EP0339196A2 - Séchoir à colonne équipé de toits déflecteurs pour matières ruisselantes - Google Patents

Séchoir à colonne équipé de toits déflecteurs pour matières ruisselantes Download PDFInfo

- Publication number

- EP0339196A2 EP0339196A2 EP89102567A EP89102567A EP0339196A2 EP 0339196 A2 EP0339196 A2 EP 0339196A2 EP 89102567 A EP89102567 A EP 89102567A EP 89102567 A EP89102567 A EP 89102567A EP 0339196 A2 EP0339196 A2 EP 0339196A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- slot

- slide

- container

- shaft dryer

- operating position

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B17/00—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement

- F26B17/12—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed solely by gravity, i.e. the material moving through a substantially vertical drying enclosure, e.g. shaft

- F26B17/14—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed solely by gravity, i.e. the material moving through a substantially vertical drying enclosure, e.g. shaft the materials moving through a counter-current of gas

- F26B17/1408—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed solely by gravity, i.e. the material moving through a substantially vertical drying enclosure, e.g. shaft the materials moving through a counter-current of gas the gas being supplied and optionally extracted through ducts extending into the moving stack of material

- F26B17/1416—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed solely by gravity, i.e. the material moving through a substantially vertical drying enclosure, e.g. shaft the materials moving through a counter-current of gas the gas being supplied and optionally extracted through ducts extending into the moving stack of material the ducts being half open or perforated and arranged horizontally

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B25/00—Details of general application not covered by group F26B21/00 or F26B23/00

- F26B25/001—Handling, e.g. loading or unloading arrangements

- F26B25/002—Handling, e.g. loading or unloading arrangements for bulk goods

Definitions

- the invention relates to a roof shaft dryer according to the preamble of claim 1.

- roof shaft dryers which have numerous roofs in the interior of a container, below which channels for the supply of drying air and for the removal of drying air are formed.

- the roofs have the effect that the free-flowing material does not completely fill the interior of the container and that free channels remain under the roofs, through which air can be supplied or removed. Drying air is introduced into some channels and air is extracted from other channels. The air escapes from the supply channels, which are open at the bottom, to close the material to be dried flow through and to be sucked into an adjacent suction channel.

- the discharge device At the lower end of the roof shaft dryer is the discharge device, from which the dried material trickles out. This discharge device should be designed so that no trickle channels form within the material to be dried.

- the goods should sink as evenly and slowly as possible in the container.

- the discharge device provided at the lower end of the container must on the one hand enable uniform trickling without the formation of trickling channels, and on the other hand must also allow the container to be completely emptied so that the next container is not mixed with the new container contents the next time it is filled.

- Discharge devices for roof shaft dryers are known in which the material trickles into a linearly moving trough. The trough must be tipped for the remaining emptying. It is also known to let the material trickle onto a plate on which a slide is moved back and forth, which loosens any blockages of the material at the funnel exit and ensures a constant discharge of the product. It is also difficult here to completely drain the dryer completely.

- discharge devices which have slits delimited by plates on the silo bottom, which can be closed by a slide in each case.

- the slides are set stationary to a certain opening position. Residual quantities of the material remain on the webs separating the slots from one another, so that complete residual emptying is not readily possible here either.

- the invention has for its object to provide a roof shaft dryer of the type specified in the preamble of claim 1, the discharge device is designed so that a uniform sinking of the goods is ensured and complete residual emptying is possible without complex tilting mechanisms.

- the discharge device has a simple slide which can be moved between different operating positions in the slot forming the lower end of the outlet funnel, the slide being able to completely close the slot.

- the movement device moves the slider so that it takes up two different operating positions, the left slot edge being released in one operating position and the right slot edge being released in the other operating position.

- the fact that the material alternately trickles down at different slit edges prevents the formation of long trickle channels.

- the slide for the complete release of the slot it is only necessary to push the slide into its end position, any material still present on the slide being stripped off.

- the slide therefore only needs to be able to carry out linear movements and it is not necessary to tilt the slide to remove residual material.

- each slot Preferably elastic strippers are attached to the lower end of each slot, which extend to the plate of the slide. This way, on the one hand when the slide is set in the center, the slot is completely closed and, on the other hand, it is ensured that in the case that the slide is pushed completely out of the area of the slot, no granular material remains on the slide.

- the push bar expediently runs at a vertical distance below the top of the plate.

- the push bar which is required for moving the slide, has a vertical distance from the slots, so that material trickling down through the slots, which accumulates on the push bar, does not reach the height of the slots and cannot impair the trickling down of other goods .

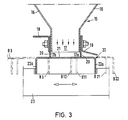

- the roof shaft dryer shown has an elongated rectangular container 10, under which the discharge device 11 is arranged.

- the side walls of the container 10 are flush and tight with the side walls of the discharge device 11.

- the container 10 is known to contain numerous internals in the form of roofs 12 which extend across the entire width of the container 10.

- the roofs 12 are below Channels 13 are open and underneath or in the roofs 12, some of these channels being supply air channels for supplying drying air and other channels being suction channels.

- the free-flowing material 14 trickles down into the container 10, trickling through between two roofs 12 in order to be deflected by an underlying roof 12.

- the gaps between two of the lower roofs 12 each lead into a funnel 15.

- the funnels 15 also extend over the entire width of the discharge device 11 and they consist of downwardly converging walls 16 which open into a slot 17, the slot edges of which are 17a and 17b are designated.

- the slot walls 16 running vertically there are reinforced by angle rails 18 and 19 fastened to the outer sides, in order to prevent the material pushing into the hopper 15 from pushing the slot walls and the hopper walls apart.

- a stripper 20, which projects freely from the lower end of the funnel wall, is clamped between each angle piece 18, 19 and the associated funnel wall 16.

- the wipers 20 are made of elastic material, such as rubber, and extend to the plate 21 of the slide 22, which is arranged under the slot 17.

- Each slider 22 consists of an inverted U-shaped rail, the base of which is formed by the top plate 21, while the legs 22a protrude downward.

- the push bar 23 is fastened to the lower end regions of the legs 22a.

- a total of four push bars 23 are present (FIG. 2), two of which are push bars near the longitudinal side walls of the discharge device 11 and two further push bars run in the middle between these side walls.

- the outer thrust beams 23 are guided on rollers 24, which are mounted on the longitudinal side walls of the discharge device 11. All four push bars 23 are connected to one another by the slides 22 running transversely to this.

- the push bar 23 are driven by the movement device 25, which in the present case consists of a piston-cylinder unit, the cylinder of which is attached to an end wall of the housing of the discharge device 11 and the piston rod 26 of which is connected to two push bars 23.

- the movement device 25 displaces the push bars 23 linearly in their longitudinal direction, as a result of which the pushers 22 fastened transversely to the push bars 23 are displaced transversely to the slots 17.

- the slide 22 is shown in the middle position, in which its plate 22 completely closes the slot 17.

- the slide 22 can be moved transversely to the slot 17 so that they assume a first operating position B11, in which a narrow area of the right edge of the slot is released, so that the free-flowing material can sink through this area.

- Position B11 is intended for fine-grained goods.

- the slide 22 is set to the position B12 in the first operating position, in which the gap on the right-hand slot edge 17a is correspondingly larger.

- the positions B11 and B12 can be set on the movement device 25, for example by means of corresponding valves which are controlled by the piston rod 26.

- the second operating position B21 for fine grain and the second operating position B22 for coarse grain are also shown in FIG. 3.

- a corresponding gap on the left slot edge 17b is released.

- the movement device 25 is controlled in such a way that either only the operating positions B11 and B21 for fine grain or only the operating positions B12 and B22 for coarse grain are set.

- the change between the left and right operating positions takes place approximately two to three times per minute. In this way, the right slot edge 17a and the left slot edge 17b are released alternately.

- the push bars are moved in the longitudinal direction so far that the slides 22 leave the slot 17 and release this slot completely, which is indicated by the position B3 in FIG. 3.

- the wipers 20 prevent material from leaving the slot 17 together with the slide 22. Rather, the material is advanced to the end of the plate 21 and then falls in the area of the slot over the edge of the plate 21.

- a major advantage of the invention is that the slide 22 between all operating positions and even when they are in the open position B3 are only moved linearly in a horizontal plane. This simplifies the movement device and, in particular, no folding mechanisms are required for the residual emptying.

- the roof shaft dryer according to the invention is particularly suitable for drying grain, but it is also suitable for drying other free-flowing goods.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Drying Of Solid Materials (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8805479U DE8805479U1 (de) | 1988-04-26 | 1988-04-26 | Dächerschachttrockner für rieselfähiges Gut |

| DE8805479U | 1988-04-26 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0339196A2 true EP0339196A2 (fr) | 1989-11-02 |

| EP0339196A3 EP0339196A3 (fr) | 1990-01-17 |

Family

ID=6823360

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89102567A Withdrawn EP0339196A3 (fr) | 1988-04-26 | 1989-02-15 | Séchoir à colonne équipé de toits déflecteurs pour matières ruisselantes |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0339196A3 (fr) |

| DE (1) | DE8805479U1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8572863B2 (en) | 2007-06-22 | 2013-11-05 | Schmidt-Seeger Gmbh | Chute dryer with special air-roof assembly |

| CN107879130A (zh) * | 2017-12-22 | 2018-04-06 | 河南中农福安农业装备有限公司 | 一种往复式排粮小车 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8805479U1 (de) * | 1988-04-26 | 1988-06-01 | Happle GmbH & Co Maschinenfabrik i.K., 89264 Weißenhorn | Dächerschachttrockner für rieselfähiges Gut |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR460577A (fr) * | 1913-07-21 | 1913-12-05 | Pellegrino Flii Soc | Séchoir à fonctionnement continu et à décharge automatique pour cocons, céréales et autres matières |

| FR578235A (fr) * | 1924-03-07 | 1924-09-20 | Séchoir pour matières granulées | |

| US2660810A (en) * | 1951-03-27 | 1953-12-01 | Bryce M Hess | Drier for granular material |

| GB1102402A (en) * | 1964-02-18 | 1968-02-07 | Hans Peter Pedersen | Improvements in or relating to silos |

| AU436777B2 (en) * | 1967-11-22 | 1973-06-13 | Blaw-Knox Company | Desolventizing and deodorizing system for granular materials |

| FR2444907A1 (fr) * | 1978-12-22 | 1980-07-18 | Buehler Miag Gmbh | Procede et dispositif pour le sechage en continu de cereales ou de matieres granuleuses analogues |

| JPS582131A (ja) * | 1981-06-30 | 1983-01-07 | Nippon Kokan Kk <Nkk> | 粉粒体切出装置 |

| DE8805479U1 (de) * | 1988-04-26 | 1988-06-01 | Happle GmbH & Co Maschinenfabrik i.K., 89264 Weißenhorn | Dächerschachttrockner für rieselfähiges Gut |

-

1988

- 1988-04-26 DE DE8805479U patent/DE8805479U1/de not_active Expired

-

1989

- 1989-02-15 EP EP89102567A patent/EP0339196A3/fr not_active Withdrawn

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR460577A (fr) * | 1913-07-21 | 1913-12-05 | Pellegrino Flii Soc | Séchoir à fonctionnement continu et à décharge automatique pour cocons, céréales et autres matières |

| FR578235A (fr) * | 1924-03-07 | 1924-09-20 | Séchoir pour matières granulées | |

| US2660810A (en) * | 1951-03-27 | 1953-12-01 | Bryce M Hess | Drier for granular material |

| GB1102402A (en) * | 1964-02-18 | 1968-02-07 | Hans Peter Pedersen | Improvements in or relating to silos |

| AU436777B2 (en) * | 1967-11-22 | 1973-06-13 | Blaw-Knox Company | Desolventizing and deodorizing system for granular materials |

| FR2444907A1 (fr) * | 1978-12-22 | 1980-07-18 | Buehler Miag Gmbh | Procede et dispositif pour le sechage en continu de cereales ou de matieres granuleuses analogues |

| JPS582131A (ja) * | 1981-06-30 | 1983-01-07 | Nippon Kokan Kk <Nkk> | 粉粒体切出装置 |

| DE8805479U1 (de) * | 1988-04-26 | 1988-06-01 | Happle GmbH & Co Maschinenfabrik i.K., 89264 Weißenhorn | Dächerschachttrockner für rieselfähiges Gut |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN, Band 7, Nr. 74 (M-203)[1219], 26. März 1983; & JP-A-58 002 131 (NIPPON KOKAN K.K.) 07-01-1983 * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8572863B2 (en) | 2007-06-22 | 2013-11-05 | Schmidt-Seeger Gmbh | Chute dryer with special air-roof assembly |

| CN107879130A (zh) * | 2017-12-22 | 2018-04-06 | 河南中农福安农业装备有限公司 | 一种往复式排粮小车 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0339196A3 (fr) | 1990-01-17 |

| DE8805479U1 (de) | 1988-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0224017A1 (fr) | Dispositif attaché à des machines d'empaquetage pour alimenter et déposer de façon ordonnée des petites pièces comme des tablettes, capsules, dragées ou similaires | |

| DE3135581C2 (fr) | ||

| DE2838945C2 (de) | Bandfilter | |

| EP0339196A2 (fr) | Séchoir à colonne équipé de toits déflecteurs pour matières ruisselantes | |

| DE4005483A1 (de) | Schaumausgiessvorrichtung | |

| DE3630077C2 (fr) | ||

| DE69524240T2 (de) | Planier-sortiervorrichtung | |

| WO1991009801A1 (fr) | Dispositif pour le deversement dose de matieres solides en vrac | |

| EP0434995B1 (fr) | Silo équipé d'un dispositif d'évacuation | |

| DE2900774C2 (de) | Saugfilterbandvorrichtung | |

| EP0756572B1 (fr) | Dispositif de prelevement dose de solides en vrac | |

| AT395140B (de) | Fahrzeug zum aufnehmen von schuettgut, insbesondere muell | |

| EP0592368A1 (fr) | Installation de compostage | |

| DD126956B1 (de) | Presse zur herstellung von zweischichtigen keramischen platten | |

| DE822920C (de) | Duengerstreumaschine | |

| DE1268062B (de) | Vorrichtung zum Entleeren einer Silozelle fuer pneumatisch in fliessbaren Zustand versetzbare Schuettgueter | |

| DE2950923B1 (de) | Vorrichtung zum kontinuierlichen Aufbringen eines breiigen Gemisches auf flache Formen zur Herstellung zementgebundener Holzspanplatten | |

| EP0303864A2 (fr) | Silo pour matières en vrac pulvérulentes et à grains serrés | |

| DE3243222C2 (fr) | ||

| DE3923645A1 (de) | Wanderbettreaktor | |

| DE1483136C3 (de) | Vorrichtung zum Beschicken eines unterhalb eines Trichters befindlichen Förderers einer Maschine zum Sintern, Agglomerieren und/oder Rösten von Schüttgut | |

| EP0174440A1 (fr) | Dispositif pour emmagasiner temporairement et charger uniformément des bandes transporteuses de matériaux en vrac, en particulier de cossettes de betteraves | |

| DE8222989U1 (de) | Siebkasten zur sortierung bzw. reinigung von getreide, saemereien und aehnlichem nutzgut | |

| DE1557990C3 (fr) | ||

| DE3546209C2 (fr) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE FR GB GR IT LI LU NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB GR IT LI LU NL |

|

| 17P | Request for examination filed |

Effective date: 19900207 |

|

| 17Q | First examination report despatched |

Effective date: 19910425 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19921103 |