CN101463472B - 沉积设备和沉积方法 - Google Patents

沉积设备和沉积方法 Download PDFInfo

- Publication number

- CN101463472B CN101463472B CN2008101856447A CN200810185644A CN101463472B CN 101463472 B CN101463472 B CN 101463472B CN 2008101856447 A CN2008101856447 A CN 2008101856447A CN 200810185644 A CN200810185644 A CN 200810185644A CN 101463472 B CN101463472 B CN 101463472B

- Authority

- CN

- China

- Prior art keywords

- electrode

- heat transfer

- control heat

- hot

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000008021 deposition Effects 0.000 title claims abstract description 88

- 238000000151 deposition Methods 0.000 title claims description 120

- 238000012546 transfer Methods 0.000 claims abstract description 118

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 86

- 238000001816 cooling Methods 0.000 claims description 76

- 239000010432 diamond Substances 0.000 claims description 67

- 229910003460 diamond Inorganic materials 0.000 claims description 66

- 229910052799 carbon Inorganic materials 0.000 claims description 64

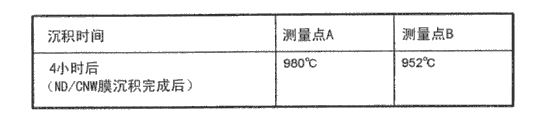

- 238000005259 measurement Methods 0.000 claims description 50

- 238000000034 method Methods 0.000 claims description 32

- 230000008569 process Effects 0.000 claims description 19

- 239000000463 material Substances 0.000 claims description 16

- 230000015572 biosynthetic process Effects 0.000 claims description 15

- 229910002804 graphite Inorganic materials 0.000 claims description 15

- 239000010439 graphite Substances 0.000 claims description 15

- 238000012545 processing Methods 0.000 claims description 15

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 claims description 11

- 229910052750 molybdenum Inorganic materials 0.000 claims description 11

- 239000011733 molybdenum Substances 0.000 claims description 11

- 229910021389 graphene Inorganic materials 0.000 claims description 8

- 238000009529 body temperature measurement Methods 0.000 claims description 3

- 239000012530 fluid Substances 0.000 claims 21

- 239000013543 active substance Substances 0.000 claims 3

- 239000000758 substrate Substances 0.000 description 147

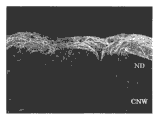

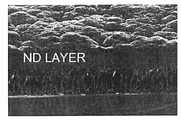

- 239000002113 nanodiamond Substances 0.000 description 54

- 239000011149 active material Substances 0.000 description 28

- 239000007789 gas Substances 0.000 description 28

- 238000001228 spectrum Methods 0.000 description 22

- 239000001307 helium Substances 0.000 description 16

- 229910052734 helium Inorganic materials 0.000 description 16

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 16

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 13

- 238000009826 distribution Methods 0.000 description 12

- 239000002105 nanoparticle Substances 0.000 description 11

- 230000005855 radiation Effects 0.000 description 11

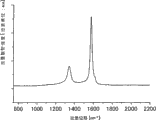

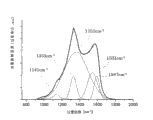

- 238000001237 Raman spectrum Methods 0.000 description 7

- 238000002441 X-ray diffraction Methods 0.000 description 7

- 239000002826 coolant Substances 0.000 description 7

- 230000002093 peripheral effect Effects 0.000 description 7

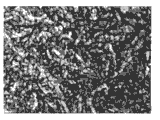

- 230000003746 surface roughness Effects 0.000 description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 6

- 239000013078 crystal Substances 0.000 description 6

- 239000002245 particle Substances 0.000 description 6

- 230000003595 spectral effect Effects 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 239000010949 copper Substances 0.000 description 5

- 230000005684 electric field Effects 0.000 description 5

- 230000007246 mechanism Effects 0.000 description 5

- 238000005268 plasma chemical vapour deposition Methods 0.000 description 5

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 4

- 238000005229 chemical vapour deposition Methods 0.000 description 4

- 150000001875 compounds Chemical class 0.000 description 4

- 239000000112 cooling gas Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 229910052739 hydrogen Inorganic materials 0.000 description 4

- 239000001257 hydrogen Substances 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 3

- 238000000295 emission spectrum Methods 0.000 description 3

- 239000010931 gold Substances 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 2

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 2

- 235000017166 Bambusa arundinacea Nutrition 0.000 description 2

- 235000017491 Bambusa tulda Nutrition 0.000 description 2

- 241001330002 Bambuseae Species 0.000 description 2

- UXVMQQNJUSDDNG-UHFFFAOYSA-L Calcium chloride Chemical compound [Cl-].[Cl-].[Ca+2] UXVMQQNJUSDDNG-UHFFFAOYSA-L 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- 235000015334 Phyllostachys viridis Nutrition 0.000 description 2

- 238000001069 Raman spectroscopy Methods 0.000 description 2

- 239000011425 bamboo Substances 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 239000012141 concentrate Substances 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

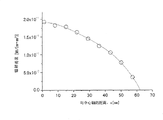

- 230000007423 decrease Effects 0.000 description 2

- 238000005137 deposition process Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 229910052759 nickel Inorganic materials 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 230000007723 transport mechanism Effects 0.000 description 2

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910003481 amorphous carbon Inorganic materials 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 239000001110 calcium chloride Substances 0.000 description 1

- 229910001628 calcium chloride Inorganic materials 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 125000004432 carbon atom Chemical group C* 0.000 description 1

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 1

- 239000003575 carbonaceous material Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- RKTYLMNFRDHKIL-UHFFFAOYSA-N copper;5,10,15,20-tetraphenylporphyrin-22,24-diide Chemical compound [Cu+2].C1=CC(C(=C2C=CC([N-]2)=C(C=2C=CC=CC=2)C=2C=CC(N=2)=C(C=2C=CC=CC=2)C2=CC=C3[N-]2)C=2C=CC=CC=2)=NC1=C3C1=CC=CC=C1 RKTYLMNFRDHKIL-UHFFFAOYSA-N 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000010891 electric arc Methods 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 230000016507 interphase Effects 0.000 description 1

- -1 iron group metals Chemical class 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 239000003058 plasma substitute Substances 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 238000010926 purge Methods 0.000 description 1

- 229910052761 rare earth metal Inorganic materials 0.000 description 1

- 150000002910 rare earth metals Chemical class 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000000523 sample Substances 0.000 description 1

- 239000003566 sealing material Substances 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

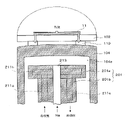

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

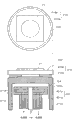

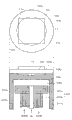

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/458—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for supporting substrates in the reaction chamber

- C23C16/4582—Rigid and flat substrates, e.g. plates or discs

- C23C16/4583—Rigid and flat substrates, e.g. plates or discs the substrate being supported substantially horizontally

- C23C16/4586—Elements in the interior of the support, e.g. electrodes, heating or cooling devices

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/26—Deposition of carbon only

- C23C16/27—Diamond only

- C23C16/272—Diamond only using DC, AC or RF discharges

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/46—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for heating the substrate

- C23C16/463—Cooling of the substrate

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/50—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges

- C23C16/503—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges using DC or AC discharges

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/52—Controlling or regulating the coating process

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Metallurgy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Inorganic Chemistry (AREA)

- Chemical Vapour Deposition (AREA)

- Plasma Technology (AREA)

- Carbon And Carbon Compounds (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP325303/2007 | 2007-12-17 | ||

| JP2007325303A JP4533925B2 (ja) | 2007-12-17 | 2007-12-17 | 成膜装置及び成膜方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101463472A CN101463472A (zh) | 2009-06-24 |

| CN101463472B true CN101463472B (zh) | 2012-01-11 |

Family

ID=40753798

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2008101856447A Expired - Fee Related CN101463472B (zh) | 2007-12-17 | 2008-12-17 | 沉积设备和沉积方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7935548B2 (enExample) |

| JP (1) | JP4533925B2 (enExample) |

| KR (1) | KR101120590B1 (enExample) |

| CN (1) | CN101463472B (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102471883A (zh) * | 2009-07-14 | 2012-05-23 | 赫姆洛克半导体公司 | 抑制沉积物在制造系统中的形成的方法 |

| US8840693B2 (en) | 2010-10-29 | 2014-09-23 | Baker Hughes Incorporated | Coated particles and related methods |

| MX2013004563A (es) | 2010-10-29 | 2013-12-02 | Baker Hughes Inc | Particulas de diamante recubiertas con grafeno, composiciones y estructuras intermedias que comprenden las mismas, y metodos para formar particulas de diamante recubiertas con grafeno y compactos policristalinos. |

| DE102011009347B4 (de) * | 2010-11-29 | 2016-05-12 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zur Herstellung eines kohlenstoffhaltigen Schichtsystems sowie Vorrichtung zur Durchführung des Verfahrens |

| CN102367570B (zh) * | 2011-11-01 | 2014-11-19 | 南昌航空大学 | 一种制备金刚石-石墨烯复合膜的方法 |

| CN102517633B (zh) * | 2011-12-26 | 2015-05-20 | 常州二维碳素科技有限公司 | 一种生长石墨烯的支架及方法 |

| DE102012205616B4 (de) * | 2012-04-04 | 2016-07-14 | Siltronic Ag | Vorrichtung zum Abscheiden einer Schicht auf einer Halbleiterscheibe mittels Gasphasenabscheidung |

| US20150197852A1 (en) * | 2014-01-13 | 2015-07-16 | Taiwan Semiconductor Manufacturing Co., Ltd. | Plasma processing apparatus and plasma-uniformity control method |

| CN104809343B (zh) * | 2015-04-23 | 2018-09-14 | 西安理工大学 | 一种等离子体中使用电流密度卷积完全匹配层的实现方法 |

| EP3423813B1 (en) * | 2016-03-04 | 2022-03-02 | VG Systems Limited | Xps and raman sample analysis system and method |

| US10535499B2 (en) * | 2017-11-03 | 2020-01-14 | Varian Semiconductor Equipment Associates, Inc. | Varied component density for thermal isolation |

| WO2021091786A1 (en) * | 2019-11-04 | 2021-05-14 | Applied Materials, Inc. | Systems and methods for substrate support temperature control |

| CN111647879A (zh) * | 2020-04-20 | 2020-09-11 | 中国科学技术大学 | 一种化学气相沉积装置与方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6631692B1 (en) * | 1999-03-18 | 2003-10-14 | Asm Japan K.K. | Plasma CVD film-forming device |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0460552U (enExample) * | 1990-09-28 | 1992-05-25 | ||

| JP3817414B2 (ja) * | 2000-08-23 | 2006-09-06 | 株式会社日立製作所 | 試料台ユニットおよびプラズマ処理装置 |

| JP4409373B2 (ja) * | 2004-06-29 | 2010-02-03 | 日本碍子株式会社 | 基板載置装置及び基板温度調整方法 |

| JP4869610B2 (ja) * | 2005-03-17 | 2012-02-08 | 東京エレクトロン株式会社 | 基板保持部材及び基板処理装置 |

| US7418921B2 (en) | 2005-08-12 | 2008-09-02 | Asm Japan K.K. | Plasma CVD apparatus for forming uniform film |

| JP5161450B2 (ja) * | 2005-09-30 | 2013-03-13 | 財団法人高知県産業振興センター | プラズマcvd装置及びプラズマ表面処理方法 |

-

2007

- 2007-12-17 JP JP2007325303A patent/JP4533925B2/ja not_active Expired - Fee Related

-

2008

- 2008-12-15 US US12/334,832 patent/US7935548B2/en not_active Expired - Fee Related

- 2008-12-17 CN CN2008101856447A patent/CN101463472B/zh not_active Expired - Fee Related

- 2008-12-17 KR KR1020080128842A patent/KR101120590B1/ko not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6631692B1 (en) * | 1999-03-18 | 2003-10-14 | Asm Japan K.K. | Plasma CVD film-forming device |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101463472A (zh) | 2009-06-24 |

| JP2009144224A (ja) | 2009-07-02 |

| US20090155934A1 (en) | 2009-06-18 |

| JP4533925B2 (ja) | 2010-09-01 |

| KR101120590B1 (ko) | 2012-03-09 |

| KR20090065472A (ko) | 2009-06-22 |

| US7935548B2 (en) | 2011-05-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101463472B (zh) | 沉积设备和沉积方法 | |

| CN101469417B (zh) | 沉积设备和沉积方法 | |

| JP5692794B2 (ja) | 透明導電性炭素膜の製造方法 | |

| US9074278B2 (en) | Carbon film laminate | |

| TWI401999B (zh) | A soft X-ray generating device and a de-energizing device | |

| CN101016624B (zh) | 等离子体化学气相沉积装置及等离子体表面处理方法 | |

| WO2012108526A1 (ja) | グラフェンの製造方法およびグラフェン | |

| Sankaran et al. | Microplasma illumination enhancement of vertically aligned conducting ultrananocrystalline diamond nanorods | |

| US8035291B2 (en) | Field emission electrode, manufacturing method thereof, and electronic device | |

| WO2013003083A1 (en) | Method of growing graphene nanocrystalline layers | |

| US20130337195A1 (en) | Method of growing graphene nanocrystalline layers | |

| Zheng et al. | Transmission-type window of HFCVD diamond film for microfocus X-ray tube | |

| Uonis et al. | The effect of carbon rod—specimens distance on the structural and electrical properties of carbon nanotube | |

| Haque | Fabrication of Diamond and Q-Carbon by Ultrafast Nanosecond Pulsed Laser Processing and Chemical Vapor Deposition for Electron Field Emission and Electrocatalysis Applications | |

| Qiao et al. | Synthesis Of Graphene/Diamond Double-Layered Structure For Improving Electron Field Emission Properties | |

| JP2024540405A (ja) | 対象となる基板上にグラフェン又は酸化グラフェンを直接堆積させる方法 | |

| Dzbanovsky et al. | The aligned Si nanowires growth using MW plasma enhanced CVD | |

| He et al. | Electron field emission from nano-crystalline Si films deposited by inductively coupled plasma CVD at room temperature | |

| Lu | Field electron emission from diamond and related films synthesized by plasma enhanced chemical vapor deposition | |

| KAMATCHI JOTHIRAMALINGAM et al. | Hierarchical hexagonal boron nitride nanowall-diamond nanorod heterostructures with enhanced optoelectronic performance | |

| Janssen | Deposition and characterization of doped nanocrystalline diamond films and particles-toward applications in energy converters | |

| HK1109958B (en) | Field emission electrode, manufacturing method thereof, and electronic device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120111 Termination date: 20151217 |

|

| EXPY | Termination of patent right or utility model |