CN1119233C - 装配鼓轮和轮胎的制造方法 - Google Patents

装配鼓轮和轮胎的制造方法 Download PDFInfo

- Publication number

- CN1119233C CN1119233C CN99106134A CN99106134A CN1119233C CN 1119233 C CN1119233 C CN 1119233C CN 99106134 A CN99106134 A CN 99106134A CN 99106134 A CN99106134 A CN 99106134A CN 1119233 C CN1119233 C CN 1119233C

- Authority

- CN

- China

- Prior art keywords

- drum

- diameter

- bump

- central shaft

- carcass reinforcement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 15

- 238000000034 method Methods 0.000 title claims description 10

- 230000002787 reinforcement Effects 0.000 claims description 28

- 210000000078 claw Anatomy 0.000 claims description 11

- 239000002184 metal Substances 0.000 claims description 2

- 239000011324 bead Substances 0.000 description 19

- 230000008093 supporting effect Effects 0.000 description 19

- 239000007789 gas Substances 0.000 description 9

- 230000033001 locomotion Effects 0.000 description 6

- 230000000284 resting effect Effects 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 239000004575 stone Substances 0.000 description 3

- 229920000742 Cotton Polymers 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 241000239290 Araneae Species 0.000 description 1

- 238000009954 braiding Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 238000005987 sulfurization reaction Methods 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 238000013022 venting Methods 0.000 description 1

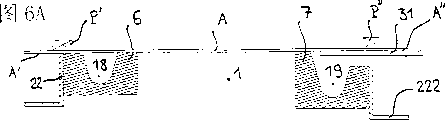

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/24—Drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/32—Fitting the bead-rings or bead-cores; Folding the textile layers around the rings or cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/24—Drums

- B29D30/244—Drums for manufacturing substantially cylindrical tyre components with cores or beads, e.g. carcasses

- B29D30/246—Drums for the multiple stage building process, i.e. the building-up of the cylindrical carcass is realised on one drum and the toroidal expansion is realised after transferring on another drum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/32—Fitting the bead-rings or bead-cores; Folding the textile layers around the rings or cores

- B29D2030/3214—Locking the beads on the drum; details of the drum in the bead locking areas, e.g. drum shoulders

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Tyre Moulding (AREA)

- Tires In General (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9805698A FR2777827A1 (fr) | 1998-04-28 | 1998-04-28 | Tambour d'assemblage pour la fabrication de pneumatiques |

| FR98/05698 | 1998-04-28 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1233554A CN1233554A (zh) | 1999-11-03 |

| CN1119233C true CN1119233C (zh) | 2003-08-27 |

Family

ID=9526067

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN99106134A Expired - Fee Related CN1119233C (zh) | 1998-04-28 | 1999-04-28 | 装配鼓轮和轮胎的制造方法 |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP0953434B1 (enExample) |

| JP (1) | JPH11333944A (enExample) |

| KR (1) | KR100559064B1 (enExample) |

| CN (1) | CN1119233C (enExample) |

| BR (1) | BR9901406A (enExample) |

| DE (1) | DE69905965T2 (enExample) |

| ES (1) | ES2193616T3 (enExample) |

| FR (1) | FR2777827A1 (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6506274B1 (en) | 1998-07-23 | 2003-01-14 | Michelin Recherche Et Technique, S.A. | Apparatus and method for manufacture of tires |

| AU2002215974A1 (en) | 2000-10-27 | 2002-05-06 | Michelin Recherche Et Technique S.A. | Tyre building drum |

| DE60219514T2 (de) * | 2001-11-28 | 2008-01-03 | Bridgestone Corp. | Reifenherstellungsverfahren und reifenformmaschine |

| JP4495912B2 (ja) * | 2003-01-14 | 2010-07-07 | 三菱樹脂株式会社 | 多層フィルムおよび容器 |

| DE102005044231A1 (de) * | 2005-09-16 | 2007-03-29 | Continental Aktiengesellschaft | Verfahren zur Herstellung von Fahrzeugluftreifen mit geklemmtem Lagenumschlag |

| US9360396B2 (en) * | 2011-10-06 | 2016-06-07 | Kobe Steel, Ltd. | Tire uniformity testing device and tire uniformity testing method |

| FR3043936B1 (fr) * | 2015-11-25 | 2017-11-24 | Michelin & Cie | Tambour et procede d’assemblage d’un adaptateur de pneumatique sur une jante |

| FR3066430B1 (fr) * | 2017-05-22 | 2020-10-30 | Michelin & Cie | Tambour et procede d'assemblage d'un adaptateur de pneumatique sur une jante |

| JP6993874B2 (ja) * | 2017-12-28 | 2022-01-14 | Toyo Tire株式会社 | シート部材の巻き取り方法及び巻き取り筒 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2045545A (en) * | 1933-10-30 | 1936-06-23 | Nat Standard Co | Process and apparatus for making drum built tires |

| US2440662A (en) * | 1945-10-31 | 1948-04-27 | Nat Standard Co | Apparatus for building tires |

| EP0481805A2 (en) * | 1990-10-18 | 1992-04-22 | Bridgestone Corporation | Methods of producing green case and green tire and tires produced by these methods |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1198054B (de) * | 1964-03-06 | 1965-08-05 | Continental Gummi Werke Ag | Aufbauvorrichtung fuer Rollbalgrohlinge, Reifenrohlinge oder aehnlich aufgebaute Hohlkoerperrohlinge |

| JPH10180901A (ja) * | 1996-12-25 | 1998-07-07 | Yokohama Rubber Co Ltd:The | 空気入りタイヤ及びその製造方法 |

-

1998

- 1998-04-28 FR FR9805698A patent/FR2777827A1/fr active Pending

-

1999

- 1999-04-15 EP EP99107551A patent/EP0953434B1/fr not_active Expired - Lifetime

- 1999-04-15 ES ES99107551T patent/ES2193616T3/es not_active Expired - Lifetime

- 1999-04-15 DE DE69905965T patent/DE69905965T2/de not_active Expired - Fee Related

- 1999-04-26 BR BR9901406A patent/BR9901406A/pt not_active Application Discontinuation

- 1999-04-28 KR KR1019990015184A patent/KR100559064B1/ko not_active Expired - Fee Related

- 1999-04-28 CN CN99106134A patent/CN1119233C/zh not_active Expired - Fee Related

- 1999-04-28 JP JP11121464A patent/JPH11333944A/ja not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2045545A (en) * | 1933-10-30 | 1936-06-23 | Nat Standard Co | Process and apparatus for making drum built tires |

| US2440662A (en) * | 1945-10-31 | 1948-04-27 | Nat Standard Co | Apparatus for building tires |

| EP0481805A2 (en) * | 1990-10-18 | 1992-04-22 | Bridgestone Corporation | Methods of producing green case and green tire and tires produced by these methods |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0953434B1 (fr) | 2003-03-19 |

| KR100559064B1 (ko) | 2006-03-10 |

| DE69905965D1 (de) | 2003-04-24 |

| ES2193616T3 (es) | 2003-11-01 |

| JPH11333944A (ja) | 1999-12-07 |

| KR19990083560A (ko) | 1999-11-25 |

| DE69905965T2 (de) | 2003-11-27 |

| BR9901406A (pt) | 2000-03-21 |

| CN1233554A (zh) | 1999-11-03 |

| EP0953434A1 (fr) | 1999-11-03 |

| FR2777827A1 (fr) | 1999-10-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6250356B1 (en) | Assembly drum and method for the manufacture of tires | |

| CN1119233C (zh) | 装配鼓轮和轮胎的制造方法 | |

| US3990931A (en) | Tire building apparatus and method | |

| RU2004135568A (ru) | Барабан для изготовления шин с устройством для выгибания вверх и способ изготовления невулканизованных шин | |

| US8689848B2 (en) | Bead lock arrangement | |

| CN1365314A (zh) | 轮胎装配设备 | |

| EP2222455A1 (en) | Process for manufacturing tyres for vehicle wheels and apparatus for building a carcass structure of a tyre for vehicle wheels | |

| CN1055265C (zh) | 制造轮胎的方法和设备 | |

| CN1369387A (zh) | 用于由单一一根线生产轮胎加强结构的摆动臂装置 | |

| CN1274484C (zh) | 制造轮胎的方法和装置 | |

| CN101665005A (zh) | 上环形胎面膨胀环及其方法 | |

| CN1974194A (zh) | 用于轮胎的分离帘线测量结构 | |

| EP1651425B1 (en) | Method and apparatus for producing tyres for vehicle wheels | |

| CN101084106B (zh) | 制造车轮轮胎的方法和设备 | |

| CN201175998Y (zh) | 成型机成型鼓的胎圈自动锁紧器 | |

| CN101058290A (zh) | 用于安装轮胎和承载支撑的运载工具轮辋以及具有这种轮辋的轮胎/轮子组件的安装工艺 | |

| KR101012072B1 (ko) | 가변형 카카스 성형드럼 | |

| JP2006515814A (ja) | ガイドリングを有するタイヤ補強材の製造装置 | |

| KR100965999B1 (ko) | 그린타이어 제조장치 | |

| US7740040B2 (en) | Bottom zone turn-up membrane | |

| KR100940427B1 (ko) | 만곡된 필라멘트 보강된 튜브 형상의 성형체를 제조하는방법 및 장치 | |

| CN1974191A (zh) | 轮胎帘线敷贴站和方法 | |

| JP2000000899A (ja) | タイヤ製造装置及びベルトリング乗り移し方法 | |

| RU2839445C1 (ru) | Способ сборки покрышек пневматических шин | |

| CN216885322U (zh) | 用于轮胎成型的滚压装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20030827 |