EP0242587A1 - Vorrichtung zum Gefrieren von auf einem Hordenwagen befindlichen Lebensmitteln - Google Patents

Vorrichtung zum Gefrieren von auf einem Hordenwagen befindlichen Lebensmitteln Download PDFInfo

- Publication number

- EP0242587A1 EP0242587A1 EP87103924A EP87103924A EP0242587A1 EP 0242587 A1 EP0242587 A1 EP 0242587A1 EP 87103924 A EP87103924 A EP 87103924A EP 87103924 A EP87103924 A EP 87103924A EP 0242587 A1 EP0242587 A1 EP 0242587A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- refrigerant

- trolley

- spray system

- food

- fans

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000007710 freezing Methods 0.000 title claims description 10

- 230000008014 freezing Effects 0.000 title claims description 10

- 239000007921 spray Substances 0.000 claims abstract description 22

- 239000003507 refrigerant Substances 0.000 claims abstract description 19

- 235000013305 food Nutrition 0.000 claims abstract description 17

- 239000007788 liquid Substances 0.000 claims abstract description 10

- 238000001704 evaporation Methods 0.000 claims abstract description 3

- 230000002441 reversible effect Effects 0.000 claims abstract 2

- 238000005507 spraying Methods 0.000 claims abstract 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 abstract description 23

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 abstract description 4

- 229910002092 carbon dioxide Inorganic materials 0.000 abstract description 2

- 239000001569 carbon dioxide Substances 0.000 abstract description 2

- JCXJVPUVTGWSNB-UHFFFAOYSA-N nitrogen dioxide Inorganic materials O=[N]=O JCXJVPUVTGWSNB-UHFFFAOYSA-N 0.000 abstract 1

- 229910052757 nitrogen Inorganic materials 0.000 description 11

- 239000007789 gas Substances 0.000 description 5

- 238000000034 method Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D3/00—Devices using other cold materials; Devices using cold-storage bodies

- F25D3/10—Devices using other cold materials; Devices using cold-storage bodies using liquefied gases, e.g. liquid air

- F25D3/11—Devices using other cold materials; Devices using cold-storage bodies using liquefied gases, e.g. liquid air with conveyors carrying articles to be cooled through the cooling space

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2317/00—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass

- F25D2317/06—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation

- F25D2317/068—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by the fans

- F25D2317/0684—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by the fans the fans allowing rotation in reverse direction

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2400/00—General features of, or devices for refrigerators, cold rooms, ice-boxes, or for cooling or freezing apparatus not covered by any other subclass

- F25D2400/30—Quick freezing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S165/00—Heat exchange

- Y10S165/918—Heated and cooled food cabinets and/or trays

- Y10S165/919—Wheeled

Definitions

- the invention relates to a device for foods located on a trolley according to the preamble of claim 1.

- Foodstuffs on a trolley are frozen by pushing them into an insulated housing and applying a cryogenic refrigerant through direct heat exchange.

- Liquid nitrogen or liquid carbon dioxide are usually used as refrigerants.

- the refrigerant is sprayed into the insulated housing by a spray system and evaporates through contact with the food to be cooled or frozen.

- the now cold gaseous refrigerant is circulated by one or more fans and through flows through the trays of the trolley several times. Finally, it is removed from the insulated housing through a vent.

- the invention is therefore based on the object of providing a device for freezing food located on a trolley, which allows a uniform cold gas application to the food located on the individual floors of the trolley.

- the mutual loading of the frozen goods which enables the device according to the invention, not only has the advantage that the food is cooled and frozen more uniformly and therefore more gently, but it also reduces the freezing time and reduces the refrigerant requirement.

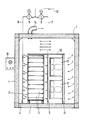

- the device shown in the drawing consists of an insulated housing 1, which also has an insulated door, not shown, through which it can be loaded with a trolley 2.

- the food to be frozen is located on the individual floors 3 of the trolley.

- a spray system 4, 5 is installed on each long side of the trolley 2.

- the spray systems 4, 5 are connected by lines 6, 7 and solenoid valves 8, 9 via a line 10 to a storage, not shown, for liquid nitrogen.

- two fans 11 are arranged, which serve to circulate the sprayed and vaporized liquid nitrogen.

- the fans 11 are fastened to a frame 12, from which a cover 13 extends over the fans 11 and the trolley 2.

- the cover 13 causes a forced gas flow through the floors 3 of the trolley 2.

- the direction of rotation and thus the direction of delivery of the fans 11 can be switched.

- the resulting gas flow is shown by arrows not shown.

- the heated refrigerant flows out of the insulated housing 1 through the discharge opening 14.

- a control cabinet 15 is located on a wall of the insulated housing 1.

- the freezing time and the spray cycle for the spray systems 4, 5 are set on the control cabinet 15. These values depend on the type of freeze Food off. Likewise, the freezing temperature is set on the control cabinet 15.

- the spray cycle is, for example, 5 minutes.

- the solenoid valve 8 opens and liquid nitrogen flows through the line 6 and the spray system 4 into the interior of the insulated housing 1.

- the fans 11 are switched at the same time depending on the opening state of the solenoid valves 8, 9, that they suck the nitrogen emerging and evaporating from the spray system 4 through the floors 3 of the trolley 2 and circulate many times. A quantity of gaseous nitrogen corresponding to the amount of nitrogen sprayed in continuously escapes through the discharge opening 14. After 5 minutes.

- the number and arrangement of the fans 11 is chosen so that a largely uniform gas flow through the floors 3 of the trolley 2 is formed. For trolleys of normal size, two on top of each other are sufficient arranged fans 11.

- the device according to the invention is primarily used for freezing food, but it is immediately apparent that it can be used in the same way if the food is only to be cooled.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Freezing, Cooling And Drying Of Foods (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3610563 | 1986-03-27 | ||

| DE19863610563 DE3610563A1 (de) | 1986-03-27 | 1986-03-27 | Vorrichtung zum gefrieren von auf einem hordewagen befindlichen lebensmitteln |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0242587A1 true EP0242587A1 (de) | 1987-10-28 |

Family

ID=6297489

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87103924A Withdrawn EP0242587A1 (de) | 1986-03-27 | 1987-03-18 | Vorrichtung zum Gefrieren von auf einem Hordenwagen befindlichen Lebensmitteln |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4739625A (OSRAM) |

| EP (1) | EP0242587A1 (OSRAM) |

| DE (2) | DE3610563A1 (OSRAM) |

| ZA (1) | ZA872233B (OSRAM) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2259357A (en) * | 1991-09-04 | 1993-03-10 | Distillers Mg Limited | Food handling and cooling system |

| WO1999047023A1 (en) * | 1998-03-17 | 1999-09-23 | Monetti S.P.A. | Method and system for aircraft catering |

| IT202200008459A1 (it) * | 2022-04-28 | 2023-10-28 | Ilca Carni srl | Metodo di surgelazione criogenica |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB9306285D0 (en) * | 1993-03-26 | 1993-05-19 | Air Prod & Chem | Rotary tunnel freezer |

| US5606860A (en) * | 1994-03-07 | 1997-03-04 | Popp; James L. | Process and apparatus for cryogenically cleaning residue from containers and reducing the bulk volume thereof |

| US5887750A (en) * | 1994-03-07 | 1999-03-30 | James L. Popp | Commodity container |

| US5456085A (en) * | 1994-03-07 | 1995-10-10 | Popp; James L. | Process and apparatus for cryogenically cleaning residue from containers and reducing the bulk volume thereof |

| US5689961A (en) * | 1996-01-30 | 1997-11-25 | Organogenesis Inc. | Ice seeding apparatus for cryopreservation systems |

| GB0619319D0 (en) * | 2006-09-30 | 2006-11-08 | Pickup Gary | Food processing apparatus and method |

| US8425424B2 (en) * | 2008-11-19 | 2013-04-23 | Inightee Ltd. | Closed-loop clot lysis |

| CN102334747A (zh) * | 2011-08-18 | 2012-02-01 | 杨贵修 | 一种水雾蒸发冷却蒸煮食品的方法及装置 |

| JP5870152B2 (ja) * | 2014-04-24 | 2016-02-24 | 大陽日酸株式会社 | 過冷却凍結装置及び方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH221413A (de) * | 1941-04-26 | 1942-05-31 | Sulzer Ag | Tiefkühlanlage. |

| CA925714A (en) * | 1971-01-15 | 1973-05-08 | W. Ahara Peter | Method and apparatus for freezing material |

| FR2271521A1 (en) * | 1974-05-15 | 1975-12-12 | Anhydride Carbonique Ind | Small batches of food frozen with dry ice - sprayed on as ten or more successive layers |

| DE2523929A1 (de) * | 1975-05-30 | 1976-12-16 | Kueleg Kuehlmoebelfabrik Und A | Tiefkuehlgeraet |

| FR2498429A1 (fr) * | 1981-01-27 | 1982-07-30 | Carboxyque Francaise | Enceinte de refrigeration perfectionnee |

| US4344291A (en) * | 1980-04-28 | 1982-08-17 | Liquid Carbonic Corporation | Cryogenic cabinet freezer |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA1005250A (en) * | 1974-03-22 | 1977-02-15 | Kuleg Kuhlmobelfabrik And Apparatebau G.M.B.H. | Refrigeration apparatus |

| DE2557870A1 (de) * | 1975-12-22 | 1977-06-23 | Linde Ag | Verfahren und vorrichtung zum tiefgefrieren von biologischen substanzen |

| US4380908A (en) * | 1982-02-10 | 1983-04-26 | Growers Ice Company | Method and apparatus for chilling produce |

| US4407136A (en) * | 1982-03-29 | 1983-10-04 | Halliburton Company | Downhole tool cooling system |

-

1986

- 1986-03-27 DE DE19863610563 patent/DE3610563A1/de active Granted

- 1986-03-27 DE DE8608538U patent/DE8608538U1/de not_active Expired

-

1987

- 1987-03-18 EP EP87103924A patent/EP0242587A1/de not_active Withdrawn

- 1987-03-19 US US07/028,114 patent/US4739625A/en not_active Expired - Fee Related

- 1987-03-26 ZA ZA872233A patent/ZA872233B/xx unknown

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH221413A (de) * | 1941-04-26 | 1942-05-31 | Sulzer Ag | Tiefkühlanlage. |

| CA925714A (en) * | 1971-01-15 | 1973-05-08 | W. Ahara Peter | Method and apparatus for freezing material |

| FR2271521A1 (en) * | 1974-05-15 | 1975-12-12 | Anhydride Carbonique Ind | Small batches of food frozen with dry ice - sprayed on as ten or more successive layers |

| DE2523929A1 (de) * | 1975-05-30 | 1976-12-16 | Kueleg Kuehlmoebelfabrik Und A | Tiefkuehlgeraet |

| US4344291A (en) * | 1980-04-28 | 1982-08-17 | Liquid Carbonic Corporation | Cryogenic cabinet freezer |

| FR2498429A1 (fr) * | 1981-01-27 | 1982-07-30 | Carboxyque Francaise | Enceinte de refrigeration perfectionnee |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2259357A (en) * | 1991-09-04 | 1993-03-10 | Distillers Mg Limited | Food handling and cooling system |

| WO1999047023A1 (en) * | 1998-03-17 | 1999-09-23 | Monetti S.P.A. | Method and system for aircraft catering |

| IT202200008459A1 (it) * | 2022-04-28 | 2023-10-28 | Ilca Carni srl | Metodo di surgelazione criogenica |

Also Published As

| Publication number | Publication date |

|---|---|

| DE8608538U1 (de) | 1988-02-18 |

| DE3610563C2 (OSRAM) | 1988-04-21 |

| ZA872233B (en) | 1987-09-21 |

| US4739625A (en) | 1988-04-26 |

| DE3610563A1 (de) | 1987-10-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60124502T2 (de) | Flüssigen stickstoff verwendende kühlung eines lastfahrzeuges für nahrungsmittel | |

| DE3610563C2 (OSRAM) | ||

| DE2402340C3 (de) | Kühlvitrine | |

| DE19641722A1 (de) | Neubelastungs-Intensiv-Kühlvorrichtung für einen Kühlschrank | |

| DE10155369A1 (de) | Gerät für die Kaltluftpassage eines Kühlschranks | |

| DE69824232T2 (de) | Gefriergerät | |

| DE3020000A1 (de) | Gekuehlter schaustellbehaelter mit rundherum sichtbarer auslage | |

| DE2227313C2 (de) | Kühlcontainer zum Frisch- und Kühlhalten von Nahrungsmitteln | |

| DE1955612A1 (de) | Kuehlanlage | |

| DE2516601A1 (de) | Verdampferschlange fuer kuehlzwecke mit bei luft arbeitenden kuehlgeraeten | |

| DE2208308C2 (de) | Offenes Kühlmöbel | |

| DE2942491A1 (de) | Kuehltruhe | |

| WO2018091323A1 (de) | Kältegerät mit luftfeuchtigkeitsoptimiertem lagerfach | |

| EP0547311B1 (de) | Haushaltskühlgerät | |

| AT520968A1 (de) | Wärmegedämmte Transportbox | |

| DE3003987A1 (de) | Mit einer kuehleinrichtung versehener kleincontainer | |

| DE4432439A1 (de) | Kühlschrank mit Null-Grad-Fach | |

| DE2540037C2 (de) | Kühlschrank mit zwei Kühlabteilen | |

| DE4343537C2 (de) | Kühltruhe | |

| CH653432A5 (de) | Verfahren zur kuehlung einer kuehlvitrine fuer lebensmittel. | |

| DE19644505C2 (de) | Anlage zum Kühlhalten von Lebensmitteln | |

| EP0727626A1 (de) | Kühlgerät, insbesondere Haushalts-Kühlschrank | |

| WO2009100747A2 (de) | Vorrichtung zum gefrieren und/oder abkühlen von produkten | |

| DE2320208C3 (de) | Tiefkühltruhe | |

| DE20108914U1 (de) | Temperier-, Erstarrungs- und Tiefkühlraumanordnung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH FR GB IT LI NL SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19880429 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HOFFMANNS, WOLFGANG Inventor name: BUCHMUELLER, JUERGEN |