EP0078519B1 - Dispositif pour desserrer une formation en écailles de produits imprimés - Google Patents

Dispositif pour desserrer une formation en écailles de produits imprimés Download PDFInfo

- Publication number

- EP0078519B1 EP0078519B1 EP82110009A EP82110009A EP0078519B1 EP 0078519 B1 EP0078519 B1 EP 0078519B1 EP 82110009 A EP82110009 A EP 82110009A EP 82110009 A EP82110009 A EP 82110009A EP 0078519 B1 EP0078519 B1 EP 0078519B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- track

- elements

- endless conveyor

- printed products

- infeed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 230000015572 biosynthetic process Effects 0.000 title claims abstract description 29

- 230000001174 ascending effect Effects 0.000 claims 1

- 239000002184 metal Substances 0.000 claims 1

- 239000000047 product Substances 0.000 description 51

- 238000005755 formation reaction Methods 0.000 description 24

- 238000000034 method Methods 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 239000013067 intermediate product Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/003—Delivering or advancing articles from machines; Advancing articles to or into piles by grippers

- B65H29/005—Delivering or advancing articles from machines; Advancing articles to or into piles by grippers by chains or bands having mechanical grippers engaging the side edges of articles, e.g. newspaper conveyors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/66—Advancing articles in overlapping streams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H31/00—Pile receivers

- B65H31/30—Arrangements for removing completed piles

- B65H31/3081—Arrangements for removing completed piles by acting on edge of the pile for moving it along a surface, e.g. by pushing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2601/00—Problem to be solved or advantage achieved

- B65H2601/20—Avoiding or preventing undesirable effects

- B65H2601/27—Other problems

- B65H2601/273—Adhering of handled material to another handled material or to part of the handling machine

Definitions

- the invention relates to a device for loosening a scale formation of printed products perpendicular to their surface.

- the printed products leaving a printing press mostly fall in a scale formation, i.e. in such a formation in which the front region of a printed product lies directly on the rear region of the preceding printed product.

- a scale formation is also one of the most convenient formations for continuously transporting the resulting printed products by means of appropriate conveying devices.

- the device according to the invention is characterized in that a feed path and a path away from it are provided, and between these paths a coulter, guided and moved perpendicularly to the same, of path elements overlapping in their direction of movement is arranged, with funding are provided in order to transfer the printed products from the feed path via one of the path elements to the path leading away.

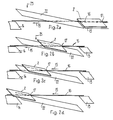

- the device 10 shown in FIG. 1 has a feed path 11 and a path 12 arranged at a distance therefrom. Both the feed path 11 and the path 12 each have a slide table 13 or 14, the two slide tables 13, 14 in this example are arranged approximately at the same height.

- an endless conveyor 16 which is driven in the direction of the arrow 15 and which is equipped with drivers 17 fastened to one another at regular intervals on a pulling element 18.

- Each of the drivers 17 engages on the trailing edge of a printed product Z, the printed products occurring in a scale formation S.

- the endless conveyor is driven by a motor 19, which is only indicated by dashed lines, and a drive wheel 20 which is driven by the motor and engages on the traction element 18.

- the feed path 11 thus comprises the sliding table 13 and a corresponding section of the endless conveyor 16. The same applies analogously to the path of travel 12.

- Each of the track elements 22 has approximately the same width as the sliding tables 13, 14 and is firmly anchored at its edge facing the viewer to two endless, chain-like traction elements 23, 24, the direction of movement of the traction elements 23, 24 and thus the share 21 in the area between the feed path 11 and the path 12 is indicated by arrows 25.

- the traction elements 23, 24 are driven by a motor 26 which is only indicated for the traction element 24 with a dashed line, the drive speed of which, as will be shown, is matched to that of the motor 19, which is to be indicated with the dashed line.

- each of the track elements 22 extends from the end of the sliding table 13 to the beginning of the sliding table 14, thus bridging the gap between them.

- the surface of each of the track elements 22 is arranged to rise with respect to the track of the endless conveyor 16 in the area of the coulter 21 in its conveying direction (arrow 15).

- the speed of movement of the coulter 21 is matched to the conveying speed of the endless conveyor 16 in such a way that each of the web elements 22 in each case the web of the endless conveyor 16 at the level of a driver 17 crosses.

- the scale formation S is loosened when passing through the coulter 21 perpendicular to the surface of the individual printed products Z in the sense that the leading area of each of the printed products Z when it hits one of the web elements 22 due to its inclined arrangement from preceding printed products is lifted without the distance between two successive printed products (given by the propensity of the drivers 17) being significantly changed in the conveying direction.

- the scale formation S is therefore also retained in the area of the sheet 21, and yet each individual print product is individually accessible in the area of this sheet.

- one or more other printed products can be placed on the viewer side, for example, on each of the printed products Z lying and advanced on one of the web elements 22 during the passage of the scale formation S through the sheet 21

- the sense of merging a main product with one or more intermediate products can be placed on the viewer side, for example, on each of the printed products Z lying and advanced on one of the web elements 22 during the passage of the scale formation S through the sheet 21.

- FIGS. 2a and 2c shows a printed product Z which has just reached the end of the sliding table 13 and is about to run onto one of the web elements 22, the printed product being pushed onto the corresponding web element by the corresponding driver 17.

- the driver 17 moves further in the direction of arrow 15, the web element 22 lowers in the direction of arrow 25, the speed of the endless conveyor 16 being matched to the sinking speed of the web element 22 in such a way that the edge of the web element shown facing away from the viewer 22 the path of the endless conveyor 16 between the feed path 13 and the path 14 always crosses at the level of the driver 17 shown.

- the driver 17 remains in engagement with the trailing edge of the printed product, which in turn is pushed further along the web element 22, as can be seen from FIGS. 2b and 2c.

- FIG. 3 again shows an embodiment variant in a very schematic representation.

- the guideway 12 with the sliding table 14 flanked by the endless conveyor 16 flanked practically the same as in the embodiment of FIG. 1 can also be seen.

- the group 21 of the track elements 22 which moves in the direction of the arrows 25 in a manner similar to that in FIG. 1 and which is individually fastened to the circumferential tension members 23, 24.

- the main difference from FIG. 1 is the feed path 11.

- This is formed by an endless conveyor belt 28, the conveying direction (arrow 29) of which is approximately at right angles to the course of the endless conveyor 16 and the conveying plane is practically parallel to the surface of the track elements 22.

- the end of the conveyor belt 28 is arranged directly adjacent to the passing edges of the web elements 22 facing the viewer.

- the scale formation S delivered on the feed path is loosened not only in the sense that the individual products Z are raised from one another, but also at an angle (without rotation of the individual ones) on the transition to the path elements 22 of the share 21 Products Z) is deflected, because the individual products Z only come into engagement with the drivers 17 when they have left the end of the conveyor belt 28 and have been pushed over the entire width of one of the track elements 22.

- the scale formation S remains in the area of the sheet 21.

- a guide or stop plate 30 can be provided on the side facing away from the viewer in order to align the scale formation which arises in the area of the coulter 21 and is transported here by the drivers 17 of the endless conveyor 16.

- part of the length of the web elements 22 is very much claimed by the feed path 11, so that the printed products are not individually accessible over the entire length of the web elements 22.

- the length of the track elements 22 is not limited in principle, but at most determined by practical considerations, this fact only appears to be a disadvantage.

- the embodiment of FIG. 3 has the following advantage, which results from the angular deflection of the delivered scale formation S.

- the printed products Z resulting from the printing press have been folded, their main fold z 'forms the leading edge, as shown in FIG. 3 on the conveyor belt 28. After the angular deflection, these main folds z 'of all printed products form the edge facing away from the viewer of the scale formation formed in the sheet 21 and transported further.

- each of the printed products (the so-called "flower") opposite the main fold z 'is thus accessible in the area of the sheet 21 from the viewer side, so that in FIG. 3, for example, inserts into the folded ones by means not shown Printed products can be pushed or placed on them.

- FIG. 4 is constructed essentially the same as that of FIG. 1. This is particularly suitable for loading with folded printed products Z which are in the scale formation S with the main fold z 'lying on the side.

- the main difference lies in a different "phase position" of the movements of the endless conveyor 16 and the coulter 21 which are synchronous with respect to one another.

- the speeds of the endless conveyor 16 on the one hand and the coulter 21 on the other hand are so coordinated that the side of a web element 22 facing the slide table 13 has not yet reached the height of this end edge at the moment, since the leading edge of a printed product reaches the end edge of the slide table 13, but is still about half the thickness of a printed product.

- each of the web elements 22 facing the sliding table 13 acts as an opening sword on the respectively arriving printed product in the sense that only the upper half of the printed product Z comes to rest on the relevant web element 22, while the lower half of the same printed product the preceding web element or on the upper half of the printed product fed along this web element.

- the printed products are opened as they pass through the sheet 21 and the opening gap which arises in the process presents itself, for example, to insert an insert into (and not onto) the printed product from the observer's side.

- FIG. 4 can also be operated with a scale formation without the different "phase position" of the movements of the endless conveyor 16 and the coulter 21 described, in which folded printed products with the main fold lying on the side are z '. Then, however, the entire printed product comes to rest on one web element 22 in each case.

- the feed and path 11 and 12 do not need to be at the same height.

- the path 12 can be arranged lower than the feed path 11.

- the path of the endless conveyor 16 in the area of the coulter 21 has to overcome the height difference between the feed path and the path 11 or 12. This can be done, for example, by appropriately deflecting the traction element 18 or by dividing the endless conveyor into a feed section, into a "coulter” section and into a removal section.

- the surfaces of the track elements 22 can also be essentially parallel to the sliding tables 13, 14. Even then, the surface of the track elements on the track of the conveyor 16, which is now sinking in the area of the coulter 21, remains increasing in its direction of movement.

- the track elements can also be arranged on circumferentially driven, circular tires and extend radially inwards or outwards therefrom. If, in such an embodiment, an endless conveyor runs along the now radial array of web elements, its web is to be laid on the side of the web elements facing away from the fastening point of the web elements on the circular tires. In addition, in this case the surfaces of the web elements are expediently not to be formed flat but twisted.

- each of the track elements itself to be effective in terms of conveying, for example to design them as a conveyor belt or to provide them with one.

- This conveyor belt would then only be expedient if the path element is located in the area between the feed and exit path.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Feeding Of Articles By Means Other Than Belts Or Rollers (AREA)

- Separation, Sorting, Adjustment, Or Bending Of Sheets To Be Conveyed (AREA)

- Discharge By Other Means (AREA)

- Collation Of Sheets And Webs (AREA)

- Photographic Processing Devices Using Wet Methods (AREA)

- Non-Metallic Protective Coatings For Printed Circuits (AREA)

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82110009T ATE18184T1 (de) | 1981-11-04 | 1982-10-29 | Einrichtung zum auflockern einer schuppenformation von druckprodukten. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH7052/81A CH652698A5 (de) | 1981-11-04 | 1981-11-04 | Einrichtung zum auflockern einer schuppenformation von druckprodukten. |

| CH7052/81 | 1981-11-04 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0078519A1 EP0078519A1 (fr) | 1983-05-11 |

| EP0078519B1 true EP0078519B1 (fr) | 1986-02-26 |

Family

ID=4319190

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82110009A Expired EP0078519B1 (fr) | 1981-11-04 | 1982-10-29 | Dispositif pour desserrer une formation en écailles de produits imprimés |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4494646A (fr) |

| EP (1) | EP0078519B1 (fr) |

| JP (1) | JPS5882938A (fr) |

| AT (1) | ATE18184T1 (fr) |

| CA (1) | CA1186705A (fr) |

| CH (1) | CH652698A5 (fr) |

| DE (1) | DE3269454D1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0771754B1 (fr) * | 1995-11-03 | 2000-01-26 | Ferag AG | Dispositif pour assembler des produits plats |

| US6511062B1 (en) | 2000-02-07 | 2003-01-28 | Lockheed Martin Corporation | Presentation control for flat article singulation mechanism and sensors suitable for use therewith |

| US6662929B1 (en) | 2000-11-17 | 2003-12-16 | Lockhead Martin Corporation | Parcel singulation software control logic |

| US6711462B2 (en) | 2002-03-05 | 2004-03-23 | Lockheed Martin Corporation | System and method for collating items |

| US9193525B2 (en) * | 2014-03-12 | 2015-11-24 | Asm Technology Singapore Pte Ltd | Apparatus for handling electronic components |

| CH711369A1 (de) * | 2015-07-31 | 2017-01-31 | Rotzinger Ag | Entladevorrichtung. |

| EP3395728A1 (fr) * | 2017-04-24 | 2018-10-31 | Siemens Aktiengesellschaft | Réglage de l'écart entre des marchandises au détail à acheminer |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH584153A5 (fr) * | 1973-10-10 | 1977-01-31 | Ferag Ag | |

| CA1009175A (en) * | 1974-04-19 | 1977-04-26 | Arthur G. Alsop | Stacking mechanism and method |

| DE2508194A1 (de) * | 1975-02-26 | 1976-09-09 | Guenther Dr Ing Schick | Vorrichtung zum oeffnen schuppenfoermig transportierter gefalzter lagen, vorzugsweise zeitungen oder zeitschriften |

| DE2553612C3 (de) * | 1975-11-28 | 1982-02-18 | Agfa-Gevaert Ag, 5090 Leverkusen | Verfahren und Vorrichtung zum Eintaschen von Filmabschnitten |

| US4145037A (en) * | 1977-04-25 | 1979-03-20 | Pitney Bowes, Inc. | Vertical collator-sorter |

-

1981

- 1981-11-04 CH CH7052/81A patent/CH652698A5/de not_active IP Right Cessation

-

1982

- 1982-10-19 US US06/435,326 patent/US4494646A/en not_active Expired - Fee Related

- 1982-10-22 CA CA000414026A patent/CA1186705A/fr not_active Expired

- 1982-10-29 AT AT82110009T patent/ATE18184T1/de not_active IP Right Cessation

- 1982-10-29 DE DE8282110009T patent/DE3269454D1/de not_active Expired

- 1982-10-29 EP EP82110009A patent/EP0078519B1/fr not_active Expired

- 1982-11-02 JP JP57191976A patent/JPS5882938A/ja active Granted

Also Published As

| Publication number | Publication date |

|---|---|

| US4494646A (en) | 1985-01-22 |

| CA1186705A (fr) | 1985-05-07 |

| JPH031226B2 (fr) | 1991-01-10 |

| EP0078519A1 (fr) | 1983-05-11 |

| ATE18184T1 (de) | 1986-03-15 |

| DE3269454D1 (en) | 1986-04-03 |

| CH652698A5 (de) | 1985-11-29 |

| JPS5882938A (ja) | 1983-05-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1686084B1 (fr) | Dispositif pour assembler des feuilles imprimées le long d'une voie de transport d'un transporteur circulant | |

| DE3134266C2 (de) | Vorrichtung zum Ändern der Bewegungsrichtung von in Richtung ihrer langen Kanten einlaufenden Briefen und ähnlichen rechteckigen Sendungen | |

| EP0075121A1 (fr) | Dispositif pour étirer des produits plats délivrés en formation imbriquée, en particulier des produits imprimés | |

| EP2277812B1 (fr) | Procédé d'alignement latéral de produits ayant une surface de base plane, notamment de produits d'impression, et dispositif de transport destiné à l'exécution du procédé | |

| DE4108397A1 (de) | Vorrichtung zur bildung einer folge von sich unterlappenden gegenstaenden | |

| EP1753681A1 (fr) | Dispositif pour inverser le sens de marchandises plates | |

| EP0078519B1 (fr) | Dispositif pour desserrer une formation en écailles de produits imprimés | |

| CH665410A5 (de) | Vorrichtung zum beschicken einer verarbeitungseinrichtung fuer biegsame, flaechige erzeugnisse, insbesondere druckprodukte. | |

| EP1456106A1 (fr) | Procede et dispositif pour former des groupes d'objets plats | |

| DE3009927C2 (de) | Einrichtung zum Abziehen und insbesondere Vereinigen von biegsamen Flächengebilden, insbesondere Bogen oder Druckprodukten aus mindestens zwei Stapeln | |

| EP1966070A1 (fr) | Procede et dispositif d'etablissement d'un ecoulement reuni de produits d'impression a partir de deux ecoulements de produits d'impression | |

| EP0346579A1 (fr) | Dispositif pour assembler, collationner et insérer des produits imprimés | |

| DE1237504B (de) | Einrichtung zum Herstellen eines gleichmaessigen Foerderflusses | |

| EP1726552A1 (fr) | Dispositif d'assemblage de produits imprimés | |

| EP0893385B1 (fr) | Dispositif pour traiter des produits imprimés | |

| DE2832660B2 (de) | Vorrichtung zum gruppenweisen Abteilen von geschuppt übereinanderliegend geförderten Werkstücken | |

| DE1937082C3 (de) | Verfahren und Vorrichtung zum Untereinander-Staffeln von Briefumschlägen, Beuteln oder ähnlichen Werkstücken | |

| DE2109468C2 (de) | Faltmaschine zum Umlegen der Laschen von Faltschachteln | |

| EP0499691A1 (fr) | Procédé pour traiter des produits imprimés alimentés de façon continue en une formation imbriquée ainsi que dispositif pour la mise en oeuvre dudit procédé | |

| EP1075445B1 (fr) | Procede et dispositif pour poursuivre l'acheminement d'objets plats arrivant dans un courant lamellaire | |

| EP0091582A1 (fr) | Dispositif pour étirer des piles de produits pliés mutuellement déplacées transversalement par rapport à la direction de transport | |

| DD245417A1 (de) | Bogenausleger in druckmaschinen | |

| DE4007333A1 (de) | Vorrichtung zum bilden von luecken zwischen bahnabschnitten einer zick-zack-foermig gefalteten bahn | |

| CH646114A5 (de) | Vorrichtung zum vereinzeln eines stapels gefalteter oder gebundener, mehrblaettriger druckprodukte. | |

| DE1549981C3 (fr) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19830429 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE DE FR GB IT NL SE |

|

| REF | Corresponds to: |

Ref document number: 18184 Country of ref document: AT Date of ref document: 19860315 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3269454 Country of ref document: DE Date of ref document: 19860403 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19920921 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19920922 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19920924 Year of fee payment: 11 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19921031 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930913 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930915 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19931029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19931031 |

|

| BERE | Be: lapsed |

Owner name: FERAG A.G. Effective date: 19931031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940501 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19941029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941030 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 82110009.6 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19941029 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82110009.6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960920 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980701 |