EP0340450B1 - Transportvorrichtung zum Verlagern von liegenden Patienten - Google Patents

Transportvorrichtung zum Verlagern von liegenden Patienten Download PDFInfo

- Publication number

- EP0340450B1 EP0340450B1 EP89105593A EP89105593A EP0340450B1 EP 0340450 B1 EP0340450 B1 EP 0340450B1 EP 89105593 A EP89105593 A EP 89105593A EP 89105593 A EP89105593 A EP 89105593A EP 0340450 B1 EP0340450 B1 EP 0340450B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- belt

- transport device

- platform

- roller

- stage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/10—Devices for lifting patients or disabled persons, e.g. special adaptations of hoists thereto

- A61G7/1025—Lateral movement of patients, e.g. horizontal transfer

- A61G7/1032—Endless belts

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G2200/00—Information related to the kind of patient or his position

- A61G2200/30—Specific positions of the patient

- A61G2200/32—Specific positions of the patient lying

Definitions

- the invention relates to a transport device for moving lying patients with a carrier and a guide attached to it, in which a stage for the positioning of the patients is slidably guided horizontally, with a drivable, preferably endless belt which is guided around the stage two mutually parallel edges of the stage is guided over deflecting rollers, with side cheeks which are arranged at the head and foot ends of the stage and which limit them parallel to the direction of the belt travel, and with a drive device for driving the belt (preamble of claim 1).

- Such a transport device is known from DE-A-2626638.

- Such transport devices are used, for example, in hospitals to shift patients between two beds that are next to one another in parallel or to take the patient out of his bed and transport him to a sterile room, for example an operating room, with the patient in turn in the clean room a patient couch is handed over.

- a sterile room for example an operating room

- the present invention has for its object to provide a transport device that reliably prevents the sheets from being drawn in during operation of the transport device.

- the band edge covers preferably contain grooves in which the side edges of the band are guided with low tolerance.

- the side cheeks which form a termination at the head and foot end of the stages, have grooves for guiding the band edges, which continuously merge into the grooves in the band edge cover.

- the band edge cover preferably comprises a part with an L-shaped cross section, in the base of which a groove extends in a U-shape around a bearing point of the deflecting roller.

- the L-shaped part also forms a bearing point for the deflection roller.

- the transport device is secured even further before sheets are drawn in if the belt edge cover is provided with a skid on its underside.

- This skid is preferably arranged so that it forms the lower edge of the stage and thus defines a distance between the lower edge of the stage and the lower band level.

- This distance is preferably at least 2 mm, preferably be at least 4 mm, whereby at the critical point where the tape engages with its side edge in the groove, an intermediate space for the sheet is created, so that this prevents the sheet from being drawn in under normal conditions.

- the carrier comprises two parallel, one-piece mounting plates, which supports the stage guide as well as a belt drive roller and belt tensioning rollers.

- the one-piece design of the mounting plate can ensure an exact mounting of these three components, which are particularly important for precise tape guidance, in a relatively simple manner, essentially only manufacturing tolerances but no additional tolerances caused by assembly being decisive for the accuracy of the tape guidance.

- the deflecting roller by means of which the strip is deflected at the edges of the stage, is preferably constructed as a shaft with roller bodies guided thereon.

- a particularly stable belt guide is obtained if the roller bodies are conical at both ends of the deflecting rollers, the tapered ends pointing towards one another and having the same diameter as the remaining roller bodies of the deflecting roller.

- Such a design of the deflection roller gives on the side edges of the Band a certain tension, whereby this centered itself again and again.

- the transport device 10 shown in FIG. 1 for moving lying patients is shown mounted in a wall opening in FIG. 1.

- the wall 12 separates a clean room, for example the operating room, from an anteroom that is not subject to the germ-free conditions of the operating room.

- the patient is transferred to the transport device in the position drawn with solid lines in FIG. 1 and lies on a conveyor belt 16 on the left side of a stage 14 of the transport device 10. Thereafter, the stage 14 is shown in dash-dotted lines in FIG. 1 Position shifted to the right, whereby the patient, as can be seen from FIG. 1, is shifted lying on the belt 16 on the stage 14 to the right side.

- the transport plane formed by the stage 14 and the conveyor belt 16 is delimited at the head and foot end of the stage 14 by side cheeks 18, 20, the side cheeks preferably being designed as a solid profile and thus for Stiffen the stage 14 and prevent the stage 14 from twisting. This is a not insignificant aspect that contributes to the straight guidance of the band 16.

- FIG. 2 shows a simplified sectional view through the transport device 10 built into the wall 12.

- the stage 14 consists essentially of a plywood panel 22 which extends essentially over the entire area of the stage 14.

- the plywood panel 22 will preferably be a solid panel with very little compliance and a high modulus of elasticity.

- the plywood panel 22 is provided on the edges of the stage 14, on which the conveyor belt 16 is deflected, with a bevelled edge area 24 which is screwed onto the plywood panel 22.

- the beveling of the edge 24 serves for the simpler and more convenient transfer of the patient from the sickbed 26 shown in broken lines in FIG. 2 to the stage 14.

- the side cheek 20 extends at the foot end of the stage 14 essentially over the entire width of the stage 14.

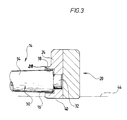

- the conclusion of the Sidewall 20 forms a band edge cover 28 on both sides, which at the same time forms a bearing for a deflecting roller 30.

- the deflection roller 30 is composed of a deflection shaft 32 and roller bodies 34 fastened thereon, the roller bodies 34 located at the ends of the deflection roller 30 each being conical - the tapered part of these roller bodies points towards the center of the deflection roller. This results in self-centering of the belt as soon as it moves over the deflection roller 30.

- the conveyor belt 16 is guided over the entire width of the stage 14 in a groove 36 of the side cheek 20.

- An essentially U-shaped guide groove 38 adjoins this groove 36 at the transition from the band edge cover 28 to the side wall 18, 20.

- a runner 40 is formed, which, as shown in FIG. 2, is at a distance from the mattress 42 and the sheet 44 spread over it to the conveyor belt 16.

- the runner 40 has, for example, a thickness of approximately 4 mm, which is sufficient to keep the sheet from the critical junction of the conveyor belt 16 into the belt edge cover 28.

- the conveyor belt 16 runs from the top of the stage 14 via the deflecting roller 30 on the underside of the stage 14 approximately parallel to the top course via a first tensioning roller 46, on which it is deflected by approximately 90 °, in a loop around a drive roller 48 to a second tension roller 50 and from there via a deflection roller, not shown, back to the stage surface.

- the guide (not shown in FIG. 2) for the horizontal displacement of the stage 14 and the mounting of the two tensioning rollers 46 and 50 and the drive roller 48 is accommodated on both sides in a one-piece mounting plate 52.

- the distance between the two mounting plates 52 is defined by a hollow steel profile 54, which is attached centrally to the mounting plate 52.

- the tensioning rollers 46, 50 can be moved parallel to the direction of displacement of the stage 14 by means of tensioning screws 56 (only shown in the case of the tensioning roller 50), so that there is always sufficient tension on the belt 16 which ensures that the conveyor belt 16 is carried along by the drive roller 48, be maintained.

- Fig. 3 finally shows in section details of the belt edge cover 28, in particular the guidance of the side edge of the conveyor belt 16 in the U-shaped groove 38.

- this figure shows how the sheet 40 from the critical junction of the side edge of the Conveyor belt 16 is held in the guide groove 38.

- the height of the stage 14 above the floor of the adjoining room is chosen so that the underside of the stage 14 presses lightly on the mattress 42 of the bed 26, so that the patient can be transferred to the stage 14 without having to be lifted.

- the conveyor belt 16 is driven by the drive roller 48 in the sense that the belt does not move relative to the patient when the patient is taken over. That is, roller 48 rotates clockwise and moves the belt relative to stage 14, the belt speed being twice the speed at which stage 14 is shifted to the left.

- the drive roller 48 is stopped and the drive mechanism for the stage 14 is started in the opposite direction.

- the conveyor belt remains because of the shutdown Drive roller 48 with respect to the tensioning rollers 46 in a constant position while it rolls around the deflection rollers 30 and shifts the patient from the left side of the stage 14 to its extreme right position (cf. the position shown in broken lines in FIG. 1).

- a patient bed or a mobile operating table can now be placed on this side, on which the patient is again taken over from the stage onto the patient bed while driving the conveyor belt 16.

- the solution of the tape guide according to the invention practically precludes the spreading of sheets and documents on the beds or patient beds in the drive mechanism of the transport device 10. All critical points, i.e. in particular the side edges of the conveyor belt 16 in the region of the deflection rollers are completely covered by the belt edge cover 28 (the groove 36, the side cheeks 18 and 20 and the groove 38).

- band edge cover 28 offers good protection against being drawn in in the region of the deflection rollers 30, which is reinforced by the precise guidance in the groove 38.

- An even more extensive protection against the sheet being drawn in is provided by the runner 40, which on the one hand smoothes the sheet 44 lying thereon when the mattress 42 is passed over the platform 14 and creates an air gap in the critical area between the sheet and the conveyor belt 16.

- the prerequisites for a long belt life i.e. Various measures are used, in particular for minimal wear on the belt on its side edges.

- the one-piece mounting plate and the precisely manufactured belt and drive rollers provide the best conditions for an exact and straight belt run.

- the specifically designed deflection rollers 30, which carry conical roller bodies at both ends quickly re-center the belt in the event that a lateral migration should still have occurred due to uneven loading of the belt.

Landscapes

- Health & Medical Sciences (AREA)

- Nursing (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Invalid Beds And Related Equipment (AREA)

- Accommodation For Nursing Or Treatment Tables (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89105593T ATE72106T1 (de) | 1988-05-03 | 1989-03-30 | Transportvorrichtung zum verlagern von liegenden patienten. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3814972A DE3814972C1 (pt) | 1988-05-03 | 1988-05-03 | |

| DE3814972 | 1988-05-03 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0340450A2 EP0340450A2 (de) | 1989-11-08 |

| EP0340450A3 EP0340450A3 (en) | 1990-03-14 |

| EP0340450B1 true EP0340450B1 (de) | 1992-01-29 |

Family

ID=6353475

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89105593A Expired - Lifetime EP0340450B1 (de) | 1988-05-03 | 1989-03-30 | Transportvorrichtung zum Verlagern von liegenden Patienten |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0340450B1 (pt) |

| AT (1) | ATE72106T1 (pt) |

| DE (1) | DE3814972C1 (pt) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8096003B2 (en) | 2008-10-23 | 2012-01-17 | Samarit Medical Industries Inc. | Transporting device for patients |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7603729B2 (en) * | 2005-10-07 | 2009-10-20 | Conmedisys, Inc. | Patient lift and transfer device |

| DE102012018555A1 (de) | 2012-09-20 | 2014-03-20 | Jochen Kassner | Transportvorrichtung zum Verlagern von liegenden Patienten |

| CN105147465B (zh) * | 2015-09-19 | 2018-02-06 | 梁博 | 一种医疗重患转移车 |

| CN105943282B (zh) * | 2016-06-01 | 2019-06-11 | 张家倩 | 一种基于危重病患转运平台实现自动更换床单的方法 |

| CN112972133B (zh) * | 2021-05-06 | 2021-08-10 | 江苏环亚医用科技集团股份有限公司 | 一种具有隐藏式输送机构的医疗机器人 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2691782A (en) * | 1952-06-26 | 1954-10-19 | Richard M West | Patient-carrying vehicle for hospitals |

| JPS5281988A (en) * | 1975-12-27 | 1977-07-08 | Toyoda Chuo Kenkyusho Kk | Apparatus for transfering materials |

| DE2626638A1 (de) * | 1976-06-14 | 1977-12-22 | Stierlen Maquet Ag | Transporteinrichtung zum verlagern von liegenden patienten, insbesondere in krankenhaeusern |

| DE3448299C2 (en) * | 1984-12-17 | 1990-04-26 | Stierlen-Maquet Ag, 7550 Rastatt, De | Transporter for persons or flat objects |

-

1988

- 1988-05-03 DE DE3814972A patent/DE3814972C1/de not_active Expired

-

1989

- 1989-03-30 AT AT89105593T patent/ATE72106T1/de not_active IP Right Cessation

- 1989-03-30 EP EP89105593A patent/EP0340450B1/de not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8096003B2 (en) | 2008-10-23 | 2012-01-17 | Samarit Medical Industries Inc. | Transporting device for patients |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0340450A3 (en) | 1990-03-14 |

| ATE72106T1 (de) | 1992-02-15 |

| EP0340450A2 (de) | 1989-11-08 |

| DE3814972C1 (pt) | 1989-05-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3903820C2 (pt) | ||

| DE2157423A1 (de) | Endlos umlaufende Vorrichtung zur Beförderung von Personen von einer Anschlußstelle zur nächsten wie Rolltreppe o. dgl | |

| EP0802129B2 (de) | Förderbahn für Stückgut, insbesondere für Gepäck-Behälter | |

| EP0166791B1 (de) | Transportvorrichtung mit Laufschiene und rädergeführter Laufkatze | |

| DE102017011880B4 (de) | Teleskopförderer | |

| DE3142378A1 (de) | "maschine zur selbsttaetigen montage von reifen auf felgen" | |

| EP1251092A2 (de) | Materialführungssystem für Spleissmaschinen | |

| DE3879510T2 (de) | Bewegbare rampen. | |

| DE10315403A1 (de) | Fördersystem, insbesondere eine Flughafen-Gepäckförderanlage, für Behälter | |

| EP0340450B1 (de) | Transportvorrichtung zum Verlagern von liegenden Patienten | |

| DE3523901A1 (de) | Glasplattenschleifmaschine | |

| EP0255620B2 (de) | Rollenbahn für Fahrzeugkarosserie-Transportschlitten | |

| DE2129871A1 (de) | Krankenbahre | |

| DE3029385A1 (de) | Vorrichtung zur behandlung photographischer filme und papiere | |

| DE2808270A1 (de) | Foerderer sowie querschwelle dafuer | |

| EP0430084B1 (de) | Vorrichtung zum Verlagern von Patienten | |

| DE20312525U1 (de) | Tragenlagerungsvorrichtung für den Patiententransport in Krankenwagen | |

| DE2534437A1 (de) | Rollen-foerdereinrichtung mit auf- und abgabe-vorrichtung | |

| EP0010548A1 (de) | In einer Horizontalebene dreh- und arretierbare Umlenkvorrichtung | |

| DE2452199C3 (de) | Vorrichtung zum schonenden Umbetten eines Kranken | |

| DE2732977A1 (de) | Uebergabeeinrichtung fuer kettenfoerderer | |

| DE8704343U1 (de) | Vorrichtung zum Übernehmen von liegend zu transportierenden Patienten aus einem Bett | |

| EP1236672B1 (de) | Balustrade für Fahrtreppe oder Fahrsteig | |

| DE4125527C2 (de) | System zum reibschlüssigen Transport von Blattgut zwischen einer Eingabe- und einer Ausgabestelle | |

| DE8713347U1 (de) | Transportmittel für Montagetransferstraßen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900220 |

|

| 17Q | First examination report despatched |

Effective date: 19910516 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19920129 Ref country code: NL Effective date: 19920129 Ref country code: SE Effective date: 19920129 Ref country code: BE Effective date: 19920129 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19920129 Ref country code: GB Effective date: 19920129 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19920129 |

|

| REF | Corresponds to: |

Ref document number: 72106 Country of ref document: AT Date of ref document: 19920215 Kind code of ref document: T |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19920225 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19920226 Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19920331 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19920619 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19930330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19930331 Ref country code: CH Effective date: 19930331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |