EP0709917B1 - Bloc de connexion avec module électronique - Google Patents

Bloc de connexion avec module électronique Download PDFInfo

- Publication number

- EP0709917B1 EP0709917B1 EP95113807A EP95113807A EP0709917B1 EP 0709917 B1 EP0709917 B1 EP 0709917B1 EP 95113807 A EP95113807 A EP 95113807A EP 95113807 A EP95113807 A EP 95113807A EP 0709917 B1 EP0709917 B1 EP 0709917B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- terminal block

- electronic module

- disconnect

- housing

- connecting terminal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/26—Clip-on terminal blocks for side-by-side rail- or strip-mounting

- H01R9/2625—Clip-on terminal blocks for side-by-side rail- or strip-mounting with built-in electrical component

- H01R9/2633—Clip-on terminal blocks for side-by-side rail- or strip-mounting with built-in electrical component with built-in switch

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/26—Clip-on terminal blocks for side-by-side rail- or strip-mounting

- H01R9/2625—Clip-on terminal blocks for side-by-side rail- or strip-mounting with built-in electrical component

- H01R9/2666—Clip-on terminal blocks for side-by-side rail- or strip-mounting with built-in electrical component with built-in test-points

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S439/00—Electrical connectors

- Y10S439/922—Telephone switchboard protector

Definitions

- the invention relates to a terminal block with a so electrically and mechanically pluggable electronic module and one on the electronic module attached separator in the electrical conductive connection between the terminal block and the Electronics module.

- a terminal block of this type (DE 41 21 836 C2) the separating device is located in the upper area of the module. It is clearly visible above the Wiring level of the terminal block, but must do this Conductor rail pieces in the electronics module are led far up and also be removed again from there. It is a fairly complex separation point to create only this separation function and there are at the design there special plug connections leading to the separation point for test plugs in the housing of the electronics module.

- the present invention is therefore based on the object to create such terminal block, with the smallest possible the separation and testing function enables.

- the solution according to the invention consists essentially in that the Disconnector a the electrical connector of the Electronic module for electrical connection to the terminal block and test plug connections containing separator, which is in the Connector zone of the electronic module on this between one Closed and a separating position is kept displaceable. Thereby, that the separator is now in the connector zone of the Electronic module is, separate, to a separation point leading busbars and the like, all the more so than this Separator also for the electronics module connector function has and the plugging in of the Test plug for testing the electronics in the module. At inserted electronics module ensures the separator in its closed position the electrical connector at this point between the electronics module and the terminal block.

- Disconnection position is the electrical connection at this point to the Terminal block interrupted and can then be plugged in the test plug into the separator the desired test of the electronics perform in the module. This remains when the electronics module is removed Adhere the separator to the electronics module as it is held on it.

- Terminal block is one between the separator and the housing of the electronic module acting blocking device provided in the separating position of the separator by inserting the test plug can be actuated. This reliably ensures that not by inserting the test plug for test purposes the separator is pushed back into the closed position.

- this extends Separator at least with a partial area on a lower outer wall area of the electronics module in its height direction and carries in the lower end area facing the terminal block the connectors of the electronics module.

- the connectors are also used in the terminal block, relative to the electronics module, relatively far placed outside so that the connectors can work together.

- the separator in the above Part of the separator in the upper side of the test plug connections.

- the separator can also be used as Handle be trained. This allows a sufficient distance to the wiring level of the terminal block so that the separator remains clearly visible and easy to handle and also the Test plugs can be easily inserted into the separator can, especially since the latter is in the upper separation position located.

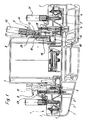

- the terminal block 1 shown in side view in Figure 1 is usually from a large number of lined up, assembled Connection disks 2 formed, seen on Figure 1 in the drawing depth lie side by side.

- Each of the connection plates 2 carries in an electrical insulating plastic housing 3 connections 4 for connection electrical conductor, which in the illustrated embodiment Busbar pieces 5 are connected to plug connections 6.

- An electronic module 7 is also provided, which is connected to the terminal block 1, formed by the connecting plates 2, electrical and is mechanically pluggable.

- the mechanical connection happens in the usual way by inserting appropriately designed housing areas of the housing 8 of the electronics module 7 into a corresponding one Receiving recess in the terminal block 2, which are lined up by the Plastic housing 3 of the connecting plate 2 is formed.

- the plug connection is appropriately mechanically locked.

- this separating device is a separating piece 9, in which both the connector 10 for insertion into the plug connections 6 of the terminal block 1 and thus for electrical Connection between terminal block 1 and electronics module 7, as also test plug connections 11 for inserting a test plug 12 are located.

- the separator 9 is between a closed position and a separation position displaceable on the electronics module 7 captive held.

- the separators are directly in the connector zone of the electronics module 7 provided on this.

- You have a case 13, which engages around the lower edge of the housing 8 of the electronic module 7 and therefore one with the inside of the electronics module housing 8 Section 14 and an outer wall portion 15, which extends in the vertical direction of the electronic module 7.

- the outside lying section 15 includes in its lower end region the connectors 10 with the corresponding plug connections 6 of the connecting disks 2 of the terminal block 1 cooperate. In the upper end region of this section 15 there are upwards open, the test plug connections 11.

- the plug connections are located 6 of the terminal block 1 related to this electronics module 7 outside. This means that this terminal block 1 also if necessary with other electronic modules without a separator can be equipped. These electronic modules would then be so wide that Plug connections or directly the correspondingly designed ends of functional circuit boards inserted directly into the plug connections 6 can be. There is also the option of an electronic module to use, which carries a separator 9 on only one side, while the other side compared to the illustrated embodiment widened accordingly and for direct electrical contacting the plug connections 6 there is set up.

- they include in the separator 9 arranged connector 10 a downward, on the plug connection 6 directional flag 16, located on a track piece 17 is located, from which a contact tab 18 for the Contacting with the pin of the test plug 12 comes off, and from that down another busbar piece 19 goes down to the with respect to the electronics module 7 inner wall portion 14 of the separator 9 runs and here in the interior of the electronics module in the illustrated Embodiment directly contacting the corresponding designed end of a functional circuit board 20 can contact.

- the separator 9 is a sliding contact configuration between the closed position and the disconnected position intended.

- the captive is relocatable Holding the separator 9 on the lower outer wall area of the Housing 8 of the electronics module 7 is achieved in that the wall sections 14 and 15 of the housing 13 of the separator 9 between them define a guide gap 21 into which the lower outer wall area of the housing 8 of the electronics module 7 occurs, so that the separator 9 on the housing 8 can move up and down.

- the wall section concerned of the housing 8 of the electronics module 7 in the height direction from each other recesses 22 and 23 are provided.

- Figures 1 and 2 show the right separator seen on the drawing 9 in its disconnected position.

- the locking hooks 24 and 25 are located in the recesses 22 and 23.

- the electrical connection between the electronics module 7 and the terminal block 2 is separated because the plug-in tabs 16 of the separator 9 upwards from the plug connections 6 are pulled out.

- the separator 9 is essentially a depth extension has according to the terminal block 1 and so many in it electrical connectors 10 are arranged, such as plug connections 6 for the electrical contact between the electrical module 7 and the terminal block 1 are to be made.

- the electronics can now be operated in the raised position by inserting one or more test plugs 12 into the corresponding ones Test connector 11 of the separator 9 are checked.

- This consists essentially of the shown Embodiment molded on the housing 13 of the separator 9 angular springs 26 with their lower legs in a further recess 27 provided for this purpose in the corresponding wall section of the housing 8 of the electronics module 7 enter blocking can.

- the arrangement is such that the spring piece 26 in Rest position on its side facing away from the electronics housing 7 in the test connector 11 protrudes so far that the pin of the test connector 12 automatically when the spring piece 26 is inserted into the Blocking position presses.

- the separators 9 remain regardless of their position on the electronics module.

- the outer-walled section 15 of the housing 13 of the separator 9 expediently as long upwards extends that the upper end also in the closed position of the Partition 9 still clearly visible and manageable above the Wiring level of the connection block 1 is and that too still offers the opportunity to save space and space close to the Separator 9 (see left side of Figure 1) a cross connector comb 28 to provide a potential transverse distribution by contacting of the adjacent conductor rail pieces 5 in the connecting disks 2 of the Terminal block 1 allows.

- the housing 13 of the separator 9 is also useful on the top provided with a bracket or hook piece 29, which the handling the separating piece 9, for example with the aid of a screwdriver, serves.

- the vertical extension of the housing 13 also ensures the good visibility and accessibility of this upper separator end for actuation and, in the upper disconnected position of the separator 9, a comfortable to use, visually well visible and clearly above the wiring level of the terminal block 1 lying plug-in for the test plug 12. The latter applies even if In addition to testing the electronics, a field device test is also useful takes place and in addition to the test plugs 12 for the Electronics test also spatially offset laterally downwards in corresponding plug connections 30 of the connecting disks 2 of the Terminal block 1 test plug 31 can be inserted.

