CN202117727U - 液压控制阀及液压控制回路 - Google Patents

液压控制阀及液压控制回路 Download PDFInfo

- Publication number

- CN202117727U CN202117727U CN2010205230859U CN201020523085U CN202117727U CN 202117727 U CN202117727 U CN 202117727U CN 2010205230859 U CN2010205230859 U CN 2010205230859U CN 201020523085 U CN201020523085 U CN 201020523085U CN 202117727 U CN202117727 U CN 202117727U

- Authority

- CN

- China

- Prior art keywords

- valve

- armature

- hydraulic control

- poppet valve

- fluid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000012530 fluid Substances 0.000 claims abstract description 51

- 241000628997 Flos Species 0.000 claims description 26

- 230000004907 flux Effects 0.000 claims description 16

- 238000007599 discharging Methods 0.000 claims description 10

- 230000009471 action Effects 0.000 claims description 5

- 230000004044 response Effects 0.000 description 12

- 230000000694 effects Effects 0.000 description 6

- 238000007789 sealing Methods 0.000 description 4

- 230000005284 excitation Effects 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 230000001276 controlling effect Effects 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 230000037361 pathway Effects 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 238000004887 air purification Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 230000005520 electrodynamics Effects 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 210000003205 muscle Anatomy 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

Images

Classifications

-

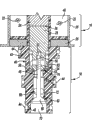

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K31/00—Actuating devices; Operating means; Releasing devices

- F16K31/02—Actuating devices; Operating means; Releasing devices electric; magnetic

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K11/00—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves

- F16K11/02—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit

- F16K11/04—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only lift valves

- F16K11/048—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only lift valves with valve seats positioned between movable valve members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K31/00—Actuating devices; Operating means; Releasing devices

- F16K31/02—Actuating devices; Operating means; Releasing devices electric; magnetic

- F16K31/06—Actuating devices; Operating means; Releasing devices electric; magnetic using a magnet, e.g. diaphragm valves, cutting off by means of a liquid

- F16K31/0603—Multiple-way valves

- F16K31/0624—Lift valves

- F16K31/0634—Lift valves with fixed seats positioned between movable valve members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01L—CYCLICALLY OPERATING VALVES FOR MACHINES OR ENGINES

- F01L1/00—Valve-gear or valve arrangements, e.g. lift-valve gear

- F01L1/34—Valve-gear or valve arrangements, e.g. lift-valve gear characterised by the provision of means for changing the timing of the valves without changing the duration of opening and without affecting the magnitude of the valve lift

- F01L1/344—Valve-gear or valve arrangements, e.g. lift-valve gear characterised by the provision of means for changing the timing of the valves without changing the duration of opening and without affecting the magnitude of the valve lift changing the angular relationship between crankshaft and camshaft, e.g. using helicoidal gear

- F01L1/3442—Valve-gear or valve arrangements, e.g. lift-valve gear characterised by the provision of means for changing the timing of the valves without changing the duration of opening and without affecting the magnitude of the valve lift changing the angular relationship between crankshaft and camshaft, e.g. using helicoidal gear using hydraulic chambers with variable volume to transmit the rotating force

- F01L2001/34423—Details relating to the hydraulic feeding circuit

- F01L2001/34426—Oil control valves

- F01L2001/3443—Solenoid driven oil control valves

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86574—Supply and exhaust

- Y10T137/86622—Motor-operated

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86574—Supply and exhaust

- Y10T137/8667—Reciprocating valve

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86574—Supply and exhaust

- Y10T137/8667—Reciprocating valve

- Y10T137/86678—Combined disk or plug and gate or piston

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86574—Supply and exhaust

- Y10T137/8667—Reciprocating valve

- Y10T137/86686—Plural disk or plug

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Magnetically Actuated Valves (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/486,035 | 2009-06-17 | ||

| US12/486,035 US8316888B2 (en) | 2009-06-17 | 2009-06-17 | Fluid-biased hydraulic control valve |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202117727U true CN202117727U (zh) | 2012-01-18 |

Family

ID=43243021

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010205230859U Expired - Fee Related CN202117727U (zh) | 2009-06-17 | 2010-06-17 | 液压控制阀及液压控制回路 |

| CN201010263171.5A Expired - Fee Related CN101929363B (zh) | 2009-06-17 | 2010-06-17 | 流体偏压式液压控制阀 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201010263171.5A Expired - Fee Related CN101929363B (zh) | 2009-06-17 | 2010-06-17 | 流体偏压式液压控制阀 |

Country Status (9)

| Country | Link |

|---|---|

| US (2) | US8316888B2 (enExample) |

| EP (1) | EP2443372B1 (enExample) |

| JP (1) | JP5692543B2 (enExample) |

| KR (1) | KR20120038969A (enExample) |

| CN (2) | CN202117727U (enExample) |

| AU (1) | AU2010261455B2 (enExample) |

| MX (1) | MX2012000011A (enExample) |

| PL (1) | PL2443372T3 (enExample) |

| WO (1) | WO2010146447A2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109070323A (zh) * | 2016-03-30 | 2018-12-21 | 卡特彼勒公司 | 阀体灌充锁 |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8316888B2 (en) * | 2009-06-17 | 2012-11-27 | Eaton Corporation | Fluid-biased hydraulic control valve |

| US8443839B2 (en) * | 2009-10-20 | 2013-05-21 | Eaton Corporation | Fluid-biased hydraulic control valve with armature piston |

| US8609293B2 (en) * | 2010-10-01 | 2013-12-17 | GM Global Technology Operations LLC | High pressure tank valve sealing by using the elastic properties of O-rings |

| US8459218B2 (en) | 2011-05-19 | 2013-06-11 | Eaton Corporation | Adjustable-stroke solenoid valve |

| CN103292003B (zh) * | 2012-02-28 | 2017-12-26 | 伊顿公司 | 带有互锁部的通量收集器以及制造带有该通量收集器的电磁阀组件的方法 |

| USD716911S1 (en) * | 2012-10-04 | 2014-11-04 | Adma Elena Faraón Chaul Huerta | Water-flow regulator |

| USD706904S1 (en) * | 2012-10-04 | 2014-06-10 | Adma Elena Faraon Chaul Huerta | Water-flow regulator |

| WO2014123755A2 (en) * | 2013-01-31 | 2014-08-14 | Eaton Corporation | Centrifugal process to eliminate air in high pressure chamber of hydraulic lash adjuster |

| US9523438B2 (en) | 2013-03-14 | 2016-12-20 | Eaton Corporation | Solenoid valve assembly with pilot pressure control |

| US10508964B2 (en) | 2013-03-14 | 2019-12-17 | Eaton Intelligent Power Limited | Solenoid valve assembly with pilot pressure control |

| CN104565497B (zh) * | 2013-10-23 | 2019-02-05 | 德昌电机(深圳)有限公司 | 电磁阀 |

| CN106460594B (zh) * | 2014-05-15 | 2019-10-25 | 博格华纳公司 | 用于发动机管理的闭锁螺线管 |

| WO2016106314A1 (en) * | 2014-12-22 | 2016-06-30 | Eaton Corporation | Two stage in-line valve |

| JP6770320B2 (ja) | 2015-02-11 | 2020-10-14 | フスコ オートモーティブ ホールディングス エル・エル・シーHUSCO Automotive Holdings LLC | 環状ポペット逆止弁を備えた調節弁 |

| JP2018520307A (ja) | 2015-05-05 | 2018-07-26 | イートン コーポレーションEaton Corporation | オイル制御弁 |

| US20170184209A1 (en) * | 2015-12-23 | 2017-06-29 | Spx Flow, Inc. | Hydraulic connection having a flexible port mouth and method for connecting same |

| DE102016212311A1 (de) * | 2016-07-06 | 2018-01-11 | Robert Bosch Gmbh | Ventil mit über Dichtungsnut entlüftetem Steuerraum |

| CN106195400B (zh) * | 2016-07-09 | 2018-04-17 | 常熟骏驰科技有限公司 | 隔磁套及其电磁阀 |

| US20180372237A1 (en) * | 2017-06-22 | 2018-12-27 | Schaeffler Technologies AG & Co. KG | Normally closed fast-acting solenoid valve |

Family Cites Families (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1188623A (fr) | 1956-12-14 | 1959-09-24 | Joints d'étanchéité de soupapes, plus particulièrement en forme de champignon, dans lesquelles la fermeture s'effectue par translation axiale d'un organe obturateur | |

| GB1258416A (enExample) | 1968-12-24 | 1971-12-30 | ||

| US3595265A (en) * | 1969-04-14 | 1971-07-27 | Caterpillar Tractor Co | Self-cleaning orifice check valve |

| JPS5443384Y2 (enExample) * | 1972-09-02 | 1979-12-14 | ||

| JPS5391031U (enExample) * | 1976-12-27 | 1978-07-25 | ||

| JPS5391031A (en) | 1977-01-24 | 1978-08-10 | Kobe Steel Ltd | Low hydrogen coating arc welding rod |

| CH624196A5 (en) | 1977-08-17 | 1981-07-15 | Ernst Franz Voegeli | Solenoid valve |

