WO2020241707A1 - 樹脂成形体の製造方法 - Google Patents

樹脂成形体の製造方法 Download PDFInfo

- Publication number

- WO2020241707A1 WO2020241707A1 PCT/JP2020/020962 JP2020020962W WO2020241707A1 WO 2020241707 A1 WO2020241707 A1 WO 2020241707A1 JP 2020020962 W JP2020020962 W JP 2020020962W WO 2020241707 A1 WO2020241707 A1 WO 2020241707A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- supply material

- resin

- mass

- resin molded

- molded product

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/20—Compounding polymers with additives, e.g. colouring

- C08J3/203—Solid polymers with solid and/or liquid additives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B17/00—Recovery of plastics or other constituents of waste material containing plastics

- B29B17/0005—Direct recuperation and re-use of scrap material during moulding operation, i.e. feed-back of used material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/002—Methods

- B29B7/007—Methods for continuous mixing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/58—Component parts, details or accessories; Auxiliary operations

- B29B7/60—Component parts, details or accessories; Auxiliary operations for feeding, e.g. end guides for the incoming material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/80—Component parts, details or accessories; Auxiliary operations

- B29B7/88—Adding charges, i.e. additives

- B29B7/90—Fillers or reinforcements, e.g. fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/0005—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor using fibre reinforcements

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08B—POLYSACCHARIDES; DERIVATIVES THEREOF

- C08B3/00—Preparation of cellulose esters of organic acids

- C08B3/20—Esterification with maintenance of the fibrous structure of the cellulose

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/20—Compounding polymers with additives, e.g. colouring

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

- C08J3/20—Compounding polymers with additives, e.g. colouring

- C08J3/201—Pre-melted polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L77/00—Compositions of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Compositions of derivatives of such polymers

- C08L77/02—Polyamides derived from omega-amino carboxylic acids or from lactams thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/40—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft

- B29B7/42—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with single shaft with screw or helix

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/34—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices

- B29B7/38—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary

- B29B7/46—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft

- B29B7/48—Mixing; Kneading continuous, with mechanical mixing or kneading devices with movable mixing or kneading devices rotary with more than one shaft with intermeshing devices, e.g. screws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/30—Mixing; Kneading continuous, with mechanical mixing or kneading devices

- B29B7/58—Component parts, details or accessories; Auxiliary operations

- B29B7/72—Measuring, controlling or regulating

- B29B7/726—Measuring properties of mixture, e.g. temperature or density

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B7/00—Mixing; Kneading

- B29B7/80—Component parts, details or accessories; Auxiliary operations

- B29B7/82—Heating or cooling

- B29B7/823—Temperature control

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2077/00—Use of PA, i.e. polyamides, e.g. polyesteramides or derivatives thereof, as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/06—Condition, form or state of moulded material or of the material to be shaped containing reinforcements, fillers or inserts

- B29K2105/16—Fillers

- B29K2105/162—Nanoparticles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2401/00—Use of cellulose, modified cellulose or cellulose derivatives, e.g. viscose, as filler

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2300/00—Characterised by the use of unspecified polymers

- C08J2300/30—Polymeric waste or recycled polymer

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2323/00—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers

- C08J2323/02—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers not modified by chemical after treatment

- C08J2323/10—Homopolymers or copolymers of propene

- C08J2323/12—Polypropene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2377/00—Characterised by the use of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Derivatives of such polymers

- C08J2377/02—Polyamides derived from omega-amino carboxylic acids or from lactams thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2400/00—Characterised by the use of unspecified polymers

- C08J2400/30—Polymeric waste or recycled polymer

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2401/00—Characterised by the use of cellulose, modified cellulose or cellulose derivatives

- C08J2401/02—Cellulose; Modified cellulose

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2401/00—Characterised by the use of cellulose, modified cellulose or cellulose derivatives

- C08J2401/08—Cellulose derivatives

- C08J2401/10—Esters of organic acids

- C08J2401/12—Cellulose acetate

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2423/00—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers

- C08J2423/02—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers not modified by chemical after treatment

- C08J2423/10—Homopolymers or copolymers of propene

- C08J2423/12—Polypropene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2477/00—Characterised by the use of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Derivatives of such polymers

- C08J2477/02—Polyamides derived from omega-amino carboxylic acids or from lactams thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/14—Polymer mixtures characterised by other features containing polymeric additives characterised by shape

- C08L2205/16—Fibres; Fibrils

Definitions

- the present invention relates to a method for producing a resin molded product containing a thermoplastic resin and cellulose nanofibers.

- Thermoplastic resin is light and has excellent processing characteristics, so it is widely used in various fields such as automobile parts, electrical / electronic parts, office equipment housings, and precision parts.

- the resin alone often has insufficient mechanical properties, slidability, thermal stability, dimensional stability, and the like, and a composite of the resin and various inorganic materials is generally used.

- a resin composition in which a thermoplastic resin is reinforced with a reinforcing material such as glass fiber, carbon fiber, talc, or clay, which is an inorganic filler, has a high specific gravity, so that there is a problem that the weight of the obtained resin molded body becomes large. Therefore, in recent years, cellulose, which has a low environmental load, has come to be used as a new reinforcing material for resins.

- Cellulose is known to have a high elastic modulus comparable to that of aramid fiber and a coefficient of linear expansion lower than that of glass fiber as its elemental properties. Also, the true density of the 1.56 g / cm 3, low glass used as a reinforcing material of a general thermoplastic resin (density 2.4 ⁇ 2.6g / cm 3) and talc (density 2.7 g / It is an overwhelmingly lighter material than cm 3 ).

- Cellulose is wide-ranging, including those made from trees, hemp, cotton, kenaf, cassava, etc. Furthermore, bacterial cellulose such as nata de coco is also known. There are a large amount of natural resources as raw materials on the earth, and for this effective utilization, technology that utilizes cellulose as a filler in the resin is drawing attention.

- CNF cellulose nanofiber

- pulp or the like as a raw material

- hydrolyzing the hemicellulose portion to make it fragile, and then defibrating it by a pulverization method such as a high-pressure homogenizer, a microfluidizer, a ball mill or a disc mill. It is known that it forms a highly dispersed state or network at a level called fine nano-dispersion in water.

- Patent Document 1 is a fiber-reinforced resin composition containing (A) chemically modified cellulose nanofibers and (B) thermoplastic resin, wherein the chemically modified cellulose nanofibers and the thermoplastic resin have the following conditions: (a). The ratio R (SP cnf / SP pol ) of (A) the dissolution parameter (SP cnf ) of (A) chemically modified cellulose nanofibers to the dissolution parameter (SP pol ) of the thermoplastic resin is in the range of 0.87 to 1.88. Described is a fiber-reinforced resin composition that satisfies the above and (b) (A) that the crystallinity of the chemically modified cellulose nanofibers is 42.7% or more.

- Patent Document 1 preferably combines a fiber having improved dispersibility and a resin in which the fiber is easily dispersed to obtain a fiber-reinforced resin composition in which cellulose nanofibers are well dispersed. It is intended to be provided, and it is considered that the dispersibility of cellulose nanofibers can be improved to some extent according to the technique. However, when the cellulose nanofibers are chemically and / or physically treated in order to improve the dispersibility of the cellulose nanofibers in the resin composition, the cellulose nanofibers also deteriorate, and the reinforcing effect of the cellulose nanofibers occurs. There is a problem that it cannot be obtained sufficiently.

- cellulose nanofibers having a large fiber length have an excellent reinforcing effect, and when they are present in the resin composition, good mechanical strength can be given to the resin composition.

- the anisotropy that is, the direction

- the physical properties for example, molding shrinkage rate and coefficient of thermal expansion

- finely dispersing cellulose nanofibers in the resin can be mentioned.

- a method of applying strong shear for example, using a twin-screw extruder or a multi-screw extruder is generally adopted.

- strong shear for example, using a twin-screw extruder or a multi-screw extruder is generally adopted.

- this method it has become a problem in recent years that cellulose is greatly discolored due to a strong heat history, causing a problem that an extremely colored molded product is given.

- machining by an extruder causes a short pass at a certain ratio, and sufficient dispersion cannot be obtained by simple kneading alone, and a huge agglomerate (specifically, a diameter of 5 ⁇ m or more) is used.

- a huge agglomerate specifically, a diameter of 5 ⁇ m or more

- the composition is a mixture of several hundred ⁇ m or more.

- cellulose nanofibers that have undergone strong shearing have a problem that, for example, tensile strength and surface impact strength are significantly reduced, probably because the fiber length is shortened.

- a cellulose nanofiber-containing resin composition having good mechanical strength, less anisotropy and warpage of physical properties, and suppressed coloring due to heat has not been obtained.

- the present invention solves the above-mentioned problems, and enables the production of a resin molded product containing cellulose nanofibers, having good mechanical strength, less anisotropy and warpage of physical properties, and suppressed coloring due to heat.

- the purpose is to provide a method for manufacturing a body.

- a method for producing a resin molded product containing (A) a thermoplastic resin and (B) cellulose nanofibers A step of preparing a main supply material (a1) containing a thermoplastic resin and (B) cellulose nanofibers, and an auxiliary supply material (a2) which is a melt treatment product of the main supply material (a1).

- a step of molding the resin composition (b) to obtain a resin molded product Including methods.

- [2] A method for improving the defibability of the (B) cellulose nanofibers in the production of a resin molded product containing (A) a thermoplastic resin and (B) cellulose nanofibers.

- the melt mixing is performed at a mixing ratio of 5 to 50% by mass of the auxiliary supply material (a2) with respect to a total of 100% by mass of the main supply material (a1) and the auxiliary supply material (a2).

- the elastic modulus of the main supply material (a1) and the elastic modulus of the resin composition (b) are expressed by the following formula: [Elastic modulus of resin composition (b)] ⁇ [Elastic modulus of main supply material (a1) x 0.99]

- the method according to any one of the above aspects 1 to 15, which satisfies the above relationship. [17] The method further comprises returning a part of the resin molded product to the resin composition forming step as at least a part of the auxiliary supply material (a2), whereby the resin molded product is the main component. It contains cellulose nanofibers that have undergone a melting process of the feed material (a1) and two or more steps of forming the resin composition.

- the ratio of the cellulose nanofibers that have undergone the melting treatment of the main supply material (a1) and the resin composition forming step two or more times to 100% by mass of the total amount of the cellulose nanofibers in the resin molded product is 20% by mass. % Or less, the method according to any one of the above aspects 1 to 16.

- the (A) thermoplastic resin is polyamide.

- a method for producing a resin molded product which contains cellulose nanofibers, has good mechanical strength, has less anisotropy and warpage of physical properties, and enables production of a resin molded product in which coloring due to heat is suppressed.

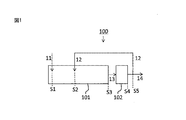

- FIG. 1 is a diagram illustrating a process 100 as an example of a method for manufacturing a resin molded product according to the first embodiment.

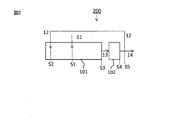

- FIG. 2 is a diagram illustrating a process 200 as an example of a method for manufacturing a resin molded product according to the first embodiment.

- FIG. 3 is a diagram illustrating a process 300 as an example of a method for manufacturing a resin molded product according to the first embodiment.

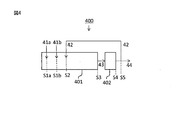

- FIG. 4 is a diagram illustrating a process 400 as an example of a method for manufacturing a resin molded product according to a second embodiment.

- One aspect of the present invention provides a method for producing a resin molded product containing (A) a thermoplastic resin and (B) cellulose nanofibers.

- the method comprises a main feed material (a1) comprising (A) a thermoplastic resin and (B) cellulose nanofibers and an auxiliary feed material (a2) which is a melt treatment product of the main feed material (a1). ), A resin composition forming step of melting and mixing the main supply material (a1) and the auxiliary supply material (a2) to obtain a resin composition (b), and the resin composition (b). ) To obtain a resin molded body, and the like.

- One aspect of the present invention provides a method for improving the defibration property of (B) cellulose nanofibers in the production of (A) a thermoplastic resin and (B) a resin molded product containing cellulose nanofibers.

- the method comprises the step of preparing a main feed material containing (A) a thermoplastic resin and (B) cellulose nanofibers and an auxiliary feed material which is a melt treatment product of the main feed material.

- a resin composition forming step of obtaining a resin composition containing two or more kinds of cellulose nanofibers having different thermal histories by melt-mixing the main supply material and the auxiliary supply material, and a resin by molding the resin composition. Includes a step of obtaining a molded product.

- the two or more types of cellulose nanofibers having different thermal histories have different fiber lengths from each other.

- the fiber length of the cellulose nanofibers in the auxiliary feed material is smaller than the fiber length of the cellulose nanofibers in the main feed material, due to the auxiliary feed material having more thermal history than the main feed material.

- the resin molding is a melt mixture of the constituents of the main feed material (ie, (A) thermoplastic resin, (B) cellulose nanofibers, and any additional ingredients) and the auxiliary feed material. ..

- the resin molded product produced in the first embodiment may be provided typically in the form of pellets or the like.

- the resin molded product has a composition different from that of a molten mixture (first material) containing (A) a thermoplastic resin, (B) cellulose nanofibers, and any additional component. It is a melt mixture with the second material of.

- the first material can be the resin molded article obtained in the first embodiment.

- the resin molded product produced in the second embodiment may be provided in the shape of various molded products in addition to the shape of pellets or the like.

- the main feed material (a1) may be in the form of a mixture containing (A) a thermoplastic resin, (B) cellulose nanofibers and any additional component, or may be a component of the main feed material (ie, (A)).

- Thermoplastic resin, (B) cellulose nanofibers, and any additional component) may be prepared individually.

- the auxiliary feed material is a melted product of the main feed material. Therefore, the auxiliary feed material has substantially the same composition as the main feed material (that is, the types and amounts of the constituents are the same), but at least a part of the constituents of the main feed material is altered due to the melting process. It may be the one that has been used.

- the alteration includes (B) a decrease in fiber length of cellulose nanofibers.

- the auxiliary supply material (a2) Since the auxiliary supply material (a2) has substantially the same composition as the main supply material, it is extremely well mixed with the supply material. In addition, since the fiber length of the cellulose nanofibers in the main supply material is reduced in the auxiliary supply material, the mixture of the main supply material and the auxiliary supply material is derived from the main supply material (that is, the fiber length is relatively large). Large) cellulose nanofibers and cellulose nanofibers derived from auxiliary feed materials (ie, relatively small fiber lengths) will be mixed. Increasing the fiber length of the cellulose nanofibers improves the mechanical strength of the resin molded product, but lowers the fluidity of the resin composition during the production of the resin molded product, so that the dispersibility of the cellulose nanofibers in the resin molded product is improved.

- the anisotropy of the physical properties (for example, thermal expansion coefficient) of the resin molded body tends to increase. Since the mechanical strength is particularly greatly affected by the presence of cellulose nanofibers having a large fiber length, the amount of cellulose nanofibers having a large fiber length used is significantly improved even in a relatively small amount. On the other hand, the degree of influence of the presence of cellulose nanofibers having a large fiber length on the anisotropy and dispersibility of physical properties is not remarkable as compared with the case of mechanical strength.

- the mechanical strength strongly contributed by the presence of the cellulose nanofibers having a large fiber length is good, while the fiber length is reduced.

- the coexistence of cellulose nanofibers also provides good effects of reducing physical anisotropy and improving dispersibility.

- the resin molded product obtained by the method of the present disclosure may have a unique advantage of achieving both good mechanical strength, good dispersibility and low anisotropy.

- the auxiliary feed material undergoes shearing during the melting process, causing crazes at the weakest points in the structure, specifically, cellulose nanofiber aggregates existing in the structure, resulting in cellulose nanofibers.

- the fiber agglomerates become finer, and the synergistic effect of increasing the viscosity of the system is also exhibited, so that the amount of cellulose nanofiber agglomerates that can be contained in the final molded product can be significantly reduced.

- the auxiliary supply material can be taken out of a part of the resin molded product and returned to the process.

- the auxiliary supply material for example, (1) the resin molded product obtained from the start of production until the process conditions are stabilized in order to obtain the target resin molded product, and (2) the composition is substantially the same.

- the resin molded products showing physical properties different from those of the target resin molded product (3) the resin molded product obtained during the transitional time period during the composition change, the target resin molded product and the composition

- resin molded products having substantially the same shape can be used within a range that does not cause any problem.

- substantially the same composition means that the amount of each component constituting the resin molded product is in the range of + 5% by mass to -5% by mass. Specifically, for example, when the content of (B) cellulose nanofibers is 7.5% by mass, it is in the range of 7.125% by mass to 7.875% by mass. This range of + 5% to -5% is a range similar to the fluctuation of the composition that occurs when the material is regularly added (refilled) to the material supply device provided in the kneader.

- the amount of (B) cellulose nanofibers in the main feed material satisfactorily obtains the property improving effect (for example, the effect of improving mechanical strength, thermal stability, durability, etc.) by the (B) cellulose nanofibers.

- the property improving effect for example, the effect of improving mechanical strength, thermal stability, durability, etc.

- it is preferably 1% by mass or more, more preferably 3% by mass or more, still more preferably 5% by mass or more, and is preferable from the viewpoint of obtaining good moldability and dispersibility, and reducing anisotropy. Is 50% by mass or less, more preferably 40% by mass or less, still more preferably 20% by mass or less.

- thermoplastic resin (A) various resins can be used.

- the (A) thermoplastic resin has a number average molecular weight of 5000 or more.

- the number average molecular weight of the present disclosure is a value obtained by converting a chromatogram measured by GPC (gel permeation chromatography) with a standard polymer for GPC.

- GPC gel permeation chromatography

- a standard polymer for GPC at this time a polymer known to those skilled in the art can be used. In general, polystyrene, polymethyl methacrylate, polyethylene glycol, polyethylene oxide and the like can be exemplified. Which standard polymer is used is selected according to the type of eluent at the time of GPC measurement.

- thermoplastic resin (A) examples include a crystalline resin having a melting point in the range of 100 ° C. to 350 ° C. and an amorphous resin having a glass transition temperature in the range of 100 to 250 ° C.

- the thermoplastic resin (A) may be composed of one kind or two or more kinds of polymers which may be homopolymers or copolymers.

- the melting point of the crystalline resin referred to here is the peak top of the endothermic peak that appears when the temperature is raised from 23 ° C. to 10 ° C./min using a differential scanning calorimetry device (DSC).

- DSC differential scanning calorimetry device

- the enthalpy of the endothermic peak at this time is preferably 10 J / g or more, and more preferably 20 J / g or more.

- the glass transition temperature of the amorphous resin referred to here is when measured at an applied frequency of 10 Hz while raising the temperature from 23 ° C. to 2 ° C./min using a dynamic viscoelasticity measuring device.

- it refers to the temperature at the peak top where the storage elastic modulus is greatly reduced and the loss elastic modulus is maximized.

- the measurement frequency is at least once every 20 seconds in order to improve the measurement accuracy.

- the method for preparing the sample for measurement is not particularly limited, but from the viewpoint of eliminating the influence of molding strain, it is desirable to use a cut piece of a hot press molded product, and the size (width and thickness) of the cut piece can be as small as possible. The smaller one is preferable from the viewpoint of heat conduction.

- thermoplastic resin (A) is modified by blending or graft-polymerizing a polyamide resin, a polyester resin, a polyacetal resin, a polycarbonate resin, a polyacrylic resin, or a polyphenylene ether resin (polyphenylene ether with another resin).

- modified polyphenylene ether polyarylate resin, polysulfone resin, polyphenylene sulfide resin, polyether sulfone resin, polyketone resin, polyphenylene ether ketone resin, polyimide resin, polyamideimide resin, polyetherimide

- polyarylate resin polysulfone resin, polyphenylene sulfide resin, polyether sulfone resin, polyketone resin, polyphenylene ether ketone resin, polyimide resin, polyamideimide resin, polyetherimide

- polyurethane resins for example, ⁇ -olefin (co) polymers

- polyolefin resins for example, ⁇ -olefin (co) polymers

- thermoplastic resin modified with at least one compound selected from unsaturated carboxylic acids, acid anhydrides thereof or derivatives thereof can also be used.

- polyolefin resins polyamide resins, polyester resins, polyacetal resins, polyacrylic resins, polyphenylene ether resins, and polyphenylene sulfide resins

- resins selected from the group consisting of are preferable.

- the (A) thermoplastic resin is a polyamide.

- the polyolefin-based resin is a polymer obtained by polymerizing a monomer unit containing olefins (for example, ⁇ -olefins).

- olefins for example, ⁇ -olefins

- Specific examples of the polyolefin-based resin are not particularly limited, but are exemplified by low-density polyethylene (for example, linear low-density polyethylene), high-density polyethylene, ultra-low-density polyethylene, ultra-high-molecular-weight polyethylene, and the like.

- Polypropylene-based (co) copolymers such as coalescence, polypropylene, ethylene-propylene copolymer, ethylene-propylene-diene copolymer, etc., ethylene-acrylic acid copolymer, ethylene-methyl methacrylate copolymer, ethylene Examples thereof include a copolymer of ⁇ -olefin represented by a glycidyl methacrylate copolymer and the like and another monomer unit.

- polypropylene is mentioned as the most preferable polyolefin resin.

- polypropylene having a melt mass flow rate (MFR) of 3 g / 10 minutes or more and 30 g / 10 minutes or less measured at 230 ° C. and a load of 21.2 N in accordance with ISO1133 is preferable.

- MFR melt mass flow rate

- the lower limit of MFR is more preferably 5 g / 10 minutes, even more preferably 6 g / 10 minutes, and most preferably 8 g / 10 minutes.

- the upper limit is more preferably 25 g / 10 minutes, even more preferably 20 g / 10 minutes, and most preferably 18 g / 10 minutes. It is desirable that the MFR does not exceed the above upper limit value from the viewpoint of improving the toughness of the composition, and it is desirable not to exceed the above lower limit value from the viewpoint of the fluidity of the composition.

- an acid-modified polyolefin resin can also be preferably used in order to enhance the affinity with cellulose.

- the acid can be appropriately selected from maleic acid, fumaric acid, succinic acid, phthalic acid and anhydrides thereof, polycarboxylic acid such as citric acid and the like. Of these, maleic acid or its anhydride is preferable because of the ease of increasing the denaturation rate.

- the modification method is not particularly limited, but a method of heating the resin to a melting point or higher and melt-kneading it in the presence / absence of a peroxide is common.

- the acid-modified polyolefin resin all of the above-mentioned polyolefin resins can be used, but polypropylene is particularly preferable.

- the acid-modified polyolefin resin may be used alone, but it is more preferable to use the acid-modified polyolefin resin in combination with the unmodified polyolefin resin in order to adjust the modification rate as a composition.

- the ratio of acid-modified polypropylene to total polypropylene is preferably 0.5% by mass to 50% by mass.

- a more preferable lower limit is 1% by mass, still more preferably 2% by mass, even more preferably 3% by mass, particularly preferably 4% by mass, and most preferably 5% by mass.

- the upper limit is more preferably 45% by mass, still more preferably 40% by mass, even more preferably 35% by mass, particularly preferably 30% by mass, and most preferably 20% by mass.

- the lower limit or more is preferable, and in order to maintain the ductility as a resin, the upper limit or less is preferable.

- the lower limit of the acid modification rate of the acid-modified polyolefin resin is preferably 0.01% by mass, more preferably 0.1% by mass, still more preferably 0.3% by mass, and particularly preferably 0.3% by mass. It is 0.5% by mass, most preferably 0.7% by mass.

- the upper limit is preferably 10% by mass, more preferably 5% by mass, further preferably 3% by mass, particularly preferably 2% by mass, and most preferably 1.5% by mass.

- the lower limit or more is preferable, and in order to maintain the mechanical properties of the acid-modified polyolefin, the upper limit or less is preferable.

- the melt mass flow rate (MFR) measured at 230 ° C. and a load of 21.2 N in accordance with the preferred ISO 1133 of acid-modified polypropylene should be 50 g / 10 min or more in order to enhance the affinity with the cellulose interface.

- a more preferable lower limit is 100 g / 10 minutes, even more preferably 150 g / 10 minutes, and most preferably 200 g / 10 minutes.

- the polyamide-based resin preferable as the thermoplastic resin is not particularly limited, but is obtained by a polycondensation reaction of lactams, polyamide 6, polyamide 11, polyamide 12, etc .; 1,6-hexanediamine, 2-methyl-1,5. -Pentanediamine, 1,7-heptanediamine, 2-methyl-1-6-hexanediamine, 1,8-octanediamine, 2-methyl-1,7-heptanediamine, 1,9-nonanediamine, 2-methyl- Diamines such as 1,8-octanediamine, 1,10-decanediamine, 1,11-undecanediamine, 1,12-dodecanediamide, m-xylylene diamine, butane diic acid, pentanic acid, hexane diic acid , Heptane diic acid, octane diacid, nonane diic acid, decane diic acid, benzene-1,2-dicarboxylic acid, benzene-1,3

- polyamide-based resins aliphatic polyamides such as polyamide 6, polyamide 11, polyamide 12, polyamide 6, 6, polyamide 6, 10, polyamide 6, 11, polyamide 6, 12 and polyamide 6, C, polyamide 2 M5, C

- the alicyclic polyamide such as is more preferable.

- the concentration of terminal carboxyl groups in the polyamide resin is not particularly limited, but the lower limit is preferably 20 ⁇ mol / g, more preferably 30 ⁇ mol / g.

- the upper limit of the terminal carboxyl group concentration is preferably 150 ⁇ mol / g, more preferably 100 ⁇ mol / g, and further preferably 80 ⁇ mol / g.

- the ratio of carboxyl terminal groups to total terminal groups is preferably 0.30 to 0.95.

- the lower limit of the carboxyl end group ratio is more preferably 0.35, even more preferably 0.40, and most preferably 0.45.

- the upper limit of the carboxyl end group ratio is more preferably 0.90, even more preferably 0.85, and most preferably 0.80.

- the ratio of carboxyl terminal groups is preferably 0.30 or more from the viewpoint of dispersibility of (B) cellulose nanofibers in the resin composition, and 0.95 or less from the viewpoint of the color tone of the obtained resin composition. It is desirable to do.

- a known method can be used as a method for adjusting the terminal group concentration of the polyamide resin.

- a diamine compound, a monoamine compound, a dicarboxylic acid compound, a monocarboxylic acid compound, an acid anhydride, a monoisocyanate, a monoacid halide, a monoester, a monoalcohol, or the like so as to have a predetermined terminal group concentration during polymerization of polyamide.

- Examples thereof include a method of adding a terminal modifier that reacts with an terminal group to the polymerization solution.

- aliphatic monocarboxylic acids aliphatic monocarboxylic acids

- alicyclic monocarboxylic acids such as cyclohexanecarboxylic acid

- aromatic products such as benzoic acid, toluic acid, ⁇ -naphthalenecarboxylic acid, ⁇ -naphthalenecarboxylic acid, methylnaphthalenecarboxylic acid, phenylacetic acid, etc.

- Carboxylic acids and a plurality of mixtures arbitrarily selected from these.

- One or more terminal modifiers selected from the group consisting of and benzoic acid are preferable, and acetic acid is most preferable.

- terminal modifier examples include aliphatic groups such as methylamine, ethylamine, propylamine, butylamine, hexylamine, octylamine, decylamine, stearylamine, dimethylamine, diethylamine, dipropylamine and dibutylamine.

- one or more terminals selected from the group consisting of butylamine, hexylamine, octylamine, decylamine, stearylamine, cyclohexylamine and aniline from the viewpoints of reactivity, boiling point, stability of sealing terminal, price and the like. Regulators are preferred.

- the concentrations of these amino-terminal groups and carboxyl-terminal groups are preferably obtained by 1 H-NMR from the integrated value of the characteristic signal corresponding to each terminal group in terms of accuracy and simplicity.

- a method for determining the concentration of these terminal groups specifically, the method described in JP-A-7-228775 is recommended. When this method is used, heavy trifluoroacetic acid is useful as a measurement solvent.

- the number of integrations of 1 1 H-NMR requires at least 300 scans even when measured with an instrument having sufficient resolution.

- the concentration of the terminal group can also be measured by a measurement method by titration as described in JP-A-2003-055549. However, in order to reduce the influence of mixed additives, lubricants, etc. as much as possible, 1 H-NMR quantification is more preferable.

- the polyamide resin has a viscosity number [VN] measured in 96% sulfuric acid according to ISO307, preferably 60 to 300, more preferably 70 to 250, and further preferably 75 to 200. It is preferably 80 to 180, and particularly preferably 80 to 180.

- a polyamide-based resin having a viscosity number in the above range is advantageous in that it can improve the fluidity in the mold when the resin composition is injection-molded to produce a resin molded product, and can improve the appearance of the resin molded product. is there.

- the polyester-based resin preferable as the thermoplastic resin is not particularly limited, but is not particularly limited, but is polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyethylene naphthalate (PEN), polybutylene succinate (PBS), polybutylene succinate adipate ( Selected from PBSA), polybutylene terephthalate (PBAT), polyallylate (PAR), polyhydroxyalkanoic acid (PHA) (polyester resin composed of 3-hydroxyalkanoic acid), polylactic acid (PLA), polycarbonate (PC), etc.

- PET polyethylene terephthalate

- PBT polybutylene terephthalate

- PEN polyethylene naphthalate

- PBS polybutylene succinate

- PBS polybutylene succinate adipate

- PAR polyallylate

- PHA polyhydroxyalkanoic acid

- PDA polylactic acid

- PC polycarbonate

- more preferable polyester-based resins include PET, PBS,

- the terminal group can be freely changed depending on the monomer ratio at the time of polymerization and the presence / absence and amount of the terminal stabilizer added, but the carboxyl terminal group ratio to the total terminal group of the polyester resin.

- ([COOH] / [all terminal groups]) is preferably 0.30 to 0.95.

- the lower limit of the carboxyl end group ratio is more preferably 0.35, further preferably 0.40, and most preferably 0.45.

- the upper limit of the carboxyl end group ratio is more preferably 0.90, further preferably 0.85, and most preferably 0.80.

- the ratio of carboxyl terminal groups is preferably 0.30 or more from the viewpoint of dispersibility of (B) cellulose nanofibers in the composition, and 0.95 or less from the viewpoint of the color tone of the obtained composition. Is desirable.

- Preferable polyacetal-based resins as thermoplastic resins are generally homopolyacetal made from formaldehyde and copolyacetal containing trioxane as a main monomer and, for example, 1,3-dioxolane as a comonomer component, and both can be used.

- copolyacetal can be preferably used.

- the amount of the comonomer component (for example, 1,3-dioxolane) is preferably in the range of 0.01 to 4 mol%.

- a more preferable lower limit of the amount of the comonomer component is 0.05 mol%, more preferably 0.1 mol%, and particularly preferably 0.2 mol%.

- a more preferable upper limit amount is 3.5 mol%, further preferably 3.0 mol%, particularly preferably 2.5 mol%, and most preferably 2.3 mol%. From the viewpoint of thermal stability during extrusion and molding, it is desirable that the lower limit is within the above range, and from the viewpoint of mechanical strength, the upper limit is preferably within the above range.

- (B) Cellulose nanofibers are cellulose having an average fiber diameter of 1000 nm or less.

- Preferable examples of (B) cellulose nanofibers are not particularly limited, but for example, cellulose nanofibers made from cellulose pulp or one or more modified products of these celluloses can be used. Among these, one or more modified cellulose products can be preferably used from the viewpoint of stability, performance and the like.

- the average fiber diameter of the (B) cellulose nanofibers is 1000 nm or less, preferably 500 nm or less, and more preferably 200 nm or less, from the viewpoint of obtaining good mechanical strength (particularly tensile elastic modulus) of the resin molded body.

- the average fiber diameter is preferably small, but from the viewpoint of ease of processing, it can be preferably 10 nm or more, more preferably 20 nm or more, and further preferably 30 nm or more.

- the average fiber diameter is a value obtained by a laser diffraction / scattering method particle size distribution meter as a spherical equivalent diameter (volume average particle diameter) of particles when the integrated volume becomes 50%.

- the average fiber diameter can be measured by the following method.

- (B) Using cellulose nanofibers as a solid content of 40% by mass, in a planetary mixer (for example, 5DM-03-R manufactured by Shinagawa Kogyo Co., Ltd., stirring blade is hook type) at 126 rpm, 30 at room temperature and normal pressure. Knead for minutes, then make a pure water suspension at a concentration of 0.5% by mass, and use a high shear homogenizer (for example, manufactured by Nippon Seiki Co., Ltd., trade name "Excel Auto Homogenizer ED-7" treatment conditions), and rotate the number of revolutions.

- a planetary mixer for example, 5DM-03-R manufactured by Shinagawa Kogyo Co., Ltd., stirring blade is hook type

- Knead for minutes then make a pure water suspension at a concentration of 0.5% by mass, and use a high shear homogenizer (for example, manufactured by Nippon Seiki Co., Ltd., trade name "Excel Auto

- centrifuge for example, manufactured by Kubota Shoji Co., Ltd., trade name "6800 type centrifuge", rotor type RA-400 type

- processing conditions centrifugal force 39200 m 2 / Centrifuge the supernatant at s for 10 minutes, and further centrifuge the supernatant at 116000 m 2 / s for 45 minutes, and collect the supernatant after centrifugation.

- a laser diffraction / scattering method particle size distribution counter for example, manufactured by Horiba Seisakusho Co., Ltd., trade name "LA-910” or trade name "LA-950", ultrasonic treatment 1 minute, refractive index 1.

- the integrated 50% particle diameter in the volume frequency particle size distribution obtained in 20 (that is, the spherical equivalent diameter of the particles when the integrated volume becomes 50% with respect to the total volume of the particles) is defined as the volume average particle diameter. ..

- the L / D ratio of (B) cellulose nanofibers is 20 or more.

- the lower limit of L / D of the cellulose nanofibers is preferably 30, more preferably 40, more preferably 50, and even more preferably 100.

- the upper limit is not particularly limited, but is preferably 10,000 or less from the viewpoint of handleability. In order to exhibit the good mechanical properties of the resin composition of the present disclosure with a small amount of cellulose nanofibers, it is desirable that the L / D ratio of the cellulose nanofibers is within the above range.

- the length (L), diameter (D) and L / D ratio of the cellulose nanofibers are such that the aqueous dispersion of the cellulose nanofibers is a high-shear homogenizer (for example, manufactured by Nippon Seiki Co., Ltd., trade name "Excel".

- a high-shear homogenizer for example, manufactured by Nippon Seiki Co., Ltd., trade name "Excel”.

- ED-7 an autohomogenizer ED-7 "

- SEM high-resolution scanning microscope

- AFM atomic force microscope

- the length (L) and diameter (D) of 100 randomly selected cellulose nanofibers in the observation field adjusted so that at least 100 cellulose nanofibers are observed. Is measured and the ratio (L / D) is calculated. Moreover, the length and diameter of the cellulose nanofibers of the present disclosure are the number average values of the above 100 celluloses.

- cellulose nanofibers are modified products (that is, modified cellulose nanofibers).

- the cellulose is modified by one or more modification agents selected from an esterifying agent, a silylating agent, an isocyanate compound, an alkyl halide agent, an alkylene oxide and / or a glycidyl compound. The ones that have been made are listed.

- the cellulose nanofiber is an unmodified product or an oxo acid modifying group (that is, a site in which the hydroxyl group of cellulose is converted with an oxo acid (for example, a carboxylic acid) or a salt thereof (for example, a carboxylic acid salt)). It is a non-containing modified product, and an example of this preferred modified product is a modified product by the modifying agent listed above.

- the esterifying agent as a modifier includes (B) an organic compound having at least one functional group capable of reacting with a hydroxyl group on the surface of cellulose nanofibers to esterify the hydroxyl group. Esterification can also be carried out by the method described in paragraph [0108] of WO 2017/159823.

- the esterifying agent may be a commercially available reagent or product.

- esterifying agent are not particularly limited, but for example, acetic acid, propionic acid, butyric acid, valeric acid, caproic acid, capric acid, lauric acid, tridecanoic acid, myristic acid, palmitic acid, stearic acid, pivalic acid, iso

- Alipid monocarboxylic acid such as butyric acid; alicyclic monocarboxylic acid such as cyclohexanecarboxylic acid; aromatics such as benzoic acid, toluic acid, ⁇ -naphthalenecarboxylic acid, ⁇ -naphthalenecarboxylic acid, methylnaphthalenecarboxylic acid, and phenylacetic acid.

- Monocarboxylic acids and a plurality of mixtures arbitrarily selected from these, and esters of these acids and vinyl alcohols (eg, vinyl acetate, vinyl propionate, vinyl butyrate, vinyl valerate, vinyl caproate, vinyl caprylate). , Vinyl laurate, etc.), and symmetric anhydrides (eg, acetic anhydride, maleic anhydride, cyclohexane-carboxylic acid anhydride, benzene-sulfonic acid anhydride), mixed acid anhydride, which are arbitrarily selected from the above-mentioned acids.

- vinyl alcohols eg, vinyl acetate, vinyl propionate, vinyl butyrate, vinyl valerate, vinyl caproate, vinyl caprylate.

- vinyl laurate, etc. and symmetric anhydrides (eg, acetic anhydride, maleic anhydride, cyclohexane-carboxylic acid anhydride, benzene-sulfonic acid anhydride), mixed

- butyric acid-valeric acid anhydride for example, butyric acid-valeric acid anhydride

- cyclic anhydride for example, succinic anhydride, phthalic anhydride, naphthalene-1,8: 4,5-tetracarboxylic hydride, cyclohexane-1,2 , 3,4-Tetracarboxylic acid 3,4-anhydride

- esteric anhydride for example, 3- (ethoxycarbonyl) propanoic anhydride, benzoylethyl carbonate

- acetic acid, propionic acid, butyric acid, valeric acid, caproic acid, caprylic acid, lauric acid, tridecanoic acid, myristic acid, palmitic acid, stearic acid, and these acids are used in terms of reactivity, stability, price, etc.

- Esterized products of vinyl alcohol, benzoic acid, acetic acid anhydride, maleic anhydride, succinic anhydride, and phthalic acid anhydride can be preferably used.

- the silylating agent as a modifier includes a Si-containing compound having at least one reactive group capable of reacting with the hydroxyl group on the surface of cellulose or the group after hydrolysis thereof.

- the silylating agent may be a commercially available reagent or product.

- silylating agent are not particularly limited, but are chlorodimethylisopropylsilane, chlorodimethylbutylsilane, chlorodimethyloctylsilane, chlorodimethyldodecylsilane, chlorodimethyloctadecylsilane, chlorodimethylphenylsilane, and chloro (1-hexenyl).

- hexamethyldisilazane, octadecyldimethylmethoxysilane, dimethyloctylmethoxysilane, and trimethylethoxysilane can be preferably used from the viewpoints of reactivity, stability, price, and the like.

- the halogenated alkylating agent as a modifier includes an organic compound having at least one functional group capable of reacting with a hydroxyl group on the surface of cellulose to alkylate the halogen.

- the halogenated alkylating agent may be a commercially available reagent or product.

- halogenated alkylating agent are not particularly limited, but chloropropane, chlorobutane, bromopropane, bromohexane, bromoheptane, iodomethane, iodoethane, iodooctane, iodooctadecane, iodobenzene and the like can be used.

- bromohexane and iodooctane can be preferably used from the viewpoints of reactivity, stability, price and the like.

- the isocyanate compound as a modifier includes (B) an organic compound having at least one isocyanate group capable of reacting with a hydroxyl group on the surface of the cellulose nanofibers. Further, the isocyanate compound may be a blocked isocyanate compound capable of regenerating an isocyanate group by desorbing a blocking group at a specific temperature, or a dimer or trimeric of polyisocyanate, or a buretted isocyanate.

- the modified product such as Polymethylenepolyphenylpolyisocyanate (Polymeric MDI) may be used. These may be commercially available reagents or products.

- isocyanate compound examples include, but are not limited to, aliphatic polyisocyanate, alicyclic polyisocyanate, aromatic polyisocyanate, aromatic aliphatic polyisocyanate, blocked isocyanate compound, polyisocyanate and the like.

- tetramethylene diisocyanate dodecamethylene diisocyanate, hexamethylene diisocyanate, 2,2,4-trimethylhexamethylene diisocyanate, 2,4,4-trimethylhexamethylene diisocyanate, lysine diisocyanate, 2-methylpentane-1,5-diisocyanate, 3-Methylpentane-1,5-diisocyanate, isophorone diisocyanate, hydrogenated xylylene diisocyanate, 4,4'-dicyclohexylmethane diisocyanate, 1,4-cyclohexanediisocyanate, methylcyclohexylene diisocyanate, 1,3-bis (isocyanate methyl) Cyclohexane), tolylene diisocyanate (TDI), 2,2'-diphenylmethane diisocyanate, 2,4'-diphenylmethane diisocyanate, 4,4

- TDI, MDI, hexamethylene diisocyanate, and blocked isocyanate made from a modified hexamethylene diisocyanate and hexamethylene diisocyanate as raw materials can be preferably used from the viewpoints of reactivity, stability, price, and the like.

- the dissociation temperature of the block group of the blocked isocyanate compound has an upper limit of preferably 210 ° C, more preferably 190 ° C, and further preferably 150 ° C.

- the lower limit is preferably 70 ° C., more preferably 80 ° C., and even more preferably 110 ° C.

- the blocking agent in which the dissociation temperature of the blocking group falls within this range include methylethylketone oxime, ortho-secondary butylphenol, caprolactam, sodium bisulfite, 3,5-dimethylpyrazole, 2-methylimidazole and the like.

- the alkylene oxide and / or glycidyl compound as a modifier includes an organic compound having at least one alkylene oxide group, glycidyl group and / or epoxy group capable of reacting with a hydroxyl group on the surface of cellulose.

- the alkylene oxide and / or glycidyl compound may be a commercially available reagent or product.

- alkylene oxide and / or the glycidyl compound are not particularly limited, but for example, methyl glycidyl ether, ethyl glycidyl ether, butyl glycidyl ether, 2-ethylhexyl glycidyl ether, 2-methyloctyl glycidyl ether, phenyl glycidyl ether, p.

- 2-methyloctyl glycidyl ether hexamethylene glycol diglycidyl ether, and pentaerythritol tetraglycidyl ether can be preferably used from the viewpoints of reactivity, stability, price and the like.

- the total degree of substitution of the modified cellulose nanofibers is 0.5 or more, 0.7 or more, or 0.75 or more from the viewpoint of obtaining (A) good dispersibility of the cellulose nanofibers in the thermoplastic resin. (B) From the viewpoint of maintaining the physical properties of the cellulose nanofibers well, it is 1.5 or less, 1.3 or less, or 1.25 or less.

- the modified cellulose nanofibers are esterified cellulose nanofibers, and the total degree of substitution is the total degree of transesterification.

- the conditions for the 13 C solid-state NMR measurement used can be exemplified as follows.

- the main feed material may optionally contain additional components in addition to (A) thermoplastic resin and (B) cellulose nanofibers.

- additional components include surface treatment agents, antioxidants, inorganic fillers, lubricating oils and the like. Each of these components may be used alone or in combination of two or more. Further, these components may be commercially available reagents or products.

- the surface treatment agent include compounds having a hydrophilic segment and a hydrophobic segment in the molecule, and more specifically, a compound giving a hydrophilic segment (for example, polyethylene glycol) and a hydrophobic segment.

- a copolymer obtained by using one or more of each of the given compounds for example, polypropylene glycol, poly (tetramethylene ether) glycol (PTMEG), polybutadiene diol, etc.

- PTMEG poly(tetramethylene ether) glycol

- PTMEG polybutadiene diol, etc.

- Block copolymer of ethylene oxide Block copolymer of ethylene oxide

- the preferable content of the surface treatment agent in the main feed material is preferably 0.1% by mass or more, or 0.2% by mass, from the viewpoint of enhancing the dispersibility of the (B) cellulose nanofibers in the resin molded body.

- the above or 0.5% by mass is preferably 50% by mass or less, or 30% by mass, or 20% by mass, or 18% by mass from the viewpoint of suppressing plasticization of the resin molded body and maintaining good strength. %, Or 15% by mass, or 10% by mass, or 5% by mass.

- the preferable amount of the surface treatment agent with respect to 100 parts by mass of the (B) cellulose nanofibers is preferably 0.1 part by mass or more, or 0, from the viewpoint of enhancing the dispersibility of the (B) cellulose nanofibers in the resin molded body. .5 parts by mass or more, or 1 part by mass or more, preferably 100 parts by mass or less, 99 parts by mass or less, or 90 parts by mass from the viewpoint of suppressing plasticization of the resin molded body and maintaining good strength. Below, or less than 80 parts by mass, or less than 70 parts by mass, or less than 50 parts by mass, or less than 40 parts by mass.

- a hindered phenolic antioxidant, a sulfur-based antioxidant, and a phosphorus-based antioxidant are preferable from the viewpoint of the effect of preventing deterioration due to heat, and a phosphorus-based antioxidant and a hindered phenol-based oxidation are preferable.

- An inhibitor is more preferable, and a combination of a phosphorus-based antioxidant and / or a hindered phenol-based antioxidant and a hindered amine-based photostabilizer (HALS) is even more preferable.

- the preferable amount of the antioxidant is 0.01% by mass or more, or 0.02% by mass or more, or 0.03% by mass or more, or 0.05% by mass or more, based on the whole resin molded product. , Preferably 5% by mass or less, 4% by mass or less, or 3% by mass or less, or 2% by mass or less, or 1% by mass or less.

- the inorganic filler examples include fibrous particles, plate-like particles, and inorganic pigments.

- the fibrous particles and the plate-like particles may have an average aspect ratio of 5 or more.

- glass fiber, glass flakes, glass balloons, carbon fiber, carnon nanotubes, carbon black, talc, mica, wollastonite, calcium carbonate, barium sulfate, magnesium hydroxide, magnesium oxide, tovamorite, halosite examples thereof include halosite nanotubes, titanium dioxide, zinc sulfide, zinc oxide, iron oxide and iron sulfide.

- the amount of the inorganic filler in the resin molded product is preferably 0.002 parts by mass with respect to 100 parts by mass of the (A) thermoplastic resin from the viewpoint of improving the handleability when molding the resin composition into the resin molded product. ⁇ 50 parts by mass.

- the lubricating oil examples include natural oils (engine oils, cylinder oils, etc.), synthetic hydrocarbons (paraffin oils, naphthenic oils, aroma oils, etc.), silicone oils, and the like.

- the molecular weight of the lubricating oil may be, for example, 100 or more, 400 or more, or 500 or more, and may be, for example, 5 million or less, 2 million or less, or 1 million or less.

- the melting point of the lubricating oil may be, for example, -50 ° C or higher, -30 ° C or higher, or -20 ° C or higher, and may be, for example, 50 ° C or lower, 30 ° C or lower, or 20 ° C or lower.

- the melting point is 2.5 ° C. lower than the pour point of the lubricating oil, and the pour point can be measured in accordance with JIS K2269.

- the content of the lubricating oil with respect to 100 parts by mass of the thermoplastic resin is preferably 0.1 part by mass or more, 0.2 parts by mass or more, or 0.3 parts by mass or more from the viewpoint of improving wear resistance. From the viewpoint of avoiding undesired softening of the resin molded body, the amount is preferably 5.0 parts by mass or less, 4.5 parts by mass or less, or 4.2 parts by mass or less.

- the total amount of the additional components in the main feed material may be, for example, 0.5% by mass or more, or 2% by mass or more, for example, 20% by mass or less, 15% by mass or less, or 20% by mass or less. You can.

- the main feedstock comprises (A) 70% to 99% by weight of the thermoplastic, (B) 1% to 30% by weight of cellulose nanofibers, and 0% to 20% by weight of additional components. ..

- the main feedstock is (A) 80% to 95% by weight of thermoplastic resin, (B) 5% to 20% by weight of cellulose nanofibers, and 1% to 15% by weight of additional components. Or, it contains (A) a thermoplastic resin of 85% by mass to 95% by mass, (B) a cellulose nanofiber of 5% by mass to 15% by mass, and an additional component of 2% by mass to 10% by mass.

- the melt mixing is performed by mixing the auxiliary feed material (a1) and the auxiliary feed material (a2) in a total of 100% by mass with respect to a mixing ratio of more than 0% by mass and 50% by mass or less, preferably 5 to 50% by mass. Perform at%.

- the mixing ratio of the auxiliary supply material is preferably 5% by mass or more, 10% by mass or more, or 15 from the viewpoint of satisfactorily obtaining the anisotropy reduction effect due to the contribution of the (B) cellulose nanofibers derived from the auxiliary supply material.

- (B) cellulose nanofibers derived from the main supply material which is 50% by mass or more or 20% by mass or more. , Or 40% by mass or less, or 25% by mass or less.

- the mass ratio of the main supply material (a1) and the mass ratio of the auxiliary supply material (a2) in the resin composition (b) are as follows: [Mass ratio of auxiliary supply material (a2)] ⁇ [Mass ratio of main supply material (a1)]

- the relationship may be satisfied. That is, 50% by mass or more of the auxiliary supply material may be present in the resin composition.

- the mass ratio of the auxiliary feed material in the resin composition may be 55% by mass or more, 60% by mass or more, or 70% by mass or more.

- the mass ratio of the auxiliary feed material is less than 100% by mass, preferably 90% by mass or less, or 80% by mass or less.

- First Embodiment 1 to 3 are diagrams for explaining processes 100, 200, and 300 as an example of a method for manufacturing a resin molded product according to the first embodiment.

- the main feed material 11 or its constituent components that is, (A) thermoplastic resin 11a, (B) cellulose nanofibers 11b, And the optional additional component 11c) and the auxiliary supply material 12 are melt-mixed to produce a resin composition 13 which is a melt mixture, and the resin composition 13 is molded by the molding unit 102 to produce a resin molded body 14.

- the resin molded body 14 may have a shape such as pellets.

- the main supply material 11 is in the form of a mixture containing (A) a thermoplastic resin 11a, (B) cellulose nanofibers 11b, and an optional additional component 11c (main supply material 11 in FIGS. 1 and 2), or a main supply. It may be in a form in which (A) a thermoplastic resin 11a, (B) a cellulose nanofiber 11b, and an optional additional component 11c as constituent components of the material 11 are individually prepared (main supply material 11 in FIG. 3). .. In the latter case, the components of the main feed material will be mixed with each other and with the auxiliary feed material in the melt mixing system.

- the auxiliary supply material 12 is a melt processing product of the main supply material 11.

- the auxiliary supply material 12 may be obtained by melting the main supply material 11 alone, or may be a part of the resin molded body 14 recovered. In the latter case, as shown in FIGS. 1 to 3, the main supply material 11 and the auxiliary supply material 12 are melt-mixed, and then a part of the resin molded body 14 obtained by molding is separated at the separation portion S5. It is returned to the melt mixing section 101 as the auxiliary supply material 12, and the rest is recovered as the target resin molded body 14.

- the auxiliary supply material 12 returned to the melt mixing section 101 is melt-mixed with the newly supplied main supply material 11. According to such a cycle, the auxiliary feed material 12 is a mixture of a plurality of compositions based on the main feed material 11, but with different melt treatment counts (ie, thermal history).

- melt mixing is melt kneading.

- the melt mixing unit 101 can be, for example, a mixing unit in a mixing device such as a single-screw extruder, a twin-screw extruder, a roll, or a Banbury mixer.

- a twin-screw extruder is preferable, and more specifically, a twin-screw extruder equipped with a decompression device and a side feeder facility can be mentioned.

- the L / D of the twin-screw extruder may be, for example, 30 to 100, or 35 to 75, or 45 to 70.

- the main feed material 11 as a mixture of (A) thermoplastic resin, (B) cellulose nanofibers and any additional component is melted and mixed with the main feed material input portion S1 of the mixing section 101.

- the auxiliary supply material 12 is charged into the auxiliary supply material input portion S2 of the melt mixing unit 101, and both are melt-mixed to produce the resin composition 13.

- the positional relationship between the main supply material input portion S1 and the auxiliary supply material input portion S2 can be appropriately designed according to the purpose.

- the auxiliary supply material input site S2 may be arranged on the downstream side of the main supply material input site S1 (FIG.

- the main supply material input site S1 may be arranged on the downstream side of the auxiliary supply material input site S2 (FIG. 1). 2) may be performed, or the main supply material 11 and the auxiliary supply material 12 may be supplied at the same time (for example, the main supply material 11 and the auxiliary supply material 12 may be supplied individually or in advance).

- thermoplastic resin 11a thermoplastic resin 11a

- (B) cellulose nanofibers 11b and any additional component 11c as constituent components of the main supply material 11 are supplied to a plurality of main supplies of the melt mixing section 101.

- the main supply material 11 and the auxiliary supply material 12 are put into the melt mixing system by charging the material input parts S1a, S1b, and S1c into each of the material input parts S1a, S1b, and S1c, and charging the auxiliary supply material 12 into the auxiliary supply material input part S2 of the melt mixing unit 101. It is introduced and both are melt-mixed to produce a resin composition 13.

- the supply mode of the constituent components of the main supply material 11 can be designed according to the purpose, and the constituent components may be individually supplied to the melt mixing unit 101, or a part of the constituent components may be melt-mixed in advance. It may be supplied to the unit 101.

- FIG. 3 shows an example in which (A) the thermoplastic resin 11a, (B) the cellulose nanofibers 11b and the optional additional component 11c are supplied in order from the upstream side of the melt mixing section 101, but the supply order is this. It is not limited to, and may be set as appropriate according to the purpose. Further, similarly to the procedure of (1) above, the positional relationship between the main supply material input portion S1 and the auxiliary supply material input portion S2 can be appropriately designed.

- the temperature and time of melt mixing can be appropriately set according to the target resin molded product.

- the preferable conditions are as follows from the viewpoint of satisfactorily obtaining the effect of improving the physical properties of the auxiliary supply material (particularly, both good mechanical strength and low anisotropy).

- a crystalline resin In the case of a crystalline resin, it means the melting point thereof, and in the case of a non-crystalline resin, it means a temperature at which it flows substantially easily.

- the measurement temperature of the melt mass flow rate can be mentioned.

- the time is 0.1 to 3 minutes, or 0.2 to 2.5 minutes, or 0.3 to 2.0 minutes.

- the pressure at the time of melt mixing may be appropriately set depending on the intended purpose, but a preferable example is a pressure of ⁇ 0.1 MPa to 10 MPa, or ⁇ 0.15 MPa to 8 MPa, or ⁇ 0.2 MPa to 5 MPa.

- the resin composition 13 is sent from the mixing end portion S3 of the melt mixing section 101 to the molding section 102, and the molding section 102 sends a desired shape (for example, pellets, sheet, film, molded body having a three-dimensional structure). Etc.), and the target resin molded body 14 is taken out from the delivery portion S4.

- the melt kneading is melt kneading, and the melt kneading and molding are performed in a single kneader (for example, those exemplified in the ⁇ resin composition forming step>).

- molding is performed in a molding machine (for example, an injection molding machine) different from melt kneading.

- a part of the resin molded body 14 is separated at the separation portion S5 and returned to the melt mixing section 101 as the auxiliary supply material 12, and the rest is recovered as a product. That is, the method according to one aspect further includes returning a part of the resin molded body 14 to the resin composition forming step as at least a part of the auxiliary supply material.

- the resin molded product contains cellulose nanofibers that have undergone a melting process of the main feed material and two or more resin composition forming steps.

- the ratio of the cellulose nanofibers that have undergone the melting treatment of the main feed material and the resin composition forming step two or more times to 100% by mass of the total amount of the cellulose nanofibers in the resin molded body is preferably 20% by mass. % Or less, or 15% by mass or less, or 10% by mass or less.

- the cellulose nanofibers contain lignin, it is desirable that the cellulose nanofibers do not undergo an excessive heat history from the viewpoint of satisfactorily avoiding coloring, odor (that is, odor due to decomposing components) and the like.

- the above ratio is in the above range, it is advantageous to avoid coloring, odor and the like.

- the above ratio may be, for example, 1% by mass or more, 2% by mass or more, or 5% by mass or more from the viewpoint of avoiding an increase in manufacturing cost of the resin molded product while avoiding coloring, odor, and the like.

- Examples of the shape of the resin molded product according to the first embodiment include pellet shape, sheet shape, fibrous shape, plate shape, rod shape, tubular shape, and the like, and the pellet shape is a preferable example from the viewpoint of ease of post-processing and transportation.

- the pellet shape can be different depending on the cutting method at the time of extrusion, and may be, for example, a round shape, an elliptical shape, a cylindrical shape, or the like.

- pellets cut by underwater cut are often round

- pellets cut by hot cut are often round or oval

- pellets cut by strand cut are cylinders. Often becomes a mold.

- the pellet diameter may be, for example, 1 mm or more and 3 mm or less.

- the pellet diameter may be, for example, 1 mm or more and 3 mm or less, and the pellet length may be, for example, 2 mm or more and 10 mm or less.

- the pellet size is preferably at least the above lower limit from the viewpoint of operational stability during extrusion, and is preferably at least the above upper limit from the viewpoint of biting into the molding machine in post-processing.

- FIG. 4 is a diagram illustrating a process 400 as an example of a method for manufacturing a resin molded product according to a second embodiment.

- the main supply material 41 and the auxiliary supply material 42 are melt-mixed to produce a resin composition 43 which is a melt mixture, and the resin is formed in the molding section 402.

- the composition 43 is molded to produce a resin molded product 44.

- the resin molded body 44 may have a shape (pellets or the like) for further processing, or may have various product shapes described later.

- the main supply material 41 can include a first material 41a and a second material 41b.

- the first material 41a is a molten mixture.

- the first material 41a is the resin molded body 14 obtained in the first embodiment.

- the first material 41a is a molded product containing (A) 100 parts by mass of a thermoplastic resin and (B) 1 to 50 parts by mass of cellulose nanofibers.

- the auxiliary supply material 42 is a melt processing product of the main supply material 41.

- the auxiliary supply material 42 may be obtained by melting the main supply material 41 alone, or may be a part of the resin molded body 44 recovered. In the latter case, as shown in FIG. 4, the main supply material 41 and the auxiliary supply material 42 are melt-mixed, and then a part of the resin molded body 44 obtained by molding is used as the auxiliary supply material 42 to melt-mix the unit 401. And the rest is collected as the target resin molded body 44.

- the auxiliary supply material 42 returned to the melt mixing section 401 is melt-mixed with the newly supplied main supply material 41.

- the auxiliary feed material 42 is a mixture of a plurality of compositions based on the main feed material 41 but having different melt treatment counts (ie, thermal history).

- melt mixing is melt kneading.

- the melt-mixing section 401 may be the same as the melt-mixing section 101 of the first embodiment. That is, the melt mixing unit 401 can be, for example, a mixing unit in a mixing device such as a single-screw extruder, a twin-screw extruder, a roll, or a Banbury mixer.