Claims (11)

- Bloc de bornes de jonction (1) avec module électronique (7) pouvant être connecté par enfichage électriquement et mécaniquement avec celui-ci et avec un dispositif de coupure (9), monté sur le module électronique (7), dans la liaison électrique entre le bloc de bornes de jonction (1) et le module électronique (7), caractérisé en ce que le dispositif de coupure est un élément de coupure (9) contenant le connecteur à fiches électrique (10) du module électronique (7) pour la connexion électrique avec le bloc de bornes de jonction (1) ainsi que des connexions de connecteur d'essai (11), l'élément de coupure étant maintenu déplaçable dans la zone de connexion par enfichage du module électronique (7) sur cet élément, entre une position de fermeture et une position de coupure.

- Bloc de bornes de jonction selon la revendication 1, caractérisé par un dispositif de blocage (26, 27), agissant entre l'élément de coupure (9) et le boítier (8) de module électronique (7), dispositif de blocage qui est actionnable dans la position de coupure de l'élément de coupure (9), par enfichage d'un connecteur à fiches d'essai (12).

- Bloc de bornes de jonction selon l'une des revendications précédentes, caractérisé en ce que le boítier (13) de l'élément de coupure (9) présente une section (15) s'étendant sur la paroi extérieure du boítier (8) du module électronique (7), dans la direction de sa hauteur, dans la zone inférieure de laquelle se trouvent les connecteurs à fiches électriques (10), pour lesquels sont prévues des connexions à enfichage (6) en un emplacement opposé correspondant dans le bloc de bornes de jonction (1).

- Bloc de bornes de jonction selon la revendication 3, caractérisé en ce que les connexions de connecteur d'essai (11) sont prévues sur la section (15) du boítier (13) de l'élément de coupure (9), dans sa zone terminale supérieure.

- Bloc de bornes de jonction selon l'une des revendications précédentes, caractérisé en ce que le boítier (13) de l'élément de coupure (9), en enserrant l'arête inférieure d'une paroi extérieure du boítier (8) du module électronique (7), présente une section (14) située à l'intérieur par rapport au boítier (8) du module électronique ainsi qu'une section (15) située à l'extérieur qui forment entre elles une fente de guidage (21) pour cette zone de paroi du boítier (8) du module électronique (7).

- Bloc de bornes de jonction selon la revendication 5, caractérisé en ce que dans la zone de paroi du boítier (8) du module électronique (7), coopérant avec l'élément de coupure (9), sont prévus des évidements d'encliquetage (22, 23) espacés et superposés dans l'extension en hauteur, pour lesquels des crochets d'encliquetage (24, 25) sont prévus suivant un écartement convenable, en vue de la fixation de l'élément de coupure (9) sur le module électronique (7) ainsi qu'en vue du blocage de la position de fermeture et de la position de coupure de l'élément de coupure (9) sur le boítier (13).

- Bloc de bornes de jonction selon la revendication 2, caractérisé en ce que le dispositif de blocage est constitué de pièces élastiques (26) prévues sur l'élément de coupure (9), qui dans leur position de repos font saillie dans des connexions de connecteur d'essai 11 de l'élément de coupure (9) et qui sont déplaçables élastiquement en direction de la paroi du boítier (8) du module électronique (7), des évidements (27) les recevant en les bloquant étant prévus dans la paroi, dans une position correspondante.

- Bloc de bornes de jonction selon l'une des revendications précédentes, caractérisé en ce que les connecteurs à fiches (10) dans les éléments de coupure (9) présentent des languettes à enfichage (7) dirigées vers le bas, vers les connexions à enfichage (6) du bloc de bornes de jonction (1), lesquelles se trouvent sur des éléments de rail conducteur (17), desquels part vers le haut une languette de contact (18) pour la connexion de connecteur d'essai et desquels part vers le bas un autre élément de rail conducteur (19), qui s'étend jusque dans la section (14) de l'élément de coupure (9), située sur la paroi intérieure par rapport au boítier (8) du module électronique, et qui est réalisé ici en tant que contact avec l'électronique du module électronique (7).

- Bloc de bornes de jonction selon la revendication 1, caractérisé en ce que le bloc de bornes de jonction (1) composé de plaques de jonction (2) individuelles présente dans les plaques de jonction 2, au voisinage dans l'espace de l'élément de coupure (9), des logements d'enfichage pour un peigne de connexion transversale (28).

- Bloc de bornes de jonction selon la revendication 9, caractérisé en ce que la section (15) du boítier (13) de l'élément de coupure (9), située sur la paroi extérieure par rapport au module électronique (7), est guidée dans l'extension en hauteur suffisamment haut pour qu'à son voisinage il reste un espace libre pour le peigne de connexion transversale 28, même dans sa position de fermeture.

- Bloc de bornes de jonction selon l'une des revendications précédentes, caractérisé par une possibilité de déplacement en hauteur de l'élément de coupure (9) et une position en hauteur des connexions de connecteur d'essai (11), de manière que dans la position de coupure de l'élément de coupure (9) les connecteurs d'essai enfichés se trouvent décalés en hauteur au-dessus de connecteurs d'essai (31), qui sont enfichés dans des connexions d'essai (30) adjacentes sur le côté extérieur du bloc de bornes de jonction (1).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4438800 | 1994-10-31 | ||

| DE4438800A DE4438800C1 (de) | 1994-10-31 | 1994-10-31 | Anschlußklemmenblock mit Elektronikmodul |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0709917A2 EP0709917A2 (fr) | 1996-05-01 |

| EP0709917A3 EP0709917A3 (fr) | 1998-03-04 |

| EP0709917B1 true EP0709917B1 (fr) | 1999-03-24 |

Family

ID=6532088

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95113807A Expired - Lifetime EP0709917B1 (fr) | 1994-10-31 | 1995-09-02 | Bloc de connexion avec module électronique |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5588881A (fr) |

| EP (1) | EP0709917B1 (fr) |

| JP (1) | JP3853408B2 (fr) |

| AT (1) | ATE178164T1 (fr) |

| DE (2) | DE4438800C1 (fr) |

| ES (1) | ES2129165T3 (fr) |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4440102C1 (de) * | 1994-11-10 | 1996-05-15 | Weidmueller Interface | Modulare Steuerungsanlage mit integriertem Feldbusanschluß |

| FR2732518B1 (fr) * | 1995-03-29 | 1997-04-30 | Entrelec Sa | Agencement de connexion pour fils conducteurs electriques et module, notamment de type bloc de jonction, equipe d'un tel agencement |

| US5890934A (en) * | 1997-09-30 | 1999-04-06 | Weidmuller Inc. | Pluggable connector assembly for printed circuit boards |

| FR2773914B1 (fr) * | 1998-01-21 | 2000-04-21 | Entrelec Sa | Bloc de raccordement electrique a piece d'interconnexion accessible par une prise de test et piece d'interconnexion pour un tel bloc |

| DE29804284U1 (de) * | 1998-03-11 | 1998-05-07 | Weidmueller Interface | Steuerungsanlage für elektronische Steuerungs- und Automatisierungssysteme |

| DE29806691U1 (de) | 1998-04-15 | 1998-05-28 | Weidmueller Interface | Montagefuß für anreihbare Einbaugehäuse oder Klemmen |

| FR2777702B1 (fr) * | 1998-04-17 | 2000-06-16 | Entrelec Sa | Dispositif de connexion auto-denudant |

| US6220901B1 (en) * | 1998-04-30 | 2001-04-24 | General Electric Company | Electric motor terminal board assembly |

| US6074241A (en) * | 1998-06-05 | 2000-06-13 | The Whitaker Corporation | Non-slip spring clamp contact |

| DE19964157A1 (de) * | 1999-01-25 | 2000-10-05 | Weidmueller Interface | Elektrisches Gerät |

| DE29901194U1 (de) | 1999-01-25 | 1999-05-20 | Weidmueller Interface | Busleiterabschnitt für ein elektrisches Gerät |

| DE29910179U1 (de) * | 1999-06-11 | 2000-11-02 | Weidmueller Interface | Steckverbinder für elektrische Steuerungen |

| DE29916303U1 (de) | 1999-09-16 | 2001-02-22 | Weidmueller Interface | Modul mit Koppelelementen |

| DE10011385A1 (de) * | 2000-03-09 | 2001-09-13 | Abb Cmc Carl Maier Ag Schaffha | Einbaugerät für elektrische Niederspannungsinstallation |

| DE10045498C5 (de) * | 2000-09-13 | 2006-06-08 | Phoenix Contact Gmbh & Co. Kg | Elektrische Reihenklemme |

| DE20106710U1 (de) * | 2001-04-18 | 2001-08-09 | Phoenix Contact Gmbh & Co | Elektrische Klemme |

| DE20211002U1 (de) | 2002-07-19 | 2003-12-04 | Weidmüller Interface Gmbh & Co. | Modul für ein elektrisches Gerät, insbesondere Feldbusmodul |

| DE102004043466B4 (de) * | 2004-09-08 | 2007-08-02 | Siemens Ag | Strom-Einspeisemodul mit Käfig-Zugfederklemmen |

| DE102005017712A1 (de) * | 2005-04-15 | 2006-12-14 | Abb Patent Gmbh | Automatisierungssystem |

| DE102006030953A1 (de) * | 2005-08-17 | 2007-03-15 | Abb Patent Gmbh | Elektrische Einrichtung, insbesondere Leitungs- Fehlerstrom- oder Motorschutzschalter |

| DE102005040657A1 (de) * | 2005-08-26 | 2007-03-15 | Phoenix Contact Gmbh & Co. Kg | Elektrische Anschlussklemme |

| DE102005043878A1 (de) * | 2005-09-14 | 2007-03-22 | Wöhner GmbH & Co. KG Elektrotechnische Systeme | Stromschienenanschlussmodul |

| DE102006053352B3 (de) * | 2006-11-10 | 2008-04-17 | Phoenix Contact Gmbh & Co. Kg | Anschlußverteiler |

| DE202007005373U1 (de) * | 2007-04-12 | 2008-08-21 | Weidmüller Interface GmbH & Co. KG | Reihenklemmensystem |

| DE102007059640B4 (de) * | 2007-12-10 | 2009-11-26 | Wago Verwaltungsgesellschaft Mbh | Anschlussmodul |

| CN102835197B (zh) * | 2010-03-31 | 2015-12-09 | 威德米勒界面有限公司及两合公司 | 能用作总线的连接模块 |

| DE102011087209B4 (de) * | 2011-11-28 | 2019-02-28 | Siemens Aktiengesellschaft | Elektroinstallationsgerät |

| TW201507300A (zh) * | 2013-08-07 | 2015-02-16 | Switchlab Inc | 導線端子座改良結構 |

| WO2015123494A1 (fr) | 2014-02-13 | 2015-08-20 | Erico International Corporation | Borne sélectionnable et protecteur de surtension modulaire |

| DE102014105316A1 (de) * | 2014-04-14 | 2015-10-15 | Weidmüller Interface GmbH & Co. KG | Reihenklemmenblock |

| FR3026238B1 (fr) * | 2014-09-23 | 2016-10-21 | Abb France | Partie de barre conductrice pour un appareil electrique |

| DE202017106533U1 (de) * | 2017-10-27 | 2019-01-30 | Wago Verwaltungsgesellschaft Mbh | Elektrische Reihenklemme |

| DE102018109861A1 (de) * | 2018-04-24 | 2019-10-24 | Phoenix Contact Gmbh & Co. Kg | Steckverbindungsanordnung für eine Reihenklemme |

| DE102020001046A1 (de) | 2020-02-18 | 2021-08-19 | Hottinger Baldwin Messtechnik Gesesllschaft mit beschränkter Haftung | Hutschienen-Befestigungsmodul für räumlich begrenzte Schaltschränke |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1238087B (de) * | 1965-03-25 | 1967-04-06 | Siemens Ag | Reihenleitungsverbinder mit Trennstelle |

| SE377636B (fr) * | 1973-11-12 | 1975-07-14 | Asea Ab | |

| DE3233255C2 (de) * | 1982-09-08 | 1984-09-27 | Phönix Elektrizitätsgesellschaft H. Knümann GmbH & Co KG, 4933 Blomberg | Elektrische Anschlußklemme, insbesondere Schaltanlagen-Reihenklemme |

| DE3311820C2 (de) * | 1983-03-31 | 1988-10-20 | C.A. Weidmüller GmbH & Co, 4930 Detmold | Reihenklemme mit ein elektrisches Wirkelement tragendem Schwenkhebel |

| FR2659118B1 (fr) * | 1990-03-02 | 1992-05-07 | Entrelec Sa | Dispositif de fixation d'un bloc de jonction sur un profile support symetrique. |

| DE4121836C2 (de) * | 1991-07-02 | 1994-07-07 | Weidmueller C A Gmbh Co | Reihenklemme mit Aufsteckmodul |

| US5407367A (en) * | 1993-09-27 | 1995-04-18 | Vernitron Corporation | Barrier terminal strip assembly |

-

1994

- 1994-10-31 DE DE4438800A patent/DE4438800C1/de not_active Expired - Fee Related

-

1995

- 1995-09-02 EP EP95113807A patent/EP0709917B1/fr not_active Expired - Lifetime

- 1995-09-02 ES ES95113807T patent/ES2129165T3/es not_active Expired - Lifetime

- 1995-09-02 DE DE59505430T patent/DE59505430D1/de not_active Expired - Lifetime

- 1995-09-02 AT AT95113807T patent/ATE178164T1/de not_active IP Right Cessation

- 1995-10-18 US US08/544,482 patent/US5588881A/en not_active Expired - Fee Related

- 1995-10-31 JP JP28327395A patent/JP3853408B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0709917A2 (fr) | 1996-05-01 |

| JP3853408B2 (ja) | 2006-12-06 |

| DE4438800C1 (de) | 1996-01-18 |

| EP0709917A3 (fr) | 1998-03-04 |

| JPH08227760A (ja) | 1996-09-03 |

| ES2129165T3 (es) | 1999-06-01 |

| DE59505430D1 (de) | 1999-04-29 |

| ATE178164T1 (de) | 1999-04-15 |

| US5588881A (en) | 1996-12-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0709917B1 (fr) | Bloc de connexion avec module électronique | |

| EP0709920B1 (fr) | Système de commande modulaire | |

| EP0272200B1 (fr) | Bloc de connexion pour les télécommunications | |

| WO1997044864A1 (fr) | Dispositif de verrouillage pour l'accouplement de connecteurs enfichables | |

| EP0914029B1 (fr) | Automate modulaire et unité d'un automate modulaire | |

| DE4121836A1 (de) | Reihenklemme mit aufsteckmodul | |

| EP0753916A2 (fr) | Système d'adaptateur barres conductrices | |

| DE19902745B4 (de) | Elektrisches Gerät | |

| DE102005033998A1 (de) | Schneidklemm-Steckverbinder und Einrichtung für die Telekommunikations- und Datentechnik | |

| EP1113525B1 (fr) | Barette à bornes, en particulier pour transformateur de mesure avec dispositif de pontage transversal | |

| DE19547557A1 (de) | Elektrische Klemmen mit steckbaren Querbrückern | |

| EP2862364B1 (fr) | Module de branchement de répartiteur | |

| WO2016107713A1 (fr) | Dispositif de protection contre des surtensions pour la technique des informations et des télécommunications | |

| EP0477664A1 (fr) | Insert de protection pour réglette à bornes installée dans un équipement de télécommunication, en particulier dans un poste annexe téléphonique | |

| DE10230292B3 (de) | Träger für Modulgehäuse | |

| EP1787358B1 (fr) | Module d'alimentation electrique comportant des bornes a ressort de rappel de cage | |

| DE102013111571A1 (de) | Gerätegehäuse, Elektronikgeräte und Steckkontaktträger | |

| EP0262325A2 (fr) | Dispositif pour distributeur | |

| EP0951105B1 (fr) | Prise multiple | |

| DE3442625A1 (de) | Ueberlastrelais | |

| DE1614401A1 (de) | Elektrische Steckfassung | |

| EP0951104B1 (fr) | Prise, particulièrement un boítier encastrable pour installations électriques | |

| DE10338787A1 (de) | Querverbinder für Reihenklemmen | |

| DE10117758A1 (de) | Baugruppe für ein Automatisierungsgerät | |

| DE7920512U1 (de) | Anordnung zum Anschließen elektrischer Leiter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE ES FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19980210 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19980911 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| ITF | It: translation for a ep patent filed |

Owner name: STUDIO INGG. FISCHETTI & WEBER |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 178164 Country of ref document: AT Date of ref document: 19990415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59505430 Country of ref document: DE Date of ref document: 19990429 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2129165 Country of ref document: ES Kind code of ref document: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990602 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20080915 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080918 Year of fee payment: 14 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090902 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20100924 Year of fee payment: 16 Ref country code: CH Payment date: 20100923 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090902 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20100922 Year of fee payment: 16 Ref country code: FR Payment date: 20101005 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110923 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110902 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110930 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20130704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110903 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130403 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59505430 Country of ref document: DE Effective date: 20130403 |