CN102160192B - 使用直接图案化的无针孔掩膜层制作太阳能电池的方法 - Google Patents

使用直接图案化的无针孔掩膜层制作太阳能电池的方法 Download PDFInfo

- Publication number

- CN102160192B CN102160192B CN200980136212.XA CN200980136212A CN102160192B CN 102160192 B CN102160192 B CN 102160192B CN 200980136212 A CN200980136212 A CN 200980136212A CN 102160192 B CN102160192 B CN 102160192B

- Authority

- CN

- China

- Prior art keywords

- pinhole

- layer

- free

- patterned

- masking layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F77/00—Constructional details of devices covered by this subclass

- H10F77/20—Electrodes

- H10F77/206—Electrodes for devices having potential barriers

- H10F77/211—Electrodes for devices having potential barriers for photovoltaic cells

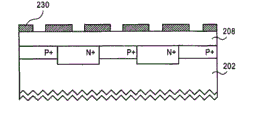

- H10F77/219—Arrangements for electrodes of back-contact photovoltaic cells

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/18—Working by laser beam, e.g. welding, cutting or boring using absorbing layers on the workpiece, e.g. for marking or protecting purposes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/362—Laser etching

- B23K26/364—Laser etching for making a groove or trench, e.g. for scribing a break initiation groove

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/36—Removing material

- B23K26/40—Removing material taking account of the properties of the material involved

- B23K26/402—Removing material taking account of the properties of the material involved involving non-metallic material, e.g. isolators

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/027—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34

- H01L21/0271—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers

- H01L21/0273—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers characterised by the treatment of photoresist layers

- H01L21/0274—Photolithographic processes

- H01L21/0275—Photolithographic processes using lasers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3105—After-treatment

- H01L21/311—Etching the insulating layers by chemical or physical means

- H01L21/31144—Etching the insulating layers by chemical or physical means using masks

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F10/00—Individual photovoltaic cells, e.g. solar cells

- H10F10/10—Individual photovoltaic cells, e.g. solar cells having potential barriers

- H10F10/14—Photovoltaic cells having only PN homojunction potential barriers

- H10F10/146—Back-junction photovoltaic cells, e.g. having interdigitated base-emitter regions on the back side

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/34—Coated articles, e.g. plated or painted; Surface treated articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/36—Electric or electronic devices

- B23K2101/40—Semiconductor devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/16—Composite materials, e.g. fibre reinforced

- B23K2103/166—Multilayered materials

- B23K2103/172—Multilayered materials wherein at least one of the layers is non-metallic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/50—Inorganic material, e.g. metals, not provided for in B23K2103/02 – B23K2103/26

- B23K2103/56—Inorganic material, e.g. metals, not provided for in B23K2103/02 – B23K2103/26 semiconducting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

- Y02E10/547—Monocrystalline silicon PV cells

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Manufacturing & Machinery (AREA)

- General Physics & Mathematics (AREA)

- Photovoltaic Devices (AREA)

- Drying Of Semiconductors (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/233,819 | 2008-09-19 | ||

| US12/233,819 US20100071765A1 (en) | 2008-09-19 | 2008-09-19 | Method for fabricating a solar cell using a direct-pattern pin-hole-free masking layer |

| PCT/US2009/050960 WO2010033296A1 (en) | 2008-09-19 | 2009-07-17 | Method for fabricating a solar cell using a direct-pattern pin-hole-free masking layer |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102160192A CN102160192A (zh) | 2011-08-17 |

| CN102160192B true CN102160192B (zh) | 2014-03-12 |

Family

ID=42036391

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN200980136212.XA Expired - Fee Related CN102160192B (zh) | 2008-09-19 | 2009-07-17 | 使用直接图案化的无针孔掩膜层制作太阳能电池的方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20100071765A1 (enExample) |

| EP (1) | EP2329529A4 (enExample) |

| JP (2) | JP2012503330A (enExample) |

| KR (1) | KR20110063546A (enExample) |

| CN (1) | CN102160192B (enExample) |

| WO (1) | WO2010033296A1 (enExample) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8324015B2 (en) * | 2009-12-01 | 2012-12-04 | Sunpower Corporation | Solar cell contact formation using laser ablation |

| US8211731B2 (en) * | 2010-06-07 | 2012-07-03 | Sunpower Corporation | Ablation of film stacks in solar cell fabrication processes |

| US8586403B2 (en) | 2011-02-15 | 2013-11-19 | Sunpower Corporation | Process and structures for fabrication of solar cells with laser ablation steps to form contact holes |

| US20140166094A1 (en) * | 2012-12-18 | 2014-06-19 | Paul Loscutoff | Solar cell emitter region fabrication using etch resistant film |

| US8936709B2 (en) | 2013-03-13 | 2015-01-20 | Gtat Corporation | Adaptable free-standing metallic article for semiconductors |

| US8916038B2 (en) | 2013-03-13 | 2014-12-23 | Gtat Corporation | Free-standing metallic article for semiconductors |

| US8569096B1 (en) * | 2013-03-13 | 2013-10-29 | Gtat Corporation | Free-standing metallic article for semiconductors |

| TWI643355B (zh) * | 2013-03-13 | 2018-12-01 | 美商梅林太陽能科技股份有限公司 | 用於半導體之自站立金屬物件(一) |

| CN105190903B (zh) * | 2013-03-15 | 2017-07-14 | 太阳能公司 | 太阳能电池降低的接触电阻及延长的寿命 |

| JP6058212B2 (ja) * | 2014-04-16 | 2017-01-11 | 三菱電機株式会社 | 太陽電池および太陽電池の製造方法 |

| US9461192B2 (en) | 2014-12-16 | 2016-10-04 | Sunpower Corporation | Thick damage buffer for foil-based metallization of solar cells |

| JP6425218B2 (ja) | 2015-03-24 | 2018-11-21 | パナソニックIpマネジメント株式会社 | 太陽電池セルの製造方法 |

| US10854767B2 (en) * | 2015-03-31 | 2020-12-01 | Kaneka Corporation | Solar cell and method for manufacturing same |

| US20160380127A1 (en) * | 2015-06-26 | 2016-12-29 | Richard Hamilton SEWELL | Leave-In Etch Mask for Foil-Based Metallization of Solar Cells |

| IT201900006740A1 (it) * | 2019-05-10 | 2020-11-10 | Applied Materials Inc | Procedimenti di strutturazione di substrati |

| KR102858844B1 (ko) * | 2020-11-24 | 2025-09-12 | 삼성디스플레이 주식회사 | 마스크, 마스크 제조 방법, 및 표시 패널 제조 방법 |

| CN117374169B (zh) | 2023-12-07 | 2024-03-12 | 浙江晶科能源有限公司 | 背接触太阳能电池的制备方法及背接触太阳能电池 |

| CN117673207B (zh) * | 2024-02-01 | 2024-05-14 | 通威太阳能(眉山)有限公司 | 一种太阳电池的制备方法、太阳电池及光伏组件 |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4353778A (en) * | 1981-09-04 | 1982-10-12 | International Business Machines Corporation | Method of etching polyimide |

| JPS6215864A (ja) * | 1985-07-15 | 1987-01-24 | Hitachi Ltd | 太陽電池の製造方法 |

| US5041361A (en) * | 1988-08-08 | 1991-08-20 | Midwest Research Institute | Oxygen ion-beam microlithography |

| JPH03285332A (ja) * | 1990-04-02 | 1991-12-16 | Ricoh Co Ltd | マスキングフィルム |

| JPH046121A (ja) * | 1990-04-23 | 1992-01-10 | Shin Etsu Chem Co Ltd | 光ファイバ用ガラス母材の製造方法 |

| JP2986875B2 (ja) * | 1990-09-07 | 1999-12-06 | キヤノン株式会社 | 集積化太陽電池 |

| WO1993018545A1 (en) * | 1992-03-10 | 1993-09-16 | Lasa Industries Inc. | Method of laser etching of silicon dioxide |

| US5759745A (en) * | 1995-12-05 | 1998-06-02 | Materials Research Group, Inc. | Method of using amorphous silicon as a photoresist |

| JP2005167291A (ja) * | 1996-12-20 | 2005-06-23 | Mitsubishi Electric Corp | 太陽電池の製造方法及び半導体装置の製造方法 |

| EP1705475B1 (en) * | 1997-12-15 | 2012-08-15 | Seiko Instruments Inc. | Optical waveguide probe and its manufacturing method |

| JPH11220101A (ja) * | 1998-01-30 | 1999-08-10 | Matsushita Electric Ind Co Ltd | 半導体装置及びその製造方法 |

| JP5121090B2 (ja) * | 2000-02-17 | 2013-01-16 | アプライド マテリアルズ インコーポレイテッド | アモルファスカーボン層の堆積方法 |

| US6696008B2 (en) * | 2000-05-25 | 2004-02-24 | Westar Photonics Inc. | Maskless laser beam patterning ablation of multilayered structures with continuous monitoring of ablation |

| US20020173157A1 (en) * | 2001-03-29 | 2002-11-21 | Taiwan Semiconductor Manufacturing Co., Ltd. | Dual damascene method employing composite low dielectric constant dielectric layer having intrinsic etch stop characteristics |

| EP1378947A1 (en) * | 2002-07-01 | 2004-01-07 | Interuniversitair Microelektronica Centrum Vzw | Semiconductor etching paste and the use thereof for localised etching of semiconductor substrates |

| US7388147B2 (en) * | 2003-04-10 | 2008-06-17 | Sunpower Corporation | Metal contact structure for solar cell and method of manufacture |

| US7122392B2 (en) * | 2003-06-30 | 2006-10-17 | Intel Corporation | Methods of forming a high germanium concentration silicon germanium alloy by epitaxial lateral overgrowth and structures formed thereby |

| JP2005136062A (ja) * | 2003-10-29 | 2005-05-26 | Sharp Corp | 太陽電池の製造方法 |

| US20050151129A1 (en) * | 2004-01-14 | 2005-07-14 | Rahul Gupta | Deposition of conducting polymers |

| JP2006080450A (ja) * | 2004-09-13 | 2006-03-23 | Sharp Corp | 太陽電池の製造方法 |

| DE102004050269A1 (de) * | 2004-10-14 | 2006-04-20 | Institut Für Solarenergieforschung Gmbh | Verfahren zur Kontakttrennung elektrisch leitfähiger Schichten auf rückkontaktierten Solarzellen und Solarzelle |

| EP1763086A1 (en) * | 2005-09-09 | 2007-03-14 | Interuniversitair Micro-Elektronica Centrum | Photovoltaic cell with thick silicon oxide and silicon nitride passivation and fabrication method |

| US7737357B2 (en) * | 2006-05-04 | 2010-06-15 | Sunpower Corporation | Solar cell having doped semiconductor heterojunction contacts |

| GB0612754D0 (en) * | 2006-06-27 | 2006-08-09 | Univ Cambridge Tech | Semiconductor device transducer and method |

| JP5329784B2 (ja) * | 2006-08-25 | 2013-10-30 | 株式会社半導体エネルギー研究所 | 半導体装置の作製方法 |

| KR101241617B1 (ko) * | 2006-12-01 | 2013-03-08 | 샤프 가부시키가이샤 | 태양 전지 및 그 제조 방법 |

| JP4630294B2 (ja) * | 2007-01-29 | 2011-02-09 | シャープ株式会社 | 光電変換装置及びその製造方法 |

| US20080314443A1 (en) * | 2007-06-23 | 2008-12-25 | Christopher Michael Bonner | Back-contact solar cell for high power-over-weight applications |

| US7517709B1 (en) * | 2007-11-16 | 2009-04-14 | Applied Materials, Inc. | Method of forming backside point contact structures for silicon solar cells |

-

2008

- 2008-09-19 US US12/233,819 patent/US20100071765A1/en not_active Abandoned

-

2009

- 2009-07-17 WO PCT/US2009/050960 patent/WO2010033296A1/en not_active Ceased

- 2009-07-17 KR KR1020117008770A patent/KR20110063546A/ko not_active Ceased

- 2009-07-17 JP JP2011527849A patent/JP2012503330A/ja active Pending

- 2009-07-17 CN CN200980136212.XA patent/CN102160192B/zh not_active Expired - Fee Related

- 2009-07-17 EP EP09814940.4A patent/EP2329529A4/en not_active Withdrawn

-

2013

- 2013-11-13 JP JP2013235039A patent/JP2014060430A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014060430A (ja) | 2014-04-03 |

| JP2012503330A (ja) | 2012-02-02 |

| WO2010033296A1 (en) | 2010-03-25 |

| US20100071765A1 (en) | 2010-03-25 |

| EP2329529A1 (en) | 2011-06-08 |

| KR20110063546A (ko) | 2011-06-10 |

| CN102160192A (zh) | 2011-08-17 |

| EP2329529A4 (en) | 2017-10-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102160192B (zh) | 使用直接图案化的无针孔掩膜层制作太阳能电池的方法 | |

| US7670638B2 (en) | Protection layer for fabricating a solar cell | |

| US10490685B2 (en) | Solar cell having an emitter region with wide bandgap semiconductor material | |

| CN105794004A (zh) | 制造具有区分开的p型和n型区架构的太阳能电池发射极区 | |

| JP2005310830A (ja) | 太陽電池および太陽電池の製造方法 | |

| TW201528344A (zh) | 使用離子佈植製造的太陽電池射極區域 | |

| US11245047B2 (en) | Method of manufacturing solar cell | |

| TWI647863B (zh) | 使用自對準植入體及覆蓋體之太陽能電池射極區之製備 | |

| KR101768907B1 (ko) | 태양 전지 제조 방법 | |

| US20160072001A1 (en) | Method for fabricating crystalline photovoltaic cells | |

| CN106133916A (zh) | 太阳能电池光接收表面的钝化 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20140312 Termination date: 20170717 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |