EP0131118B1 - Mehrfachsteckverbindung - Google Patents

Mehrfachsteckverbindung Download PDFInfo

- Publication number

- EP0131118B1 EP0131118B1 EP19840105683 EP84105683A EP0131118B1 EP 0131118 B1 EP0131118 B1 EP 0131118B1 EP 19840105683 EP19840105683 EP 19840105683 EP 84105683 A EP84105683 A EP 84105683A EP 0131118 B1 EP0131118 B1 EP 0131118B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- spring arm

- connector according

- insulating material

- contact spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000011810 insulating material Substances 0.000 claims description 8

- 239000004020 conductor Substances 0.000 claims description 7

- 239000011888 foil Substances 0.000 claims description 5

- 239000000463 material Substances 0.000 claims description 4

- 238000010276 construction Methods 0.000 claims 2

- 238000005452 bending Methods 0.000 claims 1

- 238000007373 indentation Methods 0.000 claims 1

- 238000003780 insertion Methods 0.000 description 4

- 230000037431 insertion Effects 0.000 description 4

- WABPQHHGFIMREM-UHFFFAOYSA-N lead(0) Chemical compound [Pb] WABPQHHGFIMREM-UHFFFAOYSA-N 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 2

- 229920006267 polyester film Polymers 0.000 description 2

- 210000002105 tongue Anatomy 0.000 description 2

- 229920002799 BoPET Polymers 0.000 description 1

- 239000005041 Mylar™ Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 239000000976 ink Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920006289 polycarbonate film Polymers 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/71—Coupling devices for rigid printing circuits or like structures

- H01R12/712—Coupling devices for rigid printing circuits or like structures co-operating with the surface of the printed circuit or with a coupling device exclusively provided on the surface of the printed circuit

- H01R12/716—Coupling device provided on the PCB

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/40—Securing contact members in or to a base or case; Insulating of contact members

- H01R13/42—Securing in a demountable manner

- H01R13/428—Securing in a demountable manner by resilient locking means on the contact members; by locking means on resilient contact members

- H01R13/434—Securing in a demountable manner by resilient locking means on the contact members; by locking means on resilient contact members by separate resilient locking means on contact member, e.g. retainer collar or ring around contact member

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/66—Structural association with built-in electrical component

- H01R13/70—Structural association with built-in electrical component with built-in switch

Definitions

- the innovation is based on a multiple connector according to the preamble of claim 1.

- Printed circuits e.g. B. consist of a ceramic substrate, have manufacturing-related length or thickness tolerances. In particular, circuit boards of this type are not completely flat, but rather have slight curvatures. In order to be able to guarantee a reliable contact connection even with critical tolerances with regard to the thickness, a relatively high contact pressure is chosen for the contact springs. In addition, the edge of such a circuit board is usually very sharp due to the manufacturing process, so that the conductor tracks or contact points are easily rubbed through, particularly when the circuit board is repeatedly plugged in, no more reliable contact is guaranteed.

- the conductor tracks are very thin, so that here too there is a risk of damage if they are inserted several times.

- a socket strip for force-free plug connection for printed circuit boards is already known from DE-A1-28 56 071.

- a housing there are paired contact springs along a slot, which can be expanded against their spring force for insertion and removal of the circuit board.

- the contact spring ends are bent outwards and provided with an inclined surface.

- Elements are arranged vertically adjustable between the inclined surface and the contact arm of the contact spring. These elements can be moved by slide elements which can move longitudinally in the socket housing. If the elements are in their lower position, the contact springs are closest. In the upper position, the elements spread the contact springs so that the circuit board can be inserted without force.

- the housing Due to the complex adjustment device, the housing consists of several parts.

- a connecting terminal soldered into a printed circuit board for a lead wire to be contacted is known from DE-A1-31 18057.

- a contact spring is accommodated in a chamber in a housing which is displaceable. Two legs of the contact spring are connected to one another by an essentially U-shaped apex web which has a push-through opening for the lead wire. In the area of the push-through opening, tongues are present, the lugs of which are designed as clamping lugs.

- the contact spring is fastened in the housing by means of a locking tongue which is notched outwards and which projects into a slot in the housing. The narrowing of the push-through opening is achieved in that one leg of the contact spring can be moved towards one another relative to the other leg.

- one leg has a projection which interacts with an inclined surface in the housing. If the housing is moved towards the printed circuit board, the inclined surface causes one leg to move towards the other. The result is that the push-through opening is reduced, so that the lead wire is clamped between the clamping lugs.

- the object of the present innovation is to provide a simple and therefore inexpensive multiple connector according to the type mentioned, which is suitable for flexible film circuits in both S and P versions.

- An S version is to be understood as a plug connection in which the plug direction is perpendicular to the printed circuit board. In the same way, the direction of insertion for the P version is parallel to the circuit board.

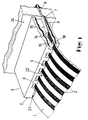

- the multiple plug connection shown in perspective in FIG. 1 consists of an insulating material housing 3 and a flexible film circuit 1.

- the one-piece rectangular housing made of plastic is flat and elongated. It has a longitudinal wall 6 and a side wall 5 each.

- a continuous elongated slot 22 extends between the two longitudinal walls, into which the flexible film circuit 1 can be inserted up to a stop.

- a plurality of chambers 4 are recessed in the housing, in which contact elements 7 are arranged.

- the flexible Foil circuit 1 is made of a thin polyester or polycarbonate film, on which conductor tracks 2 are applied to the edge on one or both sides in a screen printing process.

- polyester films are sold by Du Pont as “Mylar” rolls.

- notches 23 are left which extend inwards from the edge and whose depth corresponds approximately to the insertion depth of the flexible film circuit into the housing. These incisions together with the two side walls 5 form a kind of stop for the flexible film circuit.

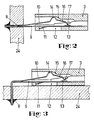

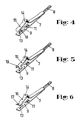

- FIGS. 2 and 3 show two different embodiments with regard to the use.

- Figure 2 shows the so-called S version and Figure 3 shows the P version.

- each contact element consists of a first contact spring arm 9, which is essentially flat, a second contact spring arm 10 and the terminal lug 8

- the connection lug 8 is bent at a right angle in the P version.

- the contact element 7 is soldered into a printed circuit board 24. Since it is a multiple connector, several lugs are attached in a row next to each other in the circuit board.

- the housing 3 is relatively displaceable.

- the first contact spring arm 9 has a raised barb 11 which projects into a recess 12.

- the recess 12 has a length corresponding to the relative stroke of the housing / contact element.

- the first contact spring arm 9 is provided with an inward stamping 13.

- the second contact spring arm 10 is produced by folding.

- the terminal lug 8 is thus double-layered.

- a solution is also conceivable in which the second contact spring arm is soldered, welded or otherwise fastened to the first.

- the second contact spring arm is soldered, welded or otherwise fastened to the first.

- materials adapted to the respective purpose can be used.

- the second contact spring arm for example, should be made of a good spring material, since it may be subjected to greater mechanical stress.

- the second contact spring arm 10 is led away from the first contact spring arm 9 by a slight slope.

- a bulge 14 is provided approximately in the middle of its length. This bulge interacts with one or more projections 15 in the housing such that when the housing is moved, the distance of the second from the first contact spring arm is changed.

- the bulge forms an end section 16 toward the free end. This end section is bent inwards and it has a specific profiling 17 at the free end at the insertion opening.

- the counterpart of the profiling represents the stamping 13 of the first contact spring arm 9.

Landscapes

- Coupling Device And Connection With Printed Circuit (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8318896U | 1983-06-30 | ||

| DE19838318896 DE8318896U1 (de) | 1983-06-30 | 1983-06-30 | Mehrfachsteckverbindung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0131118A1 EP0131118A1 (de) | 1985-01-16 |

| EP0131118B1 true EP0131118B1 (de) | 1987-01-21 |

Family

ID=6754741

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19840105683 Expired EP0131118B1 (de) | 1983-06-30 | 1984-05-18 | Mehrfachsteckverbindung |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0131118B1 (ja) |

| JP (1) | JPS6041782A (ja) |

| DE (1) | DE8318896U1 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH669043A5 (de) * | 1985-08-23 | 1989-02-15 | Mettler Instrumente Ag | Praezisionswaage. |

| JP2543195Y2 (ja) * | 1992-04-28 | 1997-08-06 | 古河電気工業株式会社 | Ffc用コネクタ |

| JP2849600B2 (ja) * | 1995-03-30 | 1999-01-20 | モレックス インコーポレーテッド | 電気コネクタ |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3474387A (en) * | 1967-04-13 | 1969-10-21 | Elco Corp | Zero insertion force connector and contact therefor |

| US3725853A (en) * | 1971-03-22 | 1973-04-03 | Bendix Corp | Electrical contact |

| DE7705029U1 (de) * | 1976-02-20 | 1977-06-02 | Japan Aviation Electronics Industry, Ltd., Tokio | Ko nta ktverbindu ngsele me nt |

| US4235500A (en) * | 1978-11-08 | 1980-11-25 | Trw Inc. | Circuit connector |

-

1983

- 1983-06-30 DE DE19838318896 patent/DE8318896U1/de not_active Expired

-

1984

- 1984-05-18 EP EP19840105683 patent/EP0131118B1/de not_active Expired

- 1984-06-29 JP JP59133414A patent/JPS6041782A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JPS6041782A (ja) | 1985-03-05 |

| EP0131118A1 (de) | 1985-01-16 |

| DE8318896U1 (de) | 1983-12-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69311169T2 (de) | Leiterplatten-Klemmverbinder | |

| DE2732912C2 (de) | Verbindungsglied zum Verbinden einer flexiblen elektrischen Flachleitung | |

| DE102009022094B4 (de) | Stapelverbinder | |

| DE69315966T2 (de) | Elektrischer Verbinder für einen Kartenleser | |

| DE3885636T2 (de) | Verbindungssystem für gedruckte Schaltungen. | |

| DE10144657C2 (de) | Schwimmender Verbinder | |

| DE3888532T2 (de) | Fassungen für chipträger mit verbesserten kontakten. | |

| DE69507921T2 (de) | Stecker für Leiterplatte | |

| DE2621984B2 (de) | Kontaktfederleiste | |

| EP3375048B1 (de) | Steckkontakt | |

| DE69326613T2 (de) | Kartenverbinder mit flacher rückseite | |

| DE2203435A1 (de) | Elektrisches Verbinderelement fuer gedruckte Schaltungen | |

| DE69308225T2 (de) | Steckverbinder zusammenwirkend mit dem Rand von gedruckten Schaltungen oder ähnlichen Vorrichtungen | |

| DE102016108825B4 (de) | Klemmanordnung und Anschlussklemme | |

| DE112012000474T5 (de) | Platinenverbindungsanschluss | |

| DE2234961B2 (de) | Verfahren zur Herstellung von Steckern für Schaltplatten | |

| DE69609030T2 (de) | Elektrischer verbinder insbesondere für den anschluss einer elektronischen speicherkarte | |

| DE102021126499A1 (de) | Elektrischer steckverbinder mit flachleiter | |

| EP0864188B1 (de) | Bandkabel mit schirmanschluss | |

| DE19945412B4 (de) | Elektrischer Kontakt und elektrischer Steckverbinder mit einem solchen Kontakt | |

| DE69821291T2 (de) | Elektrischer Verbinder für flache flexible Schaltungen | |

| EP0131118B1 (de) | Mehrfachsteckverbindung | |

| DE69808829T2 (de) | Elektrischer Steckverbinder | |

| DE3011469A1 (de) | Steckverbinderbuchse | |

| DE102016107898B4 (de) | Laterale Leiterplattenverbindung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19850213 |

|

| 17Q | First examination report despatched |

Effective date: 19860423 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): FR GB IT |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19890518 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19900131 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |