EP0623905A2 - Détecteur de mouvement - Google Patents

Détecteur de mouvement Download PDFInfo

- Publication number

- EP0623905A2 EP0623905A2 EP94106652A EP94106652A EP0623905A2 EP 0623905 A2 EP0623905 A2 EP 0623905A2 EP 94106652 A EP94106652 A EP 94106652A EP 94106652 A EP94106652 A EP 94106652A EP 0623905 A2 EP0623905 A2 EP 0623905A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- beam splitter

- sensor

- radiation

- motion detector

- infrared

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- G—PHYSICS

- G08—SIGNALLING

- G08B—SIGNALLING OR CALLING SYSTEMS; ORDER TELEGRAPHS; ALARM SYSTEMS

- G08B13/00—Burglar, theft or intruder alarms

- G08B13/18—Actuation by interference with heat, light, or radiation of shorter wavelength; Actuation by intruding sources of heat, light, or radiation of shorter wavelength

- G08B13/189—Actuation by interference with heat, light, or radiation of shorter wavelength; Actuation by intruding sources of heat, light, or radiation of shorter wavelength using passive radiation detection systems

- G08B13/19—Actuation by interference with heat, light, or radiation of shorter wavelength; Actuation by intruding sources of heat, light, or radiation of shorter wavelength using passive radiation detection systems using infrared-radiation detection systems

- G08B13/193—Actuation by interference with heat, light, or radiation of shorter wavelength; Actuation by intruding sources of heat, light, or radiation of shorter wavelength using passive radiation detection systems using infrared-radiation detection systems using focusing means

Definitions

- the invention relates to an infrared motion detector with an arc-shaped lens screen mounted in front of an infrared sensor, the lenses of which each capture a monitoring area and focus the radiation from an infrared source located in the monitoring area onto the infrared sensor, the area in the middle of the Lenses located on the lens shield throw the incident radiation directly onto the infrared sensor, while laterally incident marginal rays are directed onto the sensor by reflection.

- a passive infrared motion detector is known from EP-PS 0 113 468, which has a symmetrical mirror arrangement of two opposing mirrors, with which a folded beam path is generated and with which the laterally incident edge radiation is deflected onto the infrared sensor.

- the azimuth angle of the motion detector can be reached, which is approx. 180 °.

- This angle can be increased by an appropriate design of the lenses in the lateral area of the lens screen.

- infrared sources can be detected that are present in a range of more than 180 ° around the infrared sensor, that is, also infrared sources that are already slightly behind the level of the infrared sensor.

- a disadvantage of the mirror arrangement is that it "stands in the way" of the sensor in that the rear of the mirror switches off part of the monitoring areas and thus shadow areas occur in front of the sensor in which the motion detector is ineffective.

- the shadow areas become larger the more monitoring areas behind the sensor are to be detected.

- the mirrors are therefore moved to achieve a relatively large azimuth angle in the elevation area of the motion detector, which results in a very small elevation angle. Therefore, the area perpendicular to that under the motion detector cannot be detected in the known motion detector.

- the object of the invention is to provide a motion detector of the type described in the introduction, in which dead areas or blanking in the monitoring areas are avoided and in which an expansion of the monitoring area to radiation sources located behind the sensor is achieved in a simple manner.

- Beam splitters make it possible to split a luminous flux or another radiation, for example infrared radiation, into two identical or unequal partial beam currents. This means that, in contrast to the mirror with a degree of transmission 0 and a degree of reflection of approx. 95%, transmission radiation and reflection radiation always occur with a beam splitter.

- the transmission radiation can be directed onto the sensor, even if the beam splitter lies directly in the incident beam path of the sensor.

- the attenuation of the radiation by loss of transmission or reflection can be compensated for by a corresponding enlargement of the lenses of the lens screen located in this area.

- the use of beam splitters in general, and of geometric or physical beam splitters in particular avoids complicated optical measures for the purpose of deflecting the radiation onto the sensor. Even in the case of multiple transmission or multiple reflection of the incident radiation through or at beam splitters, the residual radiation can still be directed to the sensor in an evaluable size.

- both a detection angle in the azimuth range of more than 180 °, for example 220 °, and an increase in the detection angle in the elevation range compared to the known motion detector can be achieved.

- detection angles of more than 180 °, for example of 220 ° can also be achieved in the elevation range, so that all-round reception is made possible.

- an inclined plane-parallel beam splitter element is arranged in front of the infrared sensor, which is located directly in the beam path between the central region of the lens shield and the infrared sensor (claim 1).

- the lenses located in the central area of the lens screen throw the incident infrared radiation through the beam splitter directly onto the infrared sensor, while the edge radiation from an edge area of the lens screen adjacent to the central area is directed through the beam splitter according to its degree of reflection onto the infrared Detector is deflected, specifically from the edge region of the lens screen, to which the beam splitter element is arranged inclined.

- the central area of the lens screen is limited by the detection angle specified by the infrared sensor, then the overall monitoring area is extended to the edge area of the lens screen by this arrangement.

- a motion detector can, for example, detect areas facing forwards and areas pointing vertically downwards, as a result of which creep protection is achieved.

- the density of the monitoring areas is determined by the number of lenses of the lens screen. The greater the density of the monitoring areas, the more lenses the lens screen has. It follows from this that in the beam path of each lens of the area, side incident incident radiation, that is to say that Radiation from the edge region of the lens screen, which does not fall directly on the sensor, a beam splitter element is provided for deflecting the edge radiation onto the sensor.

- An increase in the number of monitoring areas can be achieved if, instead of only one beam splitter element, two or more beam splitter elements are used, which are combined to form a beam splitter, according to claims 11, 12, 13, 14 and 15.

- an azimuth angle of the motion detector of 220 ° can be achieved.

- the elevation angle of the motion detector can be expanded to 220 ° by appropriately supplementing this arrangement with two further beam splitter elements to form a pyramid-shaped beam splitter.

- Claims 12 and 13 in conjunction with claim 11 show two examples of the interaction of the beam splitter with the sensor.

- the deflection of the laterally incident marginal rays takes place differently according to claim 12 than according to claim 13.

- a beam from the lateral area of the lens shield striking the beam splitter (according to claim 12) is divided by the leg of the beam splitter lying in the direction of incidence into one by the divider ratio T: R fixed transmission component and a reflection component.

- the transmission component of the radiation is likewise divided into a transmission component and a reflection component on the second leg opposite the first leg of the beam splitter.

- the reflection portion of the transmission portion from the first leg is redirected to the sensor by the second leg.

- the beam is also divided into transmission and reflection components in accordance with the division ratio.

- the reflection component is already deflected from the incident beam through the first leg of the beam splitter to the sensor, as a result of which the radiation component deflected onto the sensor can be increased.

- an arrangement of the beam splitter according to claim 11 is also conceivable, in which the tip or the apex of the beam splitter is directed toward the lateral region of the lens screen, for example from the position facing with its tip towards the sensor (according to claim 13) after a 90 ° rotated position.

- the solution according to claim 2 differs from the solution according to claim 1 in that no beam splitter needs to be arranged in the direct beam path between the lenses in the central region of the lens screen and the infrared sensor, that is, the incident infrared radiation directly onto the sensor falls.

- the beam splitter is arranged in such a way that it deflects the edge radiation incident laterally through the lens screen onto the sensor.

- the individual Beam splitter elements for example two beam splitter elements arranged symmetrically to the sensor, are provided, which are inclined towards the sensor, so that the edge radiation incident from the lateral regions of the lens current either falls directly onto the surface of a beam splitter element facing the sensor and is deflected onto the sensor or onto one Beam splitter element falls, the transmission radiation of which falls on the other beam splitter element, the reflection radiation of which is deflected onto the sensor.

- This design prevents shadowing in the monitoring areas, since the beam splitter element, in contrast to a mirror, is transparent to the infrared radiation from both sides.

- the range or response sensitivity can be kept constant in all monitoring areas by enlarging the corresponding lenses of the lens screen.

- the beam splitter can consist of individual elements composed of a truncated cone or a truncated pyramid. A greater density of the reception areas results if more than four individual elements are arranged in a facetted manner around the sensor.

- a beam splitter ratio transmission to reflection T: R in the range from 4: 1 to 7: 3.

- a beam splitter made of silicon or germanium is suitable for a selective design of the beam splitter for a spectral range of 7 to 14 micrometers wavelength. These are flakes made of silicon or germanium of 0.1 to 0.5 mm thickness, which are provided on one side, preferably on the reflection side, that is to say on the side facing the sensor, with a reflective layer.

- the beam splitter elements can be produced from a wafer in different sizes and dimensions.

- holographic imaging components can be used which have a higher efficiency than beam splitters made of silicon.

- the beam splitter is provided on the side facing the incident beam path with a multi-layer system (alternating layers), on which multiple reflection occurs, so that the absorption is reduced and the reflection is increased.

- a separate sensor filter can be dispensed with.

- a development of the invention according to claim 1 provides two infrared sensors arranged side by side according to claim 14, which with a beam splitter and Lens screen form an electro-optical system.

- an approximately hemispherical lens screen with a number of individual lenses distributed over the surface covers the infrared sensors arranged in the center, so that one sensor lies in the focal point of the individual lenses of the lens screen located in a half field.

- the individual lenses can be Fresnel lenses or convex lenses.

- the two receiving lobes can already cover a range of 180 °.

- An increase in the number of reception areas is then only necessary for monitoring areas that are behind the sensor. In this case, it may be sufficient to provide an additional rearward monitoring area for each sensor.

- a beam splitter element is then to be provided in the beam path in front of each sensor, the reflection radiation of which is deflected from the laterally incident edge radiation onto the respective sensor.

- the lengthening of the beam path requires an increase in the focal length of the lenses in the edge region of the lens screen compared to the lenses in the central area of the lens screen in order to focus this edge radiation on the sensor.

- the beam splitter elements arranged in the direct beam path of the central area of the lens screen no blind spots are generated in the monitoring areas, since depending on the splitting ratio of the steel splitter, for example, 50%, 60%, 70% or 80% of the transmission radiation is directed directly to the sensors.

- a holder is provided to which the beam splitter elements are attached.

- the holder should have the smallest possible dimensions and have no influence on the monitoring areas.

- the holder itself is advantageously made of an infrared radiation-transmissive material.

- the beam splitter elements are preferably flat plates, but concave or convex curved plates can also be used.

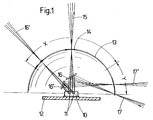

- Figures 1 to 6 show schematically the optoelectronic arrangement of a motion detector with a conventional infrared sensor 10 with two adjacent sensor elements 11.

- the sensor is provided on a holder, for example one with conductor tracks Board 12, assembled.

- Such an infrared sensor 10 is sensitive to infrared sources within a lobe-like sensitivity range, which includes a detection angle of approximately 110 °, while it is not sensitive to infrared sources lying outside the receiving lobe.

- a lens screen 13 In front of the sensor 10 there is a lens screen 13 with many individual lenses 14 arranged on its surface, each of which detects a monitoring area and focuses the radiation from an infrared radiation source located in the monitoring area onto the infrared sensor 10.

- the lenses can be designed as Fresnel lenses or as convex lenses.

- the lens shade 13 has a hemispherical shape. Of course, the lens shade can also have a differently curved surface.

- the infrared radiation incident through the lenses 14 can be focused directly on the sensor.

- the lateral edge rays incident in the region "Y" of the lens screen 13 are deflected so that they then run inside the reception lobe of the sensor 10 and are deflected onto the sensor can.

- Fig. 1 of the drawing are in the direct beam path, ie in the beam path in the area "X" of the lens hood 13 incident beams 15, 15 ', 10 slanted beam splitter elements 16, 16' arranged in front of the sensor, consisting of plane-parallel silicon chips.

- These beam splitter elements 16, 16 ' have a splitter ratio of 7: 3, ie their transmittance is 70% and their reflectance is 30%.

- the beam splitter element 16 is inclined relative to the sensor to such an extent that a beam 17 of a radiation source located behind the sensor 10 falls on the beam splitter element 16 and its reflection radiation is directed onto the sensor 10.

- Fig. 1 only two beam splitter elements 16, 16 'for two beams 17, 17' are shown. Additional beam splitter elements are to be provided for further beams that are incident laterally. The same also applies to the embodiments described with reference to the following FIGS. 2 to 7.

- 70% transmission radiation from a central bundle "X" of the lens screen 13 and striking the beam splitter element 16, 16 ' is directed directly to the sensor 10.

- a motion detector designed according to FIG. 1 can, in addition to the forward-facing reception lobe, be equipped with a further reception lobe running perpendicularly to it, which serves, for example, as a creep protection.

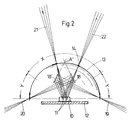

- two opposing plane-parallel beam splitter elements 18, 18 ' are arranged in front of the sensor 10 by way of example. Your inclination to each other takes place in such a way that the intersection "A" resulting in the extension of the beam splitter element planes lies on the side of the beam splitter elements 18 facing away from the sensor 10, the effective reflection surfaces are inclined towards the sensor 10. With this arrangement, lateral radiation sources or radiation sources already lying behind the plane of the sensor 10 can be detected by two opposite edge regions “Y” of the lens screen 13.

- the beam 19 incident on the right of the sensor 10 strikes the beam splitter element 18 'located on the left of the sensor 10 and throws the reflection radiation onto the sensor or the beam 20 incident on the left of the sensor 10 falls on the beam splitter element 18 located on the right of the sensor 10, which reflects its reflection radiation throws the sensor.

- Fig. 2 From Fig. 2 it can also be seen that infrared radiation incident from the central region "X" of the lens screen falls directly on the sensor 10 or strikes a beam splitter element 18, 18 'and the transmission radiation of this beam splitter element falls on the sensor.

- the beam 21 falls directly onto the sensor without hitting a beam splitter element, while the beam 22 initially hits the beam splitter element 18 and its transmission component falls on the sensor 10.

- the number of monitoring areas of the motion detector can be increased and the detection angle in the azimuth range can be expanded to approximately 220 ° to 230 °.

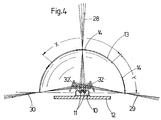

- An angular beam splitter 23 is made up of two beam splitter elements 24, 24 ', the tip of which is directed towards the sensor 10.

- the beam 25 incident on the right of the sensor 10 strikes the beam splitter element 24 on the right of the sensor, the reflection radiation of which is deflected onto the sensor.

- the beam splitter element 26 located to the left of the sensor 10 strikes the beam splitter element 24 ′ located to the left of the sensor 10, the reflection radiation of which strikes the sensor 10.

- the center of the central region of the lens screen 13 is covered by the beam splitter 23 in this arrangement. All beams 27 incident in this area first strike the beam splitter 23, penetrate it and then hit the sensor 10. In this case too, the loss due to reflection can be compensated for with “sharper” lenses 14.

- a beam splitter 31 with a symmetrical arrangement of two beam splitter elements is used to detect edge radiation incident laterally from the regions “Y”, shown here as a beam 29,30 32,32 'used.

- the beam element 29 incident on the right of the sensor 10 first strikes the beam splitter element 32 located on the right of the sensor 10, the transmission radiation of which is reflected on the beam splitter element 32 ′ located on the left of the sensor.

- the reflection radiation of the beam 29 is directed onto the sensor 10.

- the beam bundle 30 incident to the left of the sensor 10 first strikes the beam splitter element 32 ', the transmission radiation of which strikes the beam splitter element 32 to the right of the sensor 10.

- FIGS. 5 and 6 show an example of an embodiment in which the monitoring areas of laterally incident beams of rays are for all other designs 35 extend around the sensor 10.

- This all-round sensitivity is achieved by a beam splitter 33, whose beam splitter elements 34 are composed in a facet-like manner.

- the beam splitter 33 consists of eight beam splitter elements 34.

- Each beam splitter element 34 interacts with a lens 14 in the edge region "Y" of the lens screen 13. The more interacting beam splitter elements 34 and lenses 14 are present, the closer the individual monitoring areas are.

- the embodiment according to FIGS. 5 and 6 represents a further development of the embodiment according to FIG. 3. Repetition of the further details can therefore be dispensed with.

- the beam splitter 33 can be formed by several circumferential facet planes, so that not only radiation incident from the edge area of the lens screen 13 can be detected, but also that from the Areas "Y" of the lens screen that are adjacent to the central area "X" but are not in the direct detection area of the sensor 10.

- FIG. 7 shows an embodiment with two sensors 10, which are arranged at an angle to one another, each sensor 10 detecting a half field of the lens screen 13. Due to the angular position, the focal lengths of the lenses 14 of the ideal lens screen 36 shown in broken lines are approximated and by a hemispherical or semi-cylindrical lens screen 13. With the two sensors 10, an azimuth monitoring area can be obtained of more than 180 °. With the beam splitter elements 37, 37 ', the lateral areas are expanded by areas which are already behind the sensors 10, so that the radiation 38 from an infrared radiation source lying to the right behind the right sensor 10 onto the right sensor 10 or the radiation 39 from the left radiation source located behind the left sensor 10 can be deflected to the left sensor 10.

- Radiation coming from the central area of the lens screen 13 strikes one of the two sensors 10 as transmission radiation.

- the reflection losses of this radiation are compensated for by enlarging the lenses 14 in this area of the lens screen 13.

- the number of monitoring areas is increased by two, which extends the reception range of the motion detector to approx. 240 °.

- the beam splitter elements 37, 37 'of the beam splitter 47 are fastened to a holder 40 arranged between the sensors 10.

- Figures 9 and 10 show the design of the holder 40 and the attachment of the beam splitter elements 37,37 'in detail.

- the shape of the holder 40 is bow-like. It has a crossbar 41 with locking arms 42 hanging down at the ends. With the locking arms, the holder 40 is inserted into guides of a base 43, which are not described in any more detail, wherein in the end position, notches 44 engage in a form-fitting manner in locking receptacles of the base 43, not shown.

- receptacles 45 are provided in the crosspiece 41, in each of which one end of the beam splitter element 37, 37' is inserted and clamped by a fitting 46. The connection can be secured with an adhesive.

- the holder 40 and the beam splitter element 37, 37 ' are manufactured as a pre-assembled structural unit and attached to the base 43.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Photometry And Measurement Of Optical Pulse Characteristics (AREA)

- Lubrication Of Internal Combustion Engines (AREA)

- Analysing Materials By The Use Of Radiation (AREA)

- Details Of Television Scanning (AREA)

- Vehicle Body Suspensions (AREA)

- Eye Examination Apparatus (AREA)

- Burglar Alarm Systems (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4315183A DE4315183A1 (de) | 1993-05-07 | 1993-05-07 | Bewegungsmelder |

| DE4315183 | 1993-05-07 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0623905A2 true EP0623905A2 (fr) | 1994-11-09 |

| EP0623905A3 EP0623905A3 (fr) | 1996-10-02 |

| EP0623905B1 EP0623905B1 (fr) | 1999-09-15 |

Family

ID=6487456

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94106652A Expired - Lifetime EP0623905B1 (fr) | 1993-05-07 | 1994-04-28 | Détecteur de mouvement |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0623905B1 (fr) |

| AT (1) | ATE184722T1 (fr) |

| DE (2) | DE4315183A1 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29503531U1 (de) * | 1995-03-03 | 1995-05-18 | REV Ritter GmbH, 63776 Mömbris | Bewegungsmelder mit Infrarotsensor |

| EP0652422A3 (fr) * | 1993-11-06 | 1996-02-21 | Abb Patent Gmbh | Dispositif pour recevoir des rayons lumineux. |

| EP1148455A1 (fr) * | 2000-04-22 | 2001-10-24 | ABB PATENT GmbH | Détecteur passif de mouvement à infrarouge |

| EP1336944A1 (fr) * | 2002-02-14 | 2003-08-20 | Steinel GmbH & Co. KG | Miroir optique pour un détecteur de mouvement |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4445196A1 (de) * | 1994-12-17 | 1996-06-20 | Abb Patent Gmbh | Bewegungsmelder zur Erfassung der aus einem zu überwachenden Raumbereich kommenden Strahlung |

| DE4445197A1 (de) * | 1994-12-17 | 1996-06-20 | Abb Patent Gmbh | Passiv-Infrarot-Bewegungsmelder mit Sammellinsen zu einer Rundumerfassung von 360 DEG |

| DE19502521A1 (de) * | 1995-01-27 | 1996-08-01 | Abb Patent Gmbh | Passiv-Infrarot-Melder mit einer Optik, die von einem Strahlungsobjekt emittierte Wärmestrahlung auf einen Infrarotsensor fokussiert |

| DE29503532U1 (de) * | 1995-03-03 | 1995-05-18 | REV Ritter GmbH, 63776 Mömbris | Bewegungsmelder |

| KR0166870B1 (ko) * | 1995-07-13 | 1999-03-20 | 구자홍 | 적외선 센서를 이용한 인체의 위치판별장치 |

| DE19632514A1 (de) * | 1996-08-13 | 1998-02-19 | Abb Patent Gmbh | Bewegungsmelder mit mindestens einer Sammellinse |

| DE19639318C1 (de) * | 1996-09-25 | 1997-12-18 | Andreas Toeteberg | Mehrfach-Passiv-Infrarot-(PIR)-Bewegungsmelder |

| DE19805622A1 (de) * | 1998-02-12 | 1999-08-19 | Thomson Brandt Gmbh | Bewegungsmelder zum Ein- und/oder Ausschalten von einem elektronischen Gerät |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3958118A (en) * | 1975-02-03 | 1976-05-18 | Security Organization Supreme-Sos-Inc. | Intrusion detection devices employing multiple scan zones |

| DE3381729D1 (de) * | 1983-01-05 | 1990-08-16 | Zueblin Marcel | Optisches bauelement zum umlenken optischer strahlen. |

| DE3942830C2 (de) * | 1989-12-23 | 1999-03-04 | Asea Brown Boveri | Passiv-Infrarot-Bewegungsmelder |

| GB9100791D0 (en) * | 1991-01-15 | 1991-02-27 | Smiths Industries Plc | Detector assemblies |

-

1993

- 1993-05-07 DE DE4315183A patent/DE4315183A1/de not_active Withdrawn

-

1994

- 1994-04-28 DE DE59408738T patent/DE59408738D1/de not_active Expired - Fee Related

- 1994-04-28 EP EP94106652A patent/EP0623905B1/fr not_active Expired - Lifetime

- 1994-04-28 AT AT94106652T patent/ATE184722T1/de not_active IP Right Cessation

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0652422A3 (fr) * | 1993-11-06 | 1996-02-21 | Abb Patent Gmbh | Dispositif pour recevoir des rayons lumineux. |

| US5677529A (en) * | 1993-11-06 | 1997-10-14 | Abb Patent Gmbh | Passive infrared sensor using a pair of sensors and reflectors for a 270 degree field of view |

| DE29503531U1 (de) * | 1995-03-03 | 1995-05-18 | REV Ritter GmbH, 63776 Mömbris | Bewegungsmelder mit Infrarotsensor |

| EP1148455A1 (fr) * | 2000-04-22 | 2001-10-24 | ABB PATENT GmbH | Détecteur passif de mouvement à infrarouge |

| EP1336944A1 (fr) * | 2002-02-14 | 2003-08-20 | Steinel GmbH & Co. KG | Miroir optique pour un détecteur de mouvement |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59408738D1 (de) | 1999-10-21 |

| EP0623905B1 (fr) | 1999-09-15 |

| ATE184722T1 (de) | 1999-10-15 |

| EP0623905A3 (fr) | 1996-10-02 |

| DE4315183A1 (de) | 1994-11-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3350615B1 (fr) | Capteur lidar | |

| EP0050751B1 (fr) | Arrangement optique pour un détecteur d'intrusion à infrarouge | |

| EP0623905B1 (fr) | Détecteur de mouvement | |

| EP0652422A2 (fr) | Dispositif pour recevoir des rayons lumineux | |

| DE2851444A1 (de) | Lichtgitter | |

| DE2927845A1 (de) | Einen taktmasstab aufweisender lichtvorhang | |

| DE4220993A1 (de) | Optisches abtastsystem mit selbstaetiger fokussierung | |

| DE3812969A1 (de) | Infrarot-bewegungsmelder | |

| DE3143137C2 (de) | Reflexions-ausblendende, fokussierende optische Vorrichtung | |

| DE2838362C2 (de) | Optisch- mechanischer Abtaster mit zwei mechanischen Ablenkeinheiten für Zeilen- und Bildablenkung und zwischengeschalteter Reflexionseinrichtung | |

| DE69722551T2 (de) | Spektrometer mit einem orientiert-geformten Schlitz | |

| DE2951388C2 (de) | Strahlungsdetektor | |

| DE19851010B4 (de) | Einrichtung zur Erkennung und Lokalisierung von Laserstrahlungsquellen | |

| DE3707986C2 (fr) | ||

| DE3514302A1 (de) | Optische abtastvorrichtung | |

| DE2623231C3 (de) | Beleuchtungsvorrichtung für zwei Lichtleiter oder Lichtleiterbündel | |

| DE2836462A1 (de) | Raumueberwachungs-empfangseinrichtung | |

| WO2017005653A1 (fr) | Module détecteur pour un dispositif de détection optique | |

| DE3500860A1 (de) | Optische anordnung an passiv-infrarot-bewegungsmeldern | |

| DE60215012T2 (de) | Scan-einrichtung zur bilderzeugung im mikrowellen-, millimeterwellen-, oder infrarot-spektralbereich | |

| DE3022365A1 (de) | Optische abtastvorrichtung | |

| DE1957494C3 (de) | Lichtelektrische Abtastvorrichtung | |

| DE3513192C2 (de) | Vorrichtung zum optischen Abtasten eines Bildes | |

| WO2005114987A1 (fr) | Dispositif pour detecter une scene d'objets | |

| DE1283557B (de) | Optische Abtasteinrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB IE LI NL PT SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: GEBRUEDER MERTEN GMBH & CO. KG |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB IE LI NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19961024 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19981118 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB IE LI NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990915 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990915 |

|

| REF | Corresponds to: |

Ref document number: 184722 Country of ref document: AT Date of ref document: 19991015 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: TROESCH SCHEIDEGGER WERNER AG Ref country code: CH Ref legal event code: EP |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHLOTT, HARALD, DR. Inventor name: SCHLECHTINGEN, PETER Inventor name: GRINGMANN, KLAUS Inventor name: ERBSE, KARL ULRICH Inventor name: BOST, WERNER R. |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 59408738 Country of ref document: DE Date of ref document: 19991021 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19991215 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19991215 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19991202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000428 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000430 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000719 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: GEBRUDER MERTEN G.M.B.H. & CO. K.G. Effective date: 20000430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001101 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 94106652.4 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20001101 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030408 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20030425 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20030522 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040428 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041103 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040428 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |