EP0698428A1 - Dispositif pour détecter l'emprise entre deux cylindres de travail d'une cage de laminoir - Google Patents

Dispositif pour détecter l'emprise entre deux cylindres de travail d'une cage de laminoir Download PDFInfo

- Publication number

- EP0698428A1 EP0698428A1 EP95109639A EP95109639A EP0698428A1 EP 0698428 A1 EP0698428 A1 EP 0698428A1 EP 95109639 A EP95109639 A EP 95109639A EP 95109639 A EP95109639 A EP 95109639A EP 0698428 A1 EP0698428 A1 EP 0698428A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roll

- work

- hydraulic cylinders

- work roll

- roll gap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B38/00—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product

- B21B38/10—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product for measuring roll-gap, e.g. pass indicators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B29/00—Counter-pressure devices acting on rolls to inhibit deflection of same under load, e.g. backing rolls ; Roll bending devices, e.g. hydraulic actuators acting on roll shaft ends

Definitions

- the invention relates to a device for detecting the roll gap between two work rolls of a roll stand with a roll stand and a work roll bending device, in which each of a total of four work roll chocks, which support the work rolls at their ends, over two, on opposite sides of the respective Hydraulic cylinders arranged on the work roll are directly adjustable relative to the roll stand.

- the rolling stock thickness As a controlled variable of interest, cannot be measured in terms of control technology at the point of its origin, namely the roll gap, and therefore cannot be used for the direct correction of faults, such as eccentricities of the rolls, can be used.

- the invention has for its object to enable a largely direct detection of the roll gap between the work rolls of a roll stand, with a roll stand with a work roll bending device, as is assumed, for example, from "Handbook of Manufacturing Technology", volume 2/1, Carl Hanser Verlag, 1983, page 453, picture 80.

- the object is achieved in that position transmitters are installed in the hydraulic cylinders in the device of the type specified at the outset and in that the position transmitters are followed by an evaluation device for determining the roll gap from the position values supplied by the position transmitters.

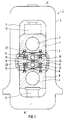

- the roll stand shown in FIG. 1 consists of a roll stand 2 in which an upper and lower support roll 3 or 4 and two work rolls 5 and 6 are arranged.

- the two support rollers 3 and 4 are supported at their two ends via Morgoil bearings in support roller chocks 7 and 8; the two work rolls 5 and 6 are mounted in corresponding work roll chocks 9 and 10.

- 1 shows the roll stand 1 from its drive side, that is from the side on which the rollers are driven, so that only the chocks 7 to 10 lying on this side can be seen.

- the backup roll chocks 7 and 8 are guided in a window 11 of the roll stand 2.

- a hydraulic adjusting device 13 is arranged between the upper crosshead 12 of the roller stand 2 and the chock 7 of the upper support roller 3.

- the chock 8 of the lower support roller 4 is supported by a wedge adjusting device 14 against the lower crosshead 15 of the roller stand

- cylinder blocks (Mae West blocks) 16 and 17, in which hydraulic cylinders 18 to 21 are installed for positive work roll bending.

- additional hydraulic cylinders 22 are installed in the support roll chocks 7 and 8, which also act against the work roll chocks 9 and 10.

- position sensors (not shown here) are installed in the hydraulic cylinders 18 to 21 in the cylinder blocks 16 and 17.

- the installation of the position sensors in the hydraulic cylinders 18 to 21 prevents damage or contamination of the position sensors during the rolling operation.

- FIG. 2 shows the work roll chock 9 with the work roll 5 mounted therein and the two hydraulic cylinders 18 and 19 in the cylinder blocks 16 and 17.

- a position transmitter 24 and 25 is installed in each of the two hydraulic cylinders 18 and 19, a position transmitter 24 and 25 is installed.

- the axis 26 of the work roll 5 lies in the middle between the two hydraulic cylinders 18 and 19, the distance between which is designated by x.

- the points of attack of the hydraulic cylinders 18 and 19 on the work roll chock 9 are designated 27 and 28.

- FIG. 3 illustrates the geometric relationships on the work roll chock 9.

- the distance r between the axis 26 of the work roll 5 and the connecting line 29 between the two points of attack 27 and 28 of the hydraulic cylinders 18 and 19 on the chock 9 is designated by r.

- the position transmitter supplies a position value s l and the position transmitter 25 supplies a position value s r .

- a total of four such common position values s01, s02, s03 and s04 are determined, with the value s01 for the upper work roll 5 on the drive side and the value s02 on the operator side and the value s03 and the value for the lower work roll 6 on the drive side the value s04 is determined.

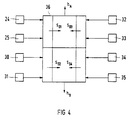

- the block diagram in FIG. 4 shows a total of eight position transmitters 24, 25, 30, 31, 32, 33, 34 and 35, which are connected to an evaluation device 36.

- the common position values s01 to s04 are calculated from the position values of two position sensors and added to the values h A and h B for the roll gap.

- the values h A and h B only have to take into account the comparatively small influences from the work roll back bend, the work roll eccentricity, the thermal work roll expansion and the elastic deformation of the work roll chocks.

- the previously required additional calculations of the suspension of the back-up rolls and the eccentricity of the back-up rolls can be omitted.

- the direct detection of the roll gap according to the invention enables a significantly more precise roll gap control to be implemented.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Control Of Metal Rolling (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4424153 | 1994-07-08 | ||

| DE4424153 | 1994-07-08 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0698428A1 true EP0698428A1 (fr) | 1996-02-28 |

| EP0698428B1 EP0698428B1 (fr) | 1999-03-31 |

Family

ID=6522687

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95109639A Expired - Lifetime EP0698428B1 (fr) | 1994-07-08 | 1995-06-21 | Dispositif pour détecter l'emprise entre deux cylindres de travail d'une cage de laminoir |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0698428B1 (fr) |

| DE (1) | DE59505484D1 (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003053604A1 (fr) | 2001-12-12 | 2003-07-03 | Sms Demag Aktiengesellschaft | Dispositif de mesure de l'emprise entre les cylindres de travail d'une structure de laminage a froid ou a chaud |

| WO2007022841A1 (fr) * | 2005-08-26 | 2007-03-01 | Sms Demag Ag | Procede de reglage d'epaisseur lors du laminage a chaud |

| WO2011003580A1 (fr) * | 2009-07-07 | 2011-01-13 | Sms Siemag Ag | Cage de laminoir à 4 cylindres/6 cylindres/18 cylindres à décalage horizontal (hs) présentant une configuration en cassette |

| US8869577B2 (en) | 2011-06-07 | 2014-10-28 | Sms Siemag Ag | Measuring device, roll stand and method of detecting the height of a roll gap |

| CN104741385A (zh) * | 2015-04-14 | 2015-07-01 | 中冶赛迪工程技术股份有限公司 | 一种四辊轧机的工作辊弯辊装置及弯辊力的控制方法 |

| DE102022125630A1 (de) | 2022-10-05 | 2024-04-11 | Karlsruher Institut für Technologie, Körperschaft des öffentlichen Rechts | Anordnung mit zwei voneinander unter Ausbildung eines Spaltes beabstandeten Walzen mit einem Spaltweitenmesssystem |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102021205275A1 (de) | 2021-05-21 | 2022-11-24 | Sms Group Gmbh | Verfahren zum Betreiben eines Walzgerüstes |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1602195A1 (de) * | 1966-08-16 | 1970-03-26 | United Eng Foundry Co | Banddickenmessgeraet fuer Walzwerke und aehnliche Vorrichtungen |

| US3733875A (en) * | 1971-07-12 | 1973-05-22 | Mesta Machine Co | Work roll sensing and/or balancing arrangements |

| JPS57209710A (en) * | 1981-06-16 | 1982-12-23 | Sumitomo Metal Ind Ltd | Plate thickness controlling method |

| JPS61199506A (ja) * | 1985-02-28 | 1986-09-04 | Ishikawajima Harima Heavy Ind Co Ltd | 圧延機 |

-

1995

- 1995-06-21 DE DE59505484T patent/DE59505484D1/de not_active Expired - Lifetime

- 1995-06-21 EP EP95109639A patent/EP0698428B1/fr not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1602195A1 (de) * | 1966-08-16 | 1970-03-26 | United Eng Foundry Co | Banddickenmessgeraet fuer Walzwerke und aehnliche Vorrichtungen |

| US3733875A (en) * | 1971-07-12 | 1973-05-22 | Mesta Machine Co | Work roll sensing and/or balancing arrangements |

| JPS57209710A (en) * | 1981-06-16 | 1982-12-23 | Sumitomo Metal Ind Ltd | Plate thickness controlling method |

| JPS61199506A (ja) * | 1985-02-28 | 1986-09-04 | Ishikawajima Harima Heavy Ind Co Ltd | 圧延機 |

Non-Patent Citations (7)

| Title |

|---|

| "Handbuch der Fertigungs-technik", vol. 2/1, 1983, CARL HANSER VERLAG, pages: 453 |

| "Neu entwickelte Ständerkonstruktion für Kaltwalzgerüste", STAHL UND EISEN., vol. 98, no. 21, 19 October 1978 (1978-10-19), DÜSSELDORF DE, pages 1101 * |

| BBC-NACHRICHTEN, no. 1, 1976, pages 38 - 44 |

| G. SPUR ET AL.: "Handbuch der Fertigungstechnik, Band 2/1, Umformen", 1983, CARL HANSER VERLAG, MÜNCHEN, WIEN * |

| G. TROEBS:: "Banddicken-Regeleinrichtungen für Kaltwalzwerke und ihre Fortentwicklung", BBC NACHRICHTEN., vol. 58, no. 1, 1976, MANNHEIM DE, pages 38 - 44 * |

| PATENT ABSTRACTS OF JAPAN vol. 11, no. 28 (M - 557) 27 January 1987 (1987-01-27) * |

| PATENT ABSTRACTS OF JAPAN vol. 7, no. 68 (M - 201) 19 March 1983 (1983-03-19) * |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003053604A1 (fr) | 2001-12-12 | 2003-07-03 | Sms Demag Aktiengesellschaft | Dispositif de mesure de l'emprise entre les cylindres de travail d'une structure de laminage a froid ou a chaud |

| US7174758B2 (en) | 2001-12-12 | 2007-02-13 | Sms Demag Aktiengesellschaft | Device for measuring the roll gap between the working rollers of a cold or warm rolling stand |

| CN1313220C (zh) * | 2001-12-12 | 2007-05-02 | Sms迪马格股份公司 | 用于测量在轧机座的工作轧辊之间的轧辊间隙的装置 |

| WO2007022841A1 (fr) * | 2005-08-26 | 2007-03-01 | Sms Demag Ag | Procede de reglage d'epaisseur lors du laminage a chaud |

| WO2011003580A1 (fr) * | 2009-07-07 | 2011-01-13 | Sms Siemag Ag | Cage de laminoir à 4 cylindres/6 cylindres/18 cylindres à décalage horizontal (hs) présentant une configuration en cassette |

| RU2492008C1 (ru) * | 2009-07-07 | 2013-09-10 | Смс Зимаг Аг | Прокатная клеть с 4-, 6- или 18-hs-валковым модульным выполнением |

| KR101382164B1 (ko) * | 2009-07-07 | 2014-04-08 | 에스엠에스 지마크 악티엔게젤샤프트 | 카세트 타입 디자인을 갖는 4-롤, 6-롤, 18-hs 롤 스탠드 |

| US9656312B2 (en) | 2009-07-07 | 2017-05-23 | Sms Group Gmbh | 4-roll, 6-roll, 18-HS-roll stand having a cassette-type design |

| US8869577B2 (en) | 2011-06-07 | 2014-10-28 | Sms Siemag Ag | Measuring device, roll stand and method of detecting the height of a roll gap |

| CN104741385A (zh) * | 2015-04-14 | 2015-07-01 | 中冶赛迪工程技术股份有限公司 | 一种四辊轧机的工作辊弯辊装置及弯辊力的控制方法 |

| DE102022125630A1 (de) | 2022-10-05 | 2024-04-11 | Karlsruher Institut für Technologie, Körperschaft des öffentlichen Rechts | Anordnung mit zwei voneinander unter Ausbildung eines Spaltes beabstandeten Walzen mit einem Spaltweitenmesssystem |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0698428B1 (fr) | 1999-03-31 |

| DE59505484D1 (de) | 1999-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2024110B1 (fr) | Dispositif de mesure de la largeur et/ou de la position d'une bande métallique ou d'une brame | |

| DE3519382C2 (de) | Mehrwalzenbiegevorrichtung | |

| EP0763391B1 (fr) | Procédé de compensation de forces résultant de mouvements horizontaux des rouleaux dans une cage de laminoir | |

| DE69604330T2 (de) | Verbesserungen in oder in Verband mit einer Einrichtung zum Kreuzen oder axialen Verschieben von Walzen | |

| DE3115461C2 (fr) | ||

| DE2618901A1 (de) | Schlingenregler | |

| EP0257383B1 (fr) | Dispositif de réglage axial des cylindres des cages de laminoir pour la fabrication des profilés en acier | |

| DE1285970B (de) | Walzwerk mit zwischen den oberen und unteren Einbaustuecken eingesetzten Distanzstuecken | |

| DE1809639A1 (de) | Verfahren und Vorrichtung zur automatischen Steuerung eines Walzwerks | |

| DE3306549A1 (de) | Walzvorrichtung | |

| EP0035009B1 (fr) | Dispositif pour soutenir le cylindre de travail d'une machine à cintrer ou dresser les tôles | |

| EP0698428B1 (fr) | Dispositif pour détecter l'emprise entre deux cylindres de travail d'une cage de laminoir | |

| DE69102689T2 (de) | Walzenbiegemaschine. | |

| DE1602197A1 (de) | Walzwerk oder Walzgeruest zum Walzen mit konstanter Dicke | |

| EP0875303B1 (fr) | Procédé pour faire fonctionner un laminoir pour le laminage à chaud et à froid de produits plats | |

| EP0371280B1 (fr) | Procédé de dressage de tôles, bandes, plaques, profilés, poutres etc. | |

| DE3413424A1 (de) | Verfahren und vorrichtung zur steuerung der seitlichen unstabilen bewegung eines einem walzvorgang unterliegenden bandes | |

| DE2335809C2 (de) | Walzgerüst | |

| AT390741B (de) | Walzwerk, insbesondere kaltwalzwerk | |

| AT390392B (de) | Walzwerk, insbesondere kaltwalzwerk | |

| AT390742B (de) | Walzwerk, insbesondere kaltwalzwerk | |

| DE1918207A1 (de) | Regelungseinrichtung fuer ein Walzwerk | |

| DE10202526B4 (de) | Einrichtung zur Messung des Walzspaltes zwischen Arbeitswalzen eines Kalt- oder Warmwalzgerüstes | |

| AT390574B (de) | Walzwerk, insbesondere kaltwalzwerk | |

| DE102020007286B4 (de) | Spannrollensatz für eine Richtanlage zum Richten eines Bandes, Richtanlage, Nachwalzgerüstanlage und Verfahren zum Betreiben einer Richtanlage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE GB IT |

|

| 17P | Request for examination filed |

Effective date: 19960604 |

|

| 17Q | First examination report despatched |

Effective date: 19970417 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE GB IT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19990331 |

|

| REF | Corresponds to: |

Ref document number: 59505484 Country of ref document: DE Date of ref document: 19990506 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990618 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20130610 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140819 Year of fee payment: 20 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140621 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59505484 Country of ref document: DE |