EP0111874B1 - Installation pour brûler la poussière de charbon - Google Patents

Installation pour brûler la poussière de charbon Download PDFInfo

- Publication number

- EP0111874B1 EP0111874B1 EP83112521A EP83112521A EP0111874B1 EP 0111874 B1 EP0111874 B1 EP 0111874B1 EP 83112521 A EP83112521 A EP 83112521A EP 83112521 A EP83112521 A EP 83112521A EP 0111874 B1 EP0111874 B1 EP 0111874B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- jets

- chamber

- burner muffle

- cross

- coal dust

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000002817 coal dust Substances 0.000 title claims description 17

- 238000002485 combustion reaction Methods 0.000 claims description 13

- 239000000654 additive Substances 0.000 claims description 9

- 230000001133 acceleration Effects 0.000 claims description 7

- 238000007664 blowing Methods 0.000 claims description 2

- 238000010304 firing Methods 0.000 claims 4

- 230000015572 biosynthetic process Effects 0.000 claims 1

- 239000002956 ash Substances 0.000 description 11

- 239000000428 dust Substances 0.000 description 10

- 239000002245 particle Substances 0.000 description 9

- 239000007789 gas Substances 0.000 description 8

- 230000000996 additive effect Effects 0.000 description 3

- 239000003245 coal Substances 0.000 description 3

- 235000002918 Fraxinus excelsior Nutrition 0.000 description 2

- 239000003546 flue gas Substances 0.000 description 2

- 244000007645 Citrus mitis Species 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006477 desulfuration reaction Methods 0.000 description 1

- 230000023556 desulfurization Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C3/00—Combustion apparatus characterised by the shape of the combustion chamber

- F23C3/006—Combustion apparatus characterised by the shape of the combustion chamber the chamber being arranged for cyclonic combustion

- F23C3/008—Combustion apparatus characterised by the shape of the combustion chamber the chamber being arranged for cyclonic combustion for pulverulent fuel

Definitions

- the invention is based on a device for burning coal dust according to the first part of claim 1.

- Such a device is known from DE-A 2527618.

- US-A 1919735 describes a coal dust burner, the combustion chamber of the coal dust is supplied helically with the help of air in an axial guide, while tangential air supply lines open into the combustion chamber wall, the air of which surrounds the internal swirl flow of the axial helical dust supply.

- rotary-flow dedusters are also known, in which an internal air flow set in a swirl movement is overlaid by an air flow in the same direction but in opposite directions, so that when the deduster is standing, the cleaned air can escape upwards near the axis of the deduster, while the centrifugal forces cause it Dust moved outside is guided downwards by the additional helical air flow and gravity and can be drawn off at the lower end of the device (VDI reports No. 363, 1980, pp. 61-68 and “Staub” 23, 1953, No. 11 , Pp. 491-509).

- VDI reports No. 363, 1980, pp. 61-68 and “Staub” 23, 1953, No. 11 , Pp. 491-509 There has also been no lack of attempts to make the principle of this three-phase dust extractor usable for a coal dust burner.

- the invention is therefore based on the object of improving the device according to the first part of patent claim 1 in such a way that the extent of the burnout, i.e. the proportion of burned matter in the ash, taking into account the fluctuations in the interior wall temperatures, the moisture content and the ash content, and thus the efficiency is increased, so that the ash obtained can also be used for other purposes, e.g. in the cement industry, when the discharged ash does not exceed a flammable content.

- the overall length is to be reduced compared to known devices; the ash should be easy to collect and discharge from the device and it should be possible to desulfurize effectively and / or otherwise free the flue gases from unwanted gases and constituents.

- the invention provides the features of the characterizing part of claim 1.

- the features of the dependent claims serve to improve and further develop the subject matter of claim 1.

- the advantage of the object of the invention over the prior art is that the flame emerging from the burner muffle maintains its cylindrical or conical shape with the diameter in the cylindrical or conical acceleration chamber which it has when it emerges from the burner muffle. This results in a shell space between the circumference of the flame and the wall of the acceleration chamber, which has a larger diameter, in which the helical circulation can take place against the front end of the device of the partially still unburned dust particles that have escaped from the combustion air flow by the centrifugal forces, and the ashes, which the flame directly surround.

- the removal of flue gases from undesired gases or components by additives is known.

- desulfurization e.g. Lime added to the combustion chamber.

- the invention offers the possibility to selectively and differently additive in the amount over the length of the acceleration chamber, i.e. at the most convenient point in connection with the gas supplied to the nozzles.

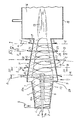

- the device according to the invention has a burner muffle 1, which is conical and widens from its front end 2 to its rear end at 3.

- the front end 2 has a swirl device 4, in which the combustion air to be introduced via the line 5 is introduced tangentially into the muffle 1 and displaced in a helical swirl flow 6 in the muffle.

- the other devices such as the ignition device, etc. are not shown in detail and are of a known type.

- a tubular blow lance 7 projects through the burner muffle 1 in its longitudinal axis and carries a cap-like part 8 at its rear end, ie in the vicinity of the rear end of the muffle 3, which causes the direction of the conveying air for the Coal dust and the coal dust itself in the blowing lance 7 (see arrow 7a) are reversed and emerge from the cap-like part in the direction of the arrows 9.

- a circulating flow of the coal dust and the conveying air occurs in the direction of the arrows 10 around the lance 7, the external flow part 10a of which is captured by the flow 6 of the combustion air and entrained in a helical shape, while the remaining part 10b along the lance 7 against the front muffle end flows.

- the combustion air passes from the muffle 1 into an accelerator chamber 11, the helical swirl movement of the combustion air being maintained as an internal swirl flow 12 along the solid line.

- the flame 13 forms, which e.g. protrudes into the boiler room 14 of the downstream boiler 15.

- the accelerator chamber 11 has a conical shape, the wall 16 of the accelerator chamber 11 tapering from its front end to its rear end 17.

- the cross section of the accelerator chamber 11 at the transition between the muffle 1 and the accelerator chamber is kept larger than the cross section at the rear end 3 of the burner muffle 1. This forms an annular channel 18 on the one hand, and a jacket-like extension 19 of the accelerator chamber on the other hand.

- the annular channel can preferably experience such a curvature or beveling of its wall 29 adjacent to the muffle 1 that the coal dust parts from the extension 19 are again guided into the interior of the muffle 1 or the accelerator chamber 11.

- the swirl flow 12 and the front end of the flame 13 retain their shape in the accelerator 11 and do not enlarge in the enlargement 19, which can thereby be used to allow the return of the dust and ash particles to take place along the wall 12 of the chamber 1 .

- the long back and forth path which the dust particles in the muffle 1 and the accelerator chamber 11 take repeatedly, ensures that a long combustion path is achieved with a short design of the device.

- the radiant heat of the already ignited coal particles acts both on the way there (from left to right) and on the way back (from right to left in the drawing) on the as yet ignited dust particles.

- the length of the accelerator chamber 11 as well as its outer shape can be varied.

- the accelerator chamber can have a cylindrical shape, and its length can also be chosen such that the flame 13 which projects into the boiler space 14 can be made longer or shorter.

- the nozzles 20-27 of the individual cross-sectional planes A to E of the acceleration chamber 11 are arranged at different inclinations to the cross-sectional plane.

- the nozzles 24-27 of levels D and E have a slight inclination towards the front end and the annular channel 18 of the chamber 11.

- the nozzles of level C have either the same direction of inclination as the nozzles 24-27, e.g. the nozzle 23, or they have no inclination to the cross-sectional plane C, e.g. the nozzle 22.

- the nozzles 20 and 21 are inclined with respect to their cross-sectional planes in the direction of the rear end 17 of the acceleration chamber 11.

- the angular position can not only differ from cross-sectional plane to cross-sectional plane, but also within a cross-sectional plane, as can be seen from the nozzles 22, 23 of plane C in FIG. 1.

- the number of nozzles can also differ from cross-sectional level to cross-sectional level. 2 shows a total of six nozzles 24-24b and 25-25b, while level B has only three nozzles 21, 31, 31a.

- Fig. 1 shows the different angles of inclination a ... Q of the planes with each other and inside the plane

- Fig. 2 shows 3 that the angles between the nozzles and the corresponding tangents T 2 and T 3 of the wall 16 of the accelerator chamber 11 can also be different.

- the feed lines 124 to 125b of the nozzles 24-25b are combined into two groups, the feed lines 124-124b opening or passing into a tube 224 with a valve 324, while the feed lines 125-125b into a common one Open or pass pipe 225 with valve 325. Both pipes receive the gas or air from a line 100.

- FIG. 3 shows that an unequal number of nozzles on one level can be supplied with different additives.

- valves 324, 325 and 425a, 525a allow precise adjustment of the gas or air quantity to be supplied or the quantity of additives. This makes it possible, on the one hand, to regulate the outer swirl flow 28 very precisely, i.e. to accelerate or decelerate in order to expose the dust particles of this flow to the radiant heat of the inner swirl flow 12 for more or less long and thus to burn as many coal dust particles as possible. On the other hand, it is also possible to introduce additives in the desired amount into the chamber 11. The additive, and this is essential when adding the additives, is not added with the coal dust or the combustion air, but at a later point in time when the coal dust has already ignited.

- the nozzles 20-27 are preferably permanently installed in the wall, but this does not preclude holding the nozzles in spherical parts and making them pivotable in spherical caps.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ZA841327A ZA841327B (en) | 1983-12-13 | 1984-02-23 | Combustion device |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3246379 | 1982-12-15 | ||

| DE3246379 | 1982-12-15 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0111874A1 EP0111874A1 (fr) | 1984-06-27 |

| EP0111874B1 true EP0111874B1 (fr) | 1987-04-22 |

Family

ID=6180704

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83112521A Expired EP0111874B1 (fr) | 1982-12-15 | 1983-12-13 | Installation pour brûler la poussière de charbon |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4507075A (fr) |

| EP (1) | EP0111874B1 (fr) |

| CA (1) | CA1209408A (fr) |

| DE (1) | DE3371114D1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101865461A (zh) * | 2010-06-08 | 2010-10-20 | 上海市特种设备监督检验技术研究院 | 一种可调式中心给粉旋流煤粉浓淡燃烧器 |

Families Citing this family (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3436624A1 (de) * | 1984-10-05 | 1986-04-10 | Norddeutsche Affinerie AG, 2000 Hamburg | Vorrichtung zur erzeugung zuendfaehiger feststoff/gas-suspensionen |

| US4539918A (en) * | 1984-10-22 | 1985-09-10 | Westinghouse Electric Corp. | Multiannular swirl combustor providing particulate separation |

| US4629416A (en) * | 1985-06-11 | 1986-12-16 | Voorheis Industries, Inc. | Bluff body register |

| DE3523172C1 (de) * | 1985-06-28 | 1986-12-11 | Gewerkschaft Sophia-Jacoba Steinkohlenbergwerk, 5142 Hückelhoven | Vorrichtung zum Verbrennen von reaktionstraegem Kohlenstaub |

| US4958619A (en) * | 1985-07-08 | 1990-09-25 | Institute Of Gas Technology | Portable, flueless, low nox, low co space heater |

| US5009174A (en) * | 1985-12-02 | 1991-04-23 | Exxon Research And Engineering Company | Acid gas burner |

| DE3636071A1 (de) * | 1986-10-23 | 1988-08-25 | Gewerk Sophia Jakoba | Einrichtung zum verbrennen, insbesondere von reaktionstraegem kohlenstaub |

| DE3643040C1 (de) * | 1986-12-17 | 1988-02-25 | Gewerk Sophia Jakoba | Vorrichtung zum Verbrennen von Kohlenstaub |

| US4873930A (en) * | 1987-07-30 | 1989-10-17 | Trw Inc. | Sulfur removal by sorbent injection in secondary combustion zones |

| US4800825A (en) * | 1987-08-31 | 1989-01-31 | Trw Inc. | Slagging-combustor sulfur removal process and apparatus |

| US5307636A (en) * | 1987-11-20 | 1994-05-03 | Sundstrand Corporation | Staged, coaxial, multiple point fuel injection in a hot gas generator having a sufficiently wide cone angle |

| US4871308A (en) * | 1987-11-25 | 1989-10-03 | Combustion Concepts Inc. | Method and apparatus for heating a fluid stream |

| US4928479A (en) * | 1987-12-28 | 1990-05-29 | Sundstrand Corporation | Annular combustor with tangential cooling air injection |

| US4920898A (en) * | 1988-09-15 | 1990-05-01 | Trw Inc. | Gas turbine slagging combustion system |

| WO1990003538A1 (fr) * | 1988-09-19 | 1990-04-05 | Regents Of The University Of Minnesota | Enceinte de confinement dynamique |

| US5111757A (en) * | 1991-05-21 | 1992-05-12 | Regents Of The University Of Minnesota | Dynamic containment vessel |

| US5809910A (en) * | 1992-05-18 | 1998-09-22 | Svendssen; Allan | Reduction and admixture method in incineration unit for reduction of contaminants |

| US5281132A (en) * | 1992-08-17 | 1994-01-25 | Wymaster Noel A | Compact combustor |

| DE4416650A1 (de) * | 1994-05-11 | 1995-11-16 | Abb Management Ag | Verbrennungsverfahren für atmosphärische Feuerungsanlagen |

| US6850532B2 (en) | 2002-09-20 | 2005-02-01 | Cisco Technology, Inc. | Arrangement in a gateway for registering mobile routers of a mobile ad hoc network to respective home agents |

| US8449288B2 (en) * | 2003-03-19 | 2013-05-28 | Nalco Mobotec, Inc. | Urea-based mixing process for increasing combustion efficiency and reduction of nitrogen oxides (NOx) |

| US7670569B2 (en) * | 2003-06-13 | 2010-03-02 | Mobotec Usa, Inc. | Combustion furnace humidification devices, systems & methods |

| US7537743B2 (en) * | 2004-02-14 | 2009-05-26 | Mobotec Usa, Inc. | Method for in-furnace regulation of SO3 in catalytic NOx reducing systems |

| US8251694B2 (en) * | 2004-02-14 | 2012-08-28 | Nalco Mobotec, Inc. | Method for in-furnace reduction flue gas acidity |

| WO2005106326A1 (fr) * | 2004-04-30 | 2005-11-10 | Icopal A/S | Dispositif de chauffage au gaz et procede permettant de generer un ecoulement d'air chaud |

| EP1869307B1 (fr) * | 2005-04-12 | 2010-08-18 | Zilkha Biomass Energy LLC | Systeme integre d'energie de biomasse |

| US7410356B2 (en) | 2005-11-17 | 2008-08-12 | Mobotec Usa, Inc. | Circulating fluidized bed boiler having improved reactant utilization |

| BRPI0719436A2 (pt) * | 2006-09-29 | 2013-12-10 | Zilkha Biomass Energy Llc | Sistema de energia de biomassa integrado |

| US8011108B2 (en) * | 2008-04-04 | 2011-09-06 | Robert Upthegrove | Leveling device |

| US8069824B2 (en) * | 2008-06-19 | 2011-12-06 | Nalco Mobotec, Inc. | Circulating fluidized bed boiler and method of operation |

| US8161725B2 (en) * | 2008-09-22 | 2012-04-24 | Pratt & Whitney Rocketdyne, Inc. | Compact cyclone combustion torch igniter |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1910735A (en) * | 1927-02-14 | 1933-05-23 | Buttnerwerke A G | Burner for coal dust firing |

| US2517015A (en) * | 1945-05-16 | 1950-08-01 | Bendix Aviat Corp | Combustion chamber with shielded fuel nozzle |

| US3579983A (en) * | 1969-05-05 | 1971-05-25 | Snecma | Improvements in or relating to combustion chambers |

| DE2527618C2 (de) * | 1975-06-20 | 1985-09-26 | Fritz Dr.-Ing. 8026 Ebenhausen Schoppe | Verfahren und Vorrichtung zur Verbrennung von Kohlenstaub |

| US4043512A (en) * | 1976-01-23 | 1977-08-23 | Foster Wheeler Energy Corporation | Coal burner |

| NL7801395A (nl) * | 1977-02-23 | 1978-08-25 | Foerenade Fabriksverken | Werkwijze en inrichting voor het verbranden van vloeibare, gasvormige of poedervormige brandstoffen. |

| US4389185A (en) * | 1980-10-31 | 1983-06-21 | Alpkvist Jan A | Combustor for burning a volatile fuel with air |

| DE3237454C2 (de) * | 1981-03-17 | 1995-09-14 | Trw Inc | Verbrennungsverfahren und Verbrennungsofen zur Durchführung des Verfahrens |

-

1983

- 1983-12-13 EP EP83112521A patent/EP0111874B1/fr not_active Expired

- 1983-12-13 DE DE8383112521T patent/DE3371114D1/de not_active Expired

-

1984

- 1984-02-13 US US06/579,483 patent/US4507075A/en not_active Expired - Fee Related

- 1984-02-21 CA CA000447871A patent/CA1209408A/fr not_active Expired

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101865461A (zh) * | 2010-06-08 | 2010-10-20 | 上海市特种设备监督检验技术研究院 | 一种可调式中心给粉旋流煤粉浓淡燃烧器 |

| CN101865461B (zh) * | 2010-06-08 | 2014-06-04 | 上海市特种设备监督检验技术研究院 | 一种可调式中心给粉旋流煤粉浓淡燃烧器 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3371114D1 (en) | 1987-05-27 |

| EP0111874A1 (fr) | 1984-06-27 |

| CA1209408A (fr) | 1986-08-12 |

| US4507075A (en) | 1985-03-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0111874B1 (fr) | Installation pour brûler la poussière de charbon | |

| DE2731562C2 (de) | Brenner für flüssige und/oder gasförmige Brennstoffe | |

| DE2539993A1 (de) | Oelbrenner | |

| DE2417147A1 (de) | Gasturbinenbrennvorrichtung und verfahren zum betrieb der vorrichtung | |

| DE69009686T2 (de) | Verbrennungsverfahren. | |

| DE2157181B2 (de) | Brennkammer für eine Gasturbine | |

| DE3933050A1 (de) | Verfahren zum betreiben eines brenners fuer drehrohroefen und brenner hierfuer | |

| DE3939197C3 (de) | Verfahren und Vorrichtung zur Minderung der Stickoxid-Konzentration im Abgasstrom von Verbrennungsprozessen | |

| CH678100A5 (fr) | ||

| DE3346536C2 (de) | Vorbrenner für Zementrohmehl | |

| DE3928214C2 (fr) | ||

| DE4008692A1 (de) | Mischeinrichtung fuer oelgeblaesebrenner | |

| DE3737321C1 (de) | Einrichtung zur Verbrennung von Schweroel | |

| DE19542373B4 (de) | Brennerkopf für Gasbrenner | |

| AT397551B (de) | Verbrennungsofen | |

| DE2364053C2 (de) | Feuerungsanlage | |

| DE2843002C2 (de) | Heizölbrenner | |

| DE539423C (de) | Vorrichtung zum Mischen von Gasen oder Fluessigkeiten mittels auf den Waenden des Mischkanals versetzt zueinander angeordneter Prallflaechen, vornehmlich zur Herstellungeines Brennstoff-Luft-Gemisches | |

| DE2612302C2 (de) | Verfahren zur Verbrennung organische Bestandteile enthaltender Abwässer | |

| DE4006805A1 (de) | Brenner mit abgasrueckfuehrung, insbesondere geblaesebrenner | |

| DE2233627C3 (fr) | ||

| DE3523172C1 (de) | Vorrichtung zum Verbrennen von reaktionstraegem Kohlenstaub | |

| DE2424053A1 (de) | Zuend- und brennkammer fuer kohlestaubfeuerungsanlagen, wie kessel, oefen o. dgl. | |

| DE343818C (de) | Brennstaubfeuerung | |

| DE4119278C2 (de) | Brennereinrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB NL |

|

| 17P | Request for examination filed |

Effective date: 19841204 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR GB NL |

|

| REF | Corresponds to: |

Ref document number: 3371114 Country of ref document: DE Date of ref document: 19870527 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19901129 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19901203 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19901219 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19901221 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19901231 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19911213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19911231 |

|

| BERE | Be: lapsed |

Owner name: GEWERKSCHAFT SOPHIA-JACOBA STEINKOHLENBERGWERK Effective date: 19911231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19920701 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19920831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |