WO2020121605A1 - 粘着シート - Google Patents

粘着シート Download PDFInfo

- Publication number

- WO2020121605A1 WO2020121605A1 PCT/JP2019/033872 JP2019033872W WO2020121605A1 WO 2020121605 A1 WO2020121605 A1 WO 2020121605A1 JP 2019033872 W JP2019033872 W JP 2019033872W WO 2020121605 A1 WO2020121605 A1 WO 2020121605A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- pressure

- sensitive adhesive

- adhesive sheet

- weight

- resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/38—Pressure-sensitive adhesives [PSA]

- C09J7/381—Pressure-sensitive adhesives [PSA] based on macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

- C09J7/385—Acrylic polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/38—Pressure-sensitive adhesives [PSA]

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/02—Non-macromolecular additives

- C09J11/04—Non-macromolecular additives inorganic

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/08—Macromolecular additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

- C09J133/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C09J133/062—Copolymers with monomers not covered by C09J133/06

- C09J133/066—Copolymers with monomers not covered by C09J133/06 containing -OH groups

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J201/00—Adhesives based on unspecified macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

- C09J7/22—Plastics; Metallised plastics

- C09J7/24—Plastics; Metallised plastics based on macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

- C09J7/22—Plastics; Metallised plastics

- C09J7/25—Plastics; Metallised plastics based on macromolecular compounds obtained otherwise than by reactions involving only carbon-to-carbon unsaturated bonds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/02—Elements

- C08K3/08—Metals

- C08K2003/0862—Nickel

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/18—Oxygen-containing compounds, e.g. metal carbonyls

- C08K3/20—Oxides; Hydroxides

- C08K3/22—Oxides; Hydroxides of metals

- C08K2003/2227—Oxides; Hydroxides of metals of aluminium

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K2201/00—Specific properties of additives

- C08K2201/002—Physical properties

- C08K2201/005—Additives being defined by their particle size in general

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/01—Use of inorganic substances as compounding ingredients characterized by their specific function

- C08K3/013—Fillers, pigments or reinforcing additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2203/00—Applications of adhesives in processes or use of adhesives in the form of films or foils

- C09J2203/326—Applications of adhesives in processes or use of adhesives in the form of films or foils for bonding electronic components such as wafers, chips or semiconductors

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/30—Additional features of adhesives in the form of films or foils characterized by the chemical, physicochemical or physical properties of the adhesive or the carrier

- C09J2301/312—Additional features of adhesives in the form of films or foils characterized by the chemical, physicochemical or physical properties of the adhesive or the carrier parameters being the characterizing feature

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/40—Additional features of adhesives in the form of films or foils characterized by the presence of essential components

- C09J2301/408—Additional features of adhesives in the form of films or foils characterized by the presence of essential components additives as essential feature of the adhesive layer

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2301/00—Additional features of adhesives in the form of films or foils

- C09J2301/40—Additional features of adhesives in the form of films or foils characterized by the presence of essential components

- C09J2301/414—Additional features of adhesives in the form of films or foils characterized by the presence of essential components presence of a copolymer

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2433/00—Presence of (meth)acrylic polymer

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2453/00—Presence of block copolymer

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2453/00—Presence of block copolymer

- C09J2453/006—Presence of block copolymer in the substrate

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2475/00—Presence of polyurethane

- C09J2475/006—Presence of polyurethane in the substrate

Definitions

- the present invention relates to an adhesive sheet.

- Adhesive sheets are widely used in the fixing of components that make up electronic devices because they are bonding means with excellent workability and high adhesive reliability.

- the pressure-sensitive adhesive tape is used for fixing sheet metals to each other or for fixing relatively large electronic devices such as flat-screen televisions, home electric appliances, and office automation equipment, fixing exterior parts to a housing, portable electronic terminals, cameras, personal computers.

- fixing exterior parts and rigid parts such as batteries to relatively small electronic devices such as etc.

- temporary fixing of the parts and labeling applications for displaying product information, etc. But it is still used.

- the extension direction be extended and peeled in the parallel direction (horizontal direction) with respect to the attachment surface of the attachment target, but it can also be easily extended and peeled even in the vertical direction, and the adhesive tape base material may be thin.

- the adhesive tape base material may be thin.

- the present invention aims to solve the above-mentioned conventional problems and achieve the following objects. That is, the present invention can be easily stretched and peeled even if the stretching direction is perpendicular to the sticking surface of the sticking target, and is difficult to tear even when the thickness of the base material of the adhesive sheet is small, and An object of the present invention is to provide a pressure-sensitive adhesive sheet having excellent impact resistance, shear adhesive strength, and split adhesive strength.

- a pressure-sensitive adhesive sheet having a pressure-sensitive adhesive layer and a base material layer, wherein the pressure-sensitive adhesive layer contains filler particles and a pressure-sensitive adhesive resin, and the content of the filler particles in the pressure-sensitive adhesive layer is 100 parts by weight of the pressure-sensitive adhesive resin.

- the volume ratio of the filler particles to the adhesive layer is 4% to 40%, and the stress at 25% elongation of the adhesive sheet is 0.15 Mpa to 82 Mpa. It is an adhesive sheet characterized by being present.

- the present invention it is possible to solve the above-mentioned problems in the related art and achieve the above-mentioned object, and easily stretch and peel even if the stretching direction is perpendicular to the sticking surface of the sticking target. It is possible to provide a pressure-sensitive adhesive sheet that is hard to be torn even when the material is thin and has excellent impact resistance, shear adhesive strength, and split adhesive strength.

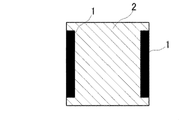

- FIG. 1 is a schematic explanatory diagram of a method for sticking the pressure-sensitive adhesive sheet 1 to the acrylic plate 2 when evaluating impact resistance in Examples.

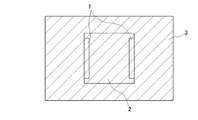

- FIG. 2 is a schematic explanatory view of a test piece produced when evaluating impact resistance in Examples.

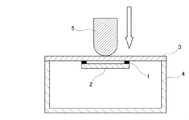

- FIG. 3 is a schematic explanatory diagram regarding a method of installing a test piece on a U-shaped measuring table when evaluating impact resistance in Examples.

- the pressure-sensitive adhesive sheet of the present invention has at least a pressure-sensitive adhesive layer and a base material layer, and further has other layers as necessary.

- the adhesive layer contains at least filler particles and an adhesive resin, and further contains other components as necessary.

- the components constituting these adhesive layers are not particularly limited as long as they are contained in the adhesive layer, but are preferably contained in the adhesive composition.

- the pressure-sensitive adhesive composition contains at least the filler particles and the pressure-sensitive adhesive resin, and further contains other components as necessary.

- the pressure-sensitive adhesive layer contains the filler particles, the filler particles are exposed from the pressure-sensitive adhesive layer when the pressure-sensitive adhesive sheet is stretched, and thus the adhesive area between the pressure-sensitive adhesive layer and the adherend is reduced,

- the extension direction of the pressure-sensitive adhesive sheet is perpendicular to the sticking surface (hereinafter, also referred to as “adhesive surface”) of the sticking target (hereinafter, also referred to as “adherent”) (“90° direction”). (Sometimes referred to)), however, it can be easily stretched and peeled.

- the type of the filler particles is not particularly limited and may be appropriately selected within a range that does not impair the effects of the present invention, and may be inorganic filler particles or organic filler particles. These may be used alone or in combination of two or more.

- the inorganic filler particles include aluminum hydroxide, magnesium hydroxide, aluminum oxide, silicon oxide, magnesium oxide, zinc oxide, titanium oxide, zirconium oxide, iron oxide, silicon carbide, boron nitride, aluminum nitride, titanium nitride.

- organic filler particles include polystyrene type filler, benzoguanamine type filler, polyethylene type filler, polypropylene type filler, silicone type filler, urea-formalin type filler, styrene/methacrylic acid copolymer, fluorine type filler, acrylic type filler.

- examples thereof include fillers, polycarbonate fillers, polyurethane fillers, polyamide fillers, epoxy resin fillers, and thermosetting resin hollow fillers.

- the shape of the filler particles is not particularly limited and may be appropriately selected depending on the purpose.

- the shape may be regular or irregular.

- Specific examples of the shape of the filler particles include polygonal shape, cubic shape, elliptical shape, spherical shape, needle shape, flat plate shape, and scale shape.

- the filler particles having these shapes may be used alone or in combination of two or more.

- filler particles of these shapes may be aggregated.

- the shape of the filler particles is preferably elliptical, spherical, or polygonal.

- the particle size distribution (D 90 /D 10 ) of the filler particles is appropriately selected depending on the intended purpose without any limitation, but it is preferably 2.5 to 20 and has an impact resistance of 1. It is more preferably 5 to 15, and even more preferably 2.5 to 5.

- the particle size distribution (D 90 /D 10 ) of the filler particles is within the preferable range, the pressure-sensitive adhesive sheet can be easily stretched and peeled even if the stretching direction is 90° with respect to the attaching surface of the adherend. Even when the thickness of the base material of the pressure-sensitive adhesive sheet is small, it is difficult to be torn and is excellent in impact resistance, shear adhesive strength, and split adhesive strength.

- the particle size distribution (D 90 /D 10 ) of the filler particles is less than 2.5, the extension and peeling in the case where the extension direction of the pressure-sensitive adhesive sheet is 90° with respect to the attaching surface of the adherend. If it exceeds 20, the adhesive properties such as impact resistance, shear adhesive strength and split adhesive strength may be impaired.

- the particle size distribution (D 90 /D 10 ) of the filler particles is converted into a particle size distribution by measuring the particle size of the filler particles by using a measuring machine (Microtrac) using a laser diffraction scattering method. It is obtained by doing.

- the volume average particle diameter of the filler particles is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 3 ⁇ m to 25 ⁇ m, more preferably 5 ⁇ m to 20 ⁇ m, still more preferably 5 ⁇ m to 14 ⁇ m.

- the volume average particle diameter of the filler particles is within the preferable range, the pressure-sensitive adhesive sheet can be easily stretched and peeled even if the stretching direction is 90° with respect to the sticking surface of the adherend, and thus the pressure-sensitive adhesive sheet Even when the base material is thin, it is not easily torn, and is excellent in impact resistance, shear adhesive strength, and split adhesive strength.

- volume average particle diameter of the filler particles when the volume average particle diameter of the filler particles is less than 3 ⁇ m, it may be difficult to elongate and peel when the extending direction of the pressure-sensitive adhesive sheet is 90° to the attaching surface of the adherend, If it exceeds 25 ⁇ m, the adhesive performance such as impact resistance, shear adhesive strength and split adhesive strength may be impaired.

- the volume average particle diameter of the filler particles can be measured, for example, by using a measuring machine (Microtrac) using a laser diffraction scattering method.

- the ratio between the volume average particle diameter of the filler particles and the average thickness of the adhesive layer described below is not particularly limited and may be appropriately selected according to the purpose.

- the average thickness of the layer], the ratio of the volume average particle diameter of the filler particles to the average thickness of the adhesive layer is preferably 5/100 or more, and 5/100 to 95/100. Is more preferable, 10/100 to 75/100 is further preferable, and 20/100 to 60/100 is particularly preferable.

- the ratio is within the preferred range, the pressure-sensitive adhesive sheet can be easily stretched and peeled even when the stretched direction is 90° with respect to the attaching surface of the adherend, and the thickness of the base material of the pressure-sensitive adhesive sheet is thin. Even if it is difficult to tear.

- the adhesive sheet can be easily stretched and peeled even when the stretched direction is 90° with respect to the sticking surface of the adherend, and Even if the thickness is thin, it is difficult to be torn, and the adhesive performance such as impact resistance, shear adhesive strength, split adhesive strength, etc. is superior, which is advantageous.

- the ratio is less than 5/100, the stretch releasability may be impaired when the stretching direction of the pressure-sensitive adhesive sheet is in the 90° direction with respect to the attaching surface of the adherend, and exceeds 95/100. If so, the adhesive performance such as impact resistance, shear adhesive strength, and split adhesive strength may be impaired.

- the content of the filler particles in the adhesive layer is 10 to 90 parts by weight, preferably 15 to 50 parts by weight, and 20 parts by weight, with respect to 100 parts by weight of the adhesive resin. More preferably, it is from 40 parts by mass.

- the adhesive sheet cannot be extended and peeled when the extending direction is 90° with respect to the attaching surface of the adherend. Moreover, the adhesive sheet is torn and the adhesive sheet does not stretch and cannot be peeled again.

- the content of the filler particles with respect to 100 parts by weight of the pressure-sensitive adhesive resin exceeds 90 parts by weight, the pressure-sensitive adhesive sheet does not expand, the pressure-sensitive adhesive composition remains on the adherend, and impact resistance is improved. It may worsen, and the shear adhesive strength and split adhesive strength may be weakened.

- the content of the filler particles relative to 100 parts by weight of the pressure-sensitive adhesive resin is 10 parts by weight to 90 parts by weight, the stretching direction of the pressure-sensitive adhesive sheet is 90° with respect to the sticking surface of the adherend. Even when the base material of the pressure-sensitive adhesive sheet is thin, it is not easily torn, and is excellent in impact resistance, shear adhesive strength, and split adhesive strength.

- the content of the filler particles in the pressure-sensitive adhesive layer can be appropriately adjusted when the pressure-sensitive adhesive composition is prepared.

- the volume ratio of the filler particles to the volume of the entire adhesive layer is 4% to 40%, preferably 5% to 30%, more preferably 5% to 20%, and further preferably 5% to 15%. Yes. If the volume ratio of the filler particles is less than 4%, the pressure-sensitive adhesive sheet cannot be stretched and peeled when the stretching direction is 90° with respect to the sticking surface of the adherend, and the pressure-sensitive adhesive sheet is shredded. Occurs, and the pressure-sensitive adhesive sheet does not stretch and cannot be peeled again. When the volume ratio of the filler particles exceeds 40%, the pressure-sensitive adhesive sheet does not expand, the pressure-sensitive adhesive composition remains on the adherend, the impact resistance deteriorates, and the shear adhesive strength and The split adhesive strength may be weakened.

- the volume ratio of the filler particles is 4% to 40%, the pressure-sensitive adhesive sheet can be easily stretched and peeled even when the stretching direction of the pressure-sensitive adhesive sheet is 90° with respect to the sticking surface of the adherend. Even if the base material is thin, it is not easily torn, and is excellent in impact resistance, shear adhesive strength, and split adhesive strength.

- the volume ratio of the filler particles to the adhesive layer can be calculated by the following formulas (1) to (3).

- Adhesive resin * 1 Weight A (g) / adhesive resin * 1 Density A (g / cm 3) adhesive resin * 1 volume A (cm 3) ⁇ ⁇ ⁇ Equation (1)

- Filler particle weight B (g)/filler particle density B (g/cm 3 ) filler particle volume B (cm 3 )...

- Formula (2) Volume B of filler particles (cm 3 )/(Volume A of adhesive resin * 1 (cm 3 )+Volume B of filler particles B (cm 3 )) ⁇ 100 Volume ratio of filler particles (%) Equation ( 3)

- the pressure-sensitive adhesive resin represented by *1 may include other components described in paragraph [0079] described later.

- the density is a value measured according to JIS Z 8804.

- the pressure-sensitive adhesive resin is not particularly limited and may be appropriately selected from known ones, for example, acrylic pressure-sensitive adhesive resin, rubber pressure-sensitive adhesive resin, urethane pressure-sensitive adhesive resin, silicone pressure-sensitive adhesive resin. And so on. These may be used alone or in combination of two or more. Among these, the acrylic adhesive resin is preferable as the adhesive resin.

- the acrylic pressure-sensitive adhesive resin is not particularly limited and may be appropriately selected depending on the purpose.

- the acrylic polymer can be produced, for example, by polymerizing a monomer mixture containing a (meth)acrylic monomer.

- a (meth)acrylic monomer for example, an alkyl(meth)acrylate having an alkyl group having 1 to 12 carbon atoms can be used.

- Specific examples of the alkyl(meth)acrylate having an alkyl group having 1 to 12 carbon atoms include methyl(meth)acrylate, ethyl(meth)acrylate, n-butyl(meth)acrylate, isobutyl(meth)acrylate, and t.

- alkyl (meth)acrylate having an alkyl group having 1 to 12 carbon atoms it is preferable to use an alkyl (meth)acrylate having an alkyl group having 4 to 12 carbon atoms, which has 4 to 8 carbon atoms. It is more preferable to use an alkyl(meth)acrylate having an alkyl group, and it is particularly preferable to use n-butyl acrylate in order to ensure excellent adhesion to an adherend.

- the alkyl (meth)acrylate having an alkyl group having 1 to 12 carbon atoms is used in the range of 80% by weight to 98.5% by weight based on the total amount of the monomers used for producing the acrylic polymer. It is preferable to use it, and it is more preferable to use it in the range of 90% by weight to 98.5% by weight.

- a high polar vinyl monomer can be used, if necessary, in addition to the above-mentioned monomers.

- the highly polar vinyl monomer include (meth)acrylic monomers having a hydroxyl group, (meth)acrylic monomers having a carboxyl group, and (meth)acrylic monomers having an amide group. )

- vinyl monomer having a hydroxyl group examples include 2-hydroxyethyl (meth)acrylate, 2-hydroxypropyl (meth)acrylate, 4-hydroxybutyl (meth)acrylate and 6-hydroxyhexyl (meth)acrylate.

- the vinyl monomer having a hydroxyl group is preferably used when the adhesive resin containing an isocyanate crosslinking agent is used. Specifically, it is preferable to use 2-hydroxyethyl (meth)acrylate, 4-hydroxybutyl (meth)acrylate, or 6-hydroxyhexyl (meth)acrylate as the vinyl monomer having a hydroxyl group.

- the vinyl monomer having a hydroxyl group is preferably used in the range of 0.01% by weight to 1.0% by weight based on the total amount of the monomers used in the production of the acrylic polymer. More preferably, it is used in the range of 03% by weight to 0.3% by weight.

- vinyl monomer having a carboxyl group examples include acrylic acid, methacrylic acid, itaconic acid, maleic acid, (meth)acrylic acid dimer, crotonic acid, ethylene oxide-modified succinic acid acrylate (meth) Examples include acrylic monomers. Of these, acrylic acid is preferred.

- vinyl having an amide group examples include (meth)acrylic monomers such as N-vinylpyrrolidone, N-vinylcaprolactam, acryloylmorpholine, acrylamide, and N,N-dimethylacrylamide.

- the highly polar vinyl monomer is preferably used in the range of 1.5% by weight to 20% by weight, and preferably 1.5% by weight, based on the total amount of the monomers used in the production of the acrylic polymer. It is more preferable to use in the range of up to 10% by weight, and it is preferable to use in the range of 2% to 8% by weight because it is possible to form a pressure-sensitive adhesive layer that is well-balanced in terms of cohesive force, holding power and adhesiveness. More preferable.

- the method for producing the acrylic polymer is not particularly limited and may be appropriately selected from known methods according to the purpose.

- the monomer may be a solution polymerization method, a bulk polymerization method, or a suspension polymerization method. Examples thereof include a method of polymerizing by a polymerization method such as a suspension polymerization method and an emulsion polymerization method.

- the acrylic polymer is preferably produced by a solution polymerization method or a bulk polymerization method.

- a peroxide-based thermal polymerization initiator such as benzoyl peroxide and lauroyl peroxide, an azo thermal polymerization initiator such as azobisisobutylnitrile, an acetophenone-based photopolymerization initiator, A benzoin ether photopolymerization initiator, a benzyl ketal photopolymerization initiator, an acylphosphine oxide photopolymerization initiator, a benzoin photopolymerization initiator, a benzophenone photopolymerization initiator, or the like can be used.

- the weight average molecular weight of the acrylic polymer obtained by the above method use one having a weight average molecular weight of 300,000 to 3,000,000 measured by gel permeation chromatography (GPC) in terms of standard polystyrene. Is preferable, and it is more preferable to use one having a viscosity of 500,000 to 2,500,000.

- GPC gel permeation chromatography

- the measurement of the weight average molecular weight of the acrylic polymer by the GPC method is a standard polystyrene conversion value measured using a GPC device (HLC-8329GPC, manufactured by Tosoh Corporation), and the measurement conditions are as follows. Is.

- acrylic pressure-sensitive adhesive resin it is preferable to use a resin containing a tackifying resin in order to improve the adhesion to the adherend and the surface adhesion strength.

- the tackifying resin contained in the acrylic pressure-sensitive adhesive resin is not particularly limited and may be appropriately selected depending on the intended purpose, but preferably has a softening point of 30° C. to 180° C., and 70° C. Those having a temperature of 140° C. are more preferable for forming a pressure-sensitive adhesive layer having high adhesion performance.

- a (meth)acrylate-based tackifying resin is used, its glass transition temperature is preferably 30°C to 200°C, more preferably 50°C to 160°C.

- the tackifying resin contained in the acrylic pressure-sensitive adhesive resin include rosin-based tackifying resin, polymerized rosin-based tackifying resin, polymerized rosin ester-based tackifying resin, rosin phenol-based tackifying resin, and stabilized rosin ester.

- -Based tackifier resin disproportionated rosin ester-based tackifier resin, hydrogenated rosin ester-based tackifier resin, terpene-based tackifier resin, terpene phenol-based tackifier resin, petroleum resin-based tackifier resin, (meth)acrylate-based tackifier

- An example is a resin to be applied.

- the tackifying resin is a polymerized rosin ester tackifying resin, a rosin phenol tackifying resin, a disproportionated rosin ester tackifying resin, a hydrogenated rosin ester tackifying resin, a terpene phenolic resin, ( A (meth)acrylate resin is preferable.

- the amount of the tackifying resin used is not particularly limited and may be appropriately selected depending on the intended purpose. It is used in the range of 5 parts by weight to 65 parts by weight with respect to 100 parts by weight of the acrylic polymer. It is preferable to use it in the range of 8 parts by weight to 55 parts by weight, and it is more preferable to use it in the range of easy adherence to the adherend.

- acrylic pressure-sensitive adhesive resin it is preferable to use a resin containing a crosslinking agent in order to further improve the cohesive force of the pressure-sensitive adhesive layer.

- the cross-linking agent is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include isocyanate cross