EP0671985B1 - Presswerkzeug - Google Patents

Presswerkzeug Download PDFInfo

- Publication number

- EP0671985B1 EP0671985B1 EP94901870A EP94901870A EP0671985B1 EP 0671985 B1 EP0671985 B1 EP 0671985B1 EP 94901870 A EP94901870 A EP 94901870A EP 94901870 A EP94901870 A EP 94901870A EP 0671985 B1 EP0671985 B1 EP 0671985B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- press

- pressing

- jaws

- ring

- groove

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002184 metal Substances 0.000 claims description 4

- 230000008878 coupling Effects 0.000 description 21

- 238000010168 coupling process Methods 0.000 description 21

- 238000005859 coupling reaction Methods 0.000 description 21

- 239000011324 bead Substances 0.000 description 11

- 238000000034 method Methods 0.000 description 10

- 238000007789 sealing Methods 0.000 description 7

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 230000000295 complement effect Effects 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B27/00—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for

- B25B27/02—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for for connecting objects by press fit or detaching same

- B25B27/10—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for for connecting objects by press fit or detaching same inserting fittings into hoses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D39/00—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders

- B21D39/04—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of tubes with tubes; of tubes with rods

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/5367—Coupling to conduit

Definitions

- the invention relates to a pressing tool for pressing tubular, nested workpieces, in particular a pipe end and a press fitting plugged over them, with a plurality of press jaw elements which carry press jaws, into which a press groove which runs in the circumferential direction on the inside and which has a press web along only one side is formed.

- press tools have been developed for the radial pressing of press fitting and pipe end. These pressing tools have pressing jaw elements which have pressing jaws which are moved radially during the pressing to form a closed pressing space. Not only are press tools known with two press jaws (DE-A-34 23 283; DE-A-38 33 748), but also with more than two press jaws in order to be able to achieve higher press-in depths.

- the latter pressing tools can be found in particular in EP-A-0 ⁇ 451 80 ⁇ 6.

- the pressing tools shown in Figures (7) and (8) are suitable for connecting pipe ends of larger and very large diameters.

- the pressing jaws of such pressing tools have a certain cross-sectional contour adapted to the shape of the press fitting. Since such press fittings have an outwardly projecting annular bead at the free end, into which a sealing ring is inserted on the inside, the press jaw has a molded-in press groove for receiving this annular bead. The individual sections of the press groove in the press jaws complement each other to form a continuous press groove.

- press ridges run on both sides of the press groove, which are pressed into the material of the press fitting and thus also of the inserted pipe end during the pressing process.

- press bars on both sides of the press groove is not absolutely necessary for the functioning of the pressing.

- the handling is foolproof if the cross-section of the press jaws is symmetrical, that is to say the press ridges run on both sides of the press groove, since it does not matter in which position the press tool is placed at the point to be pressed.

- the invention is therefore based on the object of designing a pressing tool of the type mentioned at the outset which, while maintaining the assembly security, permits pressing without endangering the tightness.

- This object is achieved in that a jig is arranged on the other side, which fits over the inserted workpiece, but not over the pushed-on workpiece.

- a specific pressing tool only fits for pressing a workpiece with a certain diameter, so the reference to the workpiece also contains a statement about the dimensioning of the pressing tool.

- the additional arrangement of a gauge prevents the press tool from being placed on the press point in the wrong position, in which the press web comes to rest on the side of the annular bead facing the free end of the press fitting, because in this position the gauge prevents it from touching down, because they don't have that Press fitting fits. Only in the reverse position, in which the gauge comes to lie outside the press fitting, is it possible to put the press tool on.

- the teaching consists in a particularly simple design of a correspondingly shaped sheet metal part which is attached to one of the press jaw elements.

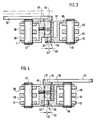

- the press ring (5) has essentially identical press jaw elements (6, 7, 8, 9, 10ildete), each press jaw element (6, 7, 8, 9, 10 ⁇ ) consisting of an external press jaw carrier (11, 12, 13, 14, 15) and an inner, arc-shaped press jaw (16, 17, 18, 19, 20 ⁇ ).

- the press jaw supports are connected to one another via intermediate pieces (21, 22, 23, 24), the press jaw supports (11, 12, 13, 14, 15) using articulated bolts (26, 27, 28, 29, 30 ⁇ , 31, 32, 33) are articulated on the intermediate pieces (21, 22, 23, 24).

- At least one hinge pin (26, 27, 28, 29, 30 ⁇ , 31, 32, 33) per intermediate piece (21, 22, 23, 24) is designed to be removable, so that the press ring (5) is divided into individual press jaw elements (6, 7, 8, 9, 10 ⁇ ) can be taken apart or assembled on site.

- the press jaws (16, 17, 18, 19, 20 ⁇ ) are slidably mounted in the circumferential direction in the press jaw carriers (11, 12, 13, 14, 15).

- a clamping device (34, 35, 36, 37, 38) is attached to each press jaw support (11, 12, 13, 14, 15), which has a clamping punch (39, 40 ⁇ , 41, 42, 43).

- the clamping devices (34, 35, 36, 37, 38) also serve to axially guide the press jaws (16, 17, 18, 19, 20 ⁇ ).

- the hinge pins (29, 30 ⁇ ) on the central press jaw support (13) carry a jaw-like gauge (44) in the form of a sheet metal part with a semicircular recess (45), the radius of the recess (45) being such that the gauge (44 ) fits on the one hand over the pipe end (1), but on the other hand does not fit over the cylindrical part of the press fitting (2) adjoining the annular bead (3).

- the lower press jaw elements (6, 10 ⁇ ) have between them a closing gap (46) in the positions shown in Figures (1) and (2). In the figures (1) it is so large that the press ring (5) can be put over the press fitting (2) and pipe end (1).

- the free ends of the pressing jaw elements (6, 10 ⁇ ) delimiting the closing gap (46) carry hinge pins (47, 48), a coupling lug (49, 50 ⁇ ) being suspended from each hinge pin (47, 48).

- the shape of the coupling straps (49, 50 ⁇ ) and their connection with the hinge pins (47, 48) result in particular from the sectional view according to Figures (3) and (4).

- the free ends of the coupling tabs (49, 50 ⁇ ) have through openings (51, 52).

- a coupling pin (53) is inserted axially. It has a first bolt section (54) with which it passes through the through hole (51).

- One end of the first bolt section (54) is connected to a hand lever (55).

- a second pin section (56) is formed on the other end of the first pin section (54), the axis of which is offset by an eccentricity (57) with respect to the axis of the first pin section (54).

- the second pin section (56) fits into the through hole (52) ) of the other coupling plate (50 ⁇ )

- the coupling plates (49, 50 ⁇ ) together with the coupling bolt (53) form a coupling element for the temporary connection of the ends of the pressing ring (5) before the actual pressing process.

- the press jaws (16, 17, 18, 19, 20 ⁇ ) are not only axially guided by the clamping devices (34, 35, 36, 37, 38), but also by the other side of the press jaw carrier (11, 12, 13, 14, 15) screwed on guide plates (62).

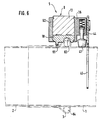

- the press jaws (16, 17, 18, 19, 20 ⁇ ) themselves have an asymmetrical cross-sectional contour. They have an annular groove (63), the pressing grooves (63) of all pressing jaws (16, 17, 18, 19, 20 ⁇ ) complementing one another to form a continuous circumferential annular groove.

- the cross section of the press groove (63) is adapted to the annular bead (3), which carries a sealing ring (64) on the inside.

- a pressing web (65) runs along one side of the annular groove (63). It also complements the press bars of the other press jaws (16, 17, 18 19, 20 ⁇ ) to form a continuous circumferential press bar.

- the press web (65) is intended to dig into the material of the press fitting (2) during the pressing process and also to dig in to deform the pipe end (1). On the other side of the annular groove (63), such a press bar is not provided.

- the opened press ring (5) is first placed over the pipe end (1) and the press fitting (2), as can be seen from the figures (1) and (6).

- the two lower press jaw elements (6, 10 ⁇ ) are pivoted towards each other and onto the pipe end (1), so that they correspond to those shown in Figure (2 ) assume the position shown.

- the coupling straps (49, 50 ⁇ ) which then still hang down and are shown in dash-dot lines in this position in FIG. (2), are then pivoted in the directions of arrows C and D with respect to one another.

- the coupling bolt (53) is in such a position that its second bolt section (56) does not protrude through the through bore (51), which is indicated in FIG. (3) by the position of the hand lever (55) shown in dotted lines.

- the coupling lugs (49, 50 ⁇ ) are pivoted into a position where they overlap and the through holes (51, 52) merge into one another.

- the hand lever (55) are in such a position that the second bolt section (56) is offset in the direction of the other coupling plate (50 ⁇ ) and therefore easily in the through bore (52) by axial displacement of the Grip the coupling pin (53) so that both coupling brackets (49, 50 ⁇ ) can couple.

- the press ring (5) still has a certain amount of slack.

- the hand lever (55) is then pivoted from the position shown in solid lines in Figure (2) to the dash-dotted position in the direction of arrow E by 180 °.

- the second pin section (56) executes an eccentric movement and thereby shortens the distance between the two hinge pins (47, 48) by twice the eccentricity (57).

- Figures (3) and (4) with Figure (4) showing the pivoted position.

- a circumferential force is applied to the press ring (5) via which the press jaws (16, 17, 18, 19, 20 ⁇ ) press onto the press fitting (2) with a certain radial preload.

- the press ring (5) then has a seat that is difficult or impossible to turn. This effect is supported by the clamping rams (39, 40 ⁇ , 41, 42, 43), which then rest against the pipe end (1) with a likewise radially directed prestress.

- a locking device belonging to the pressing tool (4) is used, as is known schematically from Figure (7) of EP-A-0 ⁇ 451 80 ⁇ 6.

- This locking device has two pincer-shaped lever arms with which the locking device can be attached to the hinge pins (47, 48). They cover gaps (58, 59) or (60 ⁇ , 61) and then lay on the outside of the hinge pin (47, 48). The pliers-like lever arms are then moved together by means of a hydraulic motor belonging to the locking device, so that the hinge pins (47, 48) approach each other.

- the pressing ring (5) assumes the position shown in FIG. (5). After axial displacement of the coupling pin (53) in such a way that the second pin section (56) moves out of the through hole (52), the press ring (5) can be removed again and used for further pressing processes.

Landscapes

- Mechanical Engineering (AREA)

- Engineering & Computer Science (AREA)

- Automatic Assembly (AREA)

- Measurement Of The Respiration, Hearing Ability, Form, And Blood Characteristics Of Living Organisms (AREA)

- Hand Tools For Fitting Together And Separating, Or Other Hand Tools (AREA)

- Treatment Of Fiber Materials (AREA)

- Jigs For Machine Tools (AREA)

- Press Drives And Press Lines (AREA)

- Perforating, Stamping-Out Or Severing By Means Other Than Cutting (AREA)

- Apparatuses For Bulk Treatment Of Fruits And Vegetables And Apparatuses For Preparing Feeds (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Fats And Perfumes (AREA)

- Non-Disconnectible Joints And Screw-Threaded Joints (AREA)

- Acyclic And Carbocyclic Compounds In Medicinal Compositions (AREA)

- Gripping Jigs, Holding Jigs, And Positioning Jigs (AREA)

- Wire Bonding (AREA)

- Finger-Pressure Massage (AREA)

- Preventing Corrosion Or Incrustation Of Metals (AREA)

- Food-Manufacturing Devices (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE9216369U DE9216369U1 (de) | 1992-12-02 | 1992-12-02 | Preßwerkzeug |

| DE9216369U | 1992-12-02 | ||

| PCT/EP1993/003302 WO1994012297A1 (de) | 1992-12-02 | 1993-11-25 | Presswerkzeug |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0671985A1 EP0671985A1 (de) | 1995-09-20 |

| EP0671985B1 true EP0671985B1 (de) | 1996-08-28 |

Family

ID=6886640

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94901870A Expired - Lifetime EP0671985B1 (de) | 1992-12-02 | 1993-11-25 | Presswerkzeug |

Country Status (20)

| Country | Link |

|---|---|

| US (1) | US5697135A (da) |

| EP (1) | EP0671985B1 (da) |

| JP (1) | JPH08503662A (da) |

| CN (1) | CN1093957A (da) |

| AT (1) | ATE141835T1 (da) |

| AU (1) | AU669039B2 (da) |

| BR (1) | BR9307578A (da) |

| CA (1) | CA2150811C (da) |

| CZ (1) | CZ282551B6 (da) |

| DE (2) | DE9216369U1 (da) |

| DK (1) | DK0671985T3 (da) |

| ES (1) | ES2093511T3 (da) |

| FI (1) | FI952672A (da) |

| GR (1) | GR3021325T3 (da) |

| HU (1) | HUT71167A (da) |

| NO (1) | NO952176D0 (da) |

| NZ (1) | NZ258548A (da) |

| PL (1) | PL171755B1 (da) |

| SK (1) | SK66595A3 (da) |

| WO (1) | WO1994012297A1 (da) |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4240427C1 (de) * | 1992-12-02 | 1994-01-20 | Novopress Gmbh | Preßwerkzeug |

| DE9312808U1 (de) * | 1993-08-26 | 1993-10-28 | Novopress GmbH Pressen und Presswerkzeuge & Co KG, 41460 Neuss | Meßgerät zur Erfassung der Einschubtiefe bei einer Rohrverbindung |

| DE19734355C2 (de) * | 1997-08-08 | 2002-08-14 | Uponor Rohrsysteme Gmbh | Preßwerkzeug |

| DE29721759U1 (de) * | 1997-12-10 | 1998-04-09 | Franz Viegener II GmbH & Co. KG, 57439 Attendorn | Preßwerkzeug zum unlösbaren Verbinden eines Fittings und eines eingeführten Metallrohrendes |

| US6185980B1 (en) * | 1999-09-23 | 2001-02-13 | Leonard J. Law | Special crimping tool |

| ES2223362T3 (es) * | 1999-10-26 | 2005-03-01 | Ridge Tool Ag | Una herramienta compresora y el metodo para unir piezas mediante deformacion en frio. |

| ES2254784T3 (es) * | 2001-12-08 | 2006-06-16 | Gustav Klauke Gmbh | Dispositivo de prensa. |

| US20030230132A1 (en) * | 2002-06-17 | 2003-12-18 | Emerson Electric Co. | Crimping apparatus |

| US7398909B2 (en) * | 2003-07-17 | 2008-07-15 | Swagelok Company | Pipe collets |

| WO2007038308A1 (en) * | 2005-09-23 | 2007-04-05 | Bruns Daniel Kidd | Tool to crimp non-metallic tubing onto fittings |

| DE102006050427A1 (de) * | 2006-08-22 | 2008-02-28 | Gustav Klauke Gmbh | Verfahren zum Verpressen eines Pressfittings sowie Presswerkzeug hierzu |

| JP5396273B2 (ja) * | 2006-10-20 | 2014-01-22 | グスタフ・クラウケ・ゲーエムベーハー | プレス継手のプレス方法及びそのプレス工具 |

| US20080122222A1 (en) * | 2006-11-29 | 2008-05-29 | H & H Tube & Manufacturing Co. | Crimp-on transition fitting |

| KR100739106B1 (ko) * | 2006-12-20 | 2007-07-12 | 웰텍 주식회사 | 강관 맞대기용 정형이음장치 |

| US7980522B2 (en) * | 2007-12-28 | 2011-07-19 | Alion Science And Technology Corporation | Trailing edge blade clamp |

| US8230714B2 (en) * | 2009-01-23 | 2012-07-31 | Custom Machining Services, Inc. | Die carrier assembly and crimping process |

| US20100253066A1 (en) * | 2009-04-02 | 2010-10-07 | Victaulic Company | Crimp-Type Coupling, Crimping Tool and Method of Crimping |

| DE202009009456U1 (de) * | 2009-07-15 | 2010-11-25 | Novopress Gmbh Pressen Und Presswerkzeuge & Co. Kommanditgesellschaft | Presswerkzeug zum Verbinden von insbesondere rohrförmigen Werkstücken |

| DE102009059053A1 (de) * | 2009-12-15 | 2011-06-16 | REMS-WERK Christian Föll und Söhne GmbH | Presswerkzeug zum Radialverpressen von Werkstücken sowie Werkzeug mit wenigstens zwei relativ zueinander bewegbaren Werkzeugteilen |

| CN101890457A (zh) * | 2010-06-25 | 2010-11-24 | 浙江毅力汽车空调有限公司 | 管路接头压接工具 |

| FR2965199B1 (fr) * | 2010-09-24 | 2012-09-07 | Serimax | Bride d'aide au travail de tubes comportant plusieurs parties. |

| DE102011052852A1 (de) * | 2011-08-19 | 2013-02-21 | Gustav Klauke Gmbh | Pressvorrichtung |

| DE202011105967U1 (de) | 2011-09-21 | 2011-12-06 | Mehmet Saldiray Atac | Presswerkzeug-Mehrfachgrössenkopf |

| CN102805676B (zh) * | 2012-08-14 | 2015-06-17 | 杭州启明医疗器械有限公司 | 人造瓣膜置换装置的压缩装置 |

| US9388885B2 (en) | 2013-03-15 | 2016-07-12 | Ideal Industries, Inc. | Multi-tool transmission and attachments for rotary tool |

| EP3548258B1 (en) * | 2017-03-30 | 2022-05-04 | IPS, Corporation - Weld-On Division | Pipe fitting apparatus and methods |

| CN108620498B (zh) * | 2018-04-28 | 2020-11-03 | 浙江康帕斯流体输送技术有限公司 | 一种卡压式管件的环压工具 |

| KR200491617Y1 (ko) * | 2019-01-21 | 2020-05-11 | 민우정공(주) | 배관용 압착 체결구 |

| CN110052991A (zh) * | 2019-05-24 | 2019-07-26 | 成都川力美亚管业有限公司 | 一种连接稳定的环压管件工具 |

| DE102019118588A1 (de) * | 2019-07-09 | 2021-01-14 | Daniel Knipping | Quetschhülse für Rohrverbindungen |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1187870B (de) * | 1958-10-01 | 1965-02-25 | Aga Plaatfoeraedling Aktiebola | Plastisch verformbare metallische Kupplungshuelse zum Verbinden von Metallrohren mit glatten Enden |

| US3756064A (en) * | 1972-03-24 | 1973-09-04 | Waldes Kohinoor Inc | Hand-operated plier-like tools |

| NL149406B (nl) * | 1973-10-02 | 1976-05-17 | Hubert Joseph Mertens | Pijpenklem. |

| DE3423283A1 (de) * | 1984-06-23 | 1986-01-02 | Helmut Dipl.-Ing. 4040 Neuss Dischler | Klemmwerkzeug, insbesondere zum verbinden von rohren und anderen profilen |

| US4934673A (en) * | 1987-12-10 | 1990-06-19 | General Dynamics Corp., Pomona Division | V-clamp installation tool |

| DE3833748A1 (de) * | 1988-09-30 | 1990-04-05 | Mannesmann Ag | Verfahren und vorrichtung zur herstellung einer unloesbaren, dichten verbindung von rohren |

| EP0361630B1 (de) * | 1988-09-30 | 1992-06-10 | MANNESMANN Aktiengesellschaft | Verfahren und Vorrichtung und Pressfitting zur Herstellung einer unlösbaren, dichten Verbindung von Rohren |

| US5209100A (en) * | 1990-04-12 | 1993-05-11 | Helmut Dischler | Compression tool |

| DE9007414U1 (de) * | 1990-04-12 | 1991-07-18 | Dischler, Helmut, Dipl.-Ing., 4040 Neuss | Preßwerkzeug |

| DE4036915A1 (de) * | 1990-11-20 | 1992-05-21 | Chiron Werke Gmbh | Werkzeugmaschine und verfahren zum oeffnen und schliessen eines greifers |

| DE9103264U1 (de) * | 1991-03-18 | 1991-06-20 | Hewing GmbH, 4434 Ochtrup | Preßzange für das Verpressen von Rohrverbindungen |

-

1992

- 1992-12-02 DE DE9216369U patent/DE9216369U1/de not_active Expired - Lifetime

-

1993

- 1993-11-25 US US08/448,437 patent/US5697135A/en not_active Expired - Lifetime

- 1993-11-25 DK DK94901870.9T patent/DK0671985T3/da active

- 1993-11-25 HU HU9501521A patent/HUT71167A/hu unknown

- 1993-11-25 CZ CZ951380A patent/CZ282551B6/cs unknown

- 1993-11-25 WO PCT/EP1993/003302 patent/WO1994012297A1/de active IP Right Grant

- 1993-11-25 PL PL93309047A patent/PL171755B1/pl unknown

- 1993-11-25 ES ES94901870T patent/ES2093511T3/es not_active Expired - Lifetime

- 1993-11-25 CA CA002150811A patent/CA2150811C/en not_active Expired - Fee Related

- 1993-11-25 DE DE59303597T patent/DE59303597D1/de not_active Expired - Fee Related

- 1993-11-25 JP JP6512759A patent/JPH08503662A/ja active Pending

- 1993-11-25 BR BR9307578-2A patent/BR9307578A/pt not_active Application Discontinuation

- 1993-11-25 AT AT94901870T patent/ATE141835T1/de not_active IP Right Cessation

- 1993-11-25 SK SK665-95A patent/SK66595A3/sk unknown

- 1993-11-25 EP EP94901870A patent/EP0671985B1/de not_active Expired - Lifetime

- 1993-11-25 NZ NZ258548A patent/NZ258548A/en unknown

- 1993-11-25 AU AU56273/94A patent/AU669039B2/en not_active Ceased

- 1993-12-01 CN CN93120082A patent/CN1093957A/zh active Pending

-

1995

- 1995-06-01 NO NO952176A patent/NO952176D0/no unknown

- 1995-06-01 FI FI952672A patent/FI952672A/fi not_active Application Discontinuation

-

1996

- 1996-10-10 GR GR960402688T patent/GR3021325T3/el unknown

Also Published As

| Publication number | Publication date |

|---|---|

| CZ138095A3 (en) | 1996-04-17 |

| FI952672A0 (fi) | 1995-06-01 |

| ATE141835T1 (de) | 1996-09-15 |

| CA2150811C (en) | 2001-05-29 |

| PL309047A1 (en) | 1995-09-18 |

| NZ258548A (en) | 1997-07-27 |

| EP0671985A1 (de) | 1995-09-20 |

| HUT71167A (en) | 1995-11-28 |

| AU5627394A (en) | 1994-06-22 |

| CN1093957A (zh) | 1994-10-26 |

| DK0671985T3 (da) | 1996-12-02 |

| NO952176L (no) | 1995-06-01 |

| DE9216369U1 (de) | 1993-02-04 |

| NO952176D0 (no) | 1995-06-01 |

| AU669039B2 (en) | 1996-05-23 |

| DE59303597D1 (de) | 1996-10-02 |

| JPH08503662A (ja) | 1996-04-23 |

| BR9307578A (pt) | 1999-08-31 |

| US5697135A (en) | 1997-12-16 |

| CZ282551B6 (cs) | 1997-08-13 |

| ES2093511T3 (es) | 1996-12-16 |

| SK66595A3 (en) | 1996-03-06 |

| CA2150811A1 (en) | 1994-06-09 |

| FI952672A (fi) | 1995-06-01 |

| WO1994012297A1 (de) | 1994-06-09 |

| PL171755B1 (pl) | 1997-06-30 |

| GR3021325T3 (en) | 1997-01-31 |

| HU9501521D0 (en) | 1995-07-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0671985B1 (de) | Presswerkzeug | |

| EP0671984B1 (de) | Presswerkzeug | |

| DE69810362T2 (de) | Dichtverbindung zwischen Fluidbohrungen | |

| DE2911708C2 (de) | Rohrverbindungsanordnung, insbesondere für Gasrohrleitungsnetze oder dergleichen, und Verfahren und Vorrichtung zur Herstellung von derartigen Rohrverbindungsanordnungen | |

| EP0452791A1 (de) | Presswerkzeug | |

| DE60305236T2 (de) | Verbindungsvorrichtung zur Verbindung von zwei Rohren | |

| EP1455969A1 (de) | Pressvorrichtung | |

| DE1934339A1 (de) | Verfahren und Vorrichtung zum dauerhaften Verbinden von umlaufenden Teilen,wie Wellenteilen od.dgl.,mittels Kerbverzahnung | |

| WO2016202478A1 (de) | Schelle mit schellenband und vorpositionierer | |

| DE19701857C2 (de) | Geschlitzter Befestigungsring | |

| DE3226868A1 (de) | Dauerhaft dichte gewindelose rohrverbindung | |

| EP0774611A1 (de) | Verfahren zur Herstellung einer Rohrverbindung sowie Kupplungsvorrichtung für die Herstellung einer Rohrverbindung | |

| DE1450396A1 (de) | Dichtverbindung fuer stroemungsfaehige Medien | |

| EP1793155B1 (de) | Rohrschelle, insbesondere Anbohrschelle | |

| EP1535677B1 (de) | Presswerkzeug | |

| CH656199A5 (de) | Verbindungselement zum kuppeln zweier flansche. | |

| DE69121548T2 (de) | Verbesserte Bandschelle mit keilförmigen, geschlitzten Nocken | |

| DE2133446A1 (de) | Axialspannfutter | |

| WO2003062694A1 (de) | Rohrpresskupplung | |

| DE29517518U1 (de) | Preßwerkzeug | |

| DE102020131455B4 (de) | Verbindungssystem | |

| EP0554699B1 (de) | Vorrichtung zum Runddrücken von Rohren | |

| WO1996021531A1 (de) | Verfahren zum verbinden eines pressfittings mit einem rohrende sowie pressgerät zur durchführung dieses verfahrens | |

| DE2545518A1 (de) | Rohrklemm- und dichtungskupplung fuer unterwasser-pipelines | |

| DE3043423C2 (de) | Flanschlose Rohrverbindung zum dichten Verbinden der Enden von Rohrleitungen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19950512 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI NL PT SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19960215 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 141835 Country of ref document: AT Date of ref document: 19960915 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 59303597 Country of ref document: DE Date of ref document: 19961002 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19961003 |

|

| ITF | It: translation for a ep patent filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 19961118 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 19961125 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19961127 Year of fee payment: 4 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2093511 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3021325 |

|

| SC4A | Pt: translation is available |

Free format text: 961004 AVAILABILITY OF NATIONAL TRANSLATION |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980531 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 19980531 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19991119 Year of fee payment: 7 Ref country code: AT Payment date: 19991119 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19991122 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19991123 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19991125 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 20001129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001130 |

|

| BERE | Be: lapsed |

Owner name: NOVOPRESS G.M.B.H. PRESSEN UND PRESSWERKZEUGE & C Effective date: 20001130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010601 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 94901870.9 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20010601 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20011102 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20011113 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20011119 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20011126 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030603 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20011214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051125 |