CN109420357B - 传质机 - Google Patents

传质机 Download PDFInfo

- Publication number

- CN109420357B CN109420357B CN201810957149.7A CN201810957149A CN109420357B CN 109420357 B CN109420357 B CN 109420357B CN 201810957149 A CN201810957149 A CN 201810957149A CN 109420357 B CN109420357 B CN 109420357B

- Authority

- CN

- China

- Prior art keywords

- rotor

- filler

- filling

- structural

- sectors

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04B—CENTRIFUGES

- B04B5/00—Other centrifuges

- B04B5/06—Centrifugal counter-current apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D3/00—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping

- B01D3/08—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping in rotating vessels; Atomisation on rotating discs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D3/00—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping

- B01D3/14—Fractional distillation or use of a fractionation or rectification column

- B01D3/26—Fractionating columns in which vapour and liquid flow past each other, or in which the fluid is sprayed into the vapour, or in which a two-phase mixture is passed in one direction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D3/00—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping

- B01D3/14—Fractional distillation or use of a fractionation or rectification column

- B01D3/30—Fractionating columns with movable parts or in which centrifugal movement is caused

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/23—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids

- B01F23/233—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids using driven stirrers with completely immersed stirring elements

- B01F23/2334—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids using driven stirrers with completely immersed stirring elements provided with stationary guiding means surrounding at least partially the stirrer

- B01F23/23342—Mixing gases with liquids by introducing gases into liquid media, e.g. for producing aerated liquids using driven stirrers with completely immersed stirring elements provided with stationary guiding means surrounding at least partially the stirrer the stirrer being of the centrifugal type, e.g. with a surrounding stator

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/051—Stirrers characterised by their elements, materials or mechanical properties

- B01F27/053—Stirrers characterised by their elements, materials or mechanical properties characterised by their materials

- B01F27/0531—Stirrers characterised by their elements, materials or mechanical properties characterised by their materials with particular surface characteristics, e.g. coated or rough

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/11—Stirrers characterised by the configuration of the stirrers

- B01F27/111—Centrifugal stirrers, i.e. stirrers with radial outlets; Stirrers of the turbine type, e.g. with means to guide the flow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/18—Stationary reactors having moving elements inside

- B01J19/1806—Stationary reactors having moving elements inside resulting in a turbulent flow of the reactants, such as in centrifugal-type reactors, or having a high Reynolds-number

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/32—Packing elements in the form of grids or built-up elements for forming a unit or module inside the apparatus for mass or heat transfer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/28—Moving reactors, e.g. rotary drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/32—Details relating to packing elements in the form of grids or built-up elements for forming a unit of module inside the apparatus for mass or heat transfer

- B01J2219/322—Basic shape of the elements

- B01J2219/32203—Sheets

- B01J2219/3221—Corrugated sheets

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Sealing Devices (AREA)

- Vaporization, Distillation, Condensation, Sublimation, And Cold Traps (AREA)

- Gasket Seals (AREA)

- Disintegrating Or Milling (AREA)

- Fish Paste Products (AREA)

- Confectionery (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Sealing Using Fluids, Sealing Without Contact, And Removal Of Oil (AREA)

- Centrifugal Separators (AREA)

Abstract

本发明涉及一种用于引起在填充物内部的液体和气体之间的传质的装置,该装置具有转动件,其中,所述液体在转动件的中心被添加并且通过由转动件转动所产生的离心力被向外驱动穿过填充物,并且,所述气体包围转动件并且被气体压力逆着转动件中的液体流动从外向内挤压穿过转动件。其中,位于转动件中的填充物分成多个单个的填充物扇段,所述填充物扇段一起形成一个圆盘,其中,每个环扇形的填充物扇段由至少一个结构填充物形成,所述结构填充物由多个机织物状的、针织物状的、筛网状的或格栅状的、由金属、尤其是金属板带或者塑料或玻璃纤维制成的彼此相叠的结构面构成,转动件的转动轴线垂直于所述结构面。

Description

技术领域

本发明涉及一种用于引起在具有填充物的转动件内部的液体和气体之间的传质的装置,其中,所述液体在转动件的中心被添加并且通过由转动件转动所产生的离心力被向外驱动穿过填充物,并且,所述气体包围转动件并且被气体压力逆着转动件中的液体流动从外向内挤压穿过转动件。

背景技术

由WO2015/101826A1和WO2016/038480A1已知传质机,其具有转动件,所述转动件具有两个侧面,其中,在这两个面之间的中间空间中存在填充物,该填充物在转动件转动时将在中间被添加的液体向外驱动。在此,所述转动件由气体包围,所述气体被气体压力逆着液体流动穿过转动件,以便引起液体和气体之间的传质。

发明内容

本发明的目的在于,提供一种开头所述类型的装置,在该装置中,传质和物质运输得以显著改进并且运行时间降低。此外,所述装置在制造、安装和使用中应是简单的。

按照本发明,所述目的通过如下方式得以实现:位于转动件中的填充物分成多个单个的填充物扇段,这些填充物扇段一起形成一个圆盘,其中,每个环扇形的填充物扇段由至少一个结构填充物形成,所述结构填充物由多个机织物状的、针织物状的、筛网状的或格栅状的、由金属、尤其是金属板带制成的或者由塑料或玻璃纤维制成的彼此相叠的结构面构成,转动件的转动轴线垂直于所述结构面。

将位于转动件中的填充物分成具有机织物状的、针织物状的、晒网状的或格栅状的结构的多个单个的填充物扇段导致传质的以及在较短的运行时间下的运输的显著改进。这种转动件的由多个单个的填充物扇段的组成(所述填充物扇段又由多个单个的结构面组成)在制造中是特别简单的并且导致如下优点:结构填充物在其结构和类型以及在结构面的尺寸方面能够非常精确地适配于相应的需求。

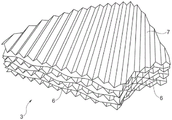

在此特别有利的是:结构面是波形的,其中,每个结构面的波彼此平行。在作用和制造中也被视为有利的是:结构面的波在横截面中是锯齿形的。为此也提出:一个结构面的波相对于相邻的结构面的波倾斜地设置、尤其是成直角地设置,从而在两个结构面之间存在交叉的流动通道。

优选地提出:结构面由金属丝和/或塑料丝或者金属板带或玻璃纤维制成。在此,所述金属丝和/或塑料丝可以具有0.1至0.5、优选0.15至0.2mm的直径。

有利的是:位于转动件中的结构填充物由2至64个、优选4至16个填充物扇段组成。在结构上提出:填充物扇段的内端部形成内部的、柱形的、同轴的环形空间,流动通道从该环形空间出发并且液体被添加到所述环形空间中。为此还提出:填充物扇段的外端部形成外部的、柱形的环,填充物扇段的流动通道在该环中结束。

被视为特别有利的是:填充物扇段由3至10个、优选5至8个彼此相叠的结构面组成。填充物扇段的结构面也可以尤其是通过激光束彼此点焊。

在直径上较大的转动件的制造在如下情况时被简化:转动件的结构填充物由彼此同轴的结构填充物环构成,所述结构填充物环分成多个单个的环扇段。还提出:所述转动件具有两个圆形的侧面,转动件转动轴线垂直于所述侧面并且所述侧面彼此形成一个中间空间,该中间空间由填充物扇段填充。

附图说明

本发明有利的设计方案在附图中示出并且在后文中进一步说明。图中示出:

图1为按照本发明的传质机的转动件的横剖视图,

图2为由结构面组成的填充物扇段的透视图,

图3为结构面的俯视图,

图4为根据图3的结构面的IV-IV的剖视图,

图5和6为带有由多个单个的环扇段构成的结构填充物环的转动件的剖视图。

具体实施方式

传质机具有转动件1,该转动件具有两个同轴的圆形的侧面2,所述两个侧面彼此平行地设置并且所述两个侧面的中间空间通过填充物填充。在此,所述填充物由以圆环扇段为形式的多个单个的填充物扇段3构成,从而填充物扇段3的内端部形成内部的柱形的、同轴的或柱形的环形空间4,液体在该空间中被添加。填充物扇段的弯曲的外端部形成柱形的外环5,填充物扇段的流动通道6在该外环中结束。

如在图2中所示,每个填充物扇段3由多个单个的彼此相叠的结构面7构成,其中,所述结构面7构成为波形的。在此,所述波如此构造,使得所述波在横截面中是锯齿形的(如在图4中所示)又或者包括倒圆的波。

