EP0028792B1 - Multi-deck screening machine - Google Patents

Multi-deck screening machine Download PDFInfo

- Publication number

- EP0028792B1 EP0028792B1 EP80106751A EP80106751A EP0028792B1 EP 0028792 B1 EP0028792 B1 EP 0028792B1 EP 80106751 A EP80106751 A EP 80106751A EP 80106751 A EP80106751 A EP 80106751A EP 0028792 B1 EP0028792 B1 EP 0028792B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- deck

- return

- stack

- screening machine

- screen

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/46—Constructional details of screens in general; Cleaning or heating of screens

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/28—Moving screens not otherwise provided for, e.g. swinging, reciprocating, rocking, tilting or wobbling screens

- B07B1/34—Moving screens not otherwise provided for, e.g. swinging, reciprocating, rocking, tilting or wobbling screens jigging or moving to-and-fro perpendicularly or approximately perpendiculary to the plane of the screen

Definitions

- the invention relates to a multi-deck sieve machine designed as a throwing sieve of the type specified in the preamble of claim 1 for classifying dry, free-flowing bulk goods of small grain size, such as grinding and steel agents, in a large number of grain size classes in one operation.

- screening machines are basically divided into throwing and face screening machines.

- the sieving is carried out by vibrating the sieve in the horizontal and especially in the vertical direction, so that the material to be sieved carries out a throwing movement with a forward component.

- plane screening machines the screening takes place without a throwing movement of the material to be screened by a type of shaking movement which takes place essentially parallel to the screen surface.

- multi-deck screening machines Another shortcoming of such multi-deck screening machines is that with them only a small number of e.g. six grain size classes can be classified in one operation. If larger numbers of e.g. 10 to 25 grain size classes have to be classified, as is necessary for the production of abrasives or abrasives, several such multi-deck screening machines have to be set up and operated in parallel and in series. In addition, transfer devices for the screenings from one machine to another and mergers for the screenings are necessary.

- multi-deck screening machines e.g. known from the company publication "Regula-Siebmaschinen" from Engelsmann AG, in which several screening, blind and return decks are clamped together in a frame to form a stack which is excited as a whole.

- the inclination of the sieve stack can be adjusted depending on the required dwell time of the material to be sieved and its flowability.

- the drive is preferably carried out by means of an eccentric acting in the horizontal direction.

- this plan sieving machine allows the material to be returned, this type of sieving machine can also only be used to classify relatively small numbers of grain size classes in one operation.

- the invention has for its object to provide a multi-deck sieve machine designed as a throwing sieve, which enables the material to be returned in a direction opposite to the direction of transport and which also works with a large degree of selectivity for a large number of grain size classes.

- the return organs arranged according to the invention form a secondary vibrating system which is only excited by the vibration exciter of the screening machine and which, compared to the primary vibrating system of the vibrating frame and the screen deck, carries out natural vibrations which bring about the return of the material to be screened in the return organs.

- the return elements are designed as channels which are inclined at an angle of 0 to 15 ° to the horizontal and which open out into channels located vertically in the sieve stack.

- a plurality of return elements of a return deck can be coupled to one another, which enables the screen passages to be brought together from two upper screen decks.

- the multi-deck screening machine according to the invention is preferably suitable for screening tasks in which the bulk material can be classified into up to 25 grain size classes with a relatively high selectivity in one operation, such as e.g. is required for abrasives and abrasives. Due to the type of vibration excitation in the sieve stack and the single or multiple return of the sieve passage from several sieve decks, a high degree of selectivity can be achieved even with fine-grained sieve material.

- the throwing angle can be set from 45 to 85 ° to the horizontal or the point of action of the vibration exciter can be changed in order to create optimal sieving ratios for different screenings.

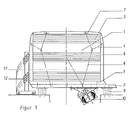

- the multi-deck screen machine shown comprises a screen stack 1, which is arranged on a swing frame 2.

- Sieve and blind decks 3 and return decks 4 are arranged one above the other in the sieve stack 1 and braced together by a base frame 5, a side frame 6, a cover frame 7 and a tensioning device 8.

- a vibration exciter 10 is slidably and pivotably arranged.

- its line of action 11 can be set such that the throw angle to the horizontal lies in the range from 45 to 85 °.

- the screened-out granules are discharged via discharges 12.

- channels 13 are provided in the return deck 4, which are inclined at an angle of 5 ° to the horizontal against the transport direction of the screened material. These channels 13 are suspended in a vertically free-swinging manner on springs 14 and are articulated at their ends to a frame 15 of the return deck 4 at 16. A plurality of channels 13 are coupled to one another at their ends 17 in order to bring together material flows of the same grain class.

- the screen stack 1 rigidly arranged on the vibrating frame 2 is excited as a whole by the vibration exciter 10.

- the vibrations can act on the screen stack 1 in accordance with the screening task to be solved.

- the return of the material to be screened against the transport direction takes place through the vertical oscillating movements of the channels 13, which are caused by the excitation of the screen stack 1.

Landscapes

- Combined Means For Separation Of Solids (AREA)

- Bakery Products And Manufacturing Methods Therefor (AREA)

- Seasonings (AREA)

- Measuring Or Testing Involving Enzymes Or Micro-Organisms (AREA)

Abstract

Description

Die Erfindung betrifft eine als Wurfsieb ausgebildete Mehrdecksiebmaschine der im Oberbegriff des Patentanspruchs 1 angegebenen Gattung zur Klassierung trockener rieselfähiger Schüttgüter kleiner Korngrösse, wie Schleif- und Stahlmittel in eine Vielzahl von Korngrössenklassen in einem Arbeitsgang.The invention relates to a multi-deck sieve machine designed as a throwing sieve of the type specified in the preamble of

Nach der Funktionsweise werden Siebmaschinen grundsätzlich in Wurf- und Plansiebmaschinen unterteilt. Bei Wurfsiebmaschinen erfolgt die Siebung durch Schwingungen des Siebes in horizontaler und besonders in vertikaler Richtung, so dass das Siebgut eine Wurfbewegung mit einer Vorwärts-Komponente ausführt. Bei Plansiebmaschinen erfolgt die Siebung ohne Wurfbewegung des Siebgutes durch eine Art von Rüttelbewegungen, die sich im wesentlichen parallel zur Siebfläche vollziehen.According to the mode of operation, screening machines are basically divided into throwing and face screening machines. In the case of throwing sieve machines, the sieving is carried out by vibrating the sieve in the horizontal and especially in the vertical direction, so that the material to be sieved carries out a throwing movement with a forward component. In the case of plane screening machines, the screening takes place without a throwing movement of the material to be screened by a type of shaking movement which takes place essentially parallel to the screen surface.

Aus dem Prospekt «Hochleistungs-Schallsiebmaschinen» Bauart WA der Firma Rhewum ist eine als Wurfsieb ausgebildete Mehrdeckmaschine der angegebenen Gattung bekannt, bei welcher mehrere auf einem Grundrahmen übereinander gestapelte Siebdecks um Neigungswinkel von 30 bis 40° zur Waagerechten geneigt angeordnet sind. Der Antrieb der Siebmaschine erfolgt mit elektromagnetischen Schwingköpfen, die am Siebgehäuse angreifen. Zur Erregung des Siebgewebes sind Wellen unter dem Siebgewebe quer zur Förderrichtung angeordnet, die Schlagleisten tragen. Auf diesen Schlagleisten befindet sich eine Kunststoffummantelung, um das Siebgewebe zu schonen. Über die Stössel, deren Stösselköpfe, Winkelhebel und Schlagleisten werden die Schwingungen auf das Siebgewebe übertragen.From the brochure “High-performance sonic screening machines” type WA from the Rhewum company, a multi-deck machine of the specified type, known as a throwing screen, is known, in which several screen decks stacked on top of one another on a base frame are inclined at an angle of 30 to 40 ° to the horizontal. The screening machine is driven by electromagnetic oscillating heads that engage the screen housing. To excite the sieve fabric, waves are arranged under the sieve fabric transversely to the conveying direction, which carry blow bars. There is a plastic coating on these blow bars to protect the screen mesh. The vibrations are transferred to the screen fabric via the tappets, their tappet heads, angle levers and blow bars.

Bei einer aus dem Prospekt «Stössel-Schwingsiebmaschinen» des VEB Chemieanlagenbau Stassfurt, DDR bekannten anderen als Wurfsieb arbeitenden Mehrdecksiebmaschine erfolgt der Antrieb mittels elektromagnetischer Schwingungserreger, wobei die Schwingungen über Stössel direkt auf das Siebgewebe übertragen werden.In a multi-deck screening machine known from the brochure “Stössel vibrating screening machines” from VEB Chemieanlagenbau Stassfurt, GDR, which is known as a throwing screen, the drive is carried out by means of electromagnetic vibration exciters, whereby the vibrations are transmitted directly to the screen fabric via tappets.

Bei diesen besonders leistungsfähigen Mehrdecksiebmaschinen ist eine Rückführung des Siebgutes vom Austragsende eines Teils der Siebdecks zum Eintragsende von unteren Siebdecks nicht möglich, so dass sie zum Klassieren eines Korngemischs in eine Vielzahl von Korngrössenklassen in einem Arbeitsgang nicht geeignet sind. Die Siebböden schwingen mit horizontaler und mit ausgeprägter vertikaler Komponente, so dass eine Rückführung des Siebgutes entgegen der Wurfrichtung des Siebgutes auf den Siebflächen erfolgen müsste. Auch durch eine übergrosse Neigung der Rückführorgane vom Austragszum Eintragsende hin könnte aufgrund der Wurfbewegungen des Siebgutes eine Rückführung nicht sichergestellt werden, da sich das Siebgut trotz der starken Neigung im Rückführdeck stauen würde. Darüber hinaus hätte eine derartige Siebmaschine eine praktisch nicht akzeptable Bauhöhe. Ein weiterer Mangel derartiger Mehrdecksiebmaschinen besteht darin, dass mit diesen nur eine geringe Anzahl von z.B. sechs Korngrössenklassen in einem Arbeitsgang klassiert werden können. Wenn grössere Anzahlen von z.B. 10 bis 25 Korngrössenklassen klassiert werden müssen, wie dies zur Herstellung von Schleif- oder Strahlmitteln notwendig ist, müssen mehrere derartige Mehrdecksiebmaschinen in Parallel- und Reihenschaltung aufgestellt und betrieben werden. Zusätzlich sind Übergabeeinrichtungen für das Siebgut von einer Maschine zur anderen und Zusammenführungen für das Siebgut notwendig.With these particularly powerful multi-deck screening machines, it is not possible to return the material to be screened from the discharge end of part of the screen deck to the entry end of lower screen decks, so that they are not suitable for classifying a grain mixture into a large number of grain size classes in one operation. The sieve trays vibrate with horizontal and with pronounced vertical components, so that the material to be sieved should be returned on the sieve surfaces against the direction of throwing of the material to be sieved. Due to the throwing movements of the material to be screened, a return could not be ensured even if the return elements were inclined too large from the discharge end to the entry end, since the material to be screened would accumulate in the return deck despite the strong inclination. In addition, such a screening machine would have a practically unacceptable height. Another shortcoming of such multi-deck screening machines is that with them only a small number of e.g. six grain size classes can be classified in one operation. If larger numbers of e.g. 10 to 25 grain size classes have to be classified, as is necessary for the production of abrasives or abrasives, several such multi-deck screening machines have to be set up and operated in parallel and in series. In addition, transfer devices for the screenings from one machine to another and mergers for the screenings are necessary.

Ferner sind auch als Plansieb arbeitende Mehrdecksiebmaschinen, z.B. aus der Firmenschrift «Regula-Siebmaschinen» der Firma Engelsmann AG bekannt, bei denen mehrere Sieb-, Blind- und Rückführdecks in einem Rahmen miteinander zu einem Stapel verspannt sind, welcher als Ganzes erregt wird. Die Neigung des Siebstapels kann je nach der erforderlichen Verweilzeit des Siebgutes und seiner Fliessfähigkeit eingestellt werden. Der Antrieb erfolgt bevorzugt mittels eines in horizontaler Richtung wirkenden Exzenters. Obwohl diese Plansiebmaschine eine Rückführung des Siebgutes gestattet, können mit diesem Siebmaschinentyp ebenfalls nur relativ geringe Anzahlen an Korngrössenklassen in einem Arbeitsgang klassiert werden. Mit zunehmender Feinheit des Siebgutes werden die zusätzlich zur Schwerkraft wirksamen Haftkräfte grösser als die relativ geringen Schwerkräfte, wodurch die Trennschärfe der Siebmaschine im Feinkornbereich beeinträchtigt wird. Bedingt durch die typspezifische Siebbewegung können sich ausserdem auf den Siebböden grossflächige Verstopfungen ausbilden, die die Siebleistung verringern.Furthermore, multi-deck screening machines, e.g. known from the company publication "Regula-Siebmaschinen" from Engelsmann AG, in which several screening, blind and return decks are clamped together in a frame to form a stack which is excited as a whole. The inclination of the sieve stack can be adjusted depending on the required dwell time of the material to be sieved and its flowability. The drive is preferably carried out by means of an eccentric acting in the horizontal direction. Although this plan sieving machine allows the material to be returned, this type of sieving machine can also only be used to classify relatively small numbers of grain size classes in one operation. With increasing fineness of the screenings, the adhesive forces effective in addition to the force of gravity become greater than the relatively low gravitational forces, whereby the selectivity of the screening machine in the fine grain area is impaired. Due to the type-specific sieve movement, large blockages can also form on the sieve bottoms, which reduce the sieving capacity.

Schliesslich ist aus der CH-PS 413 564 ein Siebtrichter mit Vibrationsantrieb für die Getreidereinigung bekannt, bei dem unter jedem Siebboden je eine als starre Rutsche ausgebildete Rückleitfläche vorgesehen ist, die zumindest an ihrer Stirnseite fest mit dem Siebgehäuse verbunden ist.Finally, from CH-PS 413 564 a sieve funnel with vibration drive for grain cleaning is known, in which a return guide surface designed as a rigid slide is provided under each sieve plate, which is firmly connected to the sieve housing at least on its end face.

Der Erfindung liegt die Aufgabe zugrunde, eine als Wurfsieb ausgebildete Mehrdecksiebmaschine zu schaffen, die eine Rückführung des Siebgutes entgegen der Transportrichtung ermöglicht und die auch bei einer Vielzahl von Korngrössenklassen mit grosser Trennschärfe arbeitet.The invention has for its object to provide a multi-deck sieve machine designed as a throwing sieve, which enables the material to be returned in a direction opposite to the direction of transport and which also works with a large degree of selectivity for a large number of grain size classes.

Diese Aufgabe wird erfindungsgemäss durch die kennzeichnenden Merkmale des Patentanspruchs 1 gelöst. Die erfindungsgemäss angeordneten Rückführorgane bilden ein sekundäres Schwingsystem, das nur von dem Schwingungserreger der Siebmaschine erregt wird und gegenüber dem primären Schwingungssystem des Schwingrahmens und der Siebdecks Eigenschwingungen ausführt, welche die Rückführung des Siebgutes in den Rückführorganen bewirken.According to the invention, this object is achieved by the characterizing features of

Gemäss einer zweckmässigen Ausgestaltung der Erfindung sind die Rückführorgane als in einem Winkel von 0 bis 15° zur Waagerechten geneigt angeordnete Rinnen ausgebildet, die in senkrecht im Siebstapel befindliche Kanäle ausmünden.According to an expedient embodiment of the invention, the return elements are designed as channels which are inclined at an angle of 0 to 15 ° to the horizontal and which open out into channels located vertically in the sieve stack.

Zweckmässig können mehrere Rückführorgane eines Rückführdecks miteinander gekoppelt sein, was die Zusammenführung der Siebdurchgänge aus zwei oberen Siebdecks ermöglicht.Advantageously, a plurality of return elements of a return deck can be coupled to one another, which enables the screen passages to be brought together from two upper screen decks.

Die erfindungsgemässe Mehrdecksiebmaschine eignet sich vorzugsweise für Siebaufgaben, bei denen das Schüttgut in einem Arbeitsgang in bis zu 25 Korngrössenklassen mit relativ hoher Trennschärfe zu klassieren ist, wie dies z.B. bei Schleif- und Strahlmitteln gefordert wird. Durch die Art der Schwingungserregung im Siebstapel und durch die ein- oder mehrmalige Rückführung des Siebdurchganges von mehreren Siebdecks kann selbst bei feinstkörnigem Siebgut eine hohe Trennschärfe erreicht werden.The multi-deck screening machine according to the invention is preferably suitable for screening tasks in which the bulk material can be classified into up to 25 grain size classes with a relatively high selectivity in one operation, such as e.g. is required for abrasives and abrasives. Due to the type of vibration excitation in the sieve stack and the single or multiple return of the sieve passage from several sieve decks, a high degree of selectivity can be achieved even with fine-grained sieve material.

Durch Verschieben oder Verschwenken des Schwingungserregers am Schwingrahmen kann der Wurfwinkel von 45 bis 85° zur Waagerechten eingestellt oder der Angriffspunkt des Schwingungserregers verändert werden, um auch für unterschiedliche Siebgüter jeweils optimale Siebverhältnisse zu schaffen.By moving or swiveling the vibration exciter on the vibrating frame, the throwing angle can be set from 45 to 85 ° to the horizontal or the point of action of the vibration exciter can be changed in order to create optimal sieving ratios for different screenings.

Im folgenden wird ein Ausführungsbeispiel der Erfindung anhand der Zeichnung im einzelnen beschrieben. Es zeigen:

- Fig. 1 eine Mehrdecksiebmaschine in schematischer Seitenansicht;

- Fig. 2 einen Vertikalschnitt 11-11 in Fig. durch ein Rückführdeck;

- Fig. das Rückführdeck nach Fig. 1 in Draufsicht.

- Figure 1 is a multi-deck screening machine in a schematic side view.

- Fig. 2 is a vertical section 11-11 in Fig. Through a return deck;

- Fig. The return deck of FIG. 1 in plan view.

Die dargestellte Mehrdecksiebmaschine umfasst einen Siebstapel 1, der auf einem Schwingrahmen 2 angeordnet ist. Im Siebstapel 1 sind Sieb- und Blinddecks 3 sowie Rückführdecks 4 übereinander angeordnet und durch einen Grundrahmen 5, einen Seitenrahmen 6, einen Deckrahmen 7 sowie eine Spanneinrichtung 8 miteinander verspannt. An dem auf Federn 9 gelagerten Schwingrahmen 2 ist ein Schwingungserreger 10 verschiebbar und schwenkbar angeordnet. Dadurch kann seine Wirkungslinie 11 so eingestellt werden, dass der Wurfwinkel zur Waagerechten im Bereich von 45 bis 85° liegt. Die ausgesiebten Körnungen werden über Austräge 12 abgeführt.The multi-deck screen machine shown comprises a

Wie aus Fig. 2, 3 ersichtlich, sind im Rückführdeck 4 mehrere Rinnen 13 vorgesehen, die entgegen der Transportrichtung des Siebgutes unter einem Winkel von 5° zur Waagerechten geneigt sind. Diese Rinnen 13 sind an Federn 14 vertikal freischwingend aufgehängt und an ihren Enden mit einem Rahmen 15 des Rückführdecks 4 bei 16 gelenkig verbunden. Zum Zusammenführen von Siebgutströmen gleicher Kornklasse sind mehrere Rinnen 13 an ihren Enden 17 miteinander gekoppelt.2, 3,

Der starr auf dem Schwingrahmen 2 angeordnete Siebstapel 1 wird vom Schwingungserreger 10 als Ganzes erregt. Durch Verändern der Angriffsstelle des Schwingungserregers 10 am Schwingrahmen und durch Verstellen des Wurfwinkels a können die Schwingungen entsprechend der zu lösenden Siebaufgabe auf den Siebstapel 1 einwirken. Die Rückführung des Siebgutes entgegen der Transportrichtung erfolgt durch die vertikalen Schwingbewegungen der Rinnen 13, die durch die Erregung des Siebstapels 1 hervorgerufen werden.The

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT80106751T ATE19361T1 (en) | 1979-11-08 | 1980-11-03 | MULTI DECK SCREEN. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DD79216758A DD151882A1 (en) | 1979-11-08 | 1979-11-08 | multi deck |

| DD216758 | 1979-11-08 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0028792A2 EP0028792A2 (en) | 1981-05-20 |

| EP0028792A3 EP0028792A3 (en) | 1983-03-23 |

| EP0028792B1 true EP0028792B1 (en) | 1986-04-23 |

Family

ID=5520964

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP80106751A Expired EP0028792B1 (en) | 1979-11-08 | 1980-11-03 | Multi-deck screening machine |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0028792B1 (en) |

| AT (1) | ATE19361T1 (en) |

| DD (1) | DD151882A1 (en) |

| DE (1) | DE3071571D1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111014022A (en) * | 2019-12-13 | 2020-04-17 | 长沙而道新能源科技有限公司 | Tea processing equipment |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3524895C1 (en) * | 1985-07-12 | 1986-12-18 | Hein, Lehmann AG, 4000 Düsseldorf | Screening machine |

| DD256227A3 (en) * | 1985-09-23 | 1988-05-04 | Akad Wissenschaften Ddr | type of screen |

| EP2745941A1 (en) * | 2012-12-21 | 2014-06-25 | Sandvik Mining and Construction Oy | Vibrating equipment and method of processing material |

| CN105107718A (en) * | 2015-08-24 | 2015-12-02 | 海安县万力振动机械有限公司 | Closed vibrating screen |

| CN105621005A (en) * | 2016-03-07 | 2016-06-01 | 四川江油新川矿山机械有限公司 | Screening and vibrating feeding machine |

| CN107716283A (en) * | 2017-10-27 | 2018-02-23 | 安徽星辉工业科技有限公司 | A kind of steaming utensil type vibration screening mechanism device for conveyer |

| CN110586465B (en) * | 2019-10-11 | 2024-04-02 | 安徽康博特保健食品有限公司 | Screening device for manufacturing health-care product tablets |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR646966A (en) * | 1928-01-11 | 1928-11-19 | Anciens Etablissements Lhuilli | Improvements to shaker sieves |

| FR765692A (en) * | 1932-12-15 | 1934-06-14 | Method and devices for adjusting the movements of vibrating apparatus | |

| US2238454A (en) * | 1939-04-03 | 1941-04-15 | Oliver W Steele | Method for sizing corn |

| GB611289A (en) * | 1946-04-26 | 1948-10-27 | Simon Ltd Henry | Improvements in plansifters |

| CH298059A (en) * | 1950-09-15 | 1954-04-30 | Limited Henry Simon Holdings | Crusher for seeds. |

| CH413564A (en) * | 1964-04-02 | 1966-05-15 | Muehlenbau Dresden Veb | Sieve sifter with vibration drive for grain cleaning |

| FR2314776A1 (en) * | 1975-06-16 | 1977-01-14 | Babbitless Sa | DIRECTED ACTION VIBRATING DEVICE |

-

1979

- 1979-11-08 DD DD79216758A patent/DD151882A1/en not_active IP Right Cessation

-

1980

- 1980-11-03 AT AT80106751T patent/ATE19361T1/en not_active IP Right Cessation

- 1980-11-03 DE DE8080106751T patent/DE3071571D1/en not_active Expired

- 1980-11-03 EP EP80106751A patent/EP0028792B1/en not_active Expired

Non-Patent Citations (3)

| Title |

|---|

| Firmenschrift "Regula-Siebmaschinen" der Firma Englesmann AG * |

| Prospekt "Hochleistungs-Schallschieb-maschine" Bauart WA der Firma Rhewum * |

| Prospekt "Stössel-Schhwungsiebmaschinen" des VEB Chemieanlagenbau Stassgut * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111014022A (en) * | 2019-12-13 | 2020-04-17 | 长沙而道新能源科技有限公司 | Tea processing equipment |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3071571D1 (en) | 1986-05-28 |

| EP0028792A2 (en) | 1981-05-20 |

| DD151882A1 (en) | 1981-11-11 |

| EP0028792A3 (en) | 1983-03-23 |

| ATE19361T1 (en) | 1986-05-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0155537B1 (en) | Device for cleaning semolina | |

| DE102006041989B4 (en) | Sieving machine especially for difficult to separate mixtures, such as heavy oil-sand mixtures | |

| DE10305589B4 (en) | sieve | |

| AT6073U1 (en) | multi deck | |

| DE2855436A1 (en) | VIBRATION DEVICE | |

| DE3826996A1 (en) | VIBRATION SCREENER | |

| DE3109319C2 (en) | Multi-sieve apparatus | |

| EP0028792B1 (en) | Multi-deck screening machine | |

| DE3932645C2 (en) | Material classifier | |

| EP0139783A1 (en) | Device for processing scrap, waste or the like | |

| DE3741966C2 (en) | ||

| EP0316461B1 (en) | Vibratory screen | |

| DE102020125280B3 (en) | Vibrating screening machine | |

| DE3221344C1 (en) | Screening machine | |

| DE1813224A1 (en) | Method and device for sieving granular material that can be poured out | |

| DE2923662C2 (en) | Vibrating screen, especially circular vibrating screen | |

| DE19517850C2 (en) | Screening machine for pre-sorting material mixtures | |

| DE2923474C2 (en) | Sieving machine | |

| DE3132140C1 (en) | Screening machine | |

| DE3018741C2 (en) | ||

| AT386769B (en) | Air-jet multi-deck sieving machine | |

| DD151882B1 (en) | multi deck | |

| DE2922814C3 (en) | Scattering device for producing a chip fleece that can be pressed into chipboard. | |

| DE577130C (en) | Shuette sieve suspended on wire ropes, moved by unbalanced swing weight | |

| AT393466B (en) | VIBRATION SEPARATOR |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB LI SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH GB LI SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE GB LI SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB LI SE |

|

| 17P | Request for examination filed |

Effective date: 19830831 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE GB LI SE |

|

| REF | Corresponds to: |

Ref document number: 19361 Country of ref document: AT Date of ref document: 19860515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3071571 Country of ref document: DE Date of ref document: 19860528 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19921016 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19921021 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19921022 Year of fee payment: 13 Ref country code: CH Payment date: 19921022 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19921027 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930126 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19931103 Ref country code: AT Effective date: 19931103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19931104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19931130 Ref country code: CH Effective date: 19931130 Ref country code: BE Effective date: 19931130 |

|

| BERE | Be: lapsed |

Owner name: AKADEMIE DER WISSENSCHAFTEN DER DDR Effective date: 19931130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931103 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940802 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 80106751.3 Effective date: 19940610 |