BR112014032621B1 - tubo de aço inoxidável duplex e seu método de produção - Google Patents

tubo de aço inoxidável duplex e seu método de produção Download PDFInfo

- Publication number

- BR112014032621B1 BR112014032621B1 BR112014032621-5A BR112014032621A BR112014032621B1 BR 112014032621 B1 BR112014032621 B1 BR 112014032621B1 BR 112014032621 A BR112014032621 A BR 112014032621A BR 112014032621 B1 BR112014032621 B1 BR 112014032621B1

- Authority

- BR

- Brazil

- Prior art keywords

- stainless steel

- tube

- duplex stainless

- steel tube

- yslt

- Prior art date

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 24

- 229910001039 duplex stainless steel Inorganic materials 0.000 title claims description 85

- 230000006835 compression Effects 0.000 claims abstract description 37

- 238000007906 compression Methods 0.000 claims abstract description 37

- 230000014509 gene expression Effects 0.000 claims abstract description 21

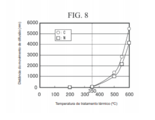

- 238000010438 heat treatment Methods 0.000 claims description 79

- 238000000034 method Methods 0.000 claims description 13

- 239000012535 impurity Substances 0.000 claims description 10

- 229910001220 stainless steel Inorganic materials 0.000 abstract description 9

- 239000010935 stainless steel Substances 0.000 abstract description 9

- 229910000831 Steel Inorganic materials 0.000 description 49

- 239000010959 steel Substances 0.000 description 49

- 239000003129 oil well Substances 0.000 description 48

- 238000005482 strain hardening Methods 0.000 description 33

- 230000000694 effects Effects 0.000 description 29

- 230000007423 decrease Effects 0.000 description 23

- 238000005260 corrosion Methods 0.000 description 20

- 230000007797 corrosion Effects 0.000 description 20

- 229910052799 carbon Inorganic materials 0.000 description 15

- PXHVJJICTQNCMI-UHFFFAOYSA-N nickel Substances [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 14

- 125000004432 carbon atom Chemical group C* 0.000 description 13

- 238000005097 cold rolling Methods 0.000 description 13

- 239000011651 chromium Substances 0.000 description 11

- 239000011572 manganese Substances 0.000 description 11

- 229910001566 austenite Inorganic materials 0.000 description 10

- 239000010949 copper Substances 0.000 description 10

- 238000009792 diffusion process Methods 0.000 description 10

- 229910052757 nitrogen Inorganic materials 0.000 description 10

- 125000004433 nitrogen atom Chemical group N* 0.000 description 10

- 239000012530 fluid Substances 0.000 description 8

- 229910000859 α-Fe Inorganic materials 0.000 description 8

- 238000009826 distribution Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 239000006104 solid solution Substances 0.000 description 5

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 239000007789 gas Substances 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 229910052759 nickel Inorganic materials 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- 238000007669 thermal treatment Methods 0.000 description 4

- 229910000765 intermetallic Inorganic materials 0.000 description 3

- 229910052750 molybdenum Inorganic materials 0.000 description 3

- 238000007670 refining Methods 0.000 description 3

- 125000004429 atom Chemical group 0.000 description 2

- 229910052804 chromium Inorganic materials 0.000 description 2

- 238000012669 compression test Methods 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 238000005261 decarburization Methods 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 238000005553 drilling Methods 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 229910052698 phosphorus Inorganic materials 0.000 description 2

- 230000003014 reinforcing effect Effects 0.000 description 2

- 238000011160 research Methods 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 229910052717 sulfur Inorganic materials 0.000 description 2

- 238000009864 tensile test Methods 0.000 description 2

- 150000003568 thioethers Chemical class 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- 101100293261 Mus musculus Naa15 gene Proteins 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- UCKMPCXJQFINFW-UHFFFAOYSA-N Sulphide Chemical compound [S-2] UCKMPCXJQFINFW-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 238000009499 grossing Methods 0.000 description 1

- 238000001192 hot extrusion Methods 0.000 description 1

- 238000005098 hot rolling Methods 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 230000003864 performance function Effects 0.000 description 1

- 239000011574 phosphorus Substances 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/08—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for tubular bodies or pipes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B3/00—Rolling materials of special alloys so far as the composition of the alloy requires or permits special rolling methods or sequences ; Rolling of aluminium, copper, zinc or other non-ferrous metals

- B21B3/02—Rolling special iron alloys, e.g. stainless steel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

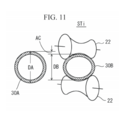

- B21D3/00—Straightening or restoring form of metal rods, metal tubes, metal profiles, or specific articles made therefrom, whether or not in combination with sheet metal parts

- B21D3/02—Straightening or restoring form of metal rods, metal tubes, metal profiles, or specific articles made therefrom, whether or not in combination with sheet metal parts by rollers

- B21D3/04—Straightening or restoring form of metal rods, metal tubes, metal profiles, or specific articles made therefrom, whether or not in combination with sheet metal parts by rollers arranged on axes skew to the path of the work

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/004—Heat treatment of ferrous alloys containing Cr and Ni

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/005—Heat treatment of ferrous alloys containing Mn

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/008—Heat treatment of ferrous alloys containing Si

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D7/00—Modifying the physical properties of iron or steel by deformation

- C21D7/02—Modifying the physical properties of iron or steel by deformation by cold working

- C21D7/10—Modifying the physical properties of iron or steel by deformation by cold working of the whole cross-section, e.g. of concrete reinforcing bars

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/10—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/10—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies

- C21D8/105—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies of ferrous alloys

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/001—Ferrous alloys, e.g. steel alloys containing N

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/42—Ferrous alloys, e.g. steel alloys containing chromium with nickel with copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B19/00—Tube-rolling by rollers arranged outside the work and having their axes not perpendicular to the axis of the work

- B21B19/02—Tube-rolling by rollers arranged outside the work and having their axes not perpendicular to the axis of the work the axes of the rollers being arranged essentially diagonally to the axis of the work, e.g. "cross" tube-rolling ; Diescher mills, Stiefel disc piercers or Stiefel rotary piercers

- B21B19/06—Rolling hollow basic material, e.g. Assel mills

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/001—Austenite

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/005—Ferrite

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Heat Treatment Of Steel (AREA)

- Heat Treatment Of Articles (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

- Metal Extraction Processes (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012190996 | 2012-08-31 | ||

| JP2012-190996 | 2012-08-31 | ||

| PCT/JP2013/072424 WO2014034522A1 (ja) | 2012-08-31 | 2013-08-22 | 二相ステンレス鋼管及びその製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| BR112014032621A2 BR112014032621A2 (pt) | 2017-06-27 |

| BR112014032621B1 true BR112014032621B1 (pt) | 2021-02-17 |

Family

ID=50183337

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| BR112014032621-5A BR112014032621B1 (pt) | 2012-08-31 | 2013-08-22 | tubo de aço inoxidável duplex e seu método de produção |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US10184160B2 (enExample) |

| EP (1) | EP2853614B1 (enExample) |

| JP (1) | JP5500324B1 (enExample) |

| CN (2) | CN108842047A (enExample) |

| AU (1) | AU2013310286B2 (enExample) |

| BR (1) | BR112014032621B1 (enExample) |

| ES (1) | ES2623731T3 (enExample) |

| IN (1) | IN2014DN09674A (enExample) |

| WO (1) | WO2014034522A1 (enExample) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015102255A1 (de) * | 2015-02-17 | 2016-08-18 | Sandvik Materials Technology Deutschland Gmbh | Verfahren zum Herstellen eines Strangs aus Edelstahl sowie Strang aus Edelstahl |

| CN116179947A (zh) * | 2015-07-20 | 2023-05-30 | 山特维克知识产权股份有限公司 | 双相不锈钢及其成型物 |

| JP6550543B2 (ja) * | 2015-12-30 | 2019-07-24 | サンドビック インテレクチュアル プロパティー アクティエボラーグ | 二相ステンレス鋼管の製造方法 |

| EP3640352A1 (en) | 2018-10-17 | 2020-04-22 | AB Sandvik Materials Technology | Method of producing tube of duplex stainless steel |

| EP3854890A4 (en) * | 2018-11-30 | 2022-01-26 | JFE Steel Corporation | SEAMLESS DUPLEX STAINLESS STEEL PIPE AND METHOD FOR MANUFACTURING THEREOF |

| US20230090789A1 (en) * | 2020-02-05 | 2023-03-23 | Jfe Steel Corporation | Stainless steel seamless pipe and method for manufacturing same |

| EP4094856B1 (en) * | 2020-02-26 | 2025-04-16 | JFE Steel Corporation | Seamless tube and method for manufacturing same |

| WO2021171837A1 (ja) | 2020-02-27 | 2021-09-02 | Jfeスチール株式会社 | ステンレス鋼管およびその製造方法 |

| JP6981573B1 (ja) * | 2020-02-27 | 2021-12-15 | Jfeスチール株式会社 | ステンレス鋼管およびその製造方法 |

| CN115667560B (zh) * | 2020-06-19 | 2024-03-15 | 杰富意钢铁株式会社 | 合金管及其制造方法 |

| CN114289513B (zh) * | 2021-12-31 | 2024-12-24 | 江苏银环精密钢管有限公司 | 一种s32760超级双相不锈钢无缝管的制造方法 |

| CN115852255A (zh) * | 2022-12-07 | 2023-03-28 | 江苏新华合金有限公司 | 一种双相不锈钢无缝管坯材料的制造工艺方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63210236A (ja) | 1987-02-25 | 1988-08-31 | Sumitomo Metal Ind Ltd | 耐サワ−用高コラプス油井管の製造法 |

| JPH0776728A (ja) * | 1993-09-07 | 1995-03-20 | Sumitomo Metal Ind Ltd | 靭性に優れた13%Cr鋼鋼管の製造方法 |

| JPH1080715A (ja) * | 1996-09-05 | 1998-03-31 | Sumitomo Metal Ind Ltd | 冷間加工のままで使用される鋼管の製造方法 |

| JPH1157842A (ja) * | 1997-08-27 | 1999-03-02 | Sumitomo Metal Ind Ltd | 管軸長方向の圧縮強度に優れた鋼管の製造方法 |

| US7892368B2 (en) * | 2002-05-24 | 2011-02-22 | Nippon Steel Corporation | UOE steel pipe excellent in collapse strength and method of production thereof |

| TWI233845B (en) | 2002-09-10 | 2005-06-11 | Nikko Materials Co Ltd | Iron-based sintered compact and its production method |

| JP4276480B2 (ja) * | 2003-06-24 | 2009-06-10 | 新日本製鐵株式会社 | 変形性能に優れたパイプライン用高強度鋼管の製造方法 |

| JP2008173643A (ja) * | 2007-01-16 | 2008-07-31 | Sumitomo Metal Ind Ltd | 二相ステンレス鋼管の製造方法、矯正方法および強度調整方法、ならびに、二相ステンレス鋼管の矯正機の操業方法 |

| JP5211841B2 (ja) * | 2007-07-20 | 2013-06-12 | 新日鐵住金株式会社 | 二相ステンレス鋼管の製造方法 |

| DE102008045705A1 (de) * | 2008-09-04 | 2010-04-22 | Macherey, Nagel Gmbh & Co. Kg Handelsgesellschaft | Verfahren zur Gewinnung von kurzer RNA sowie Kit hierfür |

| WO2010082395A1 (ja) * | 2009-01-19 | 2010-07-22 | 住友金属工業株式会社 | 二相ステンレス鋼管の製造方法 |

| JP5137048B2 (ja) * | 2011-03-24 | 2013-02-06 | 新日鐵住金株式会社 | オーステナイト系合金管及びその製造方法 |

-

2013

- 2013-08-22 US US14/402,882 patent/US10184160B2/en active Active

- 2013-08-22 BR BR112014032621-5A patent/BR112014032621B1/pt active IP Right Grant

- 2013-08-22 IN IN9674DEN2014 patent/IN2014DN09674A/en unknown

- 2013-08-22 ES ES13833720.9T patent/ES2623731T3/es active Active

- 2013-08-22 CN CN201810788186.XA patent/CN108842047A/zh active Pending

- 2013-08-22 JP JP2013542276A patent/JP5500324B1/ja active Active

- 2013-08-22 EP EP13833720.9A patent/EP2853614B1/en active Active

- 2013-08-22 CN CN201380034033.1A patent/CN104395491A/zh active Pending

- 2013-08-22 AU AU2013310286A patent/AU2013310286B2/en active Active

- 2013-08-22 WO PCT/JP2013/072424 patent/WO2014034522A1/ja not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| JP5500324B1 (ja) | 2014-05-21 |

| AU2013310286A1 (en) | 2014-12-04 |

| ES2623731T3 (es) | 2017-07-12 |

| US10184160B2 (en) | 2019-01-22 |

| CN108842047A (zh) | 2018-11-20 |

| EP2853614A1 (en) | 2015-04-01 |

| EP2853614A4 (en) | 2016-03-30 |

| CN104395491A (zh) | 2015-03-04 |

| AU2013310286B2 (en) | 2016-04-28 |

| JPWO2014034522A1 (ja) | 2016-08-08 |

| IN2014DN09674A (enExample) | 2015-07-31 |

| EP2853614B1 (en) | 2017-04-12 |

| WO2014034522A1 (ja) | 2014-03-06 |

| US20150107724A1 (en) | 2015-04-23 |

| BR112014032621A2 (pt) | 2017-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| BR112014032621B1 (pt) | tubo de aço inoxidável duplex e seu método de produção | |

| RU2716438C1 (ru) | Бесшовная высокопрочная труба из нержавеющей стали нефтепромыслового сортамента и способ её изготовления | |

| CN103443318B (zh) | 奥氏体系合金管及其制造方法 | |

| EP3604591A1 (en) | Martensitic stainless steel material | |

| JPWO2008117680A1 (ja) | 坑井内で拡管される拡管用油井管及び拡管用油井管に用いられる2相ステンレス鋼 | |

| EP3260564B1 (en) | High-strength seamless thick-walled steel pipe and process for producing same | |

| JPWO2010134498A1 (ja) | 油井用ステンレス鋼、油井用ステンレス鋼管及び油井用ステンレス鋼の製造方法 | |

| EP3569724A1 (en) | High strength seamless stainless steel pipe and production method therefor | |

| JP5804232B1 (ja) | マルテンサイト系Cr含有鋼及び油井用鋼管 | |

| WO2011136175A1 (ja) | 高強度油井用ステンレス鋼及び高強度油井用ステンレス鋼管 | |

| JP6372070B2 (ja) | フェライト・マルテンサイト二相鋼及び油井用鋼管 | |

| CN101171351A (zh) | 扩管性优良的油井管用不锈钢管 | |

| JP2008297602A (ja) | 拡管性に優れる油井用ステンレス鋼管およびその製造方法 | |

| JP4978070B2 (ja) | 拡管性に優れる油井用ステンレス鋼管 | |

| EP4592408A1 (en) | Martensitic stainless steel material | |

| EP4012053A1 (en) | Seamless stainless steel pipe and method for manufacturing same | |

| JP3451993B2 (ja) | 耐硫化水素腐食性および耐炭酸ガス腐食性能に優れたCr含有油井管用鋼 | |

| EP4293133A1 (en) | Stainless steel pipe and manufacturing method thereof | |

| JP5040215B2 (ja) | 拡管性に優れる油井用ステンレス鋼管 | |

| JP2017020086A (ja) | マルテンサイト鋼材 | |

| JP2017075343A (ja) | マルテンサイト鋼材 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| B06F | Objections, documents and/or translations needed after an examination request according art. 34 industrial property law | ||

| B07A | Technical examination (opinion): publication of technical examination (opinion) | ||

| B25D | Requested change of name of applicant approved |

Owner name: NIPPON STEEL CORPORATION (JP) |

|

| B06A | Notification to applicant to reply to the report for non-patentability or inadequacy of the application according art. 36 industrial patent law | ||

| B09A | Decision: intention to grant | ||

| B16A | Patent or certificate of addition of invention granted |

Free format text: PRAZO DE VALIDADE: 20 (VINTE) ANOS CONTADOS A PARTIR DE 22/08/2013, OBSERVADAS AS CONDICOES LEGAIS. |