EP0691284A2 - Distributeur pour masses pâteuses - Google Patents

Distributeur pour masses pâteuses Download PDFInfo

- Publication number

- EP0691284A2 EP0691284A2 EP95110328A EP95110328A EP0691284A2 EP 0691284 A2 EP0691284 A2 EP 0691284A2 EP 95110328 A EP95110328 A EP 95110328A EP 95110328 A EP95110328 A EP 95110328A EP 0691284 A2 EP0691284 A2 EP 0691284A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- dispenser according

- housing

- valve

- piston

- dispenser

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 235000011837 pasties Nutrition 0.000 title claims description 8

- 239000000126 substance Substances 0.000 title 1

- 230000000994 depressogenic effect Effects 0.000 claims description 6

- 238000007789 sealing Methods 0.000 claims description 5

- 239000011324 bead Substances 0.000 claims description 4

- 238000003860 storage Methods 0.000 claims description 4

- 239000012815 thermoplastic material Substances 0.000 claims description 4

- 230000000149 penetrating effect Effects 0.000 claims description 3

- 238000003825 pressing Methods 0.000 claims description 3

- 238000004519 manufacturing process Methods 0.000 description 4

- 150000001875 compounds Chemical class 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/0005—Containers or packages provided with a piston or with a movable bottom or partition having approximately the same section as the container

- B65D83/0033—Containers or packages provided with a piston or with a movable bottom or partition having approximately the same section as the container the piston being a follower-piston and the dispensing means comprising a hand-operated pressure-device at the opposite part of the container

Definitions

- the invention relates to a dispenser for pasty masses with a housing in which a piston which can only be displaced in the emptying direction and can be supported in the opposite direction by a ratchet against the inner wall of the housing is arranged and which is used to displace a portion of the mass to be dispensed by one stroke each Compressible push button has or can be depressed head part, the push button being arranged laterally next to the head part and this having a central valve which can be opened or closed by actuating the push button.

- a dispenser of this type is known from EP 0 282 791 B1.

- a portion of the mass to be dispensed is displaced from the contents of the housing by a stroke of the pushbutton with simultaneous opening of a valve arranged centrally in the head part and emerges from a concave wall of the head part designed as an application surface.

- a vacuum is created in the level column below the head part that straightens up again, which pulls the piston in the direction of emptying.

- the portion of pasty mass displaced by actuating the deformable head part is added for the next dispensing operation.

- the known dispenser is consequently filled with the dispenser head pointing downward.

- the initial area of the housing inner wall is designed with longitudinal grooves so that air trapped between the piston and the filling material can escape.

- a dispenser for pasty masses is also known, with a piston which is displaceably arranged in the dispenser housing, migrates in the discharge direction and is blocked in the opposite direction, and with a pushbutton actuation on a bellows-type compressible head piece, with this a pull rod penetrating the piston is coupled.

- the pull rod is coupled to the piston with the interposition of an axial free passage in the head piece.

- the headpiece has a channel-shaped dispenser mouthpiece opening, the mouth of which can be closed with a stopper for storage. This stopper is removed when the dispenser is opened, after which the mouthpiece opening remains unlocked for further withdrawals.

- the invention has for its object to further develop and improve a dispenser for pasty masses of the type mentioned in such a way that the disadvantages and difficulties mentioned are overcome and in particular none subsequent leakage of mass can take place after actuation, that the displaced portion of mass is safely brought in without damage, even from small air pockets, and that the dispenser can be manufactured and assembled inexpensively using simple structural means.

- valve and the piston are coupled by a pull rod axially penetrating the housing and cooperate with each other with each stroke of the push button.

- the valve is opened when the pushbutton is actuated and on the other hand a predetermined portion of mass is brought out of the valve opening through the opened valve and made available.

- the valve closes, and the head part, which straightens up again to its relaxed shape, pulls the piston so far over the pull rod that it replenishes the dispensed mass regardless of a more or less large suction.

- the clearance of the tie rod connection in the head part produces a shorter stroke of the piston compared to a relatively larger actuation stroke when the shape of the head part changes.

- the Tension rod in the head part has a holder in the form of a perforated radial disc, with which it is gripped in a guide cylinder of the head part with little axial clearance from the lower edge of the guide cylinder and is held so that it can be clipped in, and with its end part with the interposition of an internal locking mechanism present on the piston crown the piston can be coupled.

- the pull rod can thus be clipped into the guide cylinder and inserted through the piston without any assembly effort.

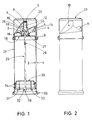

- the dispenser for pasty masses shown in FIG. 1 has a housing (1) in which a piston (30) is arranged, which can only be moved in the emptying direction and supported in the opposite direction by a locking mechanism (31) against the inner wall (2) of the housing (1) is.

- the latter has elastic sealing lips (34) that seal in both directions on its outer circumference in the usual way.

- the dispenser has a head part (3) which can be pressed together or depressed by a stroke of a pushbutton (4), the pushbutton (4) being arranged laterally next to the head part (3) and pressing the pushbutton (4) openable or closable, in the middle arranged shut-off valve (5).

- the head part (3) can be covered by a cap (23) which can be assigned to the dispenser.

- the valve (5) and the piston (30) are coupled by means of a pull rod (25) which axially penetrates the housing (1) and cooperates with each other when the pushbutton (4) is lifted.

- the interaction is achieved in that the pull rod (25) is held by a holder (26) in the form of a perforated radial disk in a guide cylinder (6) of the valve body (7) with little axial clearance and with its, the piston (30) facing End part (28) with the interposition of a locking mechanism (32) present on the piston crown (33) is non-positively coupled to the piston (30).

- the housing cover (18) is pressed down and displaces a predetermined portion of the filling compound in the direction of the closing valve (5).

- the housing cover (18) is designed to be very elastic in the manner of a membrane with a relatively thin wall thickness, so that it yields under the pressure of the pushbutton (4) and practically performs a "pump stroke".

- the valve mechanism is activated and the valve (5) opens by the head part (3) connected to the housing cover (18) with the funnel-shaped discharge (19) and the discharge tube (12) arranged thereon within the cap (11) of the Applicator (10), as can be seen from the enlarged representation of Figures 1a and 3, slides down in the direction of arrow (24) and thereby releases the valve plug (14) from its closed position in the valve opening (8) and releases it.

- the housing (1) forms a neck (9) with a reduced diameter on the upper area, which receives the applicator (10), said neck having a cylindrical cap (11) which is provided with a valve opening (8) and can be opened downwards, in which a tube (12), which first extends upward from the head part (3) and forms part of the valve (5), slides axially displaceably and carries a valve plug (14) at its tip on star-shaped arms (13).

- the tube (12) is designed with an annular, elastic sealing bead (50), as is better can be seen from Figure 3. This seal could alternatively be formed with a highly elastic sealing lip or with an O-ring.

- the applicator (10) has a lateral opening (15) within which the pushbutton (4) is arranged, said pushbutton (4) being movably articulated on the gusset-like ribs (16) formed inside the applicator (10). Furthermore, the pushbutton (4) has on its outside a stop bead (17) designed as a stroke limiting element. This sits on the outer edge of the recess (15) and in this way limits the stroke. This prevents the housing cover (18) from being deformed too much and thus being overstretched or overstressed.

- the pull rod (25) protrudes into the discharge (19) and is thus extended upwards over the holder (26). At the extended end it carries a centering plate (27). This has a valve function, by pressing the Housing cover (18) first reduced an annular gap with respect to the discharge (19) and then blocked, whereby the amount of filling material escaping during the working stroke of the key (4) is limited.

- the centering plate (27) and the pull rod (25) are each designed as an independent molded part and the two parts can be joined together by plugging on. The assembly of both parts - as is common in the mass production of small parts - can then be carried out inexpensively using automatic assembly machines.

- the dispenser has an advantageous embodiment in that the pull rod (25) is provided with a corrugation (29) in an area just below the neck (9) of the housing (1). If the piston (30) slides over this corrugation (29) shortly before the final emptying, a clicking noise is caused, which indicates that the dispenser is about to be emptied.

- the very advantageous embodiment shown in Figure 1 also provides that the housing (1) with stand base (20), storage cylinder (21), neck (9), cover (18) and head part (3) consists in one piece of medium-hard thermoplastic material. This simplifies assembly, reduces the number of parts belonging to the dispenser assembly and enables very economical production in large quantities.

- the more highly stressed elements of the dispenser such as the piston (30), applicator (10), pushbutton (4), assignable cap (23) and the pull rod (25), on the other hand, can consist of a comparatively hard thermoplastic material.

- Figure 1a shows the top of the dispenser in an enlarged view, from which the assignments of the aforementioned elements can be seen better. All elements are provided with reference numerals corresponding to FIG. 1.

- FIG. 2 shows the dispenser in a side view, from which the shape of the applicator (10), which can be recognized, for example, by a transparent cap, can be seen.

- valve plug (14) which tapers conically at both ends, is suitable for achieving a hermetic seal of the valve opening (8) with a low axial sealing force.

- the valve plug (14) is moved downward and releases the valve opening (8).

- the valve arrangement is uncomplicated, expedient and suitable for inexpensive manufacture.

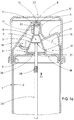

- FIG 4 shows a slightly different embodiment of the dispenser.

- the housing (1) is open at the top and forms an annular groove (35) with an inward diameter and open at the top and a collar (36) with a clip groove (37) on the outside.

- the head part (3) has a dome-shaped attachment (38) which can be inserted into the annular groove (35) and has a flange (39) which overlaps the annular groove (35) and which is separated from an inner flange (40) of the collar (36).

- clip-on applicator (10) is held.

- This version also shows a corrugation (29) on the piston rod (25).

- the head part of the piston (30) is Dome-shaped in accordance with the dome-shaped design of the attachment (38) in a compatible design, whereby an almost complete emptying of the filling content of the dispenser is achieved.

- the remaining elements of the head part (3) with the valve body (7) and further elements correspond to the design and arrangement according to FIG. 1.

- Figure 5 shows a section of the plane (VV) in Fig. 4, the tie rod holder (26) in the form of a perforated disc within the guide cylinder (6), the arrangement of the push button (4) and the applicator (10) and also the housing with the open annular groove (35) only partially indicated for reasons of clarity.

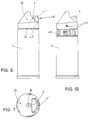

- Figure 6 shows a side view of a dispenser with the cap removed and a double push button (4 ', 4'') designed as a child safety device.

- the element (4 '') in the part (4 ') is axially telescopically displaced against the pressure of a spring in the locked state, as shown in FIG. 6, and lies on the edge (47) of the opening (15) of the applicator (10). In this state, it is not possible to depress the actuation button (4 ', 4'') for the working stroke. For this purpose, the part (4 '') must be pushed telescopically into the part (4 ') against the pressure of a return spring in the direction of the arrow (48).

- Figure 10 shows another version of the child lock.

- the dispenser has a locking ring (46) on the housing (1). This is designed in cooperation with the push button (4) so that it only releases the push button (4) in a certain position and recognizable by markings (44) if they match.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Coating Apparatus (AREA)

- Jellies, Jams, And Syrups (AREA)

- Automatic Assembly (AREA)

- Lift Valve (AREA)

- Closures For Containers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4423608A DE4423608C2 (de) | 1994-07-06 | 1994-07-06 | Spender für pastöse Massen |

| DE4423608 | 1994-07-06 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0691284A2 true EP0691284A2 (fr) | 1996-01-10 |

| EP0691284A3 EP0691284A3 (fr) | 1996-05-29 |

| EP0691284B1 EP0691284B1 (fr) | 1997-09-17 |

Family

ID=6522333

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95110328A Expired - Lifetime EP0691284B1 (fr) | 1994-07-06 | 1995-07-03 | Distributeur pour masses pâteuses |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5788123A (fr) |

| EP (1) | EP0691284B1 (fr) |

| JP (1) | JP3545845B2 (fr) |

| AT (1) | ATE158253T1 (fr) |

| DE (2) | DE4423608C2 (fr) |

| ES (1) | ES2109755T3 (fr) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6767151B1 (en) * | 2003-04-22 | 2004-07-27 | Richard L. Owens | Dispenser/spreader article for spackling and paste |

| US8595194B2 (en) * | 2009-09-15 | 2013-11-26 | At&T Intellectual Property I, L.P. | Forward decay temporal data analysis |

| CN101700209B (zh) * | 2009-10-27 | 2013-07-10 | 北京欧迈世纪科技有限公司 | 药品食品贮发瓶 |

| KR200461424Y1 (ko) * | 2010-02-12 | 2012-07-11 | 주식회사 에프에스코리아 | 에어리스펌프를 갖는 콤팩트 용기 |

| WO2012068092A2 (fr) | 2010-11-15 | 2012-05-24 | Milwaukee Electric Tool Corporation | Outil de distribution motorisé |

| WO2012067801A1 (fr) | 2010-11-15 | 2012-05-24 | Milwaukee Electric Tool Corporation | Outil de distribution motorisé |

| US8857672B2 (en) | 2011-06-20 | 2014-10-14 | Milwaukee Electric Tool Corporation | Carriage assembly for dispensing tool |

| US9039557B2 (en) | 2011-09-02 | 2015-05-26 | Milwaukee Electric Tool Corporation | Powered dispensing tool |

| US10413930B2 (en) | 2013-07-18 | 2019-09-17 | Lisa Marie Evans | System and method for application of a surface compound |

| US9272305B2 (en) | 2013-07-18 | 2016-03-01 | Lisa Marie Evans | System and method for application of a surface compound |

| FR3081113B1 (fr) * | 2018-05-18 | 2020-05-29 | Albea Le Treport | Piston pour reservoir d'un distributeur d'un produit fluide sans reprise d'air |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3045048C2 (de) | 1980-11-29 | 1986-04-17 | Bramlage Gmbh, 2842 Lohne | Spender für pastöse Massen |

| EP0282791B1 (fr) | 1987-03-18 | 1991-08-21 | Bramlage GmbH | Distributeur pour produits pâteux |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8307898U1 (de) * | 1983-03-18 | 1984-07-12 | Wella Ag, 6100 Darmstadt | Zylindrischer Behaelter fuer pastoeses Fuellgut |

| DE3526804A1 (de) * | 1985-07-26 | 1987-01-29 | Bramlage Gmbh | Spender fuer pastoese massen |

| US4836415A (en) * | 1987-11-02 | 1989-06-06 | Grussmark Stephen M | Dental timer |

| US4838461A (en) * | 1988-04-14 | 1989-06-13 | Owens-Illinois Closure Inc. | Dispensing package for a viscous product |

| CA2020223C (fr) * | 1989-07-19 | 1996-02-27 | Shinya Kobayashi | Bouchon pour aerosols |

| US5052592A (en) * | 1989-08-14 | 1991-10-01 | Bramlage Gesellschaft Mit Beschrankter Haftung | Dispenser for paste compositions |

| US5044523A (en) * | 1990-02-28 | 1991-09-03 | Photofinish Cosmetics Inc. | Method and apparatus for dispensing of volatile fluids |

-

1994

- 1994-07-06 DE DE4423608A patent/DE4423608C2/de not_active Expired - Fee Related

-

1995

- 1995-06-28 US US08/495,856 patent/US5788123A/en not_active Expired - Fee Related

- 1995-07-03 DE DE59500672T patent/DE59500672D1/de not_active Expired - Fee Related

- 1995-07-03 EP EP95110328A patent/EP0691284B1/fr not_active Expired - Lifetime

- 1995-07-03 ES ES95110328T patent/ES2109755T3/es not_active Expired - Lifetime

- 1995-07-03 AT AT95110328T patent/ATE158253T1/de not_active IP Right Cessation

- 1995-07-05 JP JP16999495A patent/JP3545845B2/ja not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3045048C2 (de) | 1980-11-29 | 1986-04-17 | Bramlage Gmbh, 2842 Lohne | Spender für pastöse Massen |

| EP0282791B1 (fr) | 1987-03-18 | 1991-08-21 | Bramlage GmbH | Distributeur pour produits pâteux |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0691284A3 (fr) | 1996-05-29 |

| DE59500672D1 (de) | 1997-10-23 |

| DE4423608C2 (de) | 1996-07-04 |

| JPH08169479A (ja) | 1996-07-02 |

| JP3545845B2 (ja) | 2004-07-21 |

| EP0691284B1 (fr) | 1997-09-17 |

| ATE158253T1 (de) | 1997-10-15 |

| DE4423608A1 (de) | 1996-02-08 |

| ES2109755T3 (es) | 1998-01-16 |

| US5788123A (en) | 1998-08-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0084638B1 (fr) | Distributeur pour produits pâteux | |

| DE69206988T2 (de) | Vorrichtung zum Spritzen einer vorbestimmten Dosis eines Mediums und Verfahren zum Füllen dieser Vorrichtung | |

| DE69300399T2 (de) | Vordruckpumpe. | |

| DE69202833T2 (de) | Verstellbares Ventil und Spender mit einem solchen Ventil. | |

| DE69503369T2 (de) | Pumpe mit vordruckaufbau | |

| DE68909310T2 (de) | Vordruck Dosierpumpe mit verbessertem Ansaugverhalten. | |

| DE69200604T2 (de) | Sprüh- oder Spendervorrichtung für Flüssigkeiten mit Mitteln zur Verhinderung einer ungewollten Betätigung. | |

| DE60216657T2 (de) | Vorrichtung zur Verpackung und zur Ausgabe eines insbesondere kosmetischen Produkts | |

| WO1986001489A1 (fr) | Recipient muni d'un obturateur | |

| DE3033392A1 (de) | Vorrichtung zur ausgabe von pasteusen oder breiigen medien | |

| EP0347546B1 (fr) | Distributeur pour produits pâteux | |

| DE3605419C2 (de) | Dosierspender | |

| DE3502520A1 (de) | Vorrichtung zur dosierten abgabe fluessiger oder pastoeser substanzen | |

| DE60003414T2 (de) | Befestigungselement für flüssigkeitsabgabevorrichtungen und abgabevorrichtung die ein solches element enthält | |

| EP0353282B1 (fr) | Distributeur-doseur de fluides, notamment de medicaments fluides contenus dans des recipients | |

| EP0691284B1 (fr) | Distributeur pour masses pâteuses | |

| DE60318205T2 (de) | Vakuumpumpe für flaschen | |

| DE3425900A1 (de) | Vorrichtung mit tropfenzaehler zum abgeben einer fluessigen oder pastoesen substanz | |

| DE69100307T2 (de) | Vordruck-Handpumpe. | |

| DE3235171A1 (de) | Spender, insbesondere fuer pastoeses gut | |

| DE69505457T2 (de) | Spender für cremige Substanzen, insbesondere Zahnpasten | |

| EP0376097A2 (fr) | Distributeur-doseur d'un produit pâteux | |

| EP0345458A2 (fr) | Distributeur | |

| EP1344570B1 (fr) | Distributeur des produits fluides | |

| EP0035588A1 (fr) | Récipient pour matières visqueuses |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: LT PAYMENT 950707;LV PAYMENT 950707;SI PAYMENT 950707 |

|

| RAX | Requested extension states of the european patent have changed |

Free format text: LT PAYMENT 950707;LV PAYMENT 950707;SI PAYMENT 950707 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: LT PAYMENT 950707;LV PAYMENT 950707;SI PAYMENT 950707 |

|

| 17P | Request for examination filed |

Effective date: 19960618 |

|

| 17Q | First examination report despatched |

Effective date: 19960723 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: RPC BRAMLAGE GMBH |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: LT PAYMENT 950707;LV PAYMENT 950707;SI PAYMENT 950707 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19970917 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970917 |

|

| REF | Corresponds to: |

Ref document number: 158253 Country of ref document: AT Date of ref document: 19971015 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19970926 |

|

| REF | Corresponds to: |

Ref document number: 59500672 Country of ref document: DE Date of ref document: 19971023 |

|

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19971217 Ref country code: PT Effective date: 19971217 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2109755 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: 76575 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20010620 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: MC Payment date: 20010723 Year of fee payment: 7 Ref country code: LU Payment date: 20010723 Year of fee payment: 7 Ref country code: CH Payment date: 20010723 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020703 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030201 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080723 Year of fee payment: 14 Ref country code: DE Payment date: 20080619 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080722 Year of fee payment: 14 Ref country code: IT Payment date: 20080726 Year of fee payment: 14 Ref country code: FR Payment date: 20080718 Year of fee payment: 14 Ref country code: AT Payment date: 20080722 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080723 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080723 Year of fee payment: 14 |

|

| BERE | Be: lapsed |

Owner name: *RPC BRAMLAGE G.M.B.H. Effective date: 20090731 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090703 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20100201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100202 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090703 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100201 |