CN100449030C - 具有线性BH回线的非晶形Fe基金属合金 - Google Patents

具有线性BH回线的非晶形Fe基金属合金 Download PDFInfo

- Publication number

- CN100449030C CN100449030C CNB038078171A CN03807817A CN100449030C CN 100449030 C CN100449030 C CN 100449030C CN B038078171 A CNB038078171 A CN B038078171A CN 03807817 A CN03807817 A CN 03807817A CN 100449030 C CN100449030 C CN 100449030C

- Authority

- CN

- China

- Prior art keywords

- alloy

- iron

- magnetic field

- atom

- amorphous iron

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/08—Ferrous alloys, e.g. steel alloys containing nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/10—Ferrous alloys, e.g. steel alloys containing cobalt

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/14—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys

- H01F1/147—Alloys characterised by their composition

- H01F1/153—Amorphous metallic alloys, e.g. glassy metals

- H01F1/15308—Amorphous metallic alloys, e.g. glassy metals based on Fe/Ni

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/14—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys

- H01F1/147—Alloys characterised by their composition

- H01F1/153—Amorphous metallic alloys, e.g. glassy metals

- H01F1/15341—Preparation processes therefor

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Dispersion Chemistry (AREA)

- Power Engineering (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Soft Magnetic Materials (AREA)

Abstract

金属玻璃合金带基本上由约70-87原子%的铁组成。高达约20原子%的铁被钴所取代,高达约3原子%的铁被镍、锰、钒、钛、或钼所取代。约13-30原子%的其余元素包括选自硼、硅、和碳的一些元素。该合金在足以消除其应力的温度下进行热处理。在热处理过程中,外加的磁场使远离带预定的容易磁化的方向的地方发生磁化。金属玻璃具有线性的直流BH回线以及低的交流损耗。因此,它们特别适合在电流/电压变换器中使用。

Description

发明背景

1.发明领域:

本发明涉及铁磁性的非晶形金属合金;更具体而言,涉及使合金退火的方法,使其对外加磁场的磁化曲线是线性的。

2.对现有技术的说明:

金属玻璃是没有长范围顺序的亚稳态材料。非晶形金属合金的X-射线衍射扫描,只出现与对无机氧化物玻璃观测到的相似的扩散晕。在US-3,856,513中已经公开了金属玻璃(非晶形的金属合金)。这些合金包括化学式为MaYbZc的组合物,式中M是选自铁、镍、钴、钒、和铬的金属,Y是选自磷、硼、和碳的元素,Z是选自铝、硅、锡、锗、铟、锑、和铍的元素,“a”为约60-90原子%,“b”为约10-30原子%,和“c”为约0.1-15原子%。其中还公开了具有化学式TiXj的金属玻璃丝,其中T是至少一种过渡金属,X是选自磷、硼、碳、铝、硅、锡、锗、铟、铍、和锑的元素,“i”为约70-87原子%,“j”为约13-30原子%。所述的材料适合采用本领域众所周知的加工技术,以约1×106℃/s的速率迅速从熔融体冷却制备。

这些公开内容还提到许多金属玻璃不寻常的或独特的磁性质,它们都落入广泛的权利要求的范围内。然而,对于电流/电压变换器等一些具体的应用,需要兼有线性磁滞回线(BH loop)和低损耗的金属玻璃的组合。

线性B-H特性一般是用软磁性材料获得的,其中材料容易磁化的轴与激磁方向垂直。在这些材料中,外部磁场H往往向磁通量B的平均方向倾斜,所以测定的B量与H成比例。然而,大多数的磁性材料都具有非线性的B-H特性。因此,不容易获得理想的线性B-H特性。与理想B-H线性的偏离,引起对外加磁场H磁性响应的相应偏离。

具有线性B-H特性的磁性材料的传统实例,是称作恒导磁率合金(Isoperm)的50%Fe-Ni冷轧合金。在非晶形的磁性合金中,已知热处理过的富Co合金能提供线性的B-H特性,目前在电流变换器中用作磁芯材料。非晶形富Co合金的饱和磁感应强度一般低于约10kG或1Tesla(泰斯拉),这限制了施加的最高磁场强度。然而,由于形成这些合金需要大量的Co,所以这些合金很昂贵。目前显然需要饱和磁感应强度高于10kG又具有线性B-H特性的便宜合金。

发明概述

本发明提供一种提高金属玻璃合金磁性能的方法,该合金兼有线性BH回线和低磁芯损耗。一般认为,金属玻璃基本上由约70-87原子%的铁,以及任选的取代高达约20原子%铁的钴,任选的取代高达约3原子%铁的至少一种镍、锰、钒、钛、或钼,和约13-30原子%选自硼、硅、和碳的一些元素组成。该方法包括金属玻璃合金的热处理步骤,热处理的时间和温度足以达到消除应力和远离带轴(ribbon axis)的磁化取向。在本发明的一个方面,该方法是在无磁场的情况下进行的。在本发明的另一个方面,该方法包括在外加磁场存在下进行的步骤,外加磁场的方向与带轴垂直。

按照本发明方法处理的金属玻璃合金,特别适合用于需要对磁场产生线性响应的装置,例如对于计量使用的电流/电压变换器。

附图简述

参照下面的详细说明和附图会更充分地理解本发明,本发明的其它优点也会变得显而易见了。图中相同的数字表示几个图中相同的元件,图中:

图1是描述本发明非晶形的Fe-B-Si基合金的B-H特性曲线;

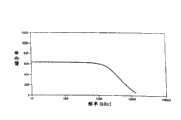

图2是描述图1起频率作用的非晶形Fe基合金的磁导率曲线;

图3是描述在没有外加磁场的情况下,在420℃热处理6.5h的本发明非晶形的Fe基合金B-H特性的曲线。

发明详述

本发明金属玻璃合金的热处理能提高该合金的磁性能。更具体而言,当按照本发明热处理时,金属玻璃合金会具有下列性质的优良组合:线性的BH回线和低的交流磁芯损耗。该合金基本上由约70-87原子%的铁,以及取代所存在的高达约20原子%铁的钴、取代高达约3原子%铁的至少一种镍、锰、钒、钛、或钼,和选自硼、硅、和碳的其余元素组成。热处理方法包括下列步骤:(a)将合金加热到足以消除应力的温度;(b)至少在冷却步骤中给合金施加磁场,磁场的方向与带轴垂直。冷却步骤一般是在冷却速率约-0.5℃/min--100℃/min,优选在约-0.5℃/min--20℃/min下进行的。在无外加磁场的情况下进行热处理,一般会获得非线性的BH回线。然而,部分结晶能产生局部磁场,它起外加磁场的作用。对于小的激磁作用,这也会获得线性的B-H特性。当出现这种情况时,沿着垂直带轴方向施加横向磁场就变成任选了。

一般都知道形成金属玻璃合金的过程会产生铸造应力。由金属玻璃合金制造磁性器械的过程可能产生另一些应力。因此,优选将金属玻璃合金加热并保持到足以消除这些应力的温度和时间。在热处理过程中施加磁场能促进在施加磁场的方向上形成磁学各向异性。当合金处于下列温度时磁场是特别有效的:(i)接近居里温度或达到低于居里温度50℃,和(ii)温度高到足以使其组成发生原子扩散或重排。

在横向上施加磁场,所述的横向定义为与操作过程中的激磁方向垂直的方向。当磁性器械是绕制的环形线圈时,将连续的金属玻璃带绕制在其本身上。对于所述的环形线圈,横向与环形线圈的轴平行。将环形线圈同轴放在永久磁体或电磁体的二个极之间,或将环形线圈同轴放在被适宜电流激磁的螺线管内,能方便地施加横向磁场。

本发明金属玻璃优选的热处理温度(T)和热处理持续时间(t)取决于合金的组成。T一般为约300-450℃,t是1-10h。

提高本发明合金磁性能的方法的另一个特性,是热处理过程中外加磁场的方向。

优选的方法包括在横向磁场存在下进行热处理,任选在混合磁场存在下进行热处理,混合磁场具有在横向上施加的第一种成分和在纵向上施加的第二种成分。当在横向磁场存在下进行热处理时,磁场强度为50-2,000 Oe(4,000-160,000A/m)。获得的材料具有线性BH回线和低磁芯损耗的特性。采用所述退火的材料制造的磁芯,特别适合电流/电压变换器等应用,用于测量交流磁场的强度。不变的磁导率或线性的BH回线,使电流/电压变换器等装置能在很宽的外加磁场范围内提供线性输出。

给出下列实施例以供更全面地了解本发明。为了说明本发明的基本原理和实际应用,所述的具体技术、条件、材料、比例、和所报告的数据都是示范性的,应当认为它们并不限制本发明的范围。

实施例

实施例1

非晶形的铁基合金

本发明非晶形的铁基合金厚度约15-30μm,是采用快速固化技术铸造的。磁性螺线管是采用带或纵切的带绕制的,在箱式炉(box oven)中进行热处理。横向磁场是将环形线圈按轴向放在二个永久磁体的磁极之间,或将环形线圈放在具有所需电流的螺线管内产生的。

将非晶形的铁基合金带绕制成环形线圈的形状,制成磁性的环形线圈。然后使环形线圈在炉中进行热处理,炉中具有沿环形线圈轴向的磁场。然后采用在市场上购买的BH磁滞曲线绘制仪(hysteresigraph)检测环形线圈,查明B-H的线性关系,其中B和H分别表示磁感应强度和磁场强度。图1比较了按照本发明制备的非晶形铁基磁芯和现有技术非晶形的Co基合金环形线圈的B-H特性。本发明的磁芯在400℃下热处理10h,外加的16,000A/m磁场与环形线圈环面的方向垂直。在外加磁场强度为约-15Oe(-1,200A/m)-+15Oe(+1,200A/m),相应的磁感应强度或磁通量的变化为-12kG(-1.2T)-+12kG(+1.2T)的范围内,本发明磁芯的B-H特性是线性的。另一方面,现有技术Co基磁芯B-H的线性区域,被限制在磁通量的变化为约-7kG(-0.7T)-+7kG(+0.7T),这限制了磁响应的能力。B-H的线性特性系指由B/H定义的磁导率是线性的。图2示出,直至频率高达约1000kHz或1MHz,本发明的非晶形Fe基合金的磁导率是不变的。这意味着在高达约1000kHz的整个频率范围内,本发明的非晶形Fe基合金的磁响应都可保持在一定的水平上。

已经发现,对小于约3Oe(240A/m)的外部磁场,采用图3所示部分结晶的非晶形Fe基合金的磁芯,得到线性的B-H特性。在这种情况下,在热处理过程中的磁场是任选的。这种磁芯能提供对低水平电流灵敏的电流变换器。

在表I中列出非晶形Fe基合金直流磁导率的典型实例,其中Fe-B-Si基环形线圈形状磁芯试样的尺寸为外径=13.0mm,内径=9.5mm,高度=4.8mm,Fe-B-Si-C基磁芯的尺寸为外径=25.5mm,内径=16.5mm,高度=9.5mm。Fe-B-Si和Fe-B-Si-C基合金的饱和磁感应强度分别为1.56和1.60T。

表I

实施例2

试样的制备

按照Chen等人在US-3,856,513中所述的技术,采用约106K/s的冷却速率,使非晶形合金从熔融体迅速退火。获得的带厚度一般为10-30μm,宽度约1cm-约20cm,采用X-射线衍射方法(采用Cu-Kα辐射)和差式扫描量热法,确定获得的带无值得注意的结晶度。带状的非晶形合金是坚固的、有光泽的、硬质的、和有延展性的。

将如此生产的带纵切成较窄的带,然后将其绕制成不同尺寸的环形线圈形状。环形线圈在有或没有磁场的情况下在炉中进行热处理,温度为300-450℃。当在热处理过程中施加磁场时,磁场的方向沿着环形线圈环面方向的横向。典型的磁场强度是50-2,000Oe(4,000-160,000A/m)。

磁性的测定

采用常规的BH磁滞曲线绘制仪,检测按照实施例2制备的磁性环形线圈,获得B-H特性。对起频率作用的环形线圈测定义为B/H的磁导率,磁导率以曲线的形式示于图2。

至此已经更详细地叙述了本发明,本领域的技术人员应当理解,这些细节没有必要被严格地附上,而可以对它们本身提出各种变更和改进,这些变更和改进全部都落在所附权利要求规定的本发明的范围内。

Claims (9)

1.一种非晶形铁基合金,其基本上由下述成分组成:70-87原子%的铁,至多20原子%的铁被钴代替,至多3原子%的铁被镍、锰、钒、钛或钼代替,以及存在的13-30原子%的其余元素为选自硼、硅和碳中的元素,将所述的合金进行热处理,以产生在外加磁场强度范围为-15Oe至+15Oe时线性的BH特性和低的磁芯损耗。

2.权利要求1所述的非晶形铁基合金,其饱和磁感应强度超过10kG或1Tesla。

3.权利要求1所述的非晶形铁基合金,所述的合金是带状的,具有预定的容易磁化的方向,

所述合金在磁场中进行热处理,所述磁场的幅度为50Oe(4,000A/m)至2,000Oe(160,000A/m),并且施加所述的磁场与所述带的预定的容易磁化的方向垂直。

4.权利要求1所述的非晶形铁基合金,所述的合金热处理在温度接近合金的居里温度下进行。

5.权利要求4所述的非晶形铁基合金,所述的合金热处理在温度高到足以使其组成发生原子扩散或重排的温度下进行。

6.一种非晶形铁基合金,其基本上由下述成分组成:70-87原子%的铁,至多20原子%的铁被钴代替,至多3原子%的铁被镍、锰、钒、钛或钼代替,存在的13-30原子%的其余元素为选自硼、硅和碳中的元素,所述的合金在磁场存在下进行热处理,以产生在外加磁场强度范围为-15Oe至+15Oe时线性的BH特性和低的磁芯损耗。

7.权利要求6所述的非晶形铁基合金,其饱和磁感应强度超过10kG或1Tesla。

8.权利要求6所述的非晶形铁基合金,所述的合金热处理在温度接近合金的居里温度进行。

9.权利要求8所述的非晶形铁基合金,所述的合金热处理在高到足以使其组成发生原子扩散或重排的温度进行。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/071,990 | 2002-02-08 | ||

| US10/071,990 US6749695B2 (en) | 2002-02-08 | 2002-02-08 | Fe-based amorphous metal alloy having a linear BH loop |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1646719A CN1646719A (zh) | 2005-07-27 |

| CN100449030C true CN100449030C (zh) | 2009-01-07 |

Family

ID=27659365

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB038078171A Expired - Fee Related CN100449030C (zh) | 2002-02-08 | 2003-02-03 | 具有线性BH回线的非晶形Fe基金属合金 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US6749695B2 (zh) |

| EP (1) | EP1472384A2 (zh) |

| JP (2) | JP2005520931A (zh) |

| KR (1) | KR101057463B1 (zh) |

| CN (1) | CN100449030C (zh) |

| AU (1) | AU2003217302A1 (zh) |

| HK (1) | HK1081238A1 (zh) |

| TW (1) | TWI271439B (zh) |

| WO (1) | WO2003066925A2 (zh) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6749695B2 (en) * | 2002-02-08 | 2004-06-15 | Ronald J. Martis | Fe-based amorphous metal alloy having a linear BH loop |

| US6946096B2 (en) * | 2002-05-03 | 2005-09-20 | Honeywell International, Inc. | Use of powder metal sintering/diffusion bonding to enable applying silicon carbide or rhenium alloys to face seal rotors |

| US7056595B2 (en) * | 2003-01-30 | 2006-06-06 | Metglas, Inc. | Magnetic implement using magnetic metal ribbon coated with insulator |

| JP6346440B2 (ja) | 2010-07-21 | 2018-06-20 | ロレックス・ソシエテ・アノニムRolex Sa | アモルファス金属合金 |

| JP6346441B2 (ja) | 2010-07-21 | 2018-06-20 | ロレックス・ソシエテ・アノニムRolex Sa | アモルファス金属合金を含む時計部品 |

| US8968490B2 (en) * | 2010-09-09 | 2015-03-03 | Metglas, Inc. | Ferromagnetic amorphous alloy ribbon with reduced surface protrusions, method of casting and application thereof |

| KR101522879B1 (ko) * | 2012-05-30 | 2015-05-26 | (주)제이엠씨 | 고경도 철계 비정질 소재의 조성 및 제조 방법 |

| CN103484747A (zh) * | 2013-05-28 | 2014-01-01 | 江苏迈盛新材料有限公司 | 一种制备具有超软铁磁性能的铁基非晶合金的方法 |

| US10316396B2 (en) * | 2015-04-30 | 2019-06-11 | Metglas, Inc. | Wide iron-based amorphous alloy, precursor to nanocrystalline alloy |

| CN104801708A (zh) * | 2015-05-15 | 2015-07-29 | 福建农林大学 | 一种粉末冶金用全金属组元铁基非晶态合金粉末及其制备 |

| EP3426806B1 (en) * | 2016-03-10 | 2024-05-15 | Tata Steel Limited | A method for heat treating an iron-carbon alloy |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5110378A (en) * | 1988-08-17 | 1992-05-05 | Allied-Signal Inc. | Metallic glasses having a combination of high permeability, low coercivity, low ac core loss, low exciting power and high thermal stability |

| US5841348A (en) * | 1997-07-09 | 1998-11-24 | Vacuumschmelze Gmbh | Amorphous magnetostrictive alloy and an electronic article surveillance system employing same |

| JPH10324961A (ja) * | 1997-05-26 | 1998-12-08 | Kawasaki Steel Corp | 軟磁気特性に優れた鉄基非晶質合金薄帯およびその製造方法 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3856513A (en) | 1972-12-26 | 1974-12-24 | Allied Chem | Novel amorphous metals and amorphous metal articles |

| DE2924280A1 (de) | 1979-06-15 | 1981-01-08 | Vacuumschmelze Gmbh | Amorphe weichmagnetische legierung |

| US4409041A (en) | 1980-09-26 | 1983-10-11 | Allied Corporation | Amorphous alloys for electromagnetic devices |

| JPS57202709A (en) * | 1981-06-08 | 1982-12-11 | Hitachi Metals Ltd | Magnetic material and manufacture therefor |

| US4473413A (en) | 1983-03-16 | 1984-09-25 | Allied Corporation | Amorphous alloys for electromagnetic devices |

| US5284528A (en) | 1983-05-23 | 1994-02-08 | Allied-Signal Inc. | Metallic glasses having a combination of high permeability, low coercivity, low ac core loss, low exciting power and high thermal stability |

| DE3611527A1 (de) | 1986-04-05 | 1987-10-08 | Vacuumschmelze Gmbh | Verfahren zur erzielung einer flachen magnetisierungsschleife in amorphen kernen durch eine waermebehandlung |

| JPH02175813A (ja) * | 1988-12-27 | 1990-07-09 | Tokin Corp | 非晶質磁性合金薄帯の製造方法 |

| US5252144A (en) * | 1991-11-04 | 1993-10-12 | Allied Signal Inc. | Heat treatment process and soft magnetic alloys produced thereby |

| US5871593A (en) | 1992-12-23 | 1999-02-16 | Alliedsignal Inc. | Amorphous Fe-B-Si-C alloys having soft magnetic characteristics useful in low frequency applications |

| JPH06275417A (ja) * | 1993-03-17 | 1994-09-30 | Nippon Steel Corp | Fe基非晶質合金を用いたコイルのインダクタンスの改善方法 |

| US5628840A (en) * | 1995-04-13 | 1997-05-13 | Alliedsignal Inc. | Metallic glass alloys for mechanically resonant marker surveillance systems |

| US6093261A (en) * | 1995-04-13 | 2000-07-25 | Alliedsignals Inc. | Metallic glass alloys for mechanically resonant marker surveillance systems |

| US6187112B1 (en) * | 1995-04-13 | 2001-02-13 | Ryusuke Hasegawa | Metallic glass alloys for mechanically resonant marker surveillance systems |

| CA2216897A1 (en) * | 1996-09-30 | 1998-03-30 | Unitika Ltd. | Fe group-based amorphous alloy ribbon and magnetic marker |

| DE19653430A1 (de) * | 1996-12-20 | 1999-04-01 | Vacuumschmelze Gmbh | Anzeigeelement für die Verwendung in einem magnetischen Warenüberwachungssystem |

| US6144279A (en) | 1997-03-18 | 2000-11-07 | Alliedsignal Inc. | Electrical choke for power factor correction |

| US6018296A (en) * | 1997-07-09 | 2000-01-25 | Vacuumschmelze Gmbh | Amorphous magnetostrictive alloy with low cobalt content and method for annealing same |

| US6432226B2 (en) * | 1999-04-12 | 2002-08-13 | Alliedsignal Inc. | Magnetic glassy alloys for high frequency applications |

| US6749695B2 (en) * | 2002-02-08 | 2004-06-15 | Ronald J. Martis | Fe-based amorphous metal alloy having a linear BH loop |

-

2002

- 2002-02-08 US US10/071,990 patent/US6749695B2/en not_active Expired - Fee Related

-

2003

- 2003-02-03 CN CNB038078171A patent/CN100449030C/zh not_active Expired - Fee Related

- 2003-02-03 AU AU2003217302A patent/AU2003217302A1/en not_active Abandoned

- 2003-02-03 JP JP2003566266A patent/JP2005520931A/ja active Pending

- 2003-02-03 KR KR1020047012289A patent/KR101057463B1/ko not_active IP Right Cessation

- 2003-02-03 WO PCT/US2003/003101 patent/WO2003066925A2/en active Application Filing

- 2003-02-03 EP EP03713344A patent/EP1472384A2/en not_active Withdrawn

- 2003-02-07 TW TW092102531A patent/TWI271439B/zh not_active IP Right Cessation

-

2006

- 2006-01-24 HK HK06101083.0A patent/HK1081238A1/xx not_active IP Right Cessation

-

2010

- 2010-12-28 JP JP2010292040A patent/JP2011102438A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5110378A (en) * | 1988-08-17 | 1992-05-05 | Allied-Signal Inc. | Metallic glasses having a combination of high permeability, low coercivity, low ac core loss, low exciting power and high thermal stability |

| JPH10324961A (ja) * | 1997-05-26 | 1998-12-08 | Kawasaki Steel Corp | 軟磁気特性に優れた鉄基非晶質合金薄帯およびその製造方法 |

| US5841348A (en) * | 1997-07-09 | 1998-11-24 | Vacuumschmelze Gmbh | Amorphous magnetostrictive alloy and an electronic article surveillance system employing same |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2003066925A3 (en) | 2004-04-29 |

| US6749695B2 (en) | 2004-06-15 |

| TWI271439B (en) | 2007-01-21 |

| JP2005520931A (ja) | 2005-07-14 |

| EP1472384A2 (en) | 2004-11-03 |

| TW200400274A (en) | 2004-01-01 |

| CN1646719A (zh) | 2005-07-27 |

| AU2003217302A8 (en) | 2003-09-02 |

| KR101057463B1 (ko) | 2011-08-17 |

| WO2003066925A2 (en) | 2003-08-14 |

| KR20040081770A (ko) | 2004-09-22 |

| JP2011102438A (ja) | 2011-05-26 |

| HK1081238A1 (en) | 2006-05-12 |

| US20030150528A1 (en) | 2003-08-14 |

| AU2003217302A1 (en) | 2003-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107210108B (zh) | 基于纳米晶磁性合金的磁芯 | |

| US8665055B2 (en) | Soft magnetic alloy and uses thereof | |

| JP2011102438A (ja) | 直線的なbhループを有する鉄系アモルファス合金 | |

| KR100317794B1 (ko) | 저주파용에유효한연자성특성을갖는비정질철-봉소-실리콘-탄소합금 | |

| US5256211A (en) | Rapid annealing method using shorted secondary technique | |

| CN107464649A (zh) | 一种具有线性磁滞回线的磁芯 | |

| JP2001508129A (ja) | 低周波数用途で有用な軟磁性特性を有するアモルファスFe−B−Si−C合金 | |

| US5593513A (en) | Amorphous Fe-B-Si-C alloys having soft magnetic characteristics useful in low frequency applications | |

| CN114807758A (zh) | 一种低矫顽力铁基纳米晶合金及其制备方法 | |

| US4834816A (en) | Metallic glasses having a combination of high permeability, low coercivity, low ac core loss, low exciting power and high thermal stability | |

| JP2710949B2 (ja) | 超微結晶軟磁性合金の製造方法 | |

| JPH08188858A (ja) | パーミンバー特性を備えたガラス質合金 | |

| US5284528A (en) | Metallic glasses having a combination of high permeability, low coercivity, low ac core loss, low exciting power and high thermal stability | |

| JPS6332244B2 (zh) | ||

| CN100372033C (zh) | 漏电保护器用抗直流偏磁互感器磁芯及其制造方法 | |

| US5110378A (en) | Metallic glasses having a combination of high permeability, low coercivity, low ac core loss, low exciting power and high thermal stability | |

| US4769091A (en) | Magnetic core | |

| JPH0811818B2 (ja) | トロイダル型非晶質磁芯の熱処理方法 | |

| JP2009293132A (ja) | 軟磁性薄帯、磁心、磁性部品、および軟磁性薄帯の製造方法 | |

| Davis | Metals Handbook Desk Edition | |

| Hasegawa | Application of metallic glasses in low-frequency magnetic devices | |

| JPH06200357A (ja) | 非晶質合金 | |

| JPS62167840A (ja) | 磁性材料とその製造方法 | |

| Hasiak et al. | Microstructure and magnetic properties of Fe/sub 86-x/Co/sub x/Zr/sub 6/B/sub 8/alloys | |

| JP2801983B2 (ja) | コアの磁場中熱処理方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1081238 Country of ref document: HK |

|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1081238 Country of ref document: HK |

|

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20090107 Termination date: 20150203 |

|

| EXPY | Termination of patent right or utility model |