每个结构面7的彼此平行的波在其波谷中形成流动通道6,其中,彼此贴靠的结构面彼此这样旋转并且因此彼此倾斜地、尤其是彼此成直角地设置,使得在两个结构面之间,流动通道如由图2可见的那样彼此交叉。

优选,所述填充物扇段分别由3至150个、优选5至25个彼此相叠的结构面组成。此外,位于转动件中的结构填充物由2至64个填充物扇段组成,如图1所示。

但备选地,转动件的结构填充物也可以由彼此同轴的结构填充物环构成,所述结构填充物环又分成多个单个的环扇段,如图5和6所示。

结构面7或是由全金属的和/或塑料丝的带、机织物或针织物制成或是由玻璃纤维制成,其中,所述丝优选具有0.1至0.5mm、优选0.15至0.2mm的直径。但备选地,所述结构面7也可以由金属或塑料制成的筛网或格栅形成。

填充物扇段3的结构面7优选通过激光光束彼此点焊在一起。

Claims (16)

1.用于引起在具有填充物的转动件(1)内部的液体和气体之间的传质的装置,其中,液体在转动件的中心被添加并且通过由转动件转动所产生的离心力被向外驱动穿过填充物,并且气体包围转动件并且被气体压力逆着转动件中的液体流动由外向内挤压穿过转动件,其特征在于,位于转动件(1)中的填充物分成多个单个的填充物扇段(3),所述多个单个的填充物扇段在周向上彼此相邻以一起形成一个圆盘,其中,每个环扇形的填充物扇段(3)由至少一个结构填充物形成,所述至少一个结构填充物由多个机织物状的、针织物状的、筛网状的或格栅状的彼此轴向地相叠的结构面(7)构成,所述结构面由金属或者塑料或玻璃纤维制成,转动件的转动轴线垂直于所述结构面。

2.如权利要求1所述的装置,其特征在于,所述结构面(7)是波形的,其中,每个结构面的波彼此平行。

3.如权利要求2所述的装置,其特征在于,所述结构面的波在横截面中是锯齿形的。

4.如权利要求2所述的装置,其特征在于,一个结构面(7)的波相对于相邻的结构面的波倾斜地设置,从而在两个结构面之间存在交叉的流动通道。

5.如权利要求1-4中任一项所述的装置,其特征在于,所述结构面(7)由金属丝和/或塑料丝制成或者由金属板带或玻璃纤维制成。

6.如权利要求5所述的装置,其特征在于,所述金属丝和/或塑料丝具有0.1至0.5mm的直径。

7.如权利要求1-4中任一项所述的装置,其特征在于,位于转动件中的结构填充物由2至64个填充物扇段(3)组成。

8.如权利要求1-4中任一项所述的装置,其特征在于,所述填充物扇段(3)的内端部形成内部的、柱形的同轴的环形空间(4),流动通道从该环形空间出发并且液体被添加到所述环形空间中。

9.如权利要求1-4中任一项所述的装置,其特征在于,所述填充物扇段(3)的外端部形成外部的柱形的环(5),填充物扇段的流动通道(6)在该环中结束。

10.如权利要求1-4中任一项所述的装置,其特征在于,所述填充物扇段(3)由3至150个彼此相叠的结构面(7)组成。

11.如权利要求1-4中任一项所述的装置,其特征在于,所述填充物扇段(3)的结构面通过激光束彼此点焊在一起。

12.如权利要求1-4中任一项所述的装置,其特征在于,所述转动件(1)的结构填充物由彼此同轴的结构填充物环(10)构成,所述结构填充物环分成多个单个的环扇段(3)。

13.如权利要求1-4中任一项所述的装置,其特征在于,所述转动件具有两个圆形的侧面(2),转动件转动轴线与所述侧面垂直并且所述侧面彼此形成一个中间空间,该中间空间由填充物扇段(3)填充。

14.如权利要求4所述的装置,其特征在于,一个结构面(7)的波相对于相邻的结构面的波成直角地设置。

15.如权利要求6所述的装置,其特征在于,所述金属丝和/或塑料丝具有0.15至0.2mm的直径。

16.如权利要求10所述的装置,其特征在于,所述填充物扇段(3)由5至25个彼此相叠的结构面(7)组成。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102017007861.0A DE102017007861A1 (de) | 2017-08-23 | 2017-08-23 | Stoffaustauschmaschine |

| DE102017007861.0 | 2017-08-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109420357A CN109420357A (zh) | 2019-03-05 |

| CN109420357B true CN109420357B (zh) | 2021-10-08 |

Family

ID=63012776

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201810957149.7A Active CN109420357B (zh) | 2017-08-23 | 2018-08-22 | 传质机 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10710100B2 (zh) |

| EP (1) | EP3446764B1 (zh) |

| JP (1) | JP7189697B2 (zh) |

| CN (1) | CN109420357B (zh) |

| DE (1) | DE102017007861A1 (zh) |

| TW (1) | TWI791570B (zh) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11988451B2 (en) * | 2020-04-23 | 2024-05-21 | Brentwood Industries, Inc. | Drift eliminator and method of making |

| CN118142443B (zh) * | 2024-05-11 | 2024-08-20 | 万华化学集团股份有限公司 | 涓流床反应器及用其制备苯甲胺的方法 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0089128A1 (en) * | 1982-03-12 | 1983-09-21 | Imperial Chemical Industries Plc | Process for displacing dissolved gas from water |

| US5363909A (en) * | 1991-11-27 | 1994-11-15 | Praxair Technology, Inc. | Compact contacting device |

| CN101125263A (zh) * | 2007-06-11 | 2008-02-20 | 刘辉 | 一种垂直式旋转床超重力场设备 |

| CN101596400A (zh) * | 2009-07-14 | 2009-12-09 | 薛碧 | 逆顺流水波纹环板填料超重力除尘脱硫机 |

| CN105148685A (zh) * | 2015-09-23 | 2015-12-16 | 中北大学 | 恒定通道式旋转填料床传质与反应设备 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB265120A (en) * | 1926-01-26 | 1927-07-13 | Louise Theisen | Improvements in apparatus for producing pressure and suctional effects |

| GB757149A (en) * | 1953-06-29 | 1956-09-12 | Claes Wilhelm Pilo | Apparatus for the performance of an exchange of heat and/or soluble substances between two flowing media of different specific gravity |

| US2944801A (en) * | 1955-05-09 | 1960-07-12 | Katz Robert | Rotary interchanger with direct interfacial fluid contact |

| US2941872A (en) * | 1959-06-09 | 1960-06-21 | Pilo | Apparatus for intimate contacting of two fluid media having different specific weight |

| US3095149A (en) * | 1961-06-23 | 1963-06-25 | Foremost Dairies Inc | Centrifugal atomizer and method |

| US3701513A (en) * | 1970-07-21 | 1972-10-31 | Shirley J Carter | Fuel feeding apparatus |

| US3991143A (en) * | 1973-07-12 | 1976-11-09 | Carter Shirley J | Apparatus for producing and delivering a combustible fuel mixture and improved nebulizer rotor |

| EP0002568B1 (en) * | 1977-12-01 | 1984-06-20 | Imperial Chemical Industries Plc | Mass transfer apparatus and its use |

| ATE21043T1 (de) * | 1981-10-26 | 1986-08-15 | Ici Plc | Gas-fluessigkeits-zentrifugalreaktor. |

| EP0080311B1 (en) * | 1981-11-24 | 1986-01-15 | Imperial Chemical Industries Plc | Contacting device |

| ZA83242B (en) * | 1982-01-19 | 1983-11-30 | Ici Plc | The removal of hydrogen sulphide from gas streams |

| GB8305595D0 (en) * | 1983-03-01 | 1983-03-30 | Ici Plc | Evaporator |

| JP2984290B2 (ja) * | 1988-09-02 | 1999-11-29 | ゲブリユーダー ズルツアー アクチエンゲゼルシヤフト | 触媒反応を行う装置 |

| JP3500983B2 (ja) | 1998-09-21 | 2004-02-23 | 松下電器産業株式会社 | 多重画像形成装置 |

| CN103831075B (zh) * | 2013-12-24 | 2016-08-17 | 北京化工大学 | 一种电机内置式超重力旋转床装置及其应用 |

| WO2015101826A1 (en) | 2013-12-31 | 2015-07-09 | Hindustan Petroleum Corporation Ltd. | Rotating packed bed unit |

| DK3071309T3 (en) | 2014-09-09 | 2019-01-14 | Hindustan Petroleum Corp Ltd | Rotating packed bed unit |

| CN104843946A (zh) * | 2015-05-14 | 2015-08-19 | 上海秀特化工科技有限公司 | 超重力湿法氧化反应器及其污水处理设备与方法 |

| CN106040159B (zh) * | 2016-07-13 | 2018-11-09 | 云南民族大学 | 一种超重力旋转填充床装置 |

| CN205761206U (zh) * | 2016-07-16 | 2016-12-07 | 吴一鸣 | 超重力旋转床用拼装式填料板 |

-

2017

- 2017-08-23 DE DE102017007861.0A patent/DE102017007861A1/de not_active Withdrawn

-

2018

- 2018-07-18 EP EP18000608.2A patent/EP3446764B1/de active Active

- 2018-07-25 TW TW107125764A patent/TWI791570B/zh active

- 2018-08-17 JP JP2018153457A patent/JP7189697B2/ja active Active

- 2018-08-21 US US16/106,713 patent/US10710100B2/en active Active

- 2018-08-22 CN CN201810957149.7A patent/CN109420357B/zh active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0089128A1 (en) * | 1982-03-12 | 1983-09-21 | Imperial Chemical Industries Plc | Process for displacing dissolved gas from water |

| US5363909A (en) * | 1991-11-27 | 1994-11-15 | Praxair Technology, Inc. | Compact contacting device |

| CN101125263A (zh) * | 2007-06-11 | 2008-02-20 | 刘辉 | 一种垂直式旋转床超重力场设备 |

| CN101596400A (zh) * | 2009-07-14 | 2009-12-09 | 薛碧 | 逆顺流水波纹环板填料超重力除尘脱硫机 |

| CN105148685A (zh) * | 2015-09-23 | 2015-12-16 | 中北大学 | 恒定通道式旋转填料床传质与反应设备 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3446764A1 (de) | 2019-02-27 |

| DE102017007861A1 (de) | 2019-02-28 |

| TWI791570B (zh) | 2023-02-11 |

| CN109420357A (zh) | 2019-03-05 |

| JP2019037972A (ja) | 2019-03-14 |

| EP3446764B1 (de) | 2019-11-20 |

| US20190060916A1 (en) | 2019-02-28 |

| JP7189697B2 (ja) | 2022-12-14 |

| US10710100B2 (en) | 2020-07-14 |

| TW201912227A (zh) | 2019-04-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109420357B (zh) | 传质机 | |

| JP2008008490A (ja) | セグメント間の「l」字形突合せギャップシールを備えるシール組立体及び回転機械 | |

| RU2017144769A (ru) | Узел венца диска турбины, поддерживаемый фланцами | |

| CN107110199A (zh) | 箔轴承、用于调节箔轴承的间隙几何形状的方法以及箔轴承的相应制造方法 | |

| RU2017123813A (ru) | Перистальтические насосы | |

| JP2018053752A (ja) | 真空ポンプ、および真空ポンプに備わる固定円板 | |

| CN109499087B (zh) | 传质机 | |

| JP2016191311A5 (zh) | ||

| JP2019037972A5 (zh) | ||

| JP2016011591A (ja) | 風車用回転駆動機構 | |

| JP2018531346A5 (zh) | ||

| JP5250201B2 (ja) | 真空ポンプ | |

| US3480148A (en) | Conical honeycomb structure | |

| JP6180358B2 (ja) | 円柱構造体及びモータ | |

| CN104895617B (zh) | 无扇叶涡轮发动机 | |

| CN208634254U (zh) | 一种螺旋弹簧 | |

| JP6751472B2 (ja) | 分割型の支持エレメント | |

| CN210531244U (zh) | 航空发动机压气机转子及减涡管 | |

| JP6655426B2 (ja) | 吸込ベルマウス及び立軸ポンプ、吸込ベルマウスの製造方法 | |

| JP5484948B2 (ja) | 回転流体機械 | |

| US10376947B2 (en) | Multiple wire wrap screen fabrication method | |

| CN108854445B (zh) | 热交换转轮及其制造方法 | |

| CN205336000U (zh) | 电机定子通风槽板 | |

| JP7090218B2 (ja) | シロッコファンの羽根車、それを用いたレンジフード | |

| JP2011527892A5 (zh) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |