the expansion of the burnt gases of the combustion engine of the motor vehicle.

- Exhaust also includes tubing inlet 6, connecting it to the engine exhaust manifold and a outlet pipe 7 allowing gases to be evacuated to the atmosphere exhaust relaxed and rid of a certain amount of harmful particles.

- the steel is obtained by hot rolling at a final rolling temperature exceeding the point Ar 3 to obtain a strip, which is coiled at a temperature above 600 degrees Celsius, and after cold rolling, is subjected to recrystallization annealing.

- recrystallization annealing which can be indifferently a base bell annealing or a continuous annealing.

- the strip winding temperature is greater than 700 degrees Celsius.

- the steel is obtained by hot rolling at a final rolling temperature exceeding the point Ar 3 to obtain a strip, which is coiled at a temperature above 700 degrees Celsius, and after cold rolling, is subjected to recrystallization annealing. .

- the strip winding temperature is greater than 750 degrees Celsius.

- Annealing is a base decarburizing annealing in an expanded coil, that is to say a bell annealing of the coil wound in turns contiguous.

- the non-contiguous turn coil is heated in a bell under HNx atmosphere up to about 600 degrees Celsius, then continue the annealing by subjecting it to a current of water vapour.

- the steel is obtained by hot rolling at a final rolling temperature exceeding the point Ar 3 to obtain a strip, which is coiled at a temperature above 600 degrees Celsius, and after cold rolling, is subjected to recrystallization annealing. , basic annealing or continuous annealing.

- the strip is wound at a temperature greater than 700 degrees Celsius.

- the central part 3 can be made of an enameled steel exhaust pipe, perfectly resistant to corrosion, easy to use, using a standard type of enamel, while avoiding the defects linked to the annealing of enamel and defects of the "nail stroke defect" type, and which is low cost.

- the inner casing 2 of the exhaust pipe can be made either of stainless steel or aluminized steel, as well as the outer casing 1.

- the best compromise between efficiency, i.e. essentially corrosion resistance, and cost, consists in making either an exhaust pipe whose central part 3 and the inner envelope 2 are made of enamelled steel, the outer casing 1 being made of aluminized steel, ie an exhaust pipe whose central part 3 is in enamelled steel, the inner envelope 2 is in stainless steel and the outer casing 1 is made of aluminized steel.

- Two exhaust pipes were produced with an envelope inner 2 in stainless steel, outer casing 1 in steel aluminized and a central part 3 in enamelled steel.

- the steel was obtained by hot rolling at a temperature final rolling equal to 890 degrees Celsius to obtain a strip, which was wound at a temperature of 760 degrees Celsius, and after cold rolling, was subjected to recrystallization annealing in coil expanded.

- This central part 3 was enameled by immersing it in a bath of enamel of common mass resistant to heat and corrosion, having the following composition in weight percent: S i O 2 54 Z r O 2 2 P 2 O 5 1 B 2 O 3 14 Al 2 O 3 3 C a O 4 B a O 5 Na 2 O 11 K 2 O 2 Li 2 O 2 N i O 1 C o O 0.5 C u O 0.5.

- the steel was obtained by hot rolling at a temperature final rolling equal to 890 degrees Celsius to obtain a strip, which was wound at a temperature of 710 degrees Celsius, and after cold rolling, was subjected to continuous recrystallization annealing.

- This central part 3 has been enamelled by immersing it in a bath of the same enamel as before.

- the use of enamelled steels to make at least the central part of a pot exhaust said steel having a composition according to the invention, allows guarantee good resistance of the enamelled steel to the thermal shocks it undergoes in operation, that is to say that the cracking of the enamel is avoided.

- steel containing in thousandths of a percent weight between 0 and 10 carbon and between 50 and 150 titanium has a better resistance to thermal shock than steel containing in thousandths of per hundred weight between 0 and 4 of carbon and between 0 and 10 of titanium, which still has very good resistance to thermal shock, better than standard mild steels.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Combustion & Propulsion (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Exhaust Silencers (AREA)

- Heat Treatment Of Sheet Steel (AREA)

- Control Of Throttle Valves Provided In The Intake System Or In The Exhaust System (AREA)

- Valve Device For Special Equipments (AREA)

- Exhaust-Gas Circulating Devices (AREA)

- Heat Treatment Of Steel (AREA)

Claims (2)

- Auspufftopf für ein Kraftfahrzeug, umfassend eine äußere Umhüllung (1), eine innere Umhüllung (2) und einen mittleren Teil (3), der gebildet wird aus perforierten Rohren (4) und Quertrennwänden (5), die untereinander so verbunden sind, dass sie Hindernisse bilden, dadurch gekennzeichnet, dass die innere Umhüllung (2) und/oder der mittlere Teil (3) aus einem emailliertem Stahl gebildet ist, wobei der Stahl folgende Zusammensetzung in Tausendstel Gewichtsprozent aufweist:und der Rest Eisen und restliche Verunreinigungen,Kohlenstoff zwischen 0 und 10Mangan zwischen 150 und 400Phosphor zwischen 0 und 20Schwefel zwischen 10 und 30Aluminium zwischen 10 und 50Titan zwischen 50 und 150Kupfer zwischen 10 und 60Stickstoff zwischen 5 und 15,

wobei der genannte Stahl durch Warmwalzen bei einer Walzendtemperatur über dem Ar3-Punkt hergestellt wird, um ein Band zu erhalten, das bei einer Temperatur von über 600 Grad Celsius gerollt wird und nach einem Kaltwalzen einem Rekristallisationsglühen unterzogen wird. - Auspufftopf für ein Kraftfahrzeug nach Anspruch 1, dadurch gekennzeichnet, dass das Band bei einer Temperatur von über 700 Grad Celsius gerollt wird.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9515087 | 1995-12-20 | ||

| FR9515087A FR2742802B1 (fr) | 1995-12-20 | 1995-12-20 | Pot d'echappement de vehicule automobile |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0780552A1 EP0780552A1 (de) | 1997-06-25 |

| EP0780552B1 true EP0780552B1 (de) | 2001-09-12 |

Family

ID=9485673

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96402533A Expired - Lifetime EP0780552B1 (de) | 1995-12-20 | 1996-11-26 | Auspuffanlage für Kraftfahrzeuge |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US5739485A (de) |

| EP (1) | EP0780552B1 (de) |

| JP (1) | JPH09189223A (de) |

| KR (1) | KR970044261A (de) |

| AT (1) | ATE205580T1 (de) |

| DE (1) | DE69615137T2 (de) |

| DK (1) | DK0780552T3 (de) |

| ES (1) | ES2161997T3 (de) |

| FR (1) | FR2742802B1 (de) |

| PT (1) | PT780552E (de) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6571910B2 (en) | 2000-12-20 | 2003-06-03 | Quiet Storm, Llc | Method and apparatus for improved noise attenuation in a dissipative internal combustion engine exhaust muffler |

| KR100623538B1 (ko) * | 2001-10-29 | 2006-09-19 | 신닛뽄세이테쯔 카부시키카이샤 | 유리질 에나멜링용 강판 및 이의 제조 방법 |

| US6837235B2 (en) * | 2002-03-14 | 2005-01-04 | Ssw Holdings Company, Inc. | Porcelain oven rack |

| US20070272231A1 (en) * | 2006-05-25 | 2007-11-29 | Ssw Holding Company, Inc. | Oven rack having an integral lubricious, dry porcelain surface |

| CN108251752B (zh) * | 2018-01-18 | 2019-11-22 | 唐山钢铁集团有限责任公司 | 一种机动车消音片基板及其生产方法 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU2433671A (en) * | 1970-02-06 | 1972-07-20 | Armco Steel Corporation | Product and method for making drawing quality enameling stock |

| US4141724A (en) * | 1978-06-21 | 1979-02-27 | United States Steel Corporation | Low-cost, high temperature oxidation-resistant steel |

| EP0007131B1 (de) * | 1978-07-07 | 1982-03-24 | Reimbold & Strick GmbH & Co. KG | Emaillierter Schalldämpfer und Verfahren zum Emaillieren desselben |

| US4254684A (en) * | 1979-01-25 | 1981-03-10 | Helpinstill Iii Charles T | Breakdown piano |

| DE2917586C2 (de) * | 1979-04-30 | 1982-11-18 | Werner Dr.-Ing. 8450 Amberg Baumann | Auspufftopf aus emailliertem Stahlblech |

| US4264684A (en) * | 1979-12-17 | 1981-04-28 | Bethlehem Steel Corporation | Zinc-alloy coated ferrous product resistant to embrittlement |

| JPH01275736A (ja) * | 1988-04-28 | 1989-11-06 | Nippon Steel Corp | 加工性に優れた連続鋳造製ほうろう用鋼板およびその製造法 |

| WO1991001390A1 (en) * | 1989-07-19 | 1991-02-07 | Kawasaki Steel Corporation | Method of manufacturing enameling steel sheet excellent in adhesiveness |

| JPH04154919A (ja) * | 1990-10-15 | 1992-05-27 | Sumitomo Metal Ind Ltd | 加工性に優れたほうろう用冷延鋼板の製造法 |

| DE9318921U1 (de) * | 1993-12-09 | 1994-02-03 | Audi Ag, 85057 Ingolstadt | Auspuffanlage für eine Diesel-Brennkraftmaschine |

-

1995

- 1995-12-20 FR FR9515087A patent/FR2742802B1/fr not_active Expired - Fee Related

-

1996

- 1996-11-26 PT PT96402533T patent/PT780552E/pt unknown

- 1996-11-26 AT AT96402533T patent/ATE205580T1/de not_active IP Right Cessation

- 1996-11-26 ES ES96402533T patent/ES2161997T3/es not_active Expired - Lifetime

- 1996-11-26 EP EP96402533A patent/EP0780552B1/de not_active Expired - Lifetime

- 1996-11-26 DK DK96402533T patent/DK0780552T3/da active

- 1996-11-26 DE DE69615137T patent/DE69615137T2/de not_active Expired - Fee Related

- 1996-12-20 KR KR1019960069233A patent/KR970044261A/ko not_active Abandoned

- 1996-12-20 JP JP8355278A patent/JPH09189223A/ja not_active Withdrawn

- 1996-12-20 US US08/772,272 patent/US5739485A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| FR2742802A1 (fr) | 1997-06-27 |

| EP0780552A1 (de) | 1997-06-25 |

| PT780552E (pt) | 2002-02-28 |

| JPH09189223A (ja) | 1997-07-22 |

| DE69615137T2 (de) | 2002-06-20 |

| US5739485A (en) | 1998-04-14 |

| ATE205580T1 (de) | 2001-09-15 |

| KR970044261A (ko) | 1997-07-26 |

| FR2742802B1 (fr) | 1998-01-30 |

| ES2161997T3 (es) | 2001-12-16 |

| DK0780552T3 (da) | 2001-12-31 |

| DE69615137D1 (de) | 2001-10-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0835947B1 (de) | Aluminisiertes Blech mit schwacher Wärmeabstrahlung und Verfahren zu dessen Herstellung | |

| US4546051A (en) | Aluminum coated steel sheet and process for producing the same | |

| FR2835533A1 (fr) | TOLE EN ALLIAGE Al-Si-Mg POUR PEAU DE CARROSSERIE AUTOMOBILE | |

| JP4918044B2 (ja) | 高張力鋼ストリップを溶融浸漬コーティングする方法 | |

| EP0780552B1 (de) | Auspuffanlage für Kraftfahrzeuge | |

| FR2480311A1 (fr) | Tole d'acier laminee a froid a faible limite d'allongement et haute resistance apte a un emboutissage profond | |

| EP3972462B1 (de) | Kulinarischer artikel mit aluminiumkappe | |

| BE1014997A3 (fr) | Procede de recuit en continu de bandes en acier en vue de leur galvanisation au trempe et four pour sa mise en oeuvre. | |

| WO1995002708A1 (fr) | Procede de fabrication d'une feuille mince apte a la confection d'elements constitutifs de boites | |

| FR2694575A1 (fr) | Procédé pour le traitement de revêtements en MCrAlZ. | |

| FR2775297A1 (fr) | Tole dotee d'un revetement d'aluminium resistant a la fissuration | |

| CN100561078C (zh) | 铝包铜毛细管的生产工艺 | |

| CH636379A5 (fr) | Alliage d'aluminium et ses applications. | |

| FI4437155T3 (fi) | Sinkkipinnoitettu Mn:ää sisältävä kehittynyt erityisluja teräs ja sen valmistusmenetelmä | |

| BE1008566A6 (fr) | Substrat aluminie, son utilisation et methode pour le fabriquer. | |

| JP5589262B2 (ja) | 断熱鋼板及び金属製真空二重容器 | |

| FR2622632A1 (fr) | Pot d'echappement catalytique pour gaz brules de moteurs thermiques | |

| FR3096248A1 (fr) | Article culinaire comportant une paroi laterale amincie | |

| JP6075707B2 (ja) | 電極材料、点火プラグ用電極、及び点火プラグ | |

| FR2471415A1 (fr) | Procede de recuit final pour une tole ou bande d'acier a grains orientes pour applications electriques | |

| JPS5935667A (ja) | 鋼管の表面処理方法 | |

| FR2930023A1 (fr) | Procede de traitement de surface d'un echangeur de chaleur resistant a la corrosion | |

| JPS59103919A (ja) | 車両用排気系部品の製造方法 | |

| BE1004077A3 (fr) | Procede pour le revetement au trempe d'une bande d'acier en continu. | |

| JPS6063363A (ja) | 耐熱性溶融アルミメッキ鋼板 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19970707 |

|

| 17Q | First examination report despatched |

Effective date: 19991227 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 205580 Country of ref document: AT Date of ref document: 20010915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 69615137 Country of ref document: DE Date of ref document: 20011018 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2161997 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20011214 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20011108 Ref country code: GR Ref legal event code: EP Ref document number: 20010402046 Country of ref document: GR |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20021017 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20021021 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20021023 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20021024 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20021028 Year of fee payment: 7 Ref country code: DK Payment date: 20021028 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20021029 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20021030 Year of fee payment: 7 Ref country code: FI Payment date: 20021030 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20021104 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20021105 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20021111 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20021114 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20021118 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20021122 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031126 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031126 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031126 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031126 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031127 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031130 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031201 |

|

| BERE | Be: lapsed |

Owner name: S.A. *SOLLAC Effective date: 20031130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040602 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040603 |

|

| EUG | Se: european patent has lapsed | ||

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20031126 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040730 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20040601 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20040531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20031127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051126 |