EP0436140B1 - Procédé et dispositif de refroidissement d'une substance pulvérulente - Google Patents

Procédé et dispositif de refroidissement d'une substance pulvérulente Download PDFInfo

- Publication number

- EP0436140B1 EP0436140B1 EP90123424A EP90123424A EP0436140B1 EP 0436140 B1 EP0436140 B1 EP 0436140B1 EP 90123424 A EP90123424 A EP 90123424A EP 90123424 A EP90123424 A EP 90123424A EP 0436140 B1 EP0436140 B1 EP 0436140B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- baffle plate

- liquified gas

- cooling

- implementation

- sprayed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 24

- 238000001816 cooling Methods 0.000 title claims abstract description 23

- 239000011236 particulate material Substances 0.000 title 1

- 239000000843 powder Substances 0.000 claims abstract description 33

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims abstract description 16

- 239000007788 liquid Substances 0.000 claims abstract description 9

- 229910052757 nitrogen Inorganic materials 0.000 claims abstract description 8

- 239000000126 substance Substances 0.000 claims description 22

- 239000007789 gas Substances 0.000 claims description 21

- 239000004568 cement Substances 0.000 claims description 16

- 238000003860 storage Methods 0.000 claims description 2

- 230000015572 biosynthetic process Effects 0.000 claims 1

- 238000009826 distribution Methods 0.000 abstract description 9

- 239000000110 cooling liquid Substances 0.000 abstract description 6

- 239000000463 material Substances 0.000 abstract description 4

- 239000000945 filler Substances 0.000 description 16

- 239000002826 coolant Substances 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000003892 spreading Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 235000008733 Citrus aurantifolia Nutrition 0.000 description 1

- 229920000426 Microplastic Polymers 0.000 description 1

- 235000011941 Tilia x europaea Nutrition 0.000 description 1

- 238000009435 building construction Methods 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000003337 fertilizer Substances 0.000 description 1

- 238000005429 filling process Methods 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 239000004571 lime Substances 0.000 description 1

- 239000008267 milk Substances 0.000 description 1

- 210000004080 milk Anatomy 0.000 description 1

- 235000013336 milk Nutrition 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 235000013599 spices Nutrition 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28C—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA COME INTO DIRECT CONTACT WITHOUT CHEMICAL INTERACTION

- F28C3/00—Other direct-contact heat-exchange apparatus

- F28C3/10—Other direct-contact heat-exchange apparatus one heat-exchange medium at least being a fluent solid, e.g. a particulate material

- F28C3/12—Other direct-contact heat-exchange apparatus one heat-exchange medium at least being a fluent solid, e.g. a particulate material the heat-exchange medium being a particulate material and a gas, vapour, or liquid

- F28C3/14—Other direct-contact heat-exchange apparatus one heat-exchange medium at least being a fluent solid, e.g. a particulate material the heat-exchange medium being a particulate material and a gas, vapour, or liquid the particulate material moving by gravity, e.g. down a tube

Definitions

- the invention relates to a method for cooling a powdery substance, in particular cement, which is filled as a powder jet through a nozzle into a container and sprayed with a liquefied gas for cooling, and a device for carrying out the method.

- DE-A-36 23 724 discloses a method and a device for producing fresh concrete using cement that is precooled by liquid nitrogen.

- the cement is cooled when the cement is fed into a storage silo.

- the liquid nitrogen is blown into the cement silo at the same time as the cement.

- the connections for cement and nitrogen are arranged adjacent in the upper silo area.

- this known method has the disadvantage that adequate cooling cannot be achieved with it: because the cement emerges from the filler neck in the form of a water jet.

- the water-like behavior of the cement means that the contact surface is in no way sufficient for the required heat exchange.

- DE-A-33 16 030 proposes a method and a device for moistening granular or powdery spreading material, such as road salt, synthetic fertilizer or lime, in order to increase the accuracy when spreading and the duration of the spreading material.

- the grit is run over two roof-shaped inclined surfaces and each of the two grit flows is sprayed with a liquid such as lye from the outside, ie from locations above and below the inclined surface.

- a liquid such as lye from the outside, ie from locations above and below the inclined surface.

- the granular substances required for the production of concrete are passed separately from one another into a container with different partial containers arranged next to one another. Cooling water is then sprayed from above onto the substances in the partial containers from spray nozzles. The various substances are then drained. The drying time and cooling time depend on the grain size of the respective substance. The still moist, cooled substances are finally mixed to form concrete.

- This complex process also shows the disadvantages of only a low heat exchange and the low cold content of cold water.

- the invention has for its object to provide a method and a device for cooling a powdery substance, in particular cement, which is filled as a powder jet through a nozzle in a container and sprayed with a liquefied gas for cooling, which meet the requirements described above and ensure in particular an increased heat exchange between the powdery substance and the cooling liquid.

- This object is achieved in that the powder jet is first directed onto a baffle plate inclined to the filling direction and then the liquefied gas is sprayed into the finely distributed baffle stream which widens in cross section.

- the essential feature of the invention is that a baffle plate is placed below the powder filler neck in the powder stream of the powder to be cooled. When it hits this inclined baffle plate, the powder jet is torn, causing the powder to form a finely divided baffle flow and creating an effective contact surface for heat exchange with the liquefied gas.

- Another advantage is that the temperature distribution in the container is much more homogeneous than can be achieved according to the prior art. The above-mentioned sufficient cooling can also be achieved with a lower coolant throughput, and it can also be far surpassed if necessary.

- the invention can be applied to a wide variety of powdery substances.

- One example is the cement mentioned above in the course of the production of concrete, which is of particular importance because of its widespread use in building construction and civil engineering.

- the use of liquid nitrogen as a coolant is recommended, since nitrogen does not leave any residues, but evaporates and degasses 100 percent.

- the invention can be used with the same success, for example in the production of milk powder and plastic granules, and in particular in the grinding of spices which, for. T. are very temperature sensitive, use.

- a great advantage of the invention is that it can be easily installed in a conventional cooling device for powdery substances which are fed into a container.

- the filler neck of such a conventional cooling device can be in the container be arranged decentrally or centrally in the upper container area.

- the decentralized arrangement is characterized by a flat baffle plate arranged obliquely below the outlet openings of the powder filler neck, which is fastened to the powder filler neck with brackets at an angle between approximately 30 ° and approximately 75 ° to the direction in which the powder falls.

- a flat baffle plate arranged obliquely below the outlet openings of the powder filler neck, which is fastened to the powder filler neck with brackets at an angle between approximately 30 ° and approximately 75 ° to the direction in which the powder falls.

- a blunt baffle cone with brackets is attached to it below the centrally positioned powder filler neck in such a way that the axis of the filler neck points to the cone tip pointing upwards.

- the liquid nitrogen is added via a ring line provided on its underside with numerous outlet openings for the liquid coolant as a distribution rake to the truncated cone-shaped impingement flow of the powder which is formed by the cone.

- This arrangement of a ring line arranged centrally around the filler neck ensures particularly effective cooling of the powder.

- the baffle plate is fastened to the powder filler neck with brackets. A separate fastening of the baffle plate is also conceivable.

- the powdery substance fed into the container from above through the powder filler neck hits the baffle plate mounted underneath the filler neck and that the powdery substance that bounces off flows below the coolant distribution rake so that it flows through the outlet openings of the distribution rake Liquefied gas sprayed onto the powdery substance makes an effective thermal contact with it.

- a particularly effective thermal contact results if the cross section of the sprayed impingement stream is enlarged compared to the cross section of the powder stream in the powder filler neck.

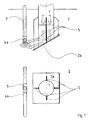

- FIG. 1 shows a device for cooling a powdery substance (symbolized by arrows) in a decentralized arrangement.

- Figure 1 shows one

- FIG. 1 Side view, Figure 1, II a top view.

- the powder to be cooled passes through a powder filler neck 1 into a container (not shown), where it meets a flat, obliquely positioned baffle plate 2a and bounces off it again.

- the liquefied gas passes from a feed line 3 into a straight distribution rake 4a, which has numerous outlet openings for the liquefied gas on its underside, and is sprayed onto the baffle flow of the powder generated by the baffle plate 2a in order to achieve the desired cooling of the powder.

- the baffle plate 2a is fastened to the powder filler neck 1 with brackets 5.

- FIG. 2 shows an alternative form of arrangement of a device for cooling powdery substances, namely a central one, FIG. 2, I again representing the side view of FIG. 2, II (top view).

- the same or comparable parts of the device are provided with the same reference numbers as in FIG. 1.

- the powder (arrows) fed through the filler neck 1 into the container (not shown) hits the conical baffle plate 2b and is thereby widened to form a frustoconical baffle flow.

- the liquefied gas is fed via the feed line 3 into a ring line 4b provided on its underside with numerous outlet openings for the liquefied gas, which serves as a distribution screen for spraying the liquefied gas onto the impingement stream and thus achieves the necessary cooling.

- the brackets 5 fix the impact cone 2b below the filler neck 1.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Vaporization, Distillation, Condensation, Sublimation, And Cold Traps (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

Claims (10)

- Procédé pour refroidir un produit pulvérulent, en particulier du ciment, qui est introduit sous la forme d'un courant de poudre au moyen d'une tubulure de remplissage dans un récipient, et qui est arrosé au moyen d'un gaz liquéfié, pour assurer son refroidissement, caractérisé en ce qu'on dirige d'abord le courant de poudre sur une plaque de déflexion disposée en biais par rapport à direction de remplissage, et qu'on pulvérise ensuite le gaz liquéfié dans le courant de rebondissement, finement divisé, et s'élargissant en section transversale.

- Procédé selon la revendication 1, caractérisé en ce qu'on conduit le courant de poudre contre une plaque de déflexion, après quoi l'on pulvérise dans le courant de rebondissement qui en résulte le gaz liquéfié à partir d'un ratelier de distribution.

- Procédé selon la revendication 1, caractérisé en ce que l'on conduit le courant de poudre contre une plaque de déflexion conique, après quoi l'on pulvérise dans le courant de rebondissement qui en résulte le gaz liquéfié à partir d'une conduite annulaire servant de râtelier de distribution.

- Procédé selon les revendications 1 à 3, caractérisé en ce que l'on introduit comme gaz liquéfié de l'azote liquide.

- Dispositif pour la mise en oeuvre du procédé selon la revendication 1, présentant un récipient de stockage pour un produit pulvérulent, muni à sa partie supérieure d'une tubulure de remplissage (1) pour le produit pulvérulent et d'un organe de distribution (4a ; 4b) pour un gaz liquéfié, caractérisé en ce qu'une plaque de déflexion (2) disposée obliquement par rapport à la direction de remplissage est disposée à distance de l'extrémité de sortie de la tubulure de remplissage (1) et à proximité des ouvertures de sortie de l'organe de distribution (4a ; 4b) du gaz liquéfié.

- Dispositif pour la mise en oeuvre du procédé selon la revendication 5, caractérisé en ce que la plaque de déflexion (2a) présente une forme plane.

- Dispositif pour la mise en oeuvre du procédé selon la revendication 5, caractérisé en ce que la plaque de déflexion (2b) présente une forme tronconique avec le sommet du cône dirigé vers la tubulure de remplissage en étant disposé centralement en-dessous de cette dernière.

- Dispositif pour la mise en oeuvre du procédé selon les revendications 5 à 7, caractérisé en ce que la plaque de déflexion (2a ; 2b) est fixée sur la tubulure de remplissage (1) au moyen d'attaches de fixation (5).

- Dispositif pour la mise en oeuvre du procédé selon la revendication 6, caractérisé en ce que l'organe de distribution (4a) pour le gaz liquéfié est composé d'un ratelier droit (4a) disposé latéralement à côté de la plaque de déflexion et dans la zone inférieure de cette plaque de déflexion.

- Dispositif pour la mise en oeuvre du procédé selon la revendication 7, caractérisé en ce que le dispositif de distribution (4b) pour le gaz liquéfié est composé d'une conduite annulaire (4b) servant de râtelier et disposée symétriquement par rapport au cône.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT90123424T ATE102701T1 (de) | 1989-12-14 | 1990-12-06 | Verfahren und vorrichtung zur kuehlung einer pulverfoermigen substanz. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3941262 | 1989-12-14 | ||

| DE3941262A DE3941262C1 (fr) | 1989-12-14 | 1989-12-14 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0436140A1 EP0436140A1 (fr) | 1991-07-10 |

| EP0436140B1 true EP0436140B1 (fr) | 1994-03-09 |

Family

ID=6395436

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90123424A Expired - Lifetime EP0436140B1 (fr) | 1989-12-14 | 1990-12-06 | Procédé et dispositif de refroidissement d'une substance pulvérulente |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0436140B1 (fr) |

| AT (1) | ATE102701T1 (fr) |

| DE (2) | DE3941262C1 (fr) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005504948A (ja) * | 2001-07-05 | 2005-02-17 | カー−マギー ピグメンツ インターナショナル ゲゼルシャフト ミット ベシュレンクテル ハフツング | 微粒の固形物を直接的に冷却する方法 |

| DE102005037081A1 (de) * | 2005-08-03 | 2007-02-08 | Messer Group Gmbh | Verfahren und Vorrichtung zum Kühlen von Zement oder zementartigen Pulvern |

| EP2077933B1 (fr) * | 2006-10-04 | 2012-02-01 | Messer Group GmbH | Procédé et dispositif de fabrication de béton frais refroidi |

| CN102774669A (zh) * | 2011-05-11 | 2012-11-14 | 贵州航天凯山特种车改装有限公司 | 粉粒物料运输气动卸料车主进气管冷却装置 |

| CN105775795B (zh) * | 2016-03-28 | 2017-10-31 | 重庆钢铁(集团)有限责任公司 | 一种可提升烧结制粒效果的返矿喷淋系统 |

| US12044447B2 (en) | 2017-03-06 | 2024-07-23 | Nitrocrete Ip, Llc | Cooling system and method |

| AT522559B1 (de) * | 2019-04-25 | 2022-10-15 | Thomas Wallner Dipl Ing Fh | Verfahren zum Regulieren der Aggregattemperatur beim Herstellen von Beton |

| DE102021005340A1 (de) | 2021-10-27 | 2023-04-27 | Messer Austria Gmbh | Vorrichtung und Verfahren zur Herstellung von gekühltem Frischbeton |

| DE102021005339A1 (de) | 2021-10-27 | 2023-04-27 | Messer Austria Gmbh | Verfahren und Vorrichtung zur Herstellung von gekühltem Frischbeton |

| DE102021005338A1 (de) | 2021-10-27 | 2023-04-27 | Messer Austria Gmbh | Vorrichtung zur Herstellung von gekühltem Frischbeton |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2727734A (en) * | 1951-06-14 | 1955-12-20 | Johnson Co C S | Method of and apparatus for cooling concrete aggregates |

| NL290527A (fr) * | 1962-03-22 | |||

| US3358976A (en) * | 1965-03-15 | 1967-12-19 | Conrad Y Siktberg | Apparatus for heating concrete ingredients |

| DE1911965A1 (de) * | 1968-03-13 | 1969-11-06 | Prerovske Strojirny Np | Vorrichtung zum Vorwaermen von pulverfoermigen Materialien,insbesondere von Zementrohmehl |

| DE2438969A1 (de) * | 1974-08-14 | 1976-02-26 | Messer Griesheim Gmbh | Verfahren zur kuehlung von beton |

| AT358617B (de) * | 1979-01-30 | 1980-09-25 | Voest Alpine Ag | Verfahren und vorrichtung zum abkuehlen von gebranntem material, wie sinter oder pellets |

| DE3316030C2 (de) * | 1983-05-03 | 1986-05-07 | Adolf 2720 Rotenburg Biere | Verfahren und Vorrichtung zum Befeuchten und Ausstreuen von körnigem oder pulverförmigem Streugut |

| DE3623724A1 (de) * | 1986-07-14 | 1988-01-28 | Held & Francke Bau Ag | Verfahren und vorrichtung zum herstellen von frischbeton unter verwendung von durch fluessigen stickstoff gekuehltem zement |

-

1989

- 1989-12-14 DE DE3941262A patent/DE3941262C1/de not_active Expired - Fee Related

-

1990

- 1990-12-06 AT AT90123424T patent/ATE102701T1/de not_active IP Right Cessation

- 1990-12-06 EP EP90123424A patent/EP0436140B1/fr not_active Expired - Lifetime

- 1990-12-06 DE DE90123424T patent/DE59004918D1/de not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ATE102701T1 (de) | 1994-03-15 |

| EP0436140A1 (fr) | 1991-07-10 |

| DE59004918D1 (de) | 1994-04-14 |

| DE3941262C1 (fr) | 1991-08-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69819264T2 (de) | Verfahren und Einrichtung zur Granulierung | |

| DE1958610C3 (de) | Verfahren und Vorrichtung zum Zersprengen oder Zerstäuben eines freifallenden Flüssigkeitsstromes | |

| DE3043428C2 (de) | Verfahren zur Herstellung eines Granulats und Vorrichtung zur Durchführung des Verfahrens | |

| EP0436140B1 (fr) | Procédé et dispositif de refroidissement d'une substance pulvérulente | |

| DE1592793A1 (de) | Verfahren zur Herstellung einer granularen Duengemittelverbindung | |

| DD223643A5 (de) | Verfahren zur herstellung von koernern | |

| EP0007352A1 (fr) | Granulats obtenus à partir de masses en fusion, procédé et dispositif de fabrication. | |

| EP0787682A1 (fr) | Procédé de préparation de percarbonate de sodium en granules | |

| DE69100891T2 (de) | Herstellungseinrichtung eines gefrorenen Granulates. | |

| DE4010045C2 (de) | Verfahren und Vorrichtung zur Kühlung einer pulverförmigen Substanz | |

| DD151881A5 (de) | Vorrichtung zur befeuchtung von salzgranulaten | |

| EP0230964A2 (fr) | Dispositif pour appliquer de la poudre | |

| DE3124200C2 (de) | Verfahren zur Herstellung von Schwefel in Granulatform | |

| DE2222008C3 (de) | Düsenplatte zum Prillieren von geschmolzenem Material und Verwendung einer solchen Düsenplatte zum Prillieren von Ammoniumnitrat und/oder Harnstoff | |

| DE2227306A1 (de) | Pulverförmiges Paraffinwachs, Herstellungsverfahren und -vorrichtung | |

| AT404098B (de) | Verfahren zur herstellung von granuliertem stranggiesspulver | |

| DE3300415A1 (de) | Verfahren zur herstellung eines granularen mischduengers | |

| DE3731150C2 (de) | Verfahren und Vorrichtung zum Granulieren von Schwefel | |

| DE1263707B (de) | Granulierverfahren | |

| EP1252116A1 (fr) | Procede et dispositif pour l'expansion de matiere en fusion | |

| DE960821C (de) | Verfahren und Vorrichtung zur Einpuderung von koernigen Stoffen | |

| DE1792206A1 (de) | Wirbelreaktor fuer die Granulierung von Schmelzen | |

| DE3318652A1 (de) | Verfahren und vorrichtung zum kristallisieren von stoffen aus ihrer schmelze | |

| DE2056387C3 (fr) | ||

| WO1997033965A1 (fr) | Procede et dispositif pour fabriquer un produit pulverulent en vrac presentant des taches colorees |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT DE ES FR IT NL |

|

| 17P | Request for examination filed |

Effective date: 19910903 |

|

| 17Q | First examination report despatched |

Effective date: 19920710 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE ES FR IT NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940309 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19940309 |

|

| REF | Corresponds to: |

Ref document number: 102701 Country of ref document: AT Date of ref document: 19940315 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59004918 Country of ref document: DE Date of ref document: 19940414 |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19941206 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19951212 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19970829 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19981216 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051206 |