| JPS54113723U (enExample) * | 1978-01-23 | 1979-08-10 | ||

| JPS54113723A (en) | 1978-02-25 | 1979-09-05 | Yukiko Imai | Fuel economizer for car engine |

| US4627272A (en) | 1984-11-28 | 1986-12-09 | Cambridge Applied Systems, Inc. | Viscometer |

| US4762000A (en) * | 1986-10-06 | 1988-08-09 | Bond Jr Charles R | Fluid level indicating apparatus |

| DE8806867U1 (de) * | 1987-06-06 | 1988-07-21 | A. u. K. Müller GmbH & Co KG, 4000 Düsseldorf | Elektromagnetisch betätigbares 5/2-Wegeventil |

| JP2603489B2 (ja) | 1987-12-15 | 1997-04-23 | 日本石油化学 株式会社 | 粉末塗装用エチレン系重合体組成物 |

| JPH01156377U (enExample) * | 1988-04-21 | 1989-10-27 | ||

| WO1991013322A1 (en) | 1990-02-26 | 1991-09-05 | Caterpillar Industrial Inc. | An apparatus for determining the level of liquid in a container |

| DE4125588C2 (de) | 1991-08-02 | 1998-02-05 | Renk Ag | Ölstandsmesser |

| JPH0960311A (ja) | 1995-08-22 | 1997-03-04 | Kajima Corp | リフトアップ解体工法 |

| JP4203612B2 (ja) * | 1996-12-06 | 2009-01-07 | コンティネンタル・テーベス・アクチェンゲゼルシャフト・ウント・コンパニー・オッフェネ・ハンデルスゲゼルシャフト | 多方弁 |

| JP3471568B2 (ja) * | 1997-06-18 | 2003-12-02 | 三菱電機株式会社 | 三方電磁弁 |

| DE19902991C1 (de) | 1999-01-26 | 2000-07-06 | Mar Tec Marine Gmbh | Verfahren und Einrichtung zur Bestimmung der Viskosität von Flüssigkeiten, insbesondere Mineralölen |

| GB9916974D0 (en) | 1999-07-21 | 1999-09-22 | Imi Webber Limited | Fluid flow control valve |

| DE10242959A1 (de) | 2002-04-26 | 2003-11-06 | Continental Teves Ag & Co Ohg | Verfahren zur Bestimmung der Viskosität einer Flüssigkeit |

| DE10223431B4 (de) | 2002-05-25 | 2004-07-08 | Ina-Schaeffler Kg | Brennkraftmaschine mit zumindest zwei nebeneinander angeordneten, jeweils mit einer Vorrichtung zur Drehwinkelverstellung gegenüber einer Kurbelwelle ausgebildeten Nockenwellen |

| US6871668B2 (en) * | 2003-01-13 | 2005-03-29 | Delphi Technologies Inc. | Variable force actuator with a double needle poppet assembly |

| DE10359363A1 (de) * | 2003-12-18 | 2005-07-14 | Ina-Schaeffler Kg | Elektromagnetisches Hydraulikventil, inbesondere 3/2-Wegeschaltventil zur Steuerung eines variablen Ventiltriebes einer Brennkraftmaschine |

| DE10359364B4 (de) * | 2003-12-18 | 2012-10-11 | Schaeffler Technologies Gmbh & Co. Kg | Elektromagnetisches Hydraulikventil, insbesondere 3/2-Wegeschaltventil zur Steuerung eines varialblen Ventiltriebes einer Brennkraftmaschine |

| JP4260053B2 (ja) * | 2004-03-26 | 2009-04-30 | Ntn株式会社 | オイルチェックセンサ |

| WO2005102807A1 (de) | 2004-04-20 | 2005-11-03 | Rausch & Pausch Gmbh | Magnetventil |

| DE102004057573B4 (de) * | 2004-11-30 | 2013-05-02 | Schaeffler Technologies AG & Co. KG | Elektromagnetisch ansteuerbares Wegeventil |

| CN101166926B (zh) | 2005-04-27 | 2010-08-04 | 伊格尔工业股份有限公司 | 切换阀 |

| DE102005034938B4 (de) * | 2005-07-27 | 2013-02-21 | Schaeffler Technologies AG & Co. KG | Elektromagnetisches Hydraulikventil |

| US8746408B2 (en) * | 2006-09-01 | 2014-06-10 | GM Global Technology Operations LLC | Engine oil change detection systems and methods |

| DE112008000963T5 (de) * | 2007-04-11 | 2010-03-25 | Eaton Corp., Cleveland | Integrierter Ölzustands- und -füllstandssensor |

| DE102007036925A1 (de) * | 2007-08-04 | 2009-02-05 | Schaeffler Kg | Elektromagnetische Stelleinheit |

| US8011385B2 (en) * | 2008-01-29 | 2011-09-06 | Eaton Corporation | Valve assembly and method of assembly |

| US8316888B2 (en) | 2009-06-17 | 2012-11-27 | Eaton Corporation | Fluid-biased hydraulic control valve |

| US8443839B2 (en) * | 2009-10-20 | 2013-05-21 | Eaton Corporation | Fluid-biased hydraulic control valve with armature piston |

-

2009

- 2009-06-17 US US12/486,035 patent/US8316888B2/en not_active Expired - Fee Related

-

2010

- 2010-06-16 WO PCT/IB2010/001455 patent/WO2010146447A2/en not_active Ceased

- 2010-06-16 AU AU2010261455A patent/AU2010261455B2/en not_active Ceased

- 2010-06-16 JP JP2012515575A patent/JP5692543B2/ja not_active Expired - Fee Related

- 2010-06-16 MX MX2012000011A patent/MX2012000011A/es unknown

- 2010-06-16 EP EP20100742553 patent/EP2443372B1/en not_active Not-in-force

- 2010-06-16 PL PL10742553T patent/PL2443372T3/pl unknown

- 2010-06-16 KR KR20127001202A patent/KR20120038969A/ko not_active Abandoned

- 2010-06-17 CN CN2010205230859U patent/CN202117727U/zh not_active Expired - Fee Related

- 2010-06-17 CN CN201010263171.5A patent/CN101929363B/zh not_active Expired - Fee Related

-

2012

- 2012-11-26 US US13/685,125 patent/US9157542B2/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109070323A (zh) * | 2016-03-30 | 2018-12-21 | 卡特彼勒公司 | 阀体灌充锁 |

| CN109070323B (zh) * | 2016-03-30 | 2022-04-08 | 卡特彼勒公司 | 阀体灌充锁 |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2010146447A3 (en) | 2011-02-24 |

| WO2010146447A2 (en) | 2010-12-23 |

| KR20120038969A (ko) | 2012-04-24 |

| EP2443372B1 (en) | 2013-04-03 |

| JP2012530234A (ja) | 2012-11-29 |

| CN101929363A (zh) | 2010-12-29 |

| JP5692543B2 (ja) | 2015-04-01 |

| US8316888B2 (en) | 2012-11-27 |

| AU2010261455A1 (en) | 2012-01-19 |

| US9157542B2 (en) | 2015-10-13 |

| US20100320407A1 (en) | 2010-12-23 |

| US20130075639A1 (en) | 2013-03-28 |

| PL2443372T3 (pl) | 2013-09-30 |

| EP2443372A2 (en) | 2012-04-25 |

| CN101929363B (zh) | 2015-03-18 |

| MX2012000011A (es) | 2012-05-29 |

| AU2010261455B2 (en) | 2013-07-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202117727U (zh) | 液压控制阀及液压控制回路 | |

| CN102713170B (zh) | 具有衔铁活塞的流体偏压液力控制阀 | |

| KR101538198B1 (ko) | 오일 제어 밸브 및 오일 유동 제어 방법 | |

| KR101236593B1 (ko) | 유체 작동 기계 | |

| JP2000161527A (ja) | ソレノイド作動流量制御弁アセンブリ | |

| US7383819B1 (en) | Electromagnetic valve device and fuel injection apparatus with the valve device | |

| JP2004132543A (ja) | 電気流体圧制御弁 | |

| RU2444666C2 (ru) | Гидравлический клапан с электрическим управлением | |

| JP2014196718A (ja) | 圧縮機の吸気部構造 | |

| CZ294387B6 (cs) | Palivové dávkovací čerpadlo pro topné těleso, zejména pro přídavné nebo parkovací topení motorového vozidla | |

| US20050166873A1 (en) | Made to an electromechanical valve actuator of an internal combustion engine | |

| US6918360B2 (en) | Engine valve actuator assembly with hydraulic feedback | |

| JP4154839B2 (ja) | 燃料噴射装置 | |

| US20040194742A1 (en) | Engine valve actuator assembly with automatic regulation | |

| JP2005233151A (ja) | 内燃機関の油圧システム | |

| JP2001173541A (ja) | 流体を噴射するための装置 | |

| JPS5923018A (ja) | 可変排気量型エンジンのバルブ停止装置 | |

| JP2001004059A (ja) | 流量制御バルブ | |

| KR20120016700A (ko) | 차량 엔진의 제이크 브레이크 시스템 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120118 Termination date: 20180617 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |