EP0631096B2 - Bac de réserve de neige carbonique - Google Patents

Bac de réserve de neige carbonique Download PDFInfo

- Publication number

- EP0631096B2 EP0631096B2 EP94401392A EP94401392A EP0631096B2 EP 0631096 B2 EP0631096 B2 EP 0631096B2 EP 94401392 A EP94401392 A EP 94401392A EP 94401392 A EP94401392 A EP 94401392A EP 0631096 B2 EP0631096 B2 EP 0631096B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- tank

- liquid

- injector

- upper wall

- towards

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 title claims description 43

- 229910002092 carbon dioxide Inorganic materials 0.000 title claims description 18

- 239000001569 carbon dioxide Substances 0.000 title claims description 14

- 239000007788 liquid Substances 0.000 claims description 16

- 239000007787 solid Substances 0.000 claims description 5

- 238000002347 injection Methods 0.000 description 15

- 239000007924 injection Substances 0.000 description 15

- 235000011089 carbon dioxide Nutrition 0.000 description 11

- 238000003860 storage Methods 0.000 description 6

- 235000013305 food Nutrition 0.000 description 5

- 238000009434 installation Methods 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000008878 coupling Effects 0.000 description 3

- 238000010168 coupling process Methods 0.000 description 3

- 238000005859 coupling reaction Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000005057 refrigeration Methods 0.000 description 3

- 239000012530 fluid Substances 0.000 description 2

- 230000015654 memory Effects 0.000 description 2

- 238000000859 sublimation Methods 0.000 description 2

- 230000008022 sublimation Effects 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- 241000287828 Gallus gallus Species 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000009172 bursting Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 235000013330 chicken meat Nutrition 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 235000013611 frozen food Nutrition 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 230000003116 impacting effect Effects 0.000 description 1

- 235000012054 meals Nutrition 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 239000008188 pellet Substances 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000010200 validation analysis Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D29/00—Arrangement or mounting of control or safety devices

- F25D29/001—Arrangement or mounting of control or safety devices for cryogenic fluid systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D3/00—Devices using other cold materials; Devices using cold-storage bodies

- F25D3/12—Devices using other cold materials; Devices using cold-storage bodies using solidified gases, e.g. carbon-dioxide snow

- F25D3/125—Movable containers

Definitions

- the present invention relates to a carbon dioxide snow bin.

- an insulated enclosure is generally used without carbon dioxide snow reserve and previously brought to the refrigerated storage temperature of the products before their storage in the enclosure and the shipment of the loaded enclosure, which requires that the transport time be reduced to a minimum.

- Patent application FR-A-2534130 describes a means allowing the distribution of meals of the kind of those made up by an insulated trolley with a perforated container likely to contain dry ice.

- US-A-3561266 relates to a method and an apparatus for refrigerating truck and truck rooms.

- rail cars used to transport food requiring refrigeration; refrigeration being carried out at by means of a container mounted in said chamber and filled with a block of solid refrigerant.

- Patent application FR-A-2604243 describes, for its part, a manufacturing process, using carbon dioxide liquid, a cold accumulating mass with a clean packaging.

- the subject of the present invention is a storage tank and a reserve of dry ice according to the claim 1 and an insulated transportable enclosure provided with such a tank.

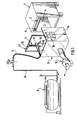

- FIG 1 we recognize a transportable insulated container 1 for the transport of fresh products, as described in document EP-A-337 860 mentioned above. comprising a side access door omitted from the drawing to show the dry ice bin 2 suspended in the upper part of the interior chamber of the container forming a volume 3 of product loading.

- the typically removable heat shield 4. extending at a distance from the inner face of the container 2 and separating the latter from the volume 3 for loading and storing fresh food products.

- the tank 2 is mounted fixed in the container 1 and comprises. in the example shown, a front face provided with an access opening 5 for loading CO 2 from the tank. as we will see later.

- the installation comprises, in a loading station, a tank 6 of liquid CO 2 at a pressure typically between 18 and 20 ⁇ 10 5 Pa and at a temperature of -20 ° C. maintained by a refrigeration unit 7. From the tank 6 leaves a liquid CO 2 supply pipe 8 provided with adequate winnowing, extended by a flexible hose 9 terminated by a distributor means 10 for introducing a flow of liquid CO 2 under pressure into the tank 2 via the opening 5.

- the distributor means 10 in this case in the form of a pistol in the example shown, is suspended by an elastic suspension means 11 from an upper frame 12 secured to an articulated awning structure 13 provided with deployable lateral flaps 14 and intended for be positioned opposite the loading face of the container 1 to form a receptacle for confining the cold gases generated during the loading of the tank 2, which are evacuated to the outside of the work premises by an evacuation device tion 15 comprising a blower.

- the suspension means 11 can be moved along the upper part of the frame 12 by a carriage 16 to allow the correct positioning of the gun 10 opposite the opening 5 of the loading of the tank 2.

- the gun 10 typically comprises a manual closing / opening valve 17 and, upstream of this, a solenoid valve 18 connected to a control unit 19 mounted on the canopy 13.

- the housing command 19 includes adjustable or pre-established time-delay means making it possible to select, according to different parameters, the opening times of the solenoid valve 18, therefore the quantities of liquid CO 2 injected into the tank 2 and, consequently, the quantities of carbon dioxide snow formed by sublimation in the tank.

- This injection is typically carried out so that the liquid CO 2 jet undergoes at least one impact in the tank 2 so as to burst the jet and cause rapid production and accumulation of carbon dioxide snow in the tank.

- FIG. 2 shows a curve showing the carbon dioxide snow formation regime in tank 2 as a function of the time of injection of liquid CO 2 in seconds.

- the container 1 and its container 2 being initially at room temperature, the quantity of carbon dioxide snow formed within 10 seconds of injection cannot be reproducibly determined.

- the points A to D of the curve represent jumps in the transformation rate of liquid / solid CO 2 as and when injected into the tank. At point A, the conversion rate is around 21%. It gradually increases to a value of around 35% up to point B, from which it remains substantially constant up to point C to increase again to a value slightly greater than 40% at point D to remain substantially constant beyond this point D. It is therefore found that an amount of 5 kg of carbon dioxide snow is generated in less than 20 seconds and that an injection time of 25 seconds is sufficient to generate a dry ice mass of 10 kg.

- the flexibility of the method according to the invention makes it possible to easily modulate, depending on predetermined parameters, taking into account in particular the climatic conditions and the planned transport times, the amount of dry ice generated in the container, as well as adapting the amounts of dry ice the storage and transport of fresh food products, the temperature of which must be between 0 and 4 ° C, like frozen products, the temperature of which should not exceed -15 ° C.

- the different injection times can be ored-established in the case 19 and selectable by fresh / frozen, winter / summer or week / weekend switches. These injection times can also be pre-programmed in memories of the housing 19 accessible by dialing codes on a keyboard or by introducing a smart card incorporating such programmable memories (SRAM or EEPROM).

- SRAM programmable memories

- FIG. 3 the temperature variations over time of a steak chopped in an enclosure have been represented. according to the invention (curve 2) and in an enclosure with simple prior cooling of the product and its container (curve 1).

- the heat shield 4 is removably mounted suspended in the upper part of the container 1 for use in the conservation and transport of fresh products, this heat shield being dismantled in the configuration for the storage and transport of frozen products less sensitive to the proximity of the very cold surface formed by the underside of tank 2.

- the tray 2 according to the invention is in the form of a housing closed parallelepiped made of metal sheets, typically stainless steel and comprising in particular a upper wall 20 and a front face 21 crossed, in the vicinity of a side wall 22, by a nozzle 50.

- This nozzle 50 constitutes the extension projecting towards the outside of an injection ramp 23 extending into the housing along the side wall 22 and typically formed, on its side opposite to the wall 22, with a series of evenly distributed ejection orifices 24.

- the ramp 23 supports an L-shaped deflector profile 25 extending parallel to the facing ramp orifices 24.

- the upper wall 20 of the tank 3 has a central cutout covered with a grid 26 so to provide, on either side of the grid 26, a first solid zone 20A overhanging the injection rail assembly 23 / deflector 25 and a second symmetrical full zone 20B.

- the orifices 24 are oriented so as to each eject a jet of liquid CO 2 towards the bottom wall of the tank 2, this jet being returned, by the deflector 25 placed under the orifices 24, towards the full veil part 20A of the upper wall 20 and from there towards the bottom of the housing under the second full veil part 20B, opposite the injection ramp 23, where it gradually accumulates, by sublimation , a mass of dry ice 27, the CO 2 vaporized during the constitution of this mass 27 escaping, as shown by the arrows dashed in FIG. 5, by the mesh 26 and spreading in the interior space 3 of the container 1 to cool the latter, before being evacuated by the hood 13.

- the tank 2 also has fixing lugs 28 for its permanent mounting in the upper part of the interior volume 3, typically on vertical posts also used for mounting removable screen thermal 4 extending below the tank 2, at a distance from the latter, when the container 1 is used for the transport of fresh food products at a temperature between 0 and 4 ° C.

- the distributor means 10 suspended from the gantry 12, is internally shaped to adapt by simply plugging in the end piece 50, this plugging being locked by an elastic lock 29 which can be actuated manually to unlock the gun and extract it from the nozzle 50.

- the crankcase of the tap 17 is also coupled mechanically to the latch 29 so as to allow the valve to be opened only when the connector 10 is correctly plugged into the nozzle 50 and only allow plugging in when the tap is in the closed position.

- the tray 2 has no front face, thus providing a wide access opening 5 for pairing with a distributor means 10, also suspended from the gantry 12 and comprising, here, a parallelepipedal injection box 30 comprising an open front face and two injection half-ramps 23A, 23B extending transversely in the housing 30, provided with ejection orifices 24 and connected, via the solenoid valve 18, to the supply hose 9.

- a distributor means 10 also suspended from the gantry 12 and comprising, here, a parallelepipedal injection box 30 comprising an open front face and two injection half-ramps 23A, 23B extending transversely in the housing 30, provided with ejection orifices 24 and connected, via the solenoid valve 18, to the supply hose 9.

- the ramps 23A, 23B are arranged in the bottom of the housing 30, at a distance of the open front face of the case, the edges of which are provided with angles 31 forming a housing for receiving the edges of the front face of tank 2 in a position of coupling of these two elements locked by a device coupling 32 constituted, in the example shown, by a lock movable in rotation and in translation carried by a side face of the housing 30 and cooperating with a shaped cut formed in a cylinder attached to the adjacent side face of tank 2.

- the lock comprises an actuating handle which, in the locked position of the lock, actuates a contactor 33 mounted on the inside of the housing 30 and providing a validation signal to the block electronic control unit 19.

- the housing 30 advantageously comprises, on its rear face, a handling handle 34.

- the injectors 24 are angularly oriented towards the upper wall of the housing 30 so as to eject jets of liquid CO 2 under pressure from impacting this upper wall to return, by bursting, the jets of Liquid CO 2 towards the bottom of the tank 2 where the liquid CO 2 , relaxed in its path with ricochet, produces the carbon dioxide snow finely divided 27 gradually accumulating in the bottom of the tank 2, as in the embodiment Figures 4 and 5.

- the injectors 24 can be oriented downward to impact a deflector returning the jets to the upper wall of the housing.

- an end-of-cycle indicator lamp lights up on the block 19 and the operator can then come and unhook the box 30 from the tank 2.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Freezing, Cooling And Drying Of Foods (AREA)

- Carbon And Carbon Compounds (AREA)

Description

- la figure 1 est une vue schématique d'une installation pouvant utiliser un bac selon l'invention ;

- la figure 2 est un graphe illustrant la production de neige carbonique avec un procédé d'injection;

- la figure 3 est un graphe comparatif montrant l'évolution de la température de produits frais dans une enceinte chargée en neige carbonique selon l'invention et une enceinte dépourvue de charge de neige carbonique;

- la figure 4 est une vue schématique en perspective, partiellement en écorché, d'un bac selon un mode de réalisation particulier de l'invention ;

- la figure 5 est une vue en coupe transversale, suivant la ligne V-V de la figure 4, du bac selon l'invention montrant le trajet des fluides dans le bac lors du chargement de ce dernier;

- la figure 6 est une vue analogue à la figure 1 montrant une installation;

- la figure 7 est une vue en coupe transversale du boítier distributeur/injecteur de la figure 6 ;

- la figure 8 est une vue en perspective montrant l'accouplement du boítier et du bac ; et

- la figure 9 est une vue schématique en coupe longitudinale de l'ensemble accouplé de la figure 8 montrant le trajet des fluides lors du chargement du bac.

| Temps d'injection CO2 secondes | Neige carbonique engendrée | |

| PRODUITS FRAIS | ||

| Transport hiver | 15 s | 4,88 kg |

| Transport été | 20 s | 5,86 kg |

| Transport week-end | 30 s | 9,32 kg |

| PRODUITS SURGELES | ||

| Transport hiver | 30 s | 9,32 kg |

| Transport été | 40 s | 12,42 kg |

| Transport week-end | 50 s | 15,88 kg |

Claims (5)

- Bac de réserve de neige carbonique destiné à être disposé dans une enceinte isolée (1) de conservation de produits, se présentant sous la forme d'un boítier clos (2) comportant une paroi supérieure (20) munie d'au moins une ouverture (26) et une face latérale avant (21) traversée par un embout (50) relié à au moins un injecteur (23) disposé dans le boítier et destiné au raccordement de l'injecteur à un circuit (9) d'amenée de CO2 liquide sou pression, ledit bac ayant une configuration générale parallélépipédique, l'injecteur (23) étant disposé au voisinage d'une face latérale (22) du bac (2) et présentant au moins un orifice d'éjection (24) orienté pour diriger un jet de CO2 liquide vers l'intérieur du bac caractérisé en ce qu'il comporte un déflecteur (25) associé à l'injecteur (23), l'orifice d'éjection (24) étant orienté pour dirigé le jet de CO2 liquide vers le déflecteur (25), et en ce que la paroi supérieure (20) comprend une première partie pleine (20A) recouvrant la zone de l'injecteur (23), l'orifice (24) étant dirigé vers la paroi inférieure du boítier et le déflecteur (25) étant agencé pour renvoyer le jet de CO2 liquide vers la première partie pleine (20A) de la paroi supérieure (20).

- Bac selon la revendication 1, caractérisé en ce que l'ouverture (26) de la paroi supérieure (20) est grillagée.

- Enceinte isolée transportable comportant un bac selon l'une des revendications 1 ou 2, monté à demeure dans l'enceinte (1).

- Enceinte selon la revendication 3, caractérisée en ce qu'elle comporte , entre le bac (2) et un volume interne de chargement de produits (3), un écran thermique amovible (4).

- Enceinte selon la revendication 4, caractérisée en ce qu'elle comporte une ouverture latérale obturable d'accès au volume interne et au bac (2).

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9307615A FR2706990B1 (fr) | 1993-06-23 | 1993-06-23 | |

| FR9307615 | 1993-06-23 | ||

| US08/285,718 US5511379A (en) | 1993-06-23 | 1994-08-04 | Process for the preservation of products at low temperature in an insulated chamber, installation for practicing the process, insulated chamber and container for such a chamber |

| CA002129863A CA2129863A1 (fr) | 1993-06-23 | 1994-08-10 | Procede de conservation a basse temperature de produits dans une enceinte isolee, installation pour la mise en oeuvre du procede, enceinte isolee et bac pour une telle enceinte |

| CH02814/94A CH690458A5 (fr) | 1993-06-23 | 1994-09-15 | Procédé de conservation à basse température de produits dans une enceinte isolée, installation pour la mise en oeuvre du procédé, enceinte isolée et bac pour une telle enceinte. |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0631096A1 EP0631096A1 (fr) | 1994-12-28 |

| EP0631096B1 EP0631096B1 (fr) | 1997-07-16 |

| EP0631096B2 true EP0631096B2 (fr) | 2001-02-07 |

Family

ID=27427162

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94401392A Expired - Lifetime EP0631096B2 (fr) | 1993-06-23 | 1994-06-22 | Bac de réserve de neige carbonique |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US5511379A (fr) |

| EP (1) | EP0631096B2 (fr) |

| CA (1) | CA2129863A1 (fr) |

| CH (1) | CH690458A5 (fr) |

| DE (1) | DE69404231T3 (fr) |

| ES (1) | ES2106468T5 (fr) |

| FR (1) | FR2706990B1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2025249A1 (fr) | 2007-07-31 | 2009-02-18 | Konings NV | Procédé de refroidissement de boissons |

Families Citing this family (48)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2867116B2 (ja) * | 1994-12-12 | 1999-03-08 | 株式会社コルポ | 低温保存品収納用コンテナ及びコンテナ冷却装置 |

| FR2734894B1 (fr) * | 1995-05-30 | 1997-07-25 | Carboxyque Francaise | Installation pour le maintien a basse temperature d'une enceinte mobile |

| FR2751623B1 (fr) * | 1996-07-23 | 1998-09-04 | Olivo | Conteneur isotherme avec bac refrigerant |

| FR2752049B1 (fr) * | 1996-07-30 | 1998-09-11 | Olivo | Conteneur isotherme avec reserve de frigories |

| FR2752456B1 (fr) * | 1996-08-13 | 1999-01-08 | Grandi Rene Vincent | Dispositif pour le transfert regule de frigories entre une reserve et une enceinte de conservation |

| FR2758620B1 (fr) | 1997-01-20 | 1999-02-26 | Carboxyque Francaise | Bac de reception de neige carbonique, et son application a une enceinte et une installation de conservation de produits |

| IT1291165B1 (it) | 1997-03-05 | 1998-12-29 | Monetti Spa | Recipiente di refrigerante solido per contenitori isotermici, particolarmente per il trasporto di prodotti a temperatura |

| FR2760826B1 (fr) | 1997-03-11 | 1999-04-23 | Carboxyque Francaise | Chariot refrigere et installation de rechargement en agent refrigerant |

| DE19749055C2 (de) * | 1997-11-06 | 2003-05-08 | Messer France Sa | Behälter zum Kühlen |

| DE19808267A1 (de) * | 1998-02-27 | 1999-09-02 | Messer France Sa | Befüll- und Entnahmemodul für ein Kühlmodul und Verfahren zum Befüllen eines Kühlmoduls |

| FR2776056B1 (fr) * | 1998-03-10 | 2000-05-26 | Olivo | Dispositif brise-jet pour compartiment cryogenique de conteneur isothermique |

| EP0964214A1 (fr) * | 1998-06-11 | 1999-12-15 | Colpo Company Limited | Système de réfrigération compact pour conteneurs et procédé de conservation du froid |

| US6220051B1 (en) | 1998-06-16 | 2001-04-24 | Cool Pack System Corp. | Compact rapid chilling system and method for reserving cold |

| NO982971A (no) * | 1998-06-26 | 1999-12-27 | H&R Ind Inc | Fremgangsmåte for transport og lagring av varer, samt container egnet for samme |

| JP3247675B2 (ja) * | 1999-02-03 | 2002-01-21 | 角林商事株式会社 | ドライアイス生成装置 |

| US6151913A (en) * | 1999-04-23 | 2000-11-28 | Praxair Technology, Inc. | Method and apparatus for agglomerating fine snow particles |

| DE19919934A1 (de) * | 1999-04-30 | 2000-11-02 | Tv Kohlensaeure Technik & Vert | Vorrichtung und Verfahren zur Temperaturhaltung von Lebensmitteln |

| US6276169B1 (en) * | 1999-10-04 | 2001-08-21 | Eco-Snow Systems, Inc. | Apparatus and method for analysis of impurities in liquid carbon dioxide |

| DE10045869A1 (de) * | 2000-09-14 | 2002-03-28 | Tv Kohlensaeure Technik & Vert | Vorrichtung und Verfahren zur Erzeugung von Kohlendioxidschnee |

| DE10129217B4 (de) * | 2001-06-19 | 2006-07-06 | Air Liquide Deutschland Gmbh | Verfahren zum Kühlen von Waren in einem Isolierbehälter unter Einsatz eines Kühlmoduls |

| FR2829567B1 (fr) * | 2001-09-07 | 2004-07-16 | Olivo | Dispositif d'alimentation automatique pour compartiment refrigerant d'un conteneur isotherme |

| US6584802B1 (en) * | 2002-04-16 | 2003-07-01 | Monty J. Cofield | Cooling apparatus employing carbon dioxide |

| DE10247489A1 (de) * | 2002-10-11 | 2004-04-22 | Messer Griesheim Gmbh | Verfahren und Vorrichtung zum Kühlen von Waren in einem wärmeisolierten Transportbehälter unter Einsatz eines Kühlmoduls |

| US7228793B2 (en) * | 2002-11-25 | 2007-06-12 | Fizzy Fruit, LLC | Carbonation system for enhancing the flavor of fruits and vegetables |

| DE10258419A1 (de) | 2002-12-13 | 2004-06-24 | TV Kohlensäure Technik & Vertrieb GmbH + Co. | Versorgung einer Einrichtung zur Temperaturhaltung mit Kohlendioxidschnee |

| WO2004071279A2 (fr) * | 2003-02-07 | 2004-08-26 | Alfred E. Mann Institute For Biomedical Engineering At The University Of Southern California | Drain chirurgical muni de capteurs servant a surveiller l'etat tissulaire interne ainsi qu'un fluide dans une lumiere |

| US20060233922A1 (en) * | 2004-05-28 | 2006-10-19 | Andrew Kegler | Packaged flavor enhanced fruits or vegetables products with extended shelf-life for mass market distribution and consumption |

| US20070292568A1 (en) * | 2006-06-14 | 2007-12-20 | Kaufman Galen D | Dynamic modified atmosphere package system |

| ES2334487B1 (es) * | 2009-03-30 | 2011-02-03 | Gaugor, S.A. | Conjunto de acoplamiento para extraccion de co2 liquido, aplicable a todo tipo de enfriadores. |

| EP2418446A1 (fr) * | 2009-03-18 | 2012-02-15 | Gaugor, S.a. | Appareil ameliore pour le refroidissement de verres ou d'autres recipients, et ensemble de raccordement pour l'extraction de co2 liquide |

| FR2952709B1 (fr) | 2009-11-19 | 2011-12-02 | Air Liquide | Procede pour conserver a basse temperature des produits dans un conteneur isole durant un transport |

| DE102010013056B4 (de) | 2010-03-26 | 2018-05-09 | Tkt Gassysteme Gmbh | Verfahren und Vorrichtung zum Befüllen einer Kühlzelle eines Isolierbehälters mit einem Kühlmedium |

| DE102010013079A1 (de) | 2010-03-26 | 2011-09-29 | Tkt Gassysteme Gmbh | Isolierbehälter |

| PT2673575T (pt) * | 2011-02-09 | 2020-11-10 | Acp Belgium N V | Sistema para introduzir um agente refrigerante num recipiente |

| DE102011119526A1 (de) * | 2011-11-26 | 2013-05-29 | Messer Austria Gmbh | Verfahren zum Befüllen eines einem Transportbehälter zum Transportieren gekühlter Produkte zugeordneten Kühlmoduls |

| DE102011121013A1 (de) | 2011-12-13 | 2013-06-13 | Linde Aktiengesellschaft | Vorrichtung und Verfahren zurTemperaturhaltung |

| FR2984473B1 (fr) | 2011-12-15 | 2014-01-24 | Acp Belgium N V /S A | Procede de conservation a basse temperature de produits dans une enceinte isolee |

| DE102012006478A1 (de) | 2012-03-29 | 2013-10-02 | Linde Aktiengesellschaft | Kühlmittelbehälter, Vorrichtung und Verfahren zur Temperaturhaltung |

| EP2881646A1 (fr) | 2013-12-05 | 2015-06-10 | YARA International ASA | Procédé et système permettant de remplir des contenants thermiquement isolés avec du dioxyde de carbone liquide |

| US11384904B2 (en) | 2013-12-05 | 2022-07-12 | Praxair Technology, Inc. | Method and system for filling thermally insulated containers with liquid carbon dioxide |

| EP3090961B1 (fr) | 2015-05-07 | 2019-02-27 | Air Liquide Deutschland GmbH | Boîte de refroidissement et procédé de transport de produits sensibles à la chaleur ou périssables dans un véhicule de transport et/ou pour distribuer des produits aux clients finaux |

| US10712072B2 (en) | 2016-07-11 | 2020-07-14 | Praxair Technology, Inc. | Transportable container, charger system, method and kit for generation of carbon dioxide snow block in-situ within the transportable container for preservation of items stored therewithin |

| US11248838B2 (en) | 2016-07-11 | 2022-02-15 | Praxair Technology, Inc. | Transportable container, charger system, method and kit for generation of carbon dioxide snow block in-situ within the transportable container for preservation of items stored there within |

| US11352262B2 (en) | 2017-12-18 | 2022-06-07 | Praxair Technology, Inc. | Methods for automatic filling, charging and dispensing carbon dioxide snow block |

| US11193708B2 (en) | 2017-12-20 | 2021-12-07 | Praxair Technology, Inc. | Methods for pre-charging carbon dioxide snow |

| EP3653976B1 (fr) | 2018-11-16 | 2021-06-30 | Neopost Technologies | Système de consigne pour la livraison des produits sensibles à la chaleur |

| DE102018009755B4 (de) * | 2018-12-12 | 2020-12-03 | Messer Group Gmbh | Vorrichtung zum Beladen eines Kältemittel-Aufnahmefachs eines Kühlbehälters mit Trockeneis |

| CN112317745B (zh) * | 2020-09-22 | 2022-05-10 | 成都飞机工业(集团)有限责任公司 | 一种自动化增材制造粉末存储装置及存储方法 |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1876915A (en) * | 1929-05-14 | 1932-09-13 | Internat Dry Refrigeration Cor | Refrigerator |

| US2217169A (en) * | 1937-11-29 | 1940-10-08 | Leo M Harvey | Machine for forming solid carbon dioxide |

| US2316423A (en) * | 1939-06-23 | 1943-04-13 | Leo M Harvey | Device for providing refrigerants in containers |

| US3163022A (en) * | 1963-01-21 | 1964-12-29 | Z Z Corp | Refrigeration system employing expendable refrigerant |

| US3447336A (en) * | 1967-09-22 | 1969-06-03 | Pullman Inc | Refrigeration arrangement |

| US3468135A (en) * | 1968-01-02 | 1969-09-23 | Brendan L Doll | Food chilling using carbon dioxide refrigerant |

| US3561226A (en) * | 1968-10-07 | 1971-02-09 | Julius Rubin | Refrigerating system for transportable vehicles |

| US3861168A (en) * | 1973-09-17 | 1975-01-21 | Union Ice Company | Carbon dioxide cooling machine |

| US3922878A (en) * | 1974-01-11 | 1975-12-02 | Karchay Javid Jalali | Portable cooling unit |

| DE2634164A1 (de) * | 1976-07-29 | 1978-02-09 | Buse Kohlensaeure | Vorrichtung zum beschneien von gegenstaenden mit kohlensaeureschnee |

| US4415346A (en) * | 1978-10-11 | 1983-11-15 | Love James H | Carbon dioxide snow horn for dry ice production |

| US4299429A (en) * | 1980-02-13 | 1981-11-10 | Franklin Jr Paul R | Cooler with inclined upper CO2 cooled surface |

| US4376511A (en) * | 1981-04-01 | 1983-03-15 | Franklin Jr Paul R | CO2 Snow forming copper line |

| US4377402A (en) * | 1981-06-01 | 1983-03-22 | Liquid Carbonic Corporation | CO2 Snow-making process |

| FR2534130B1 (fr) * | 1982-10-08 | 1986-10-17 | Beizermann Michel | Chariot de stockage des repas avant rechauffage et moyens de mise en oeuvre |

| US4502293A (en) * | 1984-03-13 | 1985-03-05 | Franklin Jr Paul R | Container CO2 cooling system |

| US4704876A (en) * | 1986-08-12 | 1987-11-10 | Hill Ralph P | Cryogenic refrigeration system |

| FR2604243B3 (fr) * | 1986-09-19 | 1988-12-23 | Anhydride Carbonique Ind | Procede de fabrication d'une masse accumulatrice de froid a partir d'anhydride carbonique et accumulateur obtenu. |

| EP0337860B1 (fr) * | 1988-04-08 | 1996-05-22 | Carboxyque Francaise | Conteneur isotherme à réservoir de produit réfrigérant et application au transport de produits frais |

| US4891954A (en) * | 1989-01-19 | 1990-01-09 | Sheffield Shipping & Management Ltd. | Refrigerated container |

| ZW7192A1 (en) * | 1991-06-28 | 1992-08-08 | African Oxygen Ltd | A method and means for providing refrigeration |

-

1993

- 1993-06-23 FR FR9307615A patent/FR2706990B1/fr not_active Expired - Lifetime

-

1994

- 1994-06-22 DE DE69404231T patent/DE69404231T3/de not_active Expired - Lifetime

- 1994-06-22 EP EP94401392A patent/EP0631096B2/fr not_active Expired - Lifetime

- 1994-06-22 ES ES94401392T patent/ES2106468T5/es not_active Expired - Lifetime

- 1994-08-04 US US08/285,718 patent/US5511379A/en not_active Expired - Fee Related

- 1994-08-10 CA CA002129863A patent/CA2129863A1/fr not_active Abandoned

- 1994-09-15 CH CH02814/94A patent/CH690458A5/fr not_active IP Right Cessation

-

1996

- 1996-02-01 US US08/595,260 patent/US5566553A/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2025249A1 (fr) | 2007-07-31 | 2009-02-18 | Konings NV | Procédé de refroidissement de boissons |

Also Published As

| Publication number | Publication date |

|---|---|

| US5511379A (en) | 1996-04-30 |

| DE69404231T2 (de) | 1997-12-18 |

| EP0631096B1 (fr) | 1997-07-16 |

| DE69404231D1 (de) | 1997-08-21 |

| US5566553A (en) | 1996-10-22 |

| FR2706990A1 (fr) | 1994-12-30 |

| ES2106468T5 (es) | 2001-03-16 |

| DE69404231T3 (de) | 2001-05-23 |

| ES2106468T3 (es) | 1997-11-01 |

| EP0631096A1 (fr) | 1994-12-28 |

| CA2129863A1 (fr) | 1996-02-11 |

| CH690458A5 (fr) | 2000-09-15 |

| FR2706990B1 (fr) | 1995-08-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0631096B2 (fr) | Bac de réserve de neige carbonique | |

| JP6189917B2 (ja) | 流動触媒分解ユニット内に触媒及び/又は添加物を注入するための方法 | |

| US4502293A (en) | Container CO2 cooling system | |

| EP0854334A1 (fr) | Bac de réception de neige carbonique | |

| EP0069688A2 (fr) | Procédé de surgélation et de conditionnement de produits individuels, et dispositif pour la mise en oeuvre de ce procédé | |

| EP1350743B1 (fr) | Procédé et dispositif de remplissage automatique d'un bac chauffant avec un produit solide | |

| EP0745816B1 (fr) | Installation pour le maintien à basse température d'une enceinte mobile | |

| FR2558337A1 (fr) | Dispositif de congelation de produits biologiques conditionnes en paillettes | |

| EP0968395B1 (fr) | Chariot refrigere | |

| FR2891899A1 (fr) | Systeme d'injection de neige carbonique dans des conteneurs isothermes et conteneurs associes | |

| EP1209420B1 (fr) | Dispositif d'évacuation de vapeur d'eau destiné à un four de cuisson à la vapeur | |

| FR2616683A1 (fr) | Autoclave de sterilisation | |

| WO2007036656A1 (fr) | Receptacle de neige carbonique a double compartiment pour conteneurs isothermes | |

| FR2963327A1 (fr) | Dispositif de stockage d'articles sous atmosphere controlee | |

| US5429269A (en) | Ice cube containing and dispensing device | |

| FR2726353A1 (fr) | Procede de dosage automatique pour conserver a basse temperature des produits dans une enceinte isolee comprenant un volume de chargement et au moins un bac a neige carbonique | |

| KR101153749B1 (ko) | 냉원용 이산화탄소 자동주입장치 및 자동주입방법 | |

| KR20000014944U (ko) | 얼음컵 성형 및 보관장치 | |

| EP1152198B1 (fr) | Dispositif de refroidissement en ligne | |

| RU1811360C (ru) | Хранилище дл овощей | |

| FR2579734A1 (fr) | Armoire frigorifique | |

| FR2544846A1 (fr) | Unite autonome de production de glace en pain notamment | |

| FR2565336A1 (fr) | Machine de production de neige carbonique | |

| BE515252A (fr) | ||

| CA2111430A1 (fr) | Tremie pour vis a grain |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19940628 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE ES GB IT NL PT |

|

| 17Q | First examination report despatched |

Effective date: 19960607 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE ES GB IT NL PT |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19970716 |

|

| REF | Corresponds to: |

Ref document number: 69404231 Country of ref document: DE Date of ref document: 19970821 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2106468 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19970723 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: LINDE AKTIENGESELLSCHAFT Effective date: 19980415 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: LINDE AKTIENGESELLSCHAFT |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| RTI2 | Title (correction) |

Free format text: RESERVE TANK FOR CARBON DIOXIDE SNOW |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20010207 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): BE DE ES GB IT NL PT |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Kind code of ref document: T5 Effective date: 20010213 |

|

| NLR2 | Nl: decision of opposition | ||

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 69404231 Country of ref document: DE Representative=s name: PATENTANWAELTE HENKEL, BREUER & PARTNER, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20120615 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20130620 Year of fee payment: 20 Ref country code: GB Payment date: 20130619 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20130618 Year of fee payment: 20 Ref country code: NL Payment date: 20130619 Year of fee payment: 20 Ref country code: IT Payment date: 20130626 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20130619 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69404231 Country of ref document: DE |

|

| BE20 | Be: patent expired |

Owner name: *CARBOXYQUE FRANCAISE Effective date: 20140622 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: MAXIMUM VALIDITY LIMIT REACHED Effective date: 20140622 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V4 Effective date: 20140622 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20140621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20140621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20140624 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20141120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20140701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20140623 |