EP0565899B1 - Fadenschneidevorrichtung - Google Patents

Fadenschneidevorrichtung Download PDFInfo

- Publication number

- EP0565899B1 EP0565899B1 EP93104508A EP93104508A EP0565899B1 EP 0565899 B1 EP0565899 B1 EP 0565899B1 EP 93104508 A EP93104508 A EP 93104508A EP 93104508 A EP93104508 A EP 93104508A EP 0565899 B1 EP0565899 B1 EP 0565899B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- yarn

- thread

- traversing

- cutter

- lifter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005520 cutting process Methods 0.000 title claims description 15

- 235000013351 cheese Nutrition 0.000 claims 1

- 238000000034 method Methods 0.000 claims 1

- 238000004804 winding Methods 0.000 description 32

- 239000002699 waste material Substances 0.000 description 3

- 230000001154 acute effect Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/02—Winding and traversing material on to reels, bobbins, tubes, or like package cores or formers

- B65H54/28—Traversing devices; Package-shaping arrangements

- B65H54/34—Traversing devices; Package-shaping arrangements for laying subsidiary winding, e.g. transfer tails

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/70—Other constructional features of yarn-winding machines

- B65H54/71—Arrangements for severing filamentary materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H54/00—Winding, coiling, or depositing filamentary material

- B65H54/86—Arrangements for taking-up waste material before or after winding or depositing

- B65H54/88—Arrangements for taking-up waste material before or after winding or depositing by means of pneumatic arrangements, e.g. suction guns

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H57/00—Guides for filamentary materials; Supports therefor

- B65H57/003—Arrangements for threading or unthreading the guide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H59/00—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators

- B65H59/10—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators by devices acting on running material and not associated with supply or take-up devices

- B65H59/12—Stationary elements arranged to deflect material from straight path

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Definitions

- the invention relates to a cutting device for a running thread according to the preamble of claim 1.

- Such a device is known from EP 0 403 949 A1. That device has proven itself for cutting threads running at any speed and without the risk of the thread ends breaking apart, the device having the particular advantage that it carries out cutting operations essentially independently of the thread tensile forces and in particular without tensile force peaks. However, it is not readily possible to create a final winding consisting of several yarn turns with the known device at the end of the winding cycle on the bobbin or on the winding formed thereon.

- the invention has for its object to provide a cutting device for a running thread which, in addition to the advantages of the known device, offers the option of forming a final winding consisting of several, essentially parallel thread turns at the end of a winding trip on the outer surface of the thread winding or Not.

- the thread lifting device after it has lifted the thread over the traversing triangle and out of the traversing thread guide, remains in its upper position for a period of time commensurate with the number of thread turns forming the final winding, before being moved back to its lower position, thereby guiding the yarn against the knife edge for cutting.

- the thread lifting device can be moved back into its lower position immediately after it has lifted the thread from the traversing thread guide, in which case no final winding is formed.

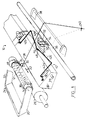

- the device 10 shown in FIGS. 1-3 shows a cross winding 12 formed by a thread on a winding tube 14.

- the winding tube 14 is rotatably supported at its opposite ends by centering plates 16 and 18.

- the centering plates 16 and 18 in turn are mounted in opposing arms 20 and 22 of a holder 24, which is part of a textile machine, not otherwise shown.

- the winding tube 14 or the one formed on it Cross winding 12 rests on a friction roller 26.

- the friction roller 26 is rotated by a drive device, not shown, and in turn drives the winding tube 14 or the cross winding 12 formed thereon.

- a housing 28 In front of the friction roller 26 there is a housing 28 which is provided with a slot which is not visible in the drawing.

- a traversing thread guide 30 protrudes from this slot.

- the traversing thread guide 30 is guided back and forth parallel to the winding tube 14 by a reversing thread shaft which is located in the housing 28 but is not shown, as shown by a double arrow 32.

- the traversing thread guide 30 is provided with a notch 34 which is open at the top.

- the rear sight 34 is used to guide a thread 36 which is under a certain tension from the bobbin 14 via a thread overflow rod 38 and through an immovable thread guide 40, e.g. B. an eyelet is used.

- an eyelet is used as a result of the movement of the traversing thread guide 30, the thread 36 sweeps over an approximately triangular surface, the so-called traversing triangle, which is shown here bent around the thread overflow rod 38. Its lateral extent is shown by a dash-dotted line.

- the area swept between the traversing thread guide 30 and the thread overflow rod 38 by the traversing thread 36 is referred to below as the "traversing surface”.

- a thread lifting device which is shown here as a bracket 42, the legs 42a and 42b of which are rotatably attached to the housing 28 at one end.

- the legs 42a and 42b are connected to one another at their other end by arms 42c and 42d forming a sliding edge in a V-shape.

- the arms 42c and 42d are connected to each other - approximately in the middle of the bracket 42 - they form a rear sight 44, the functions of which are described in detail below.

- the arms 42c and 42d are inclined towards each other between the legs 42a and 42b, so that they have the shape of a form flattened V's, the tip forming the rear sight 44 pointing downward when the bracket 42 is pivoted upright, as described below.

- a projection or thread catcher 46 protruding from the arm 42c and pointing towards the arm 42d protrudes over the rear sight.

- the projection 46 is dimensioned such that its tip projects beyond the rear sight 44 and its tip is open to the side relative to the other arm 42d Gap forms.

- the projection 46 has the same inclination as the arm 42c, from which it projects seamlessly, that is to say with a smooth transition.

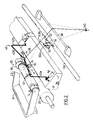

- One leg 42a of the bracket 42 is connected to a schematically illustrated drive 48, for example an electromagnet or a double-acting piston-cylinder unit. From this the bracket 42 can be moved between its flat lying rest position shown in FIG. 1 and a higher position, which is shown pivoted by approximately 90 ° in FIG. 2 by way of example. It is essential that the stirrup 42 in its rest position lies under the thread 36, ie under the traversing surface, and that its arms 42c and 42d project beyond the traversing triangle on both sides.

- a schematically illustrated drive 48 for example an electromagnet or a double-acting piston-cylinder unit. From this the bracket 42 can be moved between its flat lying rest position shown in FIG. 1 and a higher position, which is shown pivoted by approximately 90 ° in FIG. 2 by way of example. It is essential that the stirrup 42 in its rest position lies under the thread 36, ie under the traversing surface, and that its arms 42c and 42d project beyond the traversing triangle on both sides.

- FIG. 4 Another embodiment of the thread lifting device is shown in FIG. 4.

- the shape of this device differs from that described above in that it does not have a protrusion for catching the yarn that partially projects from one of the two arms. Instead, the arms, which are inclined towards each other in a V-shape at the point forming the rear sight, are connected to one another by a helical loop, the loop being open in the direction of the tip of the V.

- the yarn sliding along one of the arms when the device is lifted can slip into the loop, but it cannot escape from the loop when the device is moved downward and can therefore be guided into the knife for cutting purposes. Otherwise, the yarn is handled in the same way by the lifting device according to FIG. 4 as by the device already described.

- the bracket 42 can by an otherwise not shown Telescopic thread lifters between positions below and above the traversing surface, the upward-facing edge of which is to be made V-shaped and the rear sight of which would be provided with a thread catcher approximately in the manner described above.

- a knife 50 with an obliquely upward-facing cutting edge 50a is provided in the thread running direction in front of the stirrup 42 and is opposite an equally obliquely upward-pointing guide edge 50b.

- the knife edge 50a and the guide edge 50b form an upwardly open V-shaped slot between them. The opening of the slot is below the traversing surface.

- a thread centerer 52 In front of the knife 50 and the leading edge 50b is a thread centerer 52, the upward-facing edge of which is split in a V-shape.

- a suction device 54 In front of the thread centering device 52 there is in turn a suction device 54 connected to a vacuum source (not shown) in the form of a tube, one end of which is approximately at the same height as the tip of the V-shaped knife and thread centering slots.

- the tube 54 leads into a suction manifold 56, shown here as parallel to the thread overflow rod 38, which leads to the vacuum source and a waste device, also not shown.

- the tips of the centering slot and the rear sight 44 formed by the bracket arms 42c and 42d lie with the fixed thread guide 40 in a common vertical plane, the opening of the suction tube 52 being close to this plane and at the same height as the tips of the knife and centering slots lies.

- the cutting edge 50a of the knife 50 intersects the plane at an acute angle, ie the cutting edge 50a is oriented in the direction of the movement of the thread 36 to be guided against the knife 50 in such a way that the thread 36 has essentially no relative movement component transverse to the Cutting edge 50a. Otherwise, the knife 50 is at right angles to the vertical plane intersecting the bow sight 44, the centering slot and the fixed thread guide 40.

- the thread running through the fixed thread guide 40 and the rear sight 34 of the traversing thread guide 30 is wound up as a cross winding 12 on the rotating bobbin 14 as a result of the back and forth movement of the traversing thread guide 30. It runs above the thread lifter 42, the knife 50 and the centering device 52 and sweeps over an essentially triangular surface (traversing triangle) which is bent around the thread overflow rod 38. As soon as the cross winding 12 has reached a predetermined diameter, a signal indicating the end of the winding travel is triggered by a device (not shown here). This signal is fed to the drive 48 of the bracket 42. The signal triggers a movement of the drive 48 in the sense that the bracket 42 is pivoted into its upright position shown in FIG.

- the thread 36 is held in place by the projection 46 or by the loop 46a, guided against the knife edge 50a and cut thereon, i. H. the thread 36 is guided essentially in the vertical plane mentioned. Simultaneously with the cut, the end of the thread 36 coming from the fixed thread guide 40 is gripped by the suction device 54 and led to the waste. The other end of the thread 36 is received in the final winding 58.

- the coil 14 can then be removed from the holder 24 in a known manner by loosening the centering plates 16 and 18 and replaced by an empty coil.

- the device according to the invention is also suitable for producing yarn packages without a final winding, as may be desired under certain conditions.

- the bracket 42 only needs to be raised so far that the thread 36 is gripped by the rear sight 44 of the bracket 42 and, when the bracket 42 is pivoted back into its lower position, is cut into the knife 50 for cutting.

- the traversing thread guide 30 can advantageously be designed such that the thread 36 remains in it and continues to be shifted until it is guided and cut into the knife 50 when the bracket 42 is pivoted down, and the negligible end remaining in the traversing surface is wound up and the other End to waste.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Replacing, Conveying, And Pick-Finding For Filamentary Materials (AREA)

- Coiling Of Filamentary Materials In General (AREA)

- Winding Filamentary Materials (AREA)

- Guides For Winding Or Rewinding, Or Guides For Filamentary Materials (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4212241 | 1992-04-11 | ||

| DE4212241 | 1992-04-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0565899A1 EP0565899A1 (de) | 1993-10-20 |

| EP0565899B1 true EP0565899B1 (de) | 1995-06-21 |

Family

ID=6456648

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93104508A Expired - Lifetime EP0565899B1 (de) | 1992-04-11 | 1993-03-19 | Fadenschneidevorrichtung |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5348242A (ko) |

| EP (1) | EP0565899B1 (ko) |

| JP (1) | JP3323275B2 (ko) |

| KR (1) | KR0133500B1 (ko) |

| CN (1) | CN1031420C (ko) |

| DE (1) | DE59300271D1 (ko) |

| TW (1) | TW209256B (ko) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE59300517D1 (de) * | 1992-04-11 | 1995-10-05 | Barmag Barmer Maschf | Absaugeinrichtung für eine Vielzahl von kontinuierlich anlaufenden Fäden. |

| DE4415677C2 (de) * | 1993-05-12 | 2001-09-13 | Barmag Barmer Maschf | Verfahren zur Qualitätskennzeichnung einer Fadenspule und Spulvorrichtung |

| ES2126051T3 (es) * | 1993-05-28 | 1999-03-16 | Savio Macchine Tessili Spa | Procedimiento perfeccionado para el devanado de bobinas, y maquinas devanadoras para su realizacion. |

| IT1265444B1 (it) * | 1993-12-24 | 1996-11-22 | Menegatto Srl | Taglierina per il taglio di un filato in macchine tessili |

| JP3698873B2 (ja) * | 1997-10-03 | 2005-09-21 | ナブテスコ株式会社 | 糸条パッケージの形成方法および形成装置 |

| EP1127832B1 (de) * | 2000-02-25 | 2005-03-16 | Saurer GmbH & Co. KG | Vorrichtung zum Wickeln von rotatorisch angetriebenen Kreuzspulen |

| KR100982139B1 (ko) * | 2002-08-28 | 2010-09-15 | 고도 덴시 가부시기 가이샤 | 직사각형 단면 선재의 권선장치 |

| CN100439579C (zh) * | 2003-02-19 | 2008-12-03 | 东丽工程株式会社 | 纱条卷取装置 |

| DE10324253B4 (de) * | 2003-05-28 | 2017-03-16 | Rieter Ingolstadt Gmbh | Verfahren zum Warten einer Arbeitsstelle einer Textilmaschine sowie Textilmaschine und Nachrüstsatz für eine Textilmaschine |

| CN102587033A (zh) * | 2012-02-21 | 2012-07-18 | 李荣华 | 地毯编织色线排线机 |

| WO2014087383A2 (en) * | 2012-12-06 | 2014-06-12 | Kordsa Global Endustriyel Iplik Ve Kord Bezi Sanayi Ve Ticaret Anonim Sirketi | A method for enabling the production machines in the cord production system to be stopped synchronously |

| CN106348095B (zh) * | 2016-08-26 | 2019-04-19 | 巨石集团有限公司 | 一种用于玻璃纤维络纱机的自动上卷和切丝装置 |

| DE102021118842A1 (de) * | 2021-07-21 | 2023-01-26 | Maschinenfabrik Rieter Ag | Verfahren zum Betreiben einer Arbeitsstelle einer Textilmaschine, sowie Arbeitsstelle einer Textilmaschine |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE516234C (de) * | 1931-01-20 | Wegmann & Cie A G | Fadenfuehrungseinrichtung fuer Etagenzwirnmaschinen | |

| CN1027926C (zh) * | 1985-07-03 | 1995-03-15 | 巴马格巴默机器制造股份公司 | 运转纱线的连续监控方法 |

| DE3734478A1 (de) * | 1987-10-12 | 1989-04-27 | Schubert & Salzer Maschinen | Verfahren und vorrichtung zum fuehren, halten und trennen eines fadens beim spulenwechsel |

| US5107668A (en) * | 1989-06-19 | 1992-04-28 | Barmag Ag | Method of doffing packages of a textile machine as well as a textile machine |

| US5158241A (en) * | 1989-06-19 | 1992-10-27 | Barmag Ag | Apparatus for cutting an advancing yarn |

-

1993

- 1993-03-19 EP EP93104508A patent/EP0565899B1/de not_active Expired - Lifetime

- 1993-03-19 TW TW082102053A patent/TW209256B/zh active

- 1993-03-19 DE DE59300271T patent/DE59300271D1/de not_active Expired - Fee Related

- 1993-04-08 KR KR1019930005883A patent/KR0133500B1/ko not_active IP Right Cessation

- 1993-04-09 JP JP08315293A patent/JP3323275B2/ja not_active Expired - Fee Related

- 1993-04-10 CN CN93104208A patent/CN1031420C/zh not_active Expired - Fee Related

- 1993-04-12 US US08/046,014 patent/US5348242A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE59300271D1 (de) | 1995-07-27 |

| JP3323275B2 (ja) | 2002-09-09 |

| EP0565899A1 (de) | 1993-10-20 |

| JPH0616335A (ja) | 1994-01-25 |

| TW209256B (ko) | 1993-07-11 |

| CN1031420C (zh) | 1996-03-27 |

| KR930021524A (ko) | 1993-11-22 |

| US5348242A (en) | 1994-09-20 |

| KR0133500B1 (ko) | 1998-04-24 |

| CN1079517A (zh) | 1993-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2615909C2 (ko) | ||

| EP0565899B1 (de) | Fadenschneidevorrichtung | |

| DE3802900C2 (ko) | ||

| DE2931209C2 (ko) | ||

| DE2648621C3 (de) | Doppeldraht-Zwirnmaschine | |

| DE2506930C2 (de) | Verfahren und Vorrichtung zum Bilden einer Fadenreserve aus dem Fadenende einer Textilspule | |

| DE2551290C2 (de) | Fadeneinziehvorrichtung für Doppelspulstellen auf Spulmaschinen | |

| EP0286002A1 (de) | Verfahren und Vorrichtung zum Spulenwechsel | |

| DE102019129966B3 (de) | Vorrichtung und Verfahren zum Aufwickeln eines Fadens | |

| DE2626651A1 (de) | Kabelfang- und -abschneidevorrichtung | |

| EP0072908A1 (de) | Spulmaschine für automatischen Spulenwechsel | |

| DE3931124A1 (de) | Verfahren und vorrichtung zum trennen eines vorgarnes zwischen den pressfingern an den fluegeln einer mit einem streckwerk versehenen vorspinnmaschine und den vollen vorgarnspulen | |

| CH686669A5 (de) | Verfahren und Vorrichtung zum Wickeln einer Fadenreserve. | |

| DE4415677C2 (de) | Verfahren zur Qualitätskennzeichnung einer Fadenspule und Spulvorrichtung | |

| DE2330707A1 (de) | Automatische spulmaschine mit einer klemmvorrichtung | |

| DE2657798A1 (de) | Vorrichtung zur uebergabe eines fadens an einen leeren wickelkoerper | |

| DE3733353A1 (de) | Fadenreserve und verfahren und vorrichtung zum herstellen der fadenreserve | |

| DE8811305U1 (de) | Schneidvorrichtung zum Abtrennen von Schleppfäden von Spinnspulen | |

| DE2000051A1 (de) | Verfahren und Vorrichtung zur Behandlung eines Garnwickels | |

| DE3235135C2 (ko) | ||

| DE2927742C2 (ko) | ||

| DE3202888A1 (de) | Verfahren und vorrichtung zum fadenschneiden beim automatischen abziehen der spulen auf einer spindeltextilmaschine | |

| DE3436025A1 (de) | Verfahren und vorrichtung zum festlegen eines fadens zur verwendung in einer wickeleinrichtung | |

| DE2614252B2 (de) | Verfahren zur Herstellung einer Fadenreserve | |

| DE2441552B2 (de) | Vorrichtung an einem Wickelautomaten zur automatischen Herstellung von Garnknäueln mit festgelegten Fadenenden |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19931002 |

|

| 17Q | First examination report despatched |

Effective date: 19931125 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19950621 |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 59300271 Country of ref document: DE Date of ref document: 19950727 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19951002 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BARMAG GMBH ENGINEERING & MANUFACTURING |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20060322 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20060419 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20070326 Year of fee payment: 15 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20070319 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20070614 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070319 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20070322 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20081125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080319 |