WO2020137412A1 - 融着層付き絶縁電線 - Google Patents

融着層付き絶縁電線 Download PDFInfo

- Publication number

- WO2020137412A1 WO2020137412A1 PCT/JP2019/047565 JP2019047565W WO2020137412A1 WO 2020137412 A1 WO2020137412 A1 WO 2020137412A1 JP 2019047565 W JP2019047565 W JP 2019047565W WO 2020137412 A1 WO2020137412 A1 WO 2020137412A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- fusion

- component

- coating layer

- insulating coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/18—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances

- H01B3/30—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes

- H01B3/44—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes vinyl resins; acrylic resins

- H01B3/443—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes vinyl resins; acrylic resins from vinylhalogenides or other halogenoethylenic compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/26—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers modified by chemical after-treatment

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D123/00—Coating compositions based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Coating compositions based on derivatives of such polymers

- C09D123/02—Coating compositions based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Coating compositions based on derivatives of such polymers not modified by chemical after-treatment

- C09D123/10—Homopolymers or copolymers of propene

- C09D123/14—Copolymers of propene

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D127/00—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Coating compositions based on derivatives of such polymers

- C09D127/02—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Coating compositions based on derivatives of such polymers not modified by chemical after-treatment

- C09D127/04—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Coating compositions based on derivatives of such polymers not modified by chemical after-treatment containing chlorine atoms

- C09D127/06—Homopolymers or copolymers of vinyl chloride

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/35—Heat-activated

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/18—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances

- H01B3/30—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes

- H01B3/44—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes vinyl resins; acrylic resins

- H01B3/448—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes vinyl resins; acrylic resins from other vinyl compounds

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/40—Insulated conductors or cables characterised by their form with arrangements for facilitating mounting or securing

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2203/00—Applications of adhesives in processes or use of adhesives in the form of films or foils

- C09J2203/302—Applications of adhesives in processes or use of adhesives in the form of films or foils for bundling cables

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2203/00—Applications of adhesives in processes or use of adhesives in the form of films or foils

- C09J2203/326—Applications of adhesives in processes or use of adhesives in the form of films or foils for bonding electronic components such as wafers, chips or semiconductors

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2423/00—Presence of polyolefin

- C09J2423/10—Presence of homo or copolymers of propene

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2467/00—Presence of polyester

Definitions

- the present disclosure relates to an insulated electric wire with a fusion layer, and more particularly to an insulated electric wire with a fusion layer having a heat-fusible fusion layer on the outside of an insulation coating that coats a conductor.

- a large number of insulated wires having conductors and an insulating coating that covers the outer periphery of the conductors are used in vehicles such as automobiles and electric/electronic devices.

- the number of insulated wires used has increased.

- Conventionally, such an insulated wire has been used by being fixed to a body of an automobile, a housing of equipment, or the like by using a fixing metal fitting such as a clamp.

- a fixing metal fitting such as a clamp.

- the space occupied by the fixing brackets and the like increases, and there is a demand for space saving.

- a polyvinyl chloride composition is often used as a material for an insulating coating that covers the outer periphery of a conductor.

- the fusion bonding layer is provided outside the insulation coating layer of the insulated wire so as to come into contact with the insulation coating layer.

- the polyvinyl chloride often used for the insulation coating and the fusion bonding layer of Patent Document 1 are used.

- the modified polyolefin constituting the adhesive has a weak adhesive strength to each other, and peeling easily occurs at the interface between the insulating coating layer and the fusion bonding layer. If the interface between the insulating coating layer and the fusion layer peels off when a load is applied to the electric wire, the load is concentrated on the outer fusion layer, and as a result, the adhesive strength of the entire electric wire decreases.

- the insulating coating does not contain polyvinyl chloride, peeling at the interface between the insulating coating layer and the fusion layer as described above is less likely to occur, but the insulated wire with the fusion layer is used for automobile bodies and devices.

- the adherend such as a housing, it is required to improve the adhesive strength between the fusion layer and the adherend.

- an object of the present disclosure to provide an insulated electric wire with a fusion layer having a fusion layer as an outer layer, which has excellent adhesion strength to both the insulation coating layer and the adherend.

- the insulated wire with a fusion layer of the present disclosure has a conductor, an insulation coating layer that covers the outer periphery of the conductor, and a fusion layer that is provided outside the insulation coating layer and that is fused by heat,

- the fusing layer contains (A) modified polyolefin and (B) one or more selected from polyester resins and polyester elastomers, and the fusing layer contains (A) component and (B) component. 10 to 70 parts by mass of the component (B) per 100 parts by mass in total.

- the fusion layer has excellent adhesive strength to both the insulation coating layer and the adherend.

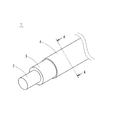

- FIG. 1 is a perspective view showing the appearance of an insulated electric wire with a fusion bonding layer according to the present disclosure.

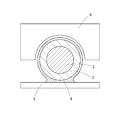

- FIG. 2 is a sectional view taken along line AA of FIG.

- FIG. 3 is a cross-sectional view in which the insulated electric wire with the fusion layer according to the present disclosure is fused to an adherend.

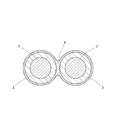

- FIG. 4 is a cross-sectional view in which two insulated electric wires with a fusion layer according to the present disclosure are bundled and fused.

- FIG. 5: is a figure which shows the evaluation method of the adhesive strength of the insulated wire with a fusion bonding layer.

- [5A] is a diagram showing a method for fusing an insulated wire with a fusion layer to an adherend

- [5B] is a diagram showing a method for a peeling test of an insulated wire with a fusion layer.

- the insulated electric wire with the fusion layer of the present disclosure has a conductor, an insulation coating layer that covers the outer periphery of the conductor, and a fusion layer that is provided outside the insulation coating layer and that is fused by heat.

- the fusion-bonding layer contains (A) a modified polyolefin and (B) one or more selected from polyester resins and polyester elastomers, and the fusion-bonding layer contains the (A) component and the (B).

- the component (B) is contained in an amount of 10 to 70 parts by mass with respect to a total of 100 parts by mass of the component ().

- the insulated wire with a fusion bonding layer of the present disclosure has a heat fusion bonding layer containing (A) a modified polyolefin and (B) one or more selected from polyester resins and polyester elastomers. According to this, even when the insulating coating layer contains polyvinyl chloride, the adhesive strength between the insulating coating layer and the fusion layer is excellent, and further, the adhesion strength between the adherend and the fusion layer is also excellent. The insulated wire with the fusion layer can be stably held on the adherend.

- the adhesive strength between the insulation coating layer and the fusion bonding layer is insufficient, peeling occurs at the interface between the insulation coating layer and the fusion bonding layer when a load is applied to the electric wire, and the adhesive bond directly to the adherend.

- the load concentrates on the fusing layer. Further, the fusion layer is stretched and broken from the thinned portion, and the electric wire falls off from the adherend.

- the electric wire with the fusion layer of the present disclosure has excellent adhesive strength between the insulating coating layer and the fusion layer, so that a part of the fusion layer is not stretched, and the load is dispersed over the entire electric wire. It is difficult for the wires to come off.

- the insulating coating layer may contain polyvinyl chloride.

- the fusion layer that has been generally used in the past has a poor adhesion strength to the insulation coating layer containing polyvinyl chloride.

- the insulation coating containing polyvinyl chloride is used. It also has excellent adhesive strength to the layers, and the effect of the present disclosure is remarkable.

- the fusion-bonding layer preferably contains (A) a modified polyolefin and (B) a polyester resin.

- component (B) contains a polyester resin, it has excellent adhesive strength with the insulating coating layer.

- the fusion layer preferably contains (A) a modified polyolefin and (B) a polyester elastomer.

- component (B) contains a polyester elastomer, it has excellent flexibility.

- the fusion bonding layer is provided outside the insulating coating layer over the entire circumference in the circumferential direction. This is because the adhesion area between the fusion layer and the insulating coating layer increases. Further, even if the fusing layer has a ring-shaped cross section and the fusing layer and the insulating coating are separated, the electric wire does not fall off immediately and the electric wire can be held.

- An insulated electric wire 1 with a fusion bonding layer has an insulated electric wire that includes a conductor 2 and an insulating coating layer 3 that covers the outer periphery of the conductor 2, and further has (A) a modified polyolefin and (B) on the outside thereof. It has fusion-bonding layer 4 containing one or more kinds selected from polyester resin and polyester elastomer. The fusion bonding layer 4 softens and fuses at a temperature lower than the heat resistant temperature of the insulating coating layer 3.

- the fusing layer 4 contains (A) a modified polyolefin.

- the component (A) that constitutes the fusing layer 4 is obtained by copolymerizing or graft-polymerizing a polymerizable monomer having a functional group such as a carboxy group, an ester group or an acid anhydride group with a base polyolefin having an ⁇ -olefin as a monomer. It is a polyolefin having a functional group introduced therein. By introducing these functional groups, the adhesive strength to the adherend 5 during fusion bonding is excellent. When the modified polyolefin has an acid anhydride group, the adhesive strength is particularly excellent.

- the modified polyolefin may be used alone or in combination of two or more.

- the component (A) preferably has a melting point of 185° C. or lower, more preferably 160° C. or lower.

- the melting point is 185° C. or lower, an increase in the softening point of the fusion bonding layer 4 can be suppressed, and the conductor 2 and the insulating coating layer 3 are less likely to deteriorate due to heating during fusion bonding.

- the lower limit of the melting point is not particularly limited, but it is preferably 80° C. or higher. When the melting point is 80° C. or higher, the fusion layer 4 is likely to be stable at the operating temperature of the insulated wire 1 with the fusion layer.

- the melting point of the component (A) is represented by the peak top temperature of the endothermic peak in "Differential scanning calorimetry (DSC)".

- the polyester resin and polyester elastomer as the component (B) are composed of a dibasic acid and a polyol, and a block copolymer of a hard segment having high crystallinity and a soft segment having low crystallinity is used as a polyester elastomer.

- a resin having substantially uniform crystallinity without distinction between hard segments and soft segments is called a polyester resin.

- the fusion-bonding layer 4 contains at least one selected from (B) polyester resin and polyester elastomer.

- the component (B) that constitutes the fusion bonding layer 4 either one of a polyester resin and a polyester elastomer may be used, or both may be used in combination.

- the component (B) is a polyester resin

- the adhesive strength with the insulating coating layer 3 is excellent

- the component (B) is a polyester elastomer

- the component (B) preferably has a low melting point and excellent tensile strength.

- the component (B) preferably has a melting point of 185° C. or lower, more preferably 160° C. or lower.

- the melting point is 185° C. or lower, an increase in the softening point of the fusion bonding layer 4 can be suppressed, and the conductor 2 and the insulating coating layer 3 are less likely to deteriorate due to heating during fusion bonding.

- the lower limit of the melting point is not particularly limited, but it is preferably 80° C. or higher. When the melting point is 80° C. or higher, the fusion layer 4 is likely to be stable at the operating temperature of the insulated wire 1 with the fusion layer.

- the melting point of the component (B) is represented by the peak top temperature of the endothermic peak in "Differential scanning calorimetry (DSC)".

- the polyester resin is not particularly limited, but a polymer containing an aromatic dibasic acid and a short-chain aliphatic glycol as main raw materials, such as polyethylene terephthalate (PET), polytrimethylene terephthalate, and polybutylene. Examples thereof include terephthalate (PBT), polyethylene naphthalate (PEN) and polybutylene naphthalate (PBN).

- PET polyethylene terephthalate

- PEN polyethylene naphthalate

- PBN polybutylene naphthalate

- the polyester resin constituting the fusion-bonding layer 4 has a low degree of polymerization, or an aliphatic dibasic acid, isophthalic acid, a long-chain or alicyclic glycol when the above resin is polymerized. It is particularly preferable that the symmetry of the molecule is reduced by copolymerizing a polyether polyol or the like as the third component.

- Polyester elastomer consists of block copolymer of hard segment and soft segment.

- the hard segment include crystalline polyesters such as PET and PBN described above.

- the soft segment include aliphatic polyether and aliphatic polyester.

- the component (B) preferably has a tensile breaking strength measured according to JIS K7161 of 19 MPa or more, and more preferably 20 MPa or more.

- the component (B) can have a tensile breaking strength of 50 MPa or less and 40 MPa or less measured according to JIS K7161.

- the tensile breaking strength of the polyester resin can be appropriately adjusted depending on the degree of polymerization or the component to be copolymerized, and the tensile breaking strength of the polyester elastomer can be appropriately adjusted depending on the types and ratios of the hard segment and the soft segment. it can.

- the component (B) is preferably contained in an amount of 10 parts by mass or more based on 100 parts by mass of the total of the components (A) and (B). It is more preferably at least 20 parts by mass.

- the adhesive strength with the insulating coating layer 3 is excellent.

- the content of the component (B) is preferably 70 parts by mass or less based on 100 parts by mass of the total of the components (A) and (B).

- the fusion layer 4 may contain component (B) in an amount of more than 70 parts by mass.

- the fusing layer 4 may be composed of one layer, or may be formed by laminating a plurality of layers. In the case of being composed of a plurality of layers, for example, by arranging a layer containing a large amount of the component (B) in the inner layer close to the insulating coating layer 3, the adhesive strength between the insulating coating layer 3 and the fusion bonding layer 4 is improved. .. At this time, the total amount of the fusion-bonding layer may contain the component (A) and the component (B) and the component (B) in an amount of 10 to 70 parts by mass.

- the fusing layer 4 may contain components other than the (A) modified polyolefin, the (B) polyester resin, and the polyester elastomer as long as the object of the present disclosure is not impaired.

- examples of other components include additives such as an inorganic filler, a plasticizer, a stabilizer, a pigment, an antioxidant, and a tackifier.

- the fusion bonding layer 4 may contain a polymer component other than the component (A) and the component (B).

- the total amount of the polymer components constituting the fusion layer 4 is 100 parts by mass. It is preferably 30 parts by mass or less.

- the inorganic filler as an additive, silica, diatomaceous earth, glass spheres, talc, clay, alumina, magnesium oxide, zinc oxide, antimony trioxide, metal oxides such as molybdenum oxide, metal hydroxide such as magnesium hydroxide.

- metal carbonates such as calcium carbonate and magnesium carbonate, metal boric acid such as zinc borate and barium metaborate, and hydrotalcites. These may be used alone or in combination of two or more.

- the softening point of the fusion bonding layer 4 is preferably at least lower than the softening point of the insulating coating layer 3. Specifically, it is preferably 80 to 170°C.

- the softening point is 170° C. or lower, when the fusion bonding layer 4 is fused, deterioration of the conductor 2 and the insulation coating layer 3 and deformation of the insulation coating layer 3 due to heating are less likely to occur.

- the softening point is 80° C. or higher, the fusing layer 4 is likely to be stable at the operating temperature of the insulated wire 1 with the fusing layer.

- the softening point of the fusion-bonding layer 4 and the softening point of the insulating coating layer 3 are represented by peak top temperatures of endothermic peaks in "Differential scanning calorimetry (DSC)".

- an ordinary insulated electric wire which is generally used in the past can be used.

- an insulated wire having the conductor 2 and the insulating coating layer 3 that covers the outer periphery of the conductor 2 may be used.

- Copper is generally used for the conductor 2, but metal materials such as aluminum and magnesium can be used in addition to copper. These metallic materials may be alloys. Other metal materials for forming an alloy include iron, nickel, magnesium, silicon, and combinations thereof.

- the conductor 2 may be composed of a single wire, or may be composed of a twisted wire formed by twisting a plurality of element wires.

- Examples of the material forming the insulating coating layer 3 include polyvinyl chloride (PVC), rubber, and polyolefin. These may be used alone or in combination of two or more. Further, various additives may be appropriately added to these materials.

- PVC polyvinyl chloride

- rubber rubber

- polyolefin polyolefin

- the insulation coating is often composed of polyvinyl chloride.

- polyvinyl chloride and the modified polyolefin contained in the fusing layer 4 have weak adhesive strength, and in the conventional fusing layer, peeling is likely to occur at the interface between the fusing layer and the insulating coating layer.

- the fusion-bonding layer 4 contains (A) modified polyolefin and (B) one or more selected from polyester resin and polyester elastomer, so that the insulating coating layer 3 contains polyvinyl chloride. Even if it is present, the adhesive strength between the fusion bonding layer 4 and the insulating coating layer 3 is excellent.

- the insulating coating layer 3 and the fusion bonding layer 4 can be formed by an extruder, for example, by heat-kneading the materials forming the respective layers. That is, the polymer that constitutes the insulating coating layer 3 and various additive components that are added as necessary are mixed, and the composition that is heated and kneaded is extruded around the conductor 2 by an extruder to form the insulating coating layer 3. , Make an insulated wire. After that, the components (A) and (B), and various additive components that are added as necessary, are mixed, and the composition obtained by heating and kneading is extruded to the outside of the insulated wire by an extrusion molding machine to form the fusion bonding layer 4.

- the insulated electric wire 1 with a fusion bonding layer can be produced.

- the insulation coating layer 3 and the fusion bonding layer 4 are simultaneously extrusion-molded using a two-layer extrusion molding machine, the respective layers are laminated in a melted state, so that the insulation coating layer 3 and the fusion bonding layer 4 are laminated. Has excellent adhesive strength with.

- the fusion bonding layer 4 may be formed on the outer side of the insulating coating layer 3 so as to have a ring-shaped cross section over the entire circumference in the circumferential direction, or on the outer side of the insulating coating layer 3. It may be formed only partially in the direction.

- the fusion bonding layer 4 is formed over the entire outer periphery of the insulating coating layer 3, the adhesion area between the fusion bonding layer 4 and the insulation coating layer 3 is large, and the adhesive strength is excellent.

- the fusing layer 4 is formed in a ring shape, even if the fusing layer 4 and the insulation coating layer 3 are separated, the electric wire does not immediately fall off, and the tensile strength of the fusing layer 4 is reduced. It can hold an electric wire within the range. Further, the fusion bonding layer 4 need not be formed over the entire area in the length direction of the insulated wire.

- the thickness of the conductor 2 and the thickness of the insulating coating layer 3 may be within the range of normally used insulated wires.

- the thickness of the fusion layer 4 is preferably 0.03 to 0.3 mm. When it is 0.03 mm or more, it is easy to secure a sufficient fusion-bonded surface, and when it is 0.3 mm or less, it is possible to prevent the thickness of the entire insulated electric wire with a fusion-bonding layer 1 from excessively increasing.

- the fusion layer 4 By heating the insulated wire 1 with the fusion layer, the fusion layer 4 is softened and can be fused.

- the heating method is not particularly limited, and in addition to directly heating the insulated wire 1 with the fusion layer or the adherend 5, as shown in FIG. 3, an ultrasonic generator such as a horn H is used, Examples thereof include a method of generating frictional heat between the fusion layer 4 and the adherend 5.

- the fused portion can be locally heated without excessively raising the temperature of the insulated wire 1 with the fused layer. Deterioration can be suppressed.

- the insulating coating layer 3 and the fusion bonding layer 4 are separately provided, and heating is performed at a temperature equal to or higher than the softening point of the fusion bonding layer 4 and lower than the softening point of the insulating coating layer 3 to insulate during fusion bonding.

- the deformation of the coating layer 3 can be suppressed, and the insulated wire 1 with the fusion layer can be fused without impairing the performance as an insulated wire.

- the adherend 5 on which the insulated wire 1 with the fusion layer is fused is not particularly limited, but examples thereof include resin members such as polyolefin and polyester, and metal members such as iron, aluminum and stainless steel. Can be mentioned. Although many members made of polyolefin are used in vehicles such as automobiles, the insulated electric wire with a fusion layer 1 according to the present disclosure contains a modified polyolefin in the fusion layer 4, so that it can be applied to a member made of a polyolefin. Excellent in adhesive strength.

- the insulated wire with a fusion layer 1 has a plurality of insulated wires 1 with a fusion layer as shown in FIG. It is also effective when used by fusing together and bundling.

- composition for polyvinyl chloride insulating coating layer 100 parts by mass of polyvinyl chloride (manufactured by Shin-Etsu Chemical, "TK-1300"), 30 parts by mass of plasticizer (manufactured by DIC, n-MOTM “Monosizer W-750”), and a Ca-Zn heat stabilizer (ADEKA) 5 parts by mass of "Adeka Stab RUP-100") and 5 parts by mass of calcium carbonate (made by Maruo Calcium, "Super 1700”) are kneaded using a twin-screw extruder to obtain a polyvinyl chloride insulating coating layer composition.

- TK-1300 polyvinyl chloride

- plasticizer manufactured by DIC, n-MOTM "Monosizer W-750

- Ca-Zn heat stabilizer ADKA 5 parts by mass of "Adeka Stab RUP-100”

- calcium carbonate made by Maruo Calcium, "Super 1700

- composition for polypropylene insulating coating layer 92 parts by mass of polypropylene (manufactured by Nippon Polypro, “Novatech EC9”), 8 parts by mass of thermoplastic elastomer (manufactured by Asahi Kasei, “Tuftec M-1913"), 70 parts by mass of magnesium hydroxide (manufactured by Kyowa Kagaku, "Kisuma 5") Part and a hindered phenolic antioxidant (manufactured by BASF, “Irganox 1010” 0.5 parts by mass) were kneaded using a twin-screw extruder to obtain a polypropylene insulating coating layer composition.

- the prepared insulating coating composition was extruded around a stranded wire conductor having a conductor cross-sectional area of 0.13 mm 2 with a coating thickness of 0.2 mm to produce an insulated electric wire.

- composition for fusing layer (Preparation of composition for fusing layer) Using the materials shown below, the components (A) and (B) were mixed in the proportions (parts by mass) shown in Tables 1 to 3 and kneaded using a twin-screw extruder to give a composition for a fusion layer. Prepared. Note that the samples 21, 22, 23, and the samples 31, 32 are only one of the component (A) or the component (B).

- a fusion bonding layer having a thickness of 0.1 mm is formed by extruding each fusion bonding layer composition at 200° C. on the entire outer circumference of an insulated wire having an insulation coating layer made of polyvinyl chloride or polypropylene. did.

- the insulated wire 11 with the fusion layer is placed on the adherend 16 so that 1 cm from the end is in contact, and the other portion is protected by the release sheet 17, and then from above, Ultrasonic waves of 20 kHz were applied for 10 seconds by the horn H to fuse the insulated wire 11 with the fusion layer and the adherend 16.

- the fusion-bonded part is left to stand at room temperature, and as shown in FIG. 5 [5B], the part protected by the release sheet is folded back 180 degrees in the direction of the fusion-bonded end, and 50 mm/sec in the axial direction.

- the insulated electric wire 11 with the fusion bonding layer was peeled off by pulling at a speed of.

- the maximum test force at the time of peeling is shown in Tables 1 to 3.

- a plate-like member made of polypropylene (PP), polyethylene terephthalate (PET), or aluminum (AL) shown in Tables 1 to 3 was used.

- Samples 1 to 12 in which the fusion layer contains the component (A) and the component (B), and the content of the component (B) is within the range of the present disclosure, are applied to both the insulating coating layer and the adherend. It has excellent adhesive strength and has a large electric wire holding force with respect to the adherend.

- Samples 1 to 8 in which the polyester resin was used as the component (B) showed particularly excellent adhesive strength to the insulating coating layer and the adherend, and the insulating coating layer and the fusion layer and the adherend and the fusion body Peeling did not occur easily at the interface of the adhesive layer, and cohesive failure occurred inside the adhesive layer.

- the component (A) or the component (B) having a large tensile rupture strength is used like Samples 7 and 8, the fusion layer is less likely to be broken and the holding force of the electric wire is increased. .. Further, the samples 9 and 10 using the polyester elastomer as the component (B) are slightly inferior to the samples 1 and 8 using the polyester resin as the component (B), but have excellent flexibility.

- the sample 21 not containing the component (B) in the fusion-bonding layer and the sample 24 containing a small amount of the component (B) have poor adhesive strength with the insulating coating layer made of polyvinyl chloride. Further, the samples 22 and 23 not containing the component (A) in the fusion-bonding layer and the sample 25 containing a large amount of the component (B) have inferior adhesive strength to the adherend made of polypropylene.

- the fusion-bonding layer does not contain the component (B)

- the insulation coating layer is made of polypropylene (Samples 31, 32)

- the adhesive strength between the insulation coating layer and the fusion-bonding layer is satisfied, and although the electric wire can be sufficiently held with respect to the adhered body, when the samples 31 and 32 and the samples 5 and 6 are compared, the fusion layer contains the component (B) in addition to the component (A).

- the adhesive strength between the fusion layer and the adherend was improved and the electric wire holding power was improved.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Wood Science & Technology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Insulated Conductors (AREA)

- Organic Insulating Materials (AREA)

- Adhesives Or Adhesive Processes (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE112019006404.5T DE112019006404B4 (de) | 2018-12-25 | 2019-12-05 | Isolierter draht mit klebeschicht |

| US17/416,687 US20220064502A1 (en) | 2018-12-25 | 2019-12-05 | Insulated wire with bonding layer |

| CN201980085469.0A CN113287177B (zh) | 2018-12-25 | 2019-12-05 | 带熔接层的绝缘电线 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018-240720 | 2018-12-25 | ||

| JP2018240720A JP7001048B2 (ja) | 2018-12-25 | 2018-12-25 | 融着層付き絶縁電線 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020137412A1 true WO2020137412A1 (ja) | 2020-07-02 |

Family

ID=71129029

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/047565 Ceased WO2020137412A1 (ja) | 2018-12-25 | 2019-12-05 | 融着層付き絶縁電線 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20220064502A1 (enExample) |

| JP (1) | JP7001048B2 (enExample) |

| CN (1) | CN113287177B (enExample) |

| DE (1) | DE112019006404B4 (enExample) |

| WO (1) | WO2020137412A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI849330B (zh) * | 2020-10-05 | 2024-07-21 | 日商Totoku股份有限公司 | 熔接性絕緣電線之製造方法、及自熔接線圈之製造方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10149725A (ja) * | 1996-11-19 | 1998-06-02 | Sekisui Chem Co Ltd | 難燃性接着フィルム及びそれを用いたフラットケーブル |

| JP2002237219A (ja) * | 2001-02-08 | 2002-08-23 | Yazaki Corp | 融着層付き電線及び融着層付き電線の製造方法 |

| JP2009048934A (ja) * | 2007-08-22 | 2009-03-05 | Fujikura Ltd | 集合電線、コイルアンテナ、及び携帯型無線機器 |

| JP2014191885A (ja) * | 2013-03-26 | 2014-10-06 | Hitachi Metals Ltd | フラットケーブル及びその製造方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102471646B (zh) * | 2009-07-03 | 2013-09-11 | 三井化学东赛璐株式会社 | 表面保护膜 |

| WO2015033958A1 (ja) * | 2013-09-03 | 2015-03-12 | 大日本印刷株式会社 | 電池用包装材料のシーラント層用の樹脂組成物 |

| WO2015104992A1 (ja) * | 2014-01-09 | 2015-07-16 | 株式会社オートネットワーク技術研究所 | コネクタ付電線及びその製造方法 |

-

2018

- 2018-12-25 JP JP2018240720A patent/JP7001048B2/ja active Active

-

2019

- 2019-12-05 CN CN201980085469.0A patent/CN113287177B/zh active Active

- 2019-12-05 US US17/416,687 patent/US20220064502A1/en not_active Abandoned

- 2019-12-05 DE DE112019006404.5T patent/DE112019006404B4/de active Active

- 2019-12-05 WO PCT/JP2019/047565 patent/WO2020137412A1/ja not_active Ceased

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10149725A (ja) * | 1996-11-19 | 1998-06-02 | Sekisui Chem Co Ltd | 難燃性接着フィルム及びそれを用いたフラットケーブル |

| JP2002237219A (ja) * | 2001-02-08 | 2002-08-23 | Yazaki Corp | 融着層付き電線及び融着層付き電線の製造方法 |

| JP2009048934A (ja) * | 2007-08-22 | 2009-03-05 | Fujikura Ltd | 集合電線、コイルアンテナ、及び携帯型無線機器 |

| JP2014191885A (ja) * | 2013-03-26 | 2014-10-06 | Hitachi Metals Ltd | フラットケーブル及びその製造方法 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI849330B (zh) * | 2020-10-05 | 2024-07-21 | 日商Totoku股份有限公司 | 熔接性絕緣電線之製造方法、及自熔接線圈之製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2020102392A (ja) | 2020-07-02 |

| US20220064502A1 (en) | 2022-03-03 |

| DE112019006404T5 (de) | 2021-09-09 |

| CN113287177A (zh) | 2021-08-20 |

| DE112019006404B4 (de) | 2024-10-02 |

| JP7001048B2 (ja) | 2022-01-19 |

| CN113287177B (zh) | 2023-01-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10886506B2 (en) | Cell packaging material, method for manufacturing same, and cell | |

| JPH1153945A (ja) | ケーブル | |

| US10388428B2 (en) | Electric wire with connector, and wire harness | |

| WO2020137412A1 (ja) | 融着層付き絶縁電線 | |

| JP7124723B2 (ja) | 融着層付き絶縁電線 | |

| JP2014191885A (ja) | フラットケーブル及びその製造方法 | |

| JP2011018634A (ja) | 積層体、チューブ、絶縁電線、及びこれらの製造方法 | |

| KR101814481B1 (ko) | 이차전지의 리드탭용 실부재 및 그 제조방법 | |

| JP6638630B2 (ja) | 電線被覆材用組成物および絶縁電線 | |

| JPH05220908A (ja) | 多層チューブ | |

| JP4851013B2 (ja) | ケーブル | |

| WO2015077409A1 (en) | Heat shrinkable tube and system including heat-recovered heat shrinkable tubing | |

| JP7789626B2 (ja) | 端子付電線 | |

| JP2001237055A (ja) | ヒータ線 | |

| JP2024000326A (ja) | 端子付電線 | |

| JP2013161766A (ja) | 過電流遮断機能付き電線 | |

| JP2010284895A (ja) | 積層体、チューブ、絶縁電線、及びこれらの製造方法 | |

| JP2547802B2 (ja) | 複合型制振材料用組成物 | |

| JPH1153947A (ja) | ケーブル | |

| JP2011032395A (ja) | 低温性にすぐれる成型用樹脂組成物 | |

| CN110741047A (zh) | 密封用树脂组合物 | |

| JP2004192865A (ja) | ツイストフラットケーブル | |

| TW201839783A (zh) | 電傳導零件及電線束 | |

| JP2010284894A (ja) | 積層体、チューブ、絶縁電線、及びこれらの製造方法 | |

| JPH10233120A (ja) | ケーブル |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19901417 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19901417 Country of ref document: EP Kind code of ref document: A1 |