EP0600123A1 - Distributeur de pilules avec orifice de distribution dans sa base - Google Patents

Distributeur de pilules avec orifice de distribution dans sa base Download PDFInfo

- Publication number

- EP0600123A1 EP0600123A1 EP92120627A EP92120627A EP0600123A1 EP 0600123 A1 EP0600123 A1 EP 0600123A1 EP 92120627 A EP92120627 A EP 92120627A EP 92120627 A EP92120627 A EP 92120627A EP 0600123 A1 EP0600123 A1 EP 0600123A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- container part

- tablet dispenser

- dispensing

- shaft

- outer part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 claims description 33

- 230000000994 depressogenic effect Effects 0.000 claims description 5

- 235000003599 food sweetener Nutrition 0.000 claims description 5

- 230000002829 reductive effect Effects 0.000 claims description 5

- 239000003765 sweetening agent Substances 0.000 claims description 5

- 238000005336 cracking Methods 0.000 claims description 3

- 210000003746 feather Anatomy 0.000 claims 1

- 239000003826 tablet Substances 0.000 description 44

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000006378 damage Effects 0.000 description 3

- 238000003860 storage Methods 0.000 description 3

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000008094 contradictory effect Effects 0.000 description 1

- 239000007947 dispensing tablet Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000009191 jumping Effects 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/04—Containers or packages with special means for dispensing contents for dispensing annular, disc-shaped, or spherical or like small articles, e.g. tablets or pills

- B65D83/0409—Containers or packages with special means for dispensing contents for dispensing annular, disc-shaped, or spherical or like small articles, e.g. tablets or pills the dispensing means being adapted for delivering one article, or a single dose, upon each actuation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2401/00—Tamper-indicating means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2583/00—Containers or packages with special means for dispensing contents

- B65D2583/04—For dispensing annular, disc-shaped or spherical or like small articles or tablets

- B65D2583/0404—Indications, e.g. directions for use

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2583/00—Containers or packages with special means for dispensing contents

- B65D2583/04—For dispensing annular, disc-shaped or spherical or like small articles or tablets

- B65D2583/0472—For dispensing annular, disc-shaped or spherical or like small articles or tablets characterised by the dispensing action

- B65D2583/0477—For dispensing annular, disc-shaped or spherical or like small articles or tablets characterised by the dispensing action the container is maintained in the same position during the dispensing of several successive articles or doses

- B65D2583/0481—One reciprocating action, e.g. to or from

Definitions

- the invention relates to a tablet dispenser for dispensing tablets or tablet-shaped bodies, in particular sweetener tablets, with a lower opening in the position of use, which is preceded by a separating mechanism which, when actuated, releases one tablet to drop out on the upper surface of a container part in the position of use of the tablet dispenser.

- the container part in the position of use is displaceably guided in a vertical direction in an outer part having an end plate and has an inclined to its lower region, relative to an opening in the end plate movable bottom chute sloping bottom plate, which tablets inside the container part to the leads to the lowest point of the bottom surface of this container part starting chute, and at least to return the container part from the dispensing position to its starting position s a return spring arranged between the container part and the outer part is provided.

- Such a tablet dispenser is known from EP 0188 278 B1.

- an approximately horizontally projecting leaf spring is provided which is formed on the container part which can be moved downwards in the vertical direction and which is supported on the inside on the outer part on a shoulder. So that these If there is space between the two parts which can be displaced relative to one another, it must protrude on the outside of the output shaft, because only in its area there is a sufficiently large distance from the outer part and thus a sufficiently large free space for the spring and its movement. The result of this is that this protruding spring on the container part is at risk of breakage during storage and assembly until it is finally enclosed and protected in its final assembly position by the outer part.

- the invention is therefore based on the object to provide a tablet dispenser of the type mentioned, in which the advantages are retained that no separate spring element is required as a return spring and the return spring is protected in the assembled position by the outer part, whereby at the same time it should be achieved that the risk of mutual interlocking of return springs in the phase between manufacture and assembly and the resulting risk of damage can be avoided. Nevertheless, the production, in particular from plastic by injection molding, should remain possible in a simple manner.

- the return spring is arranged in the outer part from its end bottom upwards, that the length of the return spring is at least the distance between the inside of the end bottom of the outer part and the underside of the sloping bottom plate of the container part in the initial position of the container part corresponds to before the dispensing process and that the return spring facing the free end of the underside of the sloping bottom plate of the container part can be deflected against its spring force by this sloping underside during the dispensing process.

- the spring which stands up from the bottom of the outer part and is in contact with the oblique underside of the container part is laterally deflected by the corresponding inclined surface and is therefore also placed under spring tension.

- the return spring is located from the start in the interior of the outer part, where it is not endangered even during transport operations before assembly and cannot lead to snagging with other parts. It is therefore protected from the outset inside the outer part. A separate spring part to be used separately, or even a metal spring, which would have to be manufactured and used during assembly, is also avoided. As before, only the outer part and the container part have to be put together for assembly and then already have the return spring.

- a further embodiment of the invention with advantages for a favorable direction of the resulting total restoring force can consist in that two, in particular symmetrically arranged, sloping base plates lead from the walls of the container part to the delivery chute and that a spring which projects from below acts on each inclined base plate, both of them Springs in particular arranged symmetrically to a longitudinal center plane of the tablet dispenser running between them and are of the same length or of the same strength.

- the two springs which can be deflected laterally away from one another for example by the sloping floor surfaces, then bring about an overall effective restoring force in the longitudinal center, by means of which the container part can be pushed back into its original position without any problem and without the risk of tilting in the outer part.

- the spring or springs both keep a distance from both the dispensing shaft and from the outside in the radial direction furthest from this dispensing shaft and if the distance from the outside corresponds at least to the radial evasive movement of the spring during the dispensing process.

- the springs can each be arranged approximately in the middle between the delivery shaft and the outside.

- the radial outer distance between the respective spring and the outside of the outer part and the helix angle of the the bottom plate of the container part leading the collecting shaft can be coordinated with one another in such a way that the deflected spring end in the dispensing position, when the container part is depressed, abuts approximately on the inside of the outer wall of the outer part or is at a short distance therefrom.

- a return spring is optimally positioned, on the one hand to allow a sufficiently large return force, but on the other hand not to be able to overstretch it.

- the spring can be integrally connected to the end plate and the spring width oriented transversely to the deflection direction of the spring can in particular be greater than the spring thickness.

- an embodiment of the invention is of its own protection worthy of protection, according to which the restoring force of the spring and the helix angle of the base plate of the container part can be chosen so large that in addition to the provision of the container part an acoustic display device can be moved and actuated. This has the great advantage that the user who falls out of the relatively small tablet from the output shaft often cannot see clearly enough, in any case hears that the donation process has taken place properly.

- the acoustic display device can be mechanically actuated and a sound, noise or cracking can be heard by its actuation. There is therefore no need for any special electrical device, for example, to acoustically display the dispensing process, that is to say to make it audible.

- a protrusion can be arranged in the bottom area at the opening of the outer part for the dispensing shaft, which protrudes on the side of the dispensing shaft facing it from itself or with another protrusion arranged on the dispensing shaft during the dispensing movement and through the continuation and in particular the termination of the dispensing process on the one hand and the return movement on the other hand can be moved past against a sound-generating resistance. Due to the contact with the projection on the collecting channel, the projection generates a double clicking sound by deflecting and jumping back, namely once during the dispensing process and for the second time when the container part is released and returned.

- the projection serving as an acoustic indicator and projecting into the range of movement of the delivery chute is a resiliently deflectable tongue which is initially overlapped by a projection arranged on the delivery chute and facing it, and if the resilient tongue is moved by the downwardly moving delivery channel and its projection can be deflected in the opposite direction during the dispensing process and during the return movement and can be released after a short deflection movement with the generation of a clicking sound.

- the tongue can thus first be gripped and depressed by the projection located on the output shaft until the protrusion is displaced during the dispensing process so far that the dispensing position is reached and the tongue can then slide past the protrusion and spring back again.

- the resilient tongue can be formed in a simple manner by two incisions in the end floor, which lead away from the floor opening for the passage of the delivery shaft and in particular run parallel to one another. If the tongue protrudes somewhat into the area of the bottom opening, the projection on the outlet shaft could lie within a corresponding recess in the wall of this outlet shaft.

- the width of the tongue or the distance between the incisions delimiting the resilient tongue can correspond to the width of the wall of the collecting shaft facing the tongue.

- the tongue can be made correspondingly stable and wide.

- a further embodiment of the invention which can be used expediently in the tablet dispenser described above, but also has its own importance worthy of protection, because it could also have corresponding advantages for tablet dispensers of a different construction, can provide that the return spring or the return springs prevent deflection, for example is protected by the weight of the container part and its filling up to a first dispensing movement in that the relative movement between the container part and the outer part is caused by a predetermined breaking point Intermediate piece is blocked and that the force required to overcome the predetermined breaking point is greater than the weight of the filled container part.

- This has the further advantage that not only are the return springs spared and do not tire in the course of long storage, but also that a user can see whether he is really the first user of this tablet dispenser.

- the predetermined breaking point is intact, he can assume that the tablet dispenser has not yet been used. However, if the predetermined breaking point is broken, he can refuse to buy such a tablet dispenser. This measure of blocking the movement between the container part and the outer part before first use therefore has two advantages going in very different directions.

- a development of the tablet dispenser and in particular the arrangement of the predetermined breaking point can consist in that a cap, in particular a closure cap, is attached to the upper actuating end of the container part, which is connected via predetermined breaking points to a support ring which is supported on the outer part, and that the outer diameter of the Cap is smaller than the inside diameter of the support ring - or, conversely, the inside diameter of the cap may be larger than the outside diameter of the support ring.

- the predetermined breaking point is therefore destroyed by pressure on the cap and thus the upper end of the container part, because the cap can be moved relative to the support ring if this is no longer prevented by the predetermined breaking point.

- the cap can then dip into the support ring and thereby enable the container part to be displaced for a dispensing process.

- the support ring has a larger diameter than the cap, it can be removed after this first dispensing movement due to the destruction of the connection with the cap.

- the outer diameter of the cap is at least a fraction of the wall thickness of this cap and / or the support ring smaller than the inner diameter of the support ring and if the predetermined breaking point is arranged on a front, radially inward collar of the support ring.

- the outside of the container part in the area encompassed by the cap can be reduced approximately by the wall thickness of the annular circumferential cap wall, and the support ring can be adjacent to this in particular for example on the inside diameter of the outer part of the enlarged portion of the container part on the end face of the outer part, in particular lifted off.

- this tablet dispenser consists of very few parts, but still allows a good return movement due to correspondingly strong return springs, without these springs being prone to breakage during assembly or leading to snagging, although no separate spring element is required.

- this tablet dispenser can be designed so that the springs are strong enough to be able to acoustically indicate the dispensing process.

- it can be ensured that the springs are not unnecessarily loaded during storage prior to first use, so that the buyer can see whether he is really the first user.

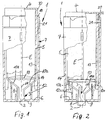

- a tablet dispenser designated as a whole, serves for the single delivery of tablets or tablet-shaped bodies, for example sweetener tablets. It has a lower outlet opening 2 located in its use position on its underside, which is preceded by a separating mechanism 3 (see FIG. 2).

- a separating mechanism 3 see FIG. 2.

- the displacement of the container part 5 takes place within an outer part 7 having a bottom 6, in which the container part 5 is guided according to FIGS. 1 and 2.

- the container part 5 In its lower region, the container part 5 has an outlet shaft 8 which can be moved downwards together with it in the vertical direction, at the lower end of which the already mentioned outlet opening 2 is located. During the dispensing movement, this dispensing shaft 8 can be moved relative to an opening 9 in the closing bottom 6 of the outer part 7 and, in the dispensing position according to FIG. 2, projects downwards over this closing bottom 6. It can be clearly seen in FIGS. 1, 2, 6 and 7 that the container part 5 has bottom plates 10 sloping downwards in this lower region towards this dispensing shaft 8, the inclination of which in each case leads the tablets to the inlet 11 in the dispensing shaft 8 . This inlet 11 is located at the lowest point of the bottom surface of the container part 5 formed by the bottom plates 10 and bottom plates 10a.

- the two return springs 12 are parallel to each other on the inside of the bottom 6 of the outer part 7 upright and both engage an inclined surface of the bottom plate 10 of the container part 5, so that a correspondingly doubled restoring force is available.

- two approximately symmetrically arranged oblique bottom plate pieces 10a are provided, which lead from the walls 13 of the container part 5 to the output shaft 8 and on each of these oblique bottom plate pieces 10a attacks one of the upright return springs 12 from below, both return springs 12 being arranged symmetrically to a longitudinal center plane E of the tablet dispenser 1 running between them and being of the same length or of the same strength. Accordingly, a resulting restoring force is generated in the direction of the central axis of the tablet dispenser 1, so that the container part 5 can be easily pushed back in relation to the outer part 7 in the starting position when a dispensing process has ended.

- the return springs 12 are each at a distance both from the outlet shaft 8 and from the outside in the radial direction furthest from this outlet shaft 8 or from the outer wall 14 of the outer part 7.

- the distance from the outside corresponds at least to the radial evasive movement of the return springs 12 during the dispensing process, as is clear from FIG. 2.

- the radial outer distance between the respective return spring 12 and the outer wall 14 of the outer part 7 and the helix angle of the bottom plates 10 of the container part 5 leading to the collecting shaft 8 are so matched that the deflected spring end 12a in the dispensing position when the container part 5 is depressed is approximately at the Bears against the inside of the outer wall 14 of the outer part 7 or has a small distance therefrom.

- the return springs 12 can simultaneously form a stop for the lowest position of the container part 5 in the outer part 7.

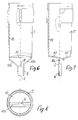

- the return springs 12 are integrally connected to the end plate 6, whereby it can be seen above all from Figure 4 that the spring width oriented transversely to the deflection direction of the return springs 12 is greater than the spring thickness.

- the return springs 12 are thus designed as one-piece leaf springs, protected in the interior of the outer part 7, the thickness and Width can possibly increase somewhat towards the end floor 6.

- the restoring force of the return springs 12 and the helix angle of the bottom plate pieces 10a of the container part 5 are chosen so large in the exemplary embodiment that, in addition to the resetting of the container part 5 together with its filling, an acoustic display device can also be moved and actuated, that is to say the dispensing process can be heard acoustically made so that even under unfavorable lighting conditions the user can see whether a dispensing process has taken place or not.

- sweetener tablets are often so small that one cannot be sure during a dispensing process whether a tablet has really been dispensed, which often leads to unnecessary repetitions of the dispensing process.

- this acoustic display device which is explained in more detail below, can be actuated mechanically and a sound, in particular a crack, can be heard by its actuation.

- the inclined base plates consist of several parts which are inclined in different directions, the parts serving for the installation of the return springs 12 lying between two base plates 10 leading obliquely towards them and approximately 90 degrees in addition run obliquely.

- the return springs 12 are inserted bevels belonging to the discharge shaft 8, which in this way both effect a secure feed of the tablets into the input opening 11 of the discharge shaft 8 and also form the corresponding sliding surface for the spring ends 12a during the return movement.

- FIGS. 4 and 5 and FIG. 7 show the structural design of the mechanical-acoustic display device.

- a projection 15 is arranged in the bottom area at the opening 9 of the outer part 7 for the delivery chute 8, which is arranged on the side of the delivery chute 8 on the side facing it, with the latter itself or with one that can be seen in FIG

- Another projection 16 comes into contact during the dispensing movement and can be moved past by a continuation of the dispensing process on the one hand and the return movement on the other hand against a sound-generating resistance.

- the projection 15, which serves as an acoustic display device and projects into the range of movement of the discharge shaft 8 and its projection 16, is a spring-deflectable tongue which is initially overlapped by the projection 16 arranged on the discharge shaft 8 and facing it and through the downwardly moving discharge channel 8 and its protrusion 16 can be deflected during the dispensing process on the one hand and during the return movement in the opposite direction on the other hand and can be released after a short deflection movement with the generation of a clicking sound.

- the protrusion 16 on the output shaft 8 detects this resilient tongue 15, pushes it back a little until it slides past its protrusion 16 again into its starting position due to its deflection, and the subsequent resetting movement takes place in the opposite direction an action on the resilient tongue 15 by the projection 16 from below, whereby it first deflects into the interior of the outer part 7 and then jumps back to the projection 16 in the starting position.

- a user therefore hears two clicks or clicks in quick succession when he lets a tablet drop out of the tablet dispenser 1 as a result of a dispensing process. These noises are comparable to those that occur when an electrical pressure switch is actuated.

- the resilient tongue 15 is formed by two incisions 17 in the end base 6, which lead away from the base opening 9 for the passage of the output shaft 8 and run parallel to one another. At the same time, the tongue 15 is reduced in thickness with respect to the bottom 6, as is particularly evident in FIG. 4. It is advantageous that the tongue 15 is integrally connected to the end plate 6, so that this acoustic display device is made possible without the need to install additional individual parts on the tablet dispenser 1.

- the width of the tongue 15 or the distance between the notches 17 delimiting the resilient tongue 15 corresponds to the width of the wall of the collecting shaft 8 facing the tongue, so that the tongue 15 can have the greatest possible width.

- FIGS. 1 and 9 to 12 show that and how the return springs 12 are protected against deflection, for example by the weight of the container part 5 and its filling, until a first dispensing movement. This is done in the exemplary embodiment in that the relative movement between the container part 5 and the outer part 7 is blocked by an intermediate piece 19 having one or more predetermined breaking points 18 and that the force required to overcome the predetermined breaking point 18 is greater than the weight of the filled container part 5.

- a cap 20 can be seen at the upper actuating end of the container part 5, which in this case is also the closure cap of the container part 5.

- This is connected via the predetermined breaking points 18 according to FIGS. 9 to 12 and in particular according to FIG. 10 to a support ring 21 which is at least initially supported on the outer part 7.

- the outer diameter of the cap 20 is smaller than the inner diameter of the support ring 21 and at least by a fraction of the wall thickness of this cap 20 and / or the support ring 21.

- the predetermined breaking point 18 is located on an end face, radially inward collar 22 of the support ring 21 is arranged. It is particularly clear from FIG. 2 that this makes it possible to press the container part 5 downwards relative to the support ring 21 by pressing the cap 20 and its upper surface 4 if the corresponding force is large enough to break the predetermined breaking points 18 to overcome.

- the container part 5 can be moved inside the outer part 7 and the cap 20 can also be telescopically inserted into the support ring 21, is the outside of the container part 5 in the area encompassed by the cap 20 is reduced approximately by the wall thickness of the annular circumferential cap wall.

- the support ring 21 can thus sit adjacent to the area of the container part 5 which has been enlarged to the inside diameter of the outer part 7 in the manner already mentioned on the end face of the outer part 7. If the support ring 21 can be lifted off, it can be removed above the cap 20 after breaking the predetermined breaking points 18.

- This arrangement has the advantage that the return springs 12 remain unloaded as long as the tablet dispenser 1 has not yet been used. At the same time, there is the further advantage that a first user can recognize whether he is facing a really unused tablet dispenser 1.

- the tablet dispenser 1 for dispensing individual tablets essentially has a container part 5 for these tablets and an outer part 7, relative to which the container part 5 can be displaced from top to bottom during the dispensing process.

- a separating mechanism 3 is actuated, which in each case causes one tablet - in special cases maybe two tablets - to fail.

- At least one return spring 12 is provided, which is arranged in the interior of the outer part 7, rising upwards from its lower end plate 6, and engages an inclined surface of the container part 5 facing it, this inclined surface from the outside to the center of the tablet dispenser 1 runs obliquely downwards, so that tablets are directed to the delivery shaft 8, while the return spring is deformed radially laterally outwards during the dispensing movement and can push the container part 5 up again due to its return deformation during the return movement.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Filling Or Emptying Of Bunkers, Hoppers, And Tanks (AREA)

- Agricultural Chemicals And Associated Chemicals (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP92120627A EP0600123B1 (fr) | 1992-12-03 | 1992-12-03 | Distributeur de pilules avec orifice de distribution dans sa base |

| DE59204371T DE59204371D1 (de) | 1992-12-03 | 1992-12-03 | Tablettenspender mit einer unteren Ausfallöffnung. |

| AT92120627T ATE130272T1 (de) | 1992-12-03 | 1992-12-03 | Tablettenspender mit einer unteren ausfallöffnung. |

| ES92120627T ES2079776T3 (es) | 1992-12-03 | 1992-12-03 | Distribuidor de tabletas con una abertura de salida inferior. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP92120627A EP0600123B1 (fr) | 1992-12-03 | 1992-12-03 | Distributeur de pilules avec orifice de distribution dans sa base |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0600123A1 true EP0600123A1 (fr) | 1994-06-08 |

| EP0600123B1 EP0600123B1 (fr) | 1995-11-15 |

Family

ID=8210276

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92120627A Expired - Lifetime EP0600123B1 (fr) | 1992-12-03 | 1992-12-03 | Distributeur de pilules avec orifice de distribution dans sa base |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0600123B1 (fr) |

| AT (1) | ATE130272T1 (fr) |

| DE (1) | DE59204371D1 (fr) |

| ES (1) | ES2079776T3 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1996021111A1 (fr) * | 1994-12-30 | 1996-07-11 | Haas Beteiligungsgesellschaft Mbh | Ressort en plastique |

| DE19602201A1 (de) * | 1996-01-23 | 1997-07-24 | Kerplas Neuenburg Gmbh Kunstst | Tablettenspender zur Einzeldosierung von Tabletten |

| GB2412369A (en) * | 2004-03-25 | 2005-09-28 | Fold Hill Foods Ltd | A tablet dispenser |

| WO2009043489A1 (fr) * | 2007-09-27 | 2009-04-09 | Pöppelmann Holding GmbH & Co. KG | Distributeur ou récipient de distribution analogue |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19630710C1 (de) * | 1996-07-30 | 1997-09-11 | Kerplas Neuenburg Gmbh Kunstst | Tablettenspender mit einem äußeren Gehäuse und einem Behälter |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3221719A1 (de) * | 1982-06-09 | 1983-12-15 | Müller's Mühle Müller GmbH & Co KG, 4650 Gelsenkirchen | Vorrichtung zur dosierten abgabe von tabletten |

| EP0188278A2 (fr) * | 1985-01-17 | 1986-07-23 | Gallina, Ferenc, Dipl.-Ing. (FH) | Distributeur de tablettes |

| EP0221413A2 (fr) * | 1985-11-02 | 1987-05-13 | Bramlage GmbH | Distributeur pour cachets, capsules ou similaires |

| EP0284557A1 (fr) * | 1987-03-20 | 1988-09-28 | Alfatechnic Patent AG | Distributeur de comprimés |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3016834A1 (de) * | 1980-05-02 | 1981-11-05 | Ferenc Ing.(grad.) 7805 Bötzingen Gallina | Einzeldosierdose fuer tabletten |

| GB2270906B (en) * | 1992-08-19 | 1995-08-23 | Manuplastics Ltd | A tablet dispenser |

-

1992

- 1992-12-03 AT AT92120627T patent/ATE130272T1/de active

- 1992-12-03 EP EP92120627A patent/EP0600123B1/fr not_active Expired - Lifetime

- 1992-12-03 ES ES92120627T patent/ES2079776T3/es not_active Expired - Lifetime

- 1992-12-03 DE DE59204371T patent/DE59204371D1/de not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3221719A1 (de) * | 1982-06-09 | 1983-12-15 | Müller's Mühle Müller GmbH & Co KG, 4650 Gelsenkirchen | Vorrichtung zur dosierten abgabe von tabletten |

| EP0188278A2 (fr) * | 1985-01-17 | 1986-07-23 | Gallina, Ferenc, Dipl.-Ing. (FH) | Distributeur de tablettes |

| EP0221413A2 (fr) * | 1985-11-02 | 1987-05-13 | Bramlage GmbH | Distributeur pour cachets, capsules ou similaires |

| EP0284557A1 (fr) * | 1987-03-20 | 1988-09-28 | Alfatechnic Patent AG | Distributeur de comprimés |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1996021111A1 (fr) * | 1994-12-30 | 1996-07-11 | Haas Beteiligungsgesellschaft Mbh | Ressort en plastique |

| US5984285A (en) * | 1994-12-30 | 1999-11-16 | Haas Beteiligungsgesellschaft M.B.H. | Plastic spring |

| DE19602201A1 (de) * | 1996-01-23 | 1997-07-24 | Kerplas Neuenburg Gmbh Kunstst | Tablettenspender zur Einzeldosierung von Tabletten |

| EP0786420A2 (fr) | 1996-01-23 | 1997-07-30 | Kerplas Neuenburg Gmbh Kunststoffverpackungen | Distributeur de comprimés pour la distribution individuelle de comprimés |

| GB2412369A (en) * | 2004-03-25 | 2005-09-28 | Fold Hill Foods Ltd | A tablet dispenser |

| WO2009043489A1 (fr) * | 2007-09-27 | 2009-04-09 | Pöppelmann Holding GmbH & Co. KG | Distributeur ou récipient de distribution analogue |

| WO2009043493A1 (fr) * | 2007-09-27 | 2009-04-09 | Pöppelmann Holding GmbH & Co. KG | Distributeur ou récipient de distribution analogue |

| US8439225B2 (en) | 2007-09-27 | 2013-05-14 | Poppelmann Holding Gmbh & Co. Kg | Dispenser or similar discharging container |

| RU2485038C2 (ru) * | 2007-09-27 | 2013-06-20 | Пёппельманн Холдинг Гмбх Унд Ко. Кг | Дозатор или подобные раздаточные емкости |

| RU2485037C2 (ru) * | 2007-09-27 | 2013-06-20 | Пёппельманн Холдинг Гмбх Унд Ко. Кг | Дозатор или подобные раздаточные емкости |

| DE102008009021B4 (de) * | 2007-09-27 | 2015-11-05 | Pöppelmann Holding GmbH & Co. KG | Spender oder dergleichen Ausgabebehälter |

| EP2193088B1 (fr) | 2007-09-27 | 2018-05-16 | Pöppelmann Holding GmbH & Co. KG. | Distributeur ou récipient de distribution analogue |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE130272T1 (de) | 1995-12-15 |

| ES2079776T3 (es) | 1996-01-16 |

| EP0600123B1 (fr) | 1995-11-15 |

| DE59204371D1 (de) | 1995-12-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3018041C2 (fr) | ||

| DE3244645C2 (fr) | ||

| EP0199900B1 (fr) | Distributeur de tablettes | |

| DE69218789T2 (de) | Spender für pillen oder tabletten | |

| DE69600521T2 (de) | Zerstäubungsdüse | |

| DE69004182T2 (de) | Rohrförmiger Behälter mit nichtabnehmbarem Abgabeverschluss. | |

| DE3017376A1 (de) | Behaeltnis zur einzel-portionierten ausgabe von tabletten | |

| DE3230947A1 (de) | Spender fuer pastoeses gut, insbesondere zahnpasta | |

| DE3005188A1 (de) | Tablettenspender | |

| DE6608621U (de) | Vorrichtung zum abgeben von aerosolen. | |

| DE10307590B4 (de) | Kindersichere Blisterpackung | |

| DE602004005226T2 (de) | Tablettenspender | |

| DE69422903T2 (de) | Gasfeuerzeug mit Sicherheitsvorrichtung | |

| DE2925432C2 (fr) | ||

| DE2423975A1 (de) | Folgeschalter | |

| EP0600123A1 (fr) | Distributeur de pilules avec orifice de distribution dans sa base | |

| EP2081842B1 (fr) | Bouchon pour récipient | |

| DE4216454A1 (de) | Druckschalter | |

| EP1606193B1 (fr) | Distributeur de pastilles | |

| EP0408774B1 (fr) | Distributeur de comprimés pour la distribution individuelle de comprimés | |

| DE4317269C1 (de) | Originalitäts-Sicherungsvorrichtung für Behälterverschlüsse | |

| EP0481250B1 (fr) | Cartouche destinée à être introduite dans un distributeur | |

| DE3022411A1 (de) | Behaelter zur einzel-portionierten ausgabe von tabletten | |

| DE3342884A1 (de) | Kindersichere schutzkappe fuer aerosolspruehdosen | |

| DE2512542C2 (de) | Behälter zur Aufnahme von Formkörpern, insbes. Tabletten |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19931025 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19940624 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 130272 Country of ref document: AT Date of ref document: 19951215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59204371 Country of ref document: DE Date of ref document: 19951221 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2079776 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: HANS RUDOLF GACHNANG PATENTANWALT |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19960223 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: GC |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20101223 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20101123 Year of fee payment: 19 Ref country code: IT Payment date: 20101222 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20101103 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20111028 Year of fee payment: 20 Ref country code: NL Payment date: 20111220 Year of fee payment: 20 Ref country code: CH Payment date: 20111216 Year of fee payment: 20 Ref country code: BE Payment date: 20111021 Year of fee payment: 20 Ref country code: FR Payment date: 20111118 Year of fee payment: 20 Ref country code: LU Payment date: 20111223 Year of fee payment: 20 Ref country code: SE Payment date: 20111221 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59204371 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59204371 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V4 Effective date: 20121203 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20121202 |

|

| BE20 | Be: patent expired |

Owner name: *KERPLAS NEUENBURG G.M.B.H. KUNSTSTOFFVERPACKUNGEN Effective date: 20121203 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 130272 Country of ref document: AT Kind code of ref document: T Effective date: 20121203 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20121202 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20130718 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20121204 |