EP0243760B1 - Quaderförmiger stapelbarer Behälter - Google Patents

Quaderförmiger stapelbarer Behälter Download PDFInfo

- Publication number

- EP0243760B1 EP0243760B1 EP87105331A EP87105331A EP0243760B1 EP 0243760 B1 EP0243760 B1 EP 0243760B1 EP 87105331 A EP87105331 A EP 87105331A EP 87105331 A EP87105331 A EP 87105331A EP 0243760 B1 EP0243760 B1 EP 0243760B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- lid

- container

- edge

- edge profile

- welded

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007789 sealing Methods 0.000 claims description 11

- 239000011324 bead Substances 0.000 claims description 3

- 239000007788 liquid Substances 0.000 description 5

- 239000007787 solid Substances 0.000 description 5

- 238000010276 construction Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 239000013536 elastomeric material Substances 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D45/00—Clamping or other pressure-applying devices for securing or retaining closure members

- B65D45/02—Clamping or other pressure-applying devices for securing or retaining closure members for applying axial pressure to engage closure with sealing surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D21/00—Nestable, stackable or joinable containers; Containers of variable capacity

- B65D21/02—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together

- B65D21/0209—Containers specially shaped, or provided with fittings or attachments, to facilitate nesting, stacking, or joining together stackable or joined together one-upon-the-other in the upright or upside-down position

- B65D21/0217—Containers with a closure presenting stacking elements

- B65D21/0219—Containers with a closure presenting stacking elements the closure presenting projecting peripheral elements receiving or surrounding the bottom or peripheral elements projecting from the bottom of a superimposed container

Definitions

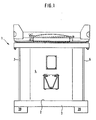

- the invention relates to a cuboid stackable container with a box-shaped container edge profile running around the upper region of the side walls, the upper side of which forms a support for the container lid, the central region of the container lid being provided with an opening which is closed by a further lid.

- Containers of this type are known in different embodiments and, depending on their particular design, serve either to absorb solid or to store liquid substances. Such containers must meet special safety requirements and must therefore be designed to be shockproof with a stable construction.

- the object of the invention is therefore to provide a square, stackable container which, with a simple, stable and shockproof construction, enables both solid and liquid substances to be stored with simple handling.

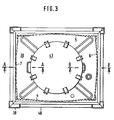

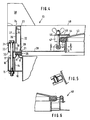

- this object is achieved in a generic container in that the container lid consists of a folded cut with tab-like extensions extended beyond the lid side edges, which are angled at right angles around the lid side edges, that profiled sheets forming a circumferential hollow lid edge profile are welded and that the edge profile of the lid is supported by a circumferential sealing ring on the top of the edge profile of the container and both edge profiles are provided with aligned bores through which the two edge profiles are tightened by clamping screws.

- DE-A 34 32 830 also discloses generic containers which, depending on their design, are suitable either for storing solid or liquid substances.

- the object is achieved in a particularly advantageous manner in containers of this type in that the tab-like extensions are bent at right angles to the outside and below to form the lid edge profile and that the profiled sheets welded to the extensions are L-shaped angled profiles that are welded with their longitudinal edges to the downward facing legs of the extensions, and that the holes aligned with the holes in the U-shaped container edge profile are provided in an outwardly facing flange or in projections in the L-shaped angled profiles.

- the lid of this container according to the invention has a stiffening hollow edge profile, which is integral with the lid due to the folding of the tab-like extensions.

- the production of the lid from folded edges not only simplifies and reduces the cost of the construction, it also forms a circumferential hollow profile which, like the bottom profile and the edge profile of the container, ensures its good stability and impact resistance. Because if the container falls off a transport vehicle or falls for any other reason, it always falls on one of its hollow profiles that protect the outer edges, which can deform without endangering the container walls, thereby consuming impact energy and keeping it away from the container walls without damage.

- liquids are stored in the container, these can be filled through the opening provided in the lid, which can be closed by a further lid. If the container cannot be emptied again simply by suction, for example because the liquid contains solid residues or solid constituents have been poured into the container, the cover sealingly resting on the container edge profile can be removed so that the entire container cross section is then available for emptying stands.

- a plastic bag can be inserted into the container, which forms a plastic insert that can be removed when the container is emptied and ensures that the inner walls of the container do not come into contact with the stored materials at all.

- the container according to the invention can thus not only be used universally, it also has shockproof crumple zones due to its hollow edge profiles.

- the upper leg of the container edge profile is expediently provided with a circumferential bead which forms a sealing edge.

- the inward-pointing legs of the L-shaped profile can be extended beyond their connection area with the cover side edges, the extended parts being bent at right angles to the cover plane and at a distance from the cover side edges to form a circumferential receiving groove for the sealing ring in the area of the cover side edges .

- the L-shaped profile to form a hollow flange between its legs at a distance from each other is provided with right-angled bends outwards, downwards and inwards.

- the corner regions of the lid can be welded to the corner pieces which protrude from the lid edge profile and form the holding pieces for foot pieces of stacked containers.

- the first cover is provided in its central region with a circular opening into which a ring with an L-profile is welded in the form of a dome, the upper leg pointing outwards serving as the sealing edge for the round, pivotable and through with clamping pieces provided clamping screws in its closed position forms lid.

- the container 1 has a base plate 2, which is provided to form a circumferential U-shaped base profile 3 as part of a folding cut with tab-like extensions extended beyond its edges, which are separated from one another by right-angled corner cutouts and whose adjoining areas are at the bottom and their outer areas Areas are bent inwards at right angles to lines parallel to the edges, the end edges of the correspondingly cut-out extensions being welded to one another in the corner areas.

- This configuration of the base plate is explained in detail in DE-OS 34 32 830 with reference to FIGS. 10-14 and is therefore not described again here.

- the lower edges of the side walls 4, 5, 6, 7 standing at right angles on this are welded to the base plate.

- the lateral edge areas of the side walls 4 to 7 are each provided with an angle with which they overlap the edge area of the respectively adjacent side wall.

- the container side walls are welded together in the area of these bends.

- the upper edge region of the container is stiffened by a circumferential U-shaped container edge profile 8, the inwardly directed legs 9, 10 of which are welded to the upper regions of the side walls 4 to 7.

- This configuration also corresponds to the configuration of the upper container edge profile, which has been described in DE-OS 34 32 830 with reference to FIGS. 4 to 6.

- the upper leg 9 of the U-shaped edge profile is, however, provided with an upwardly curved circumferential bead 11, which forms a sealing edge for the sealing ring 12 made of rubber or elastomeric material of the container lid 13.

- a reinforcing plate 14 is welded into the peripheral edge profile 8.

- the legs 9, 10 are provided in the outer regions of the container edge profile 8 with aligned bores 15, 16 for clamping screws 17.

- the container lid 13 is bent from a flat folding blank, which consists of the base plate 20 of the container lid with tab-like extensions 22 extended beyond the lid side edges 21.

- the tab-like extensions 22 are angled approximately at right angles around the lid side edges and bent outward and downward at a right angle by two further lines 23, 24.

- Corresponding cutouts are provided between the tab-like extensions 22 so that the vertically placed edges of the extensions 22 abut one another and can be welded to one another.

- the gaps between the end regions of the extensions 22 which are angled outwards and downwards in the lines 23, 24 are closed by welded-in fitting pieces. With the legs 25 of the extensions pointing downward and with the edge regions 21 of the cover, the sheet 26 profiled by bending is welded.

- the sheet 26 has an upstanding leg 27 which is welded to the leg 25 and a leg 28 which is perpendicular to the leg and which is welded to the lid side edges 21. Between the legs 27, 28, the folded sheet 26 is provided with an outwardly directed hollow flange 33 by folding around the lines 30, 31, 32. The horizontal legs of this hollow flange are provided with bores which are aligned with the bores 15, 16 when the lid 13 is placed on the container, so that the lid can be clamped to the container by the tensioning screws 17 passed through the bores.

- the lower horizontal leg 28 of the profiled sheet 26 is extended beyond its area welded to the cover side edges 21, this extended part 35 being angled downward in the region of the cover side edges and at a distance from the cover side edges to the outside, so that a circumferential groove for the is formed in this held sealing ring 12.

- Angled sheets 38 are welded to the peripheral cover flange 33 in the corner regions of the cover 13, which form holding pieces for the foot pieces of the containers stacked on the cover 13.

- the foot pieces 39 welded to the floor profiles 3 are supported on the upper edge of the cover edge profile 40 and are held laterally by the angle pieces 38.

- the base plate 20 of the cover is provided with a central circular cutout, into which a ring 41 with an L-shaped profile is welded.

- the upper outwardly angled leg 42 of the profile forms the sealing edge for the second circular cover 43.

- This is provided on its underside with a circumferential groove in which a sealing ring 44 made of rubber or elastomeric material is held.

- the cover 43 is welded to holding pieces 45, which are provided with freely running elongated holes 46, into which wing tension screws 47, which are pivotably mounted on the base plate 20 of the cover, can be pivoted.

- the cover 43 is connected to the base plate 20 of the cover 13 by a swivel bracket 48.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Containers Having Bodies Formed In One Piece (AREA)

- Rigid Containers With Two Or More Constituent Elements (AREA)

- Stacking Of Articles And Auxiliary Devices (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Packging For Living Organisms, Food Or Medicinal Products That Are Sensitive To Environmental Conditiond (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Weting (AREA)

- Stackable Containers (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87105331T ATE54279T1 (de) | 1986-04-30 | 1987-04-10 | Quaderfoermiger stapelbarer behaelter. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863614767 DE3614767A1 (de) | 1986-04-30 | 1986-04-30 | Quaderfoermiger stapelbarer behaelter |

| DE3614767 | 1986-04-30 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0243760A2 EP0243760A2 (de) | 1987-11-04 |

| EP0243760A3 EP0243760A3 (en) | 1988-10-05 |

| EP0243760B1 true EP0243760B1 (de) | 1990-07-04 |

Family

ID=6299949

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87105331A Expired - Lifetime EP0243760B1 (de) | 1986-04-30 | 1987-04-10 | Quaderförmiger stapelbarer Behälter |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4917246A (el) |

| EP (1) | EP0243760B1 (el) |

| AT (1) | ATE54279T1 (el) |

| DE (2) | DE3614767A1 (el) |

| ES (1) | ES2016299B3 (el) |

| GR (1) | GR3000625T3 (el) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1122180A1 (de) | 2000-02-03 | 2001-08-08 | Ford Global Technologies, Inc. | Zentriervorrichtung für stapelbare Behälter |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5323903A (en) * | 1989-01-23 | 1994-06-28 | Harry Bush | Portable container security device |

| US5249684A (en) * | 1991-10-21 | 1993-10-05 | Aeroquip Corporation | Fluid container |

| US5197601A (en) * | 1991-10-21 | 1993-03-30 | Aeroquip Corporation | Fluid container |

| DE19917854A1 (de) * | 1999-04-21 | 2000-11-02 | Roth Werke Gmbh | Doppelwandiger Tank, insbesondere zur Lagerung von Heizöl, Dieselkraftstoff, Schmier- und Hydraulikölen |

| US6189716B1 (en) * | 1999-12-15 | 2001-02-20 | Delphi Technologies, Inc. | Secondary sealing of a fuel tank |

| US20050266124A1 (en) * | 2004-05-25 | 2005-12-01 | Bee Excellent | Storage and transportation tote |

| CN100381340C (zh) * | 2004-12-30 | 2008-04-16 | 上海理日科技发展有限公司 | 自动弹开的夹紧机构 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE476910C (de) * | 1929-05-27 | Hochofenwerk Luebeck Akt Ges | Dichtung fuer Gichtglocken | |

| GB333400A (en) * | 1929-08-16 | 1930-08-14 | John Waddell Morton | Improvements relating to closing means for containers, particularly for containers of media under pressure |

| US3044658A (en) * | 1958-05-12 | 1962-07-17 | Zero Mfg Company | Shipping container |

| US3347412A (en) * | 1965-10-23 | 1967-10-17 | Hoover Ball & Bearing Co | Stackable container |

| US3360155A (en) * | 1966-01-04 | 1967-12-26 | Colonna Angelo | Rapid seal closure for containers |

| US3406855A (en) * | 1966-06-17 | 1968-10-22 | Andrews Of Aintree Ltd | Containers for the transportation of liquid in bulk |

| US3666340A (en) * | 1970-07-01 | 1972-05-30 | Joseph D Albeanese | Insulated air-tight container for instruments |

| US3786955A (en) * | 1971-08-30 | 1974-01-22 | Gen Am Transport | Manway cover for tank cars |

| CH547737A (de) * | 1972-02-03 | 1974-04-11 | Utz Ag Georg | Behaelter aus kunststoff, insbesondere harass. |

| NL7305209A (el) * | 1972-04-17 | 1973-10-19 | ||

| US3858752A (en) * | 1974-02-04 | 1975-01-07 | Plastics Research Corp | Container having improved resealable closure system |

| US4379513A (en) * | 1980-06-30 | 1983-04-12 | Chern Developments (Proprietary) Limited | Pressure vessel fastening means |

| US4411372A (en) * | 1980-12-04 | 1983-10-25 | Chern Developments Limited | Pressure vessel construction |

| US4378896A (en) * | 1981-06-19 | 1983-04-05 | Texaco Inc. | Removable hatch lid |

| DE3432830C2 (de) * | 1984-01-10 | 1987-01-29 | Edelhoff Polytechnik GmbH & Co, 5860 Iserlohn | Quaderförmiger stapelbarer Behälter |

| DE3425978A1 (de) * | 1984-07-14 | 1986-01-16 | Kernforschungszentrum Karlsruhe Gmbh, 7500 Karlsruhe | Stapelbarer langzeitlagerbehaelter, vorzugsweise fuer radioaktive abfaelle |

| DE3512467C1 (de) * | 1985-04-04 | 1986-10-23 | Deutsche Gesellschaft für Wiederaufarbeitung von Kernbrennstoffen mbH, 3000 Hannover | Fernbedient auswechselbares Einbauteil |

| US4746034A (en) * | 1985-10-17 | 1988-05-24 | Nalco Chemical Company | Portable liquid container |

| US4660736A (en) * | 1986-04-14 | 1987-04-28 | Stauffer Chemical Company | Resealable shipping container |

-

1986

- 1986-04-30 DE DE19863614767 patent/DE3614767A1/de not_active Withdrawn

-

1987

- 1987-04-10 EP EP87105331A patent/EP0243760B1/de not_active Expired - Lifetime

- 1987-04-10 AT AT87105331T patent/ATE54279T1/de active

- 1987-04-10 ES ES87105331T patent/ES2016299B3/es not_active Expired - Lifetime

- 1987-04-10 DE DE8787105331T patent/DE3763525D1/de not_active Expired - Fee Related

- 1987-04-22 US US07/041,337 patent/US4917246A/en not_active Expired - Fee Related

-

1990

- 1990-07-05 GR GR90400179T patent/GR3000625T3/el unknown

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1122180A1 (de) | 2000-02-03 | 2001-08-08 | Ford Global Technologies, Inc. | Zentriervorrichtung für stapelbare Behälter |

Also Published As

| Publication number | Publication date |

|---|---|

| GR3000625T3 (en) | 1991-09-27 |

| DE3763525D1 (de) | 1990-08-09 |

| EP0243760A3 (en) | 1988-10-05 |

| ES2016299B3 (es) | 1990-11-01 |

| US4917246A (en) | 1990-04-17 |

| EP0243760A2 (de) | 1987-11-04 |

| DE3614767A1 (de) | 1987-11-05 |

| ATE54279T1 (de) | 1990-07-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4206945C1 (el) | ||

| DE1942417A1 (de) | Behaelter | |

| EP0243760B1 (de) | Quaderförmiger stapelbarer Behälter | |

| DE3531554C2 (de) | Müllbehälter mit Deckel | |

| DE69500528T2 (de) | Behälter | |

| EP0657365A1 (de) | Behälter für den Transport und die Lagerung von Flüssigkeiten | |

| EP0150395B1 (de) | Stapelbarer Behälter | |

| DE4443212A1 (de) | Behälter mit faltbaren Seitenwänden | |

| DE4425630A1 (de) | Transport- und Lagerbehälter für Flüssigkeiten | |

| DE2729737C3 (de) | Dicht verschließbarer, unterteilbarer Behälter | |

| DE3448140C2 (en) | Cuboid stackable container | |

| DE8611856U1 (de) | Quaderförmiger stapelbarer Behälter | |

| DE2804406A1 (de) | Stapelbehaelter | |

| DE2405875A1 (de) | Auseinandernehmbarer kasten aus kunststoff | |

| DE3939023C1 (en) | Semi-liq. or solid product container - comprises sheet metal rectangular panels, tops folded outwards to form reinforcing channel | |

| DE4225162C1 (de) | Sammel- und Transportbehälter für Altbatterien und Altakkumulatoren | |

| DE9210207U1 (de) | Sammel- und Transportbehälter für Altbatterien und Altakkumulatoren | |

| DE2156407A1 (de) | Fahrbarer Transportkasten | |

| DE3925632A1 (de) | Palette und transportsystem mit paletten | |

| WO1988000915A1 (en) | Collection tank for reusable product | |

| EP0273192A1 (de) | Tür für einen Kühlcontainer | |

| DE3009173A1 (de) | Palettenbehaelter | |

| DE3019352A1 (de) | Silo zum transport von schuettgut | |

| DE3817043A1 (de) | Transportbehaelter | |

| DE9107212U1 (de) | Palettencontainer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19881125 |

|

| 17Q | First examination report despatched |

Effective date: 19890224 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 54279 Country of ref document: AT Date of ref document: 19900715 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3763525 Country of ref document: DE Date of ref document: 19900809 |

|

| ET | Fr: translation filed | ||

| ET1 | Fr: translation filed ** revision of the translation of the patent or the claims | ||

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3000625 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| ITTA | It: last paid annual fee | ||

| 26 | Opposition filed |

Opponent name: UMFORMTECHNIK HAUSACH GMBH Effective date: 19910404 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: UMFORMTECHNIK HAUSACH GMBH |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 19920810 |

|

| NLR2 | Nl: decision of opposition | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930325 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19930331 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930406 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19930414 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930415 Year of fee payment: 7 Ref country code: AT Payment date: 19930415 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19930419 Year of fee payment: 7 Ref country code: BE Payment date: 19930419 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930427 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19930430 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19930625 Year of fee payment: 7 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940410 Ref country code: GB Effective date: 19940410 Ref country code: AT Effective date: 19940410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19940411 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19940430 Ref country code: CH Effective date: 19940430 Ref country code: BE Effective date: 19940430 |

|

| BERE | Be: lapsed |

Owner name: EDELHOFF POLYTECHNIK G.M.B.H. & CO. Effective date: 19940430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19941031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19941101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940410 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941229 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950103 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 87105331.0 Effective date: 19941110 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: MM2A Free format text: 3000625 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050410 |