CN100430147C - 带有改进的针式关闭阀的密封装置的喷枪 - Google Patents

带有改进的针式关闭阀的密封装置的喷枪 Download PDFInfo

- Publication number

- CN100430147C CN100430147C CNB021403600A CN02140360A CN100430147C CN 100430147 C CN100430147 C CN 100430147C CN B021403600 A CNB021403600 A CN B021403600A CN 02140360 A CN02140360 A CN 02140360A CN 100430147 C CN100430147 C CN 100430147C

- Authority

- CN

- China

- Prior art keywords

- needle

- valve seat

- nozzle assembly

- sealing element

- elastic sealing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007789 sealing Methods 0.000 title claims abstract description 56

- 239000007921 spray Substances 0.000 title abstract description 23

- 238000011144 upstream manufacturing Methods 0.000 claims abstract description 17

- 239000012530 fluid Substances 0.000 claims description 79

- 238000002347 injection Methods 0.000 claims description 35

- 239000007924 injection Substances 0.000 claims description 35

- 230000008093 supporting effect Effects 0.000 claims description 30

- 239000002184 metal Substances 0.000 claims description 16

- 230000015572 biosynthetic process Effects 0.000 claims description 8

- 238000009434 installation Methods 0.000 claims description 2

- 230000008602 contraction Effects 0.000 claims 3

- 125000004122 cyclic group Chemical group 0.000 claims 1

- 239000007788 liquid Substances 0.000 abstract description 4

- 108090000565 Capsid Proteins Proteins 0.000 description 3

- 238000010276 construction Methods 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000012856 packing Methods 0.000 description 3

- 238000003908 quality control method Methods 0.000 description 3

- 230000001105 regulatory effect Effects 0.000 description 3

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 230000002950 deficient Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000003321 amplification Effects 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000003199 nucleic acid amplification method Methods 0.000 description 1

- 238000011112 process operation Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

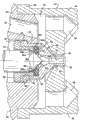

- B05B1/00—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means

- B05B1/30—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to control volume of flow, e.g. with adjustable passages

- B05B1/3033—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to control volume of flow, e.g. with adjustable passages the control being effected by relative coaxial longitudinal movement of the controlling element and the spray head

- B05B1/304—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to control volume of flow, e.g. with adjustable passages the control being effected by relative coaxial longitudinal movement of the controlling element and the spray head the controlling element being a lift valve

- B05B1/3046—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to control volume of flow, e.g. with adjustable passages the control being effected by relative coaxial longitudinal movement of the controlling element and the spray head the controlling element being a lift valve the valve element, e.g. a needle, co-operating with a valve seat located downstream of the valve element and its actuating means, generally in the proximity of the outlet orifice

- B05B1/306—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to control volume of flow, e.g. with adjustable passages the control being effected by relative coaxial longitudinal movement of the controlling element and the spray head the controlling element being a lift valve the valve element, e.g. a needle, co-operating with a valve seat located downstream of the valve element and its actuating means, generally in the proximity of the outlet orifice the actuating means being a fluid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B15/00—Details of spraying plant or spraying apparatus not otherwise provided for; Accessories

- B05B15/50—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter

- B05B15/52—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter for removal of clogging particles

- B05B15/522—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter for removal of clogging particles using cleaning elements penetrating the discharge openings

- B05B15/5223—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter for removal of clogging particles using cleaning elements penetrating the discharge openings the cleaning element, e.g. a needle, and the discharge opening being movable relative to each other in a direction substantially parallel to the flow of liquid or other fluent material through said opening

- B05B15/5225—Arrangements for cleaning; Arrangements for preventing deposits, drying-out or blockage; Arrangements for detecting improper discharge caused by the presence of foreign matter for removal of clogging particles using cleaning elements penetrating the discharge openings the cleaning element, e.g. a needle, and the discharge opening being movable relative to each other in a direction substantially parallel to the flow of liquid or other fluent material through said opening the cleaning element being located upstream of the discharge opening or being actuated upstream therefrom

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/02—Spray pistols; Apparatus for discharge

- B05B7/06—Spray pistols; Apparatus for discharge with at least one outlet orifice surrounding another approximately in the same plane

- B05B7/062—Spray pistols; Apparatus for discharge with at least one outlet orifice surrounding another approximately in the same plane with only one liquid outlet and at least one gas outlet

- B05B7/066—Spray pistols; Apparatus for discharge with at least one outlet orifice surrounding another approximately in the same plane with only one liquid outlet and at least one gas outlet with an inner liquid outlet surrounded by at least one annular gas outlet

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/02—Spray pistols; Apparatus for discharge

- B05B7/08—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point

- B05B7/0807—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point to form intersecting jets

- B05B7/0815—Spray pistols; Apparatus for discharge with separate outlet orifices, e.g. to form parallel jets, i.e. the axis of the jets being parallel, to form intersecting jets, i.e. the axis of the jets converging but not necessarily intersecting at a point to form intersecting jets with at least one gas jet intersecting a jet constituted by a liquid or a mixture containing a liquid for controlling the shape of the latter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/02—Spray pistols; Apparatus for discharge

- B05B7/12—Spray pistols; Apparatus for discharge designed to control volume of flow, e.g. with adjustable passages

- B05B7/1254—Spray pistols; Apparatus for discharge designed to control volume of flow, e.g. with adjustable passages the controlling means being fluid actuated

- B05B7/1263—Spray pistols; Apparatus for discharge designed to control volume of flow, e.g. with adjustable passages the controlling means being fluid actuated pneumatically actuated

- B05B7/1272—Spray pistols; Apparatus for discharge designed to control volume of flow, e.g. with adjustable passages the controlling means being fluid actuated pneumatically actuated actuated by gas involved in spraying, i.e. exiting the nozzle, e.g. as a spraying or jet shaping gas

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S239/00—Fluid sprinkling, spraying, and diffusing

- Y10S239/04—O-ring

Landscapes

- Nozzles (AREA)

- Details Or Accessories Of Spraying Plant Or Apparatus (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/892138 | 2001-06-26 | ||

| US09/892,138 US6776360B2 (en) | 2001-06-26 | 2001-06-26 | Spray gun with improved needle shut-off valve sealing arrangement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1394691A CN1394691A (zh) | 2003-02-05 |

| CN100430147C true CN100430147C (zh) | 2008-11-05 |

Family

ID=25399432

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB021403600A Expired - Lifetime CN100430147C (zh) | 2001-06-26 | 2002-06-26 | 带有改进的针式关闭阀的密封装置的喷枪 |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US6776360B2 (enExample) |

| EP (1) | EP1270081B1 (enExample) |

| JP (1) | JP4330848B2 (enExample) |

| CN (1) | CN100430147C (enExample) |

| AT (1) | ATE426457T1 (enExample) |

| AU (1) | AU784945B2 (enExample) |

| CA (1) | CA2389940C (enExample) |

| DE (1) | DE60231677D1 (enExample) |

| DK (1) | DK1270081T3 (enExample) |

| ES (1) | ES2322940T3 (enExample) |

Families Citing this family (44)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7640006B2 (en) * | 2001-10-03 | 2009-12-29 | Accenture Global Services Gmbh | Directory assistance with multi-modal messaging |

| US7762476B2 (en) * | 2002-08-19 | 2010-07-27 | Illinois Tool Works Inc. | Spray gun with improved atomization |

| US6808122B2 (en) * | 2002-08-19 | 2004-10-26 | Illinois Tool Works, Inc. | Spray gun with improved pre-atomization fluid mixing and breakup |

| US20050284957A1 (en) * | 2002-09-23 | 2005-12-29 | Spraying Systems Co. | External mix air atomizing spray nozzle assembly |

| US6935577B2 (en) * | 2003-02-28 | 2005-08-30 | Illinois Tool Works Inc. | One-piece fluid nozzle |

| WO2004087328A1 (en) * | 2003-03-27 | 2004-10-14 | Spraying Systems Co. | Modular spray gun with multiple control modules |

| US7926733B2 (en) * | 2004-06-30 | 2011-04-19 | Illinois Tool Works Inc. | Fluid atomizing system and method |

| US7883026B2 (en) | 2004-06-30 | 2011-02-08 | Illinois Tool Works Inc. | Fluid atomizing system and method |

| EP1836034B1 (en) | 2004-12-28 | 2013-07-17 | PIRELLI TYRE S.p.A. | Method and apparatus for manufacturing tyres for vehicle wheels |

| US8389062B2 (en) | 2005-05-12 | 2013-03-05 | Spraying Systems Co. | Spraying system for progressive spraying of non-rectangular objects |

| JP4958412B2 (ja) * | 2005-07-08 | 2012-06-20 | 株式会社ウエノコーポレーション | 塗装装置 |

| KR100554723B1 (ko) | 2005-12-08 | 2006-02-24 | 주식회사 삼진정밀 | 파일롯-릴리프 밸브 |

| FR2896293B1 (fr) * | 2006-01-17 | 2010-08-13 | Schrader Sas | Mecanisme d'ouverture ou de fermeture d'une valve a deux positions de fermeture |

| RU2329873C2 (ru) * | 2006-08-24 | 2008-07-27 | Андрей Леонидович Душкин | Распылитель жидкости |

| US20080179554A1 (en) * | 2007-01-29 | 2008-07-31 | Finn Clifford J | Dispensing Gun Valve Member And Dispensing Gun Formed Therewith |

| KR200437997Y1 (ko) * | 2007-02-08 | 2008-01-11 | 손형모 | 분사총 개폐밸브용 실링구조 |

| US9272295B2 (en) * | 2008-02-12 | 2016-03-01 | Kohler Co. | Sprayer assembly |

| GB0903275D0 (en) * | 2009-02-26 | 2009-04-08 | Earlex Ltd | Spray gun |

| CN101816986B (zh) * | 2010-04-27 | 2012-11-07 | 杭州华达喷射真空设备有限公司 | 可调式喷射器喷嘴及喷射线性流体的成型方法 |

| US8939387B2 (en) | 2010-05-03 | 2015-01-27 | Chapin Manufacturing, Inc. | Spray gun |

| GB2491929B (en) | 2011-06-17 | 2017-07-26 | Earlex Ltd | Spray gun |

| US8524312B2 (en) * | 2011-11-16 | 2013-09-03 | Csl Silicones Inc. | Applicator for spraying elastomeric materials |

| JP5613352B1 (ja) * | 2012-10-29 | 2014-10-22 | 東海ゴム工業株式会社 | スプレーガン |

| CN103292011B (zh) * | 2013-07-01 | 2015-01-14 | 核工业理化工程研究院 | 气动注油截止阀 |

| NL2011640C2 (en) * | 2013-10-18 | 2015-04-23 | Kimman Process Solutions B V | Sampling device. |

| US20150375986A1 (en) * | 2014-06-27 | 2015-12-31 | Gssc, Inc. | Rod Valve |

| CN104437940A (zh) * | 2014-12-24 | 2015-03-25 | 深圳市沃尔核材股份有限公司 | 一种可控式止漏喷头 |

| CN105805389B (zh) * | 2015-01-19 | 2021-03-12 | 莫恩股份有限公司 | 具有包括活塞和座的电子阀的电子卫生洁具配件 |

| US10213795B2 (en) * | 2015-05-07 | 2019-02-26 | Nordson Corporation | Fluid dispensing apparatus and methods utilizing a resilient nozzle |

| DE102015008661A1 (de) | 2015-07-03 | 2017-01-05 | Dürr Systems Ag | Nadelventil |

| DE102015008659B4 (de) * | 2015-07-03 | 2019-06-19 | Dürr Systems Ag | Beschichtungsmittelventil und Rotationszerstäuber |

| US9915389B1 (en) * | 2017-02-06 | 2018-03-13 | Emerson Process Management Regulator Technologies, Inc. | Mechanically-retained sealing disks for use with fluid regulators |

| DE102017122495A1 (de) | 2017-09-27 | 2019-03-28 | Dürr Systems Ag | Applikator mit einem geringen Düsenabstand |

| DE102017122493A1 (de) * | 2017-09-27 | 2019-03-28 | Dürr Systems Ag | Applikator mit geringem Düsenabstand |

| CN109225708A (zh) * | 2018-08-23 | 2019-01-18 | 浙江荣鹏气动工具有限公司 | 一种用于高压无气喷枪上的可调节的密封结构 |

| EP3902618A4 (en) * | 2018-12-28 | 2022-09-28 | Spray Nozzle Engineering Pty Ltd | SPRAY NOZZLE |

| CN110215982B (zh) * | 2019-06-03 | 2024-08-16 | 吉林市新大科机电技术有限责任公司 | 一种流化床式气流磨磨室多孔底喷嘴装置 |

| DE102020107044B4 (de) | 2020-03-13 | 2024-12-12 | André Hiessl | Sprühvorrichtung zum Ausbringen kleiner Mengen eines Sprühmediums |

| CN112058515B (zh) * | 2020-08-10 | 2022-03-04 | 浙江虹达特种橡胶制品有限公司 | 用于喷头中的香料缓释装置的制作方法及应用方法 |

| CN111841932B (zh) * | 2020-08-26 | 2024-05-03 | 玉溪市新特科技有限公司 | 一种新型高速自动喷枪 |

| DE102020123769A1 (de) * | 2020-09-11 | 2022-03-17 | Sata Gmbh & Co. Kg | Dichtelement zum Abdichten eines Übergangs zwischen einem Grundkörper einer Spritzpistole und einem Anbauteil einer Spritzpistole, Anbauteil, insbesondere Farbdüsenanordnung, für eine Spritzpistole und Spritzpistole, insbesondere Farbspritzpistole |

| JP2024515551A (ja) | 2021-04-05 | 2024-04-10 | ザイノン・テクノロジーズ・エルエルシー | 光ファイバコネクタおよび端面の非接触クリーニングのための方法 |

| CN113309881B (zh) * | 2021-05-22 | 2023-08-11 | 上海开维喜阀门有限公司 | 一种具有高密封性能的双通道阀门 |

| CN115944535B (zh) * | 2023-03-15 | 2023-06-13 | 江中药业股份有限公司 | 一种用于药品制粒机或包衣机的喷枪装置 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1152857B (de) * | 1961-01-11 | 1963-08-14 | Ruhrstahl Ag | Ventil mit einer staehlern harten und mit einer elastisch nachgiebigen Dichtung |

| FR1351077A (fr) * | 1963-03-11 | 1964-01-31 | Robinet à double fermeture, d'interception de liquides, plus particulièrement pourinstallations de chauffage central | |

| EP0109268A2 (en) * | 1982-11-10 | 1984-05-23 | Diversey Engineering (Europe) Limited | Spray gun |

| EP0116704A1 (en) * | 1983-02-10 | 1984-08-29 | Dynapac Aktiebolag | Spray bar valve |

| US5344078A (en) * | 1993-04-22 | 1994-09-06 | Ransburg Corporation | Nozzle assembly for HVLP spray gun |

| US5618025A (en) * | 1996-05-23 | 1997-04-08 | Fisher Controls International, Inc. | Protected soft seat with secondary hard seat |

| US5707010A (en) * | 1995-09-29 | 1998-01-13 | Spraying Systems Co. | Controllable spray nozzle assembly |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2929401A (en) * | 1957-03-11 | 1960-03-22 | Herbert M Cowan | Check valve with plural seating |

| US3233863A (en) * | 1963-04-15 | 1966-02-08 | Pressure Products Ind Inc | Valve having multiple seating surfaces |

| US4014510A (en) * | 1975-09-05 | 1977-03-29 | Midcon Pipeline Equipment Co. | Pilot valve |

| DE8231663U1 (de) * | 1982-11-11 | 1983-08-18 | Hermann Behr & Sohn Gmbh & Co, 7121 Ingersheim | Duese mit anschliessender koaxialanordnung fuer eine farbspritzeinrichtung |

| US4834338A (en) * | 1988-02-05 | 1989-05-30 | Fisher Controls International, Inc. | High pressure flexible seat valve trim |

| DE4009168A1 (de) * | 1990-03-22 | 1991-09-26 | Walther Spritz Lackiersyst | Spritzpistole |

| US5123436A (en) * | 1990-06-27 | 1992-06-23 | Mallory, Inc. | Plunger-type fuel pressure regulator |

| DE4213826A1 (de) * | 1991-05-08 | 1992-11-12 | Walther Spritz Lackiersyst | Spritzpistole |

| US5370357A (en) * | 1993-12-03 | 1994-12-06 | Ohmeda Inc. | Needle valve with deformable seal |

| US5462204A (en) * | 1994-03-29 | 1995-10-31 | Rhh Foam Systems, Inc. | Foam dispensing gun |

| DE19544016A1 (de) * | 1995-11-27 | 1997-05-28 | Klaschka Gmbh & Co | Zerstäubungskopf für Flüssigkeiten sowie Einrichtung zum Besprühen von Werkstücken mit Flüssigkeiten mit solchen Zerstäubungsköpfen |

| US5878993A (en) | 1997-03-27 | 1999-03-09 | St. Germain; Stephen V. | Shielded globe valve seal mechanism |

| US5899387A (en) * | 1997-09-19 | 1999-05-04 | Spraying Systems Co. | Air assisted spray system |

| US6283152B1 (en) | 1999-03-01 | 2001-09-04 | Cor-Val, Inc. | Multiple sleeve valve assembly |

-

2001

- 2001-06-26 US US09/892,138 patent/US6776360B2/en not_active Expired - Lifetime

-

2002

- 2002-06-10 CA CA2389940A patent/CA2389940C/en not_active Expired - Lifetime

- 2002-06-17 AU AU48819/02A patent/AU784945B2/en not_active Expired

- 2002-06-25 DK DK02254448T patent/DK1270081T3/da active

- 2002-06-25 ES ES02254448T patent/ES2322940T3/es not_active Expired - Lifetime

- 2002-06-25 DE DE60231677T patent/DE60231677D1/de not_active Expired - Lifetime

- 2002-06-25 AT AT02254448T patent/ATE426457T1/de active

- 2002-06-25 EP EP02254448A patent/EP1270081B1/en not_active Expired - Lifetime

- 2002-06-26 JP JP2002186526A patent/JP4330848B2/ja not_active Expired - Lifetime

- 2002-06-26 CN CNB021403600A patent/CN100430147C/zh not_active Expired - Lifetime

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1152857B (de) * | 1961-01-11 | 1963-08-14 | Ruhrstahl Ag | Ventil mit einer staehlern harten und mit einer elastisch nachgiebigen Dichtung |

| FR1351077A (fr) * | 1963-03-11 | 1964-01-31 | Robinet à double fermeture, d'interception de liquides, plus particulièrement pourinstallations de chauffage central | |

| EP0109268A2 (en) * | 1982-11-10 | 1984-05-23 | Diversey Engineering (Europe) Limited | Spray gun |

| EP0116704A1 (en) * | 1983-02-10 | 1984-08-29 | Dynapac Aktiebolag | Spray bar valve |

| US5344078A (en) * | 1993-04-22 | 1994-09-06 | Ransburg Corporation | Nozzle assembly for HVLP spray gun |

| US5707010A (en) * | 1995-09-29 | 1998-01-13 | Spraying Systems Co. | Controllable spray nozzle assembly |

| US5618025A (en) * | 1996-05-23 | 1997-04-08 | Fisher Controls International, Inc. | Protected soft seat with secondary hard seat |

Also Published As

| Publication number | Publication date |

|---|---|

| AU784945B2 (en) | 2006-08-03 |

| ES2322940T3 (es) | 2009-07-02 |

| US6776360B2 (en) | 2004-08-17 |

| EP1270081A3 (en) | 2004-03-10 |

| AU4881902A (en) | 2003-01-02 |

| DK1270081T3 (da) | 2009-06-02 |

| ATE426457T1 (de) | 2009-04-15 |

| CA2389940A1 (en) | 2002-12-26 |

| US20020195505A1 (en) | 2002-12-26 |

| EP1270081A2 (en) | 2003-01-02 |

| EP1270081B1 (en) | 2009-03-25 |

| JP2003062490A (ja) | 2003-03-04 |

| JP4330848B2 (ja) | 2009-09-16 |

| CA2389940C (en) | 2012-02-21 |

| CN1394691A (zh) | 2003-02-05 |

| DE60231677D1 (de) | 2009-05-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100430147C (zh) | 带有改进的针式关闭阀的密封装置的喷枪 | |

| CN1764502B (zh) | 具有多个控制模件的模件式喷枪组件 | |

| US7789325B2 (en) | Air atomizing spray nozzle with magnetically actuated shutoff valve | |

| US10001219B2 (en) | Double seat valve | |

| EP0427047B1 (en) | Lubricating device for knitting machine | |

| US20130020414A1 (en) | Spray gun nozzle tip with integrated seal and auto aligining fluid path | |

| KR20210027216A (ko) | 밸브 및 이러한 밸브를 포함하는 커버링 제품의 도포를 위한 시스템 | |

| JPS6138349B2 (enExample) | ||

| US6676047B1 (en) | Double sealing valve | |

| RU2142081C1 (ru) | Клапан радиатора | |

| JP6701212B2 (ja) | 燃料インジェクター | |

| KR20010020200A (ko) | 스프레이 건 | |

| KR20010029778A (ko) | 물분사식 직기의 물분사 펌프용 체크밸브 | |

| CA1285457C (en) | Valve | |

| KR102188191B1 (ko) | 2-유체 노즐, 스프레이 헤드 및 원자화 방법 | |

| KR930003051B1 (ko) | 정량분배 밸브 | |

| CN110529879A (zh) | 双相燃料喷嘴 | |

| KR19990045381A (ko) | 내연기관 연료분사기에 대한 계량밸브의 밀봉고정장치 | |

| RU2162543C2 (ru) | Форсунка для дизеля | |

| CN110671249B (zh) | 一种装有出油阀的分配泵柱塞及其工作方法 | |

| KR100287310B1 (ko) | 내연기관용연료분사노즐 | |

| CN102364081A (zh) | 一种柱塞式单体供油泵 | |

| US5472013A (en) | Fuel injection nozzle | |

| KR20170084667A (ko) | 동력분무기용 자동 압력제어밸브 | |

| CN212550090U (zh) | 一种活塞式喷雾头 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C56 | Change in the name or address of the patentee |

Owner name: SPRAYING SYSTEM CO., LTD. Free format text: FORMER NAME: SPRAY SYSTEMS INC. |

|

| CP01 | Change in the name or title of a patent holder |

Address after: Illinois State Patentee after: SPRAYING SYSTEMS Co. Address before: Illinois State Patentee before: SPRAYING SYSTEMS CO. |

|

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20081105 |