EP0190660A2 - Brûleur à air soufflé sous faible pression - Google Patents

Brûleur à air soufflé sous faible pression Download PDFInfo

- Publication number

- EP0190660A2 EP0190660A2 EP86101188A EP86101188A EP0190660A2 EP 0190660 A2 EP0190660 A2 EP 0190660A2 EP 86101188 A EP86101188 A EP 86101188A EP 86101188 A EP86101188 A EP 86101188A EP 0190660 A2 EP0190660 A2 EP 0190660A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- gas

- burner

- mixing tube

- mixing

- cross

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/02—Premix gas burners, i.e. in which gaseous fuel is mixed with combustion air upstream of the combustion zone

Definitions

- the invention relates to a gas forced draft burner with low pressure for boilers according to the preamble of the main claim.

- Such a gas fan burner is known from DE-PS 2 525 305, while gas fan burners are generally known from VDI report No. 246, 1975, in particular pages 50-52.

- DE-GM 80 25 338.9 referenced, the subject of which is, however, a burner with which both gas and oil can be burned after a simple switchover.

- Known burners of this type in principle have a so-called mixing tube into which the gas feed tube protrudes centrally, with the gas cross-distribution over the mixing tube cross-section taking place radially between so-called baffle plates which are perforated to allow the incoming air to pass through and to mix with the cross-flowing gas.

- the outflowing gas-air mixture forms a correspondingly long and concentrated flame with a high flow rate, which requires a correspondingly dimensioned combustion chamber of the boiler in question.

- the diameter of the mixing tube is usually only a fraction (about 1/4 or 1/5) of the combustion chamber diameter or the combustion chamber door, which, in view of this, must be well heat-insulated to take into account the heat radiation from the flame. Due to the high pressure with which such burners are operated, they also generate considerable noise.

- a plurality of slot channels are arranged on at least two circles concentric to the burner axis, which are increasingly inclined with respect to the burner axis in the direction of the circumference of the nozzle apparatus, in the direction of flow diverge.

- the invention is based on the object ausghend from a G as-burner of the aforementioned type, these alter the effect that the formed gas-air mixture burns in the form of a surface flame directly behind the opening of the mixing tube and, accordingly, the burner having a blower low pressure and can be operated correspondingly low noise and which should also make it possible to adapt the mixing tube opening size to the cross-sectional size of the combustion chamber of a boiler equipped with such a burner.

- blower manages with about 50 - 70% less pressure, like the blower for burners of the known type.

- Essential for this solution is the total coverage of the outflow opening of the mixing tube and the arrangement of the gas distribution elements in the middle area of the mixing tube, so that there is a sufficiently long mixing section up to the burner membrane and the gas-air mixture can flow out over the whole area.

- Any flame tubes bundling the mixture flow or the flame, which normally surround the mixing tube, or nozzle-like configurations according to DE-PS 2 525 305, are not necessary here, since an overall surface-burning flame is to be achieved, which to a certain extent is a relatively thin layer of flame "stands over the membrane ....

- So-called surface burners are known in the area of atmospheric gas burners, but they generally consist of three or four individual burners, for example in the form of a tube or box, the gas outflow surface of the individual burners also being formed from fine-hole or fine-slot surfaces.

- an area-like flame in the sense provided here cannot be achieved since, depending on the gas pressure, more or less burning individual flames form over the gas outflow openings of the burner surface, as in the case of the object according to DE-PS 2 525 305.

- the mixing tube is, as it were, the self-supporting outer part of the entire burner, at the other end of which the fan is connected in a suitable manner directly, it is also necessary to have the mixing tube on its outer circumference in a known manner to be provided with a connection flange.

- the connecting flange is advantageously arranged at the end of the mixing tube on the burner membrane side, which means that when such a burner is attached to a boiler, the mixing tube with most of its longitudinal extent is outside the burner chamber.

- the cross-sectional size of the gas supply pipe protruding centrally into the mixing pipe is only 1-5% of the cross-sectional size of the mixing pipe, in contrast to previously known burners, where this ratio is about 20% .

- the mixing tube with its connecting flange can advantageously be designed directly as a flange-lockable or swivel-lockable boiler lock door, the burner membrane forming the gas-cooled surface of the boiler lock door that is constantly gas-cooled on the inflow side.

- the burner membrane forming the gas-cooled surface of the boiler lock door that is constantly gas-cooled on the inflow side. This means that except for one very small circumferential edge area the whole combustion chamber-side surface of the vessel closure door is formed by the burner membrane, so no other heat-affected FLAE - chen are left, which otherwise bedürften thermal insulation. Due to the constant air supply or gas-air mixture supply, however, the entire outflow area is subject to permanent cooling in relation to the flat flame, which makes thermal insulation of the boiler lock door unnecessary.

- the fan manages with a much lower pressure, the whole thing is associated with a significantly lower noise level and a saving of additional energy for driving the fan. Since, as mentioned, the gas-air mixture continuously flows over the entire surface of the burner membrane, the gas burns to a certain extent "colder" and, as measurements have shown, the so-called NOx formation can also be significantly reduced.

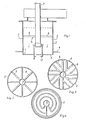

- a gas-permeable burner membrane 3 covering the entire opening cross section arranged, which consists of a suitable metal grid or metal mesh.

- the mixing tube 2 is provided on its outer circumference with a connecting flange 4 and in the central region of the mixing tube 2, gas distribution lines 6, which are evenly distributed over the entire mixing tube cross section and are provided with gas outflow openings 5, are arranged, which are connected to the gas supply tube 7 and, in this exemplary embodiment, radially from the gas supply tube 7 stand out.

- the connecting flange 4 is attached to the end of the mixing tube 2 on the burner membrane side.

- an air distributor plate 8 corresponding to the mixer tube cross section is advantageously arranged in front of the gas distributor lines 6 in the mixing tube and is fastened either to the mixer tube 2 or to the gas supply line 7.

- the gas supply pipe can also serve as a support for the ignition electrode 11 and an ionization electrode 12 at the same time.

- the gas distributor lines can be provided with branch lines 6 ', as shown in FIG. 3 will.

- the mixing tube 2 with its connecting flange 4 is designed as a pivotable lockable boiler lock door 9, the burner membrane 3 forming the gas-cooled and, on the other hand, heat-loaded surface of the boiler lock door 9 in relation to the combustion chamber 13 of the boiler in question. Since, as can be seen, only a small annular gap 14 remains free, all other heat insulation measures required on the boiler lock door itself can be omitted.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Gas Burners (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19853503553 DE3503553A1 (de) | 1985-02-02 | 1985-02-02 | Gas-geblaesebrenner mit geringer pressung |

| DE3503553 | 1985-02-02 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0190660A2 true EP0190660A2 (fr) | 1986-08-13 |

| EP0190660A3 EP0190660A3 (fr) | 1987-10-28 |

Family

ID=6261486

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86101188A Withdrawn EP0190660A3 (fr) | 1985-02-02 | 1986-01-30 | Brûleur à air soufflé sous faible pression |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0190660A3 (fr) |

| DE (1) | DE3503553A1 (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT388988B (de) * | 1987-01-23 | 1989-09-25 | Vaillant Gmbh | Kessel mit in einer oeffnung befestigtem geblaesebrenner |

| NL1008233C2 (nl) * | 1998-02-06 | 1999-08-09 | Clysan D W Bv | Gasbrander. |

| EP1026445A1 (fr) * | 1999-02-08 | 2000-08-09 | D.W. Clysan B.V. | Brûleur à gaz |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0283901B1 (fr) * | 1987-03-17 | 1990-12-12 | Viessmann Werke GmbH & Co. | Brûleur à gaz à flamme plate |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE808867C (de) * | 1949-03-25 | 1951-07-19 | Maschf Augsburg Nuernberg Ag | Industriegasbrenner |

| FR1574404A (fr) * | 1967-07-28 | 1969-07-11 | ||

| FR2209439A5 (fr) * | 1972-12-05 | 1974-06-28 | Fritsche Heinrich | |

| US3947233A (en) * | 1971-04-26 | 1976-03-30 | C. A. Sundberg Ab | Free-burning equipment |

| DE2525305A1 (de) * | 1975-06-06 | 1976-12-16 | Pensenskij Kompressornyj Sawod | Gasbrenner |

| DE2527073A1 (de) * | 1975-06-18 | 1977-01-13 | Pensenskij Kompressornyj Sawod | Gasbrenner |

| US4082497A (en) * | 1976-03-29 | 1978-04-04 | Ex-Cell-O Corporation | High capacity quiet burner for hot air heating system |

| DE3415946A1 (de) * | 1983-05-19 | 1984-11-22 | Saunier Duval Eau Chaude Chauffage - S.D.E.C.C., Montreuil-sous-Bois | Gasbrenner mit vormischung von luft und gas |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT310996B (de) * | 1970-11-02 | 1973-10-25 | Vaillant Joh Kg | Durchlauferhitzer |

| BE780415A (fr) * | 1971-04-26 | 1972-07-03 | C A Sundberg A B | Accessoires pour bruleurs a combustible gazeux |

| DE8025338U1 (de) * | 1980-09-22 | 1984-05-03 | Deutsche Forschungs- und Versuchsanstalt für Luft- und Raumfahrt e.V., 5000 Köln | Oel- und gasbrenner zum einbau in heizungs- und dampferzeugungskessel |

-

1985

- 1985-02-02 DE DE19853503553 patent/DE3503553A1/de active Granted

-

1986

- 1986-01-30 EP EP86101188A patent/EP0190660A3/fr not_active Withdrawn

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE808867C (de) * | 1949-03-25 | 1951-07-19 | Maschf Augsburg Nuernberg Ag | Industriegasbrenner |

| FR1574404A (fr) * | 1967-07-28 | 1969-07-11 | ||

| US3947233A (en) * | 1971-04-26 | 1976-03-30 | C. A. Sundberg Ab | Free-burning equipment |

| FR2209439A5 (fr) * | 1972-12-05 | 1974-06-28 | Fritsche Heinrich | |

| DE2525305A1 (de) * | 1975-06-06 | 1976-12-16 | Pensenskij Kompressornyj Sawod | Gasbrenner |

| DE2527073A1 (de) * | 1975-06-18 | 1977-01-13 | Pensenskij Kompressornyj Sawod | Gasbrenner |

| US4082497A (en) * | 1976-03-29 | 1978-04-04 | Ex-Cell-O Corporation | High capacity quiet burner for hot air heating system |

| DE3415946A1 (de) * | 1983-05-19 | 1984-11-22 | Saunier Duval Eau Chaude Chauffage - S.D.E.C.C., Montreuil-sous-Bois | Gasbrenner mit vormischung von luft und gas |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT388988B (de) * | 1987-01-23 | 1989-09-25 | Vaillant Gmbh | Kessel mit in einer oeffnung befestigtem geblaesebrenner |

| NL1008233C2 (nl) * | 1998-02-06 | 1999-08-09 | Clysan D W Bv | Gasbrander. |

| EP1026445A1 (fr) * | 1999-02-08 | 2000-08-09 | D.W. Clysan B.V. | Brûleur à gaz |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3503553A1 (de) | 1986-08-07 |

| EP0190660A3 (fr) | 1987-10-28 |

| DE3503553C2 (fr) | 1987-06-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0309838A1 (fr) | Brûleur à gaz | |

| DE2541991C3 (de) | Brenner | |

| DE1897407U (de) | Gasbrenner. | |

| DE2428622A1 (de) | Brennerkopf, insbesondere fuer gasfoermige brennstoffe | |

| DE2119831C2 (de) | Gasbrenner | |

| DE2134330C3 (de) | Vorrichtung zur Erzeugung eines Heißgasstroms hoher Geschwindigkeit mit einem Gasbrenner | |

| EP0190660A2 (fr) | Brûleur à air soufflé sous faible pression | |

| DE3503554C2 (fr) | ||

| DE1213960B (de) | Schmelz- und/oder Warmhalteofen | |

| DE2700786C3 (de) | Keramischer Gasbrenner für Winderhitzer | |

| DE2364053C2 (de) | Feuerungsanlage | |

| DE2715456A1 (de) | Mischkopf fuer brenner kleiner heizleistungen | |

| EP0601018B1 (fr) | Bruleur a gaz, notamment pour gaz liquefie | |

| DE3009764A1 (de) | Kohlebrenner | |

| DE3318860C2 (de) | Brenner zum Erwärmen von Luft | |

| EP0209703B1 (fr) | Cartouche incandescente pour fours, en particulier pour chaudières ainsi que four avec une telle cartouche | |

| DE3327140A1 (de) | Gasbrenner, insbesondere fuer fluessiggas, zum einbau in einen waermetauscher | |

| DE2242037C2 (de) | Rohrförmiger Gasbrenner, insbesondere für Trockner | |

| EP0115858A1 (fr) | Brûleur à monter dans les installations de chauffage et de production de vapeur | |

| DE69212790T2 (de) | Brenner mit Verbrennungsgitter und Heizungsanlage mit einem solchen Brenner | |

| DE3024637C2 (de) | Gasherd mit einem durch eine wärmeübertragende Platte gebildeten Kochfeld | |

| DE3131948C2 (fr) | ||

| DE3506640A1 (de) | Mischkopf fuer einen vergasungs-oelbrenner | |

| DE2351418C3 (de) | Vorrichtung zur Verbrennung von veränderlichen Abgasmengen | |

| DE2125365C3 (de) | Strahlungsbrenner für gasförmige Brennstoffe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH FR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH FR IT LI LU NL SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19880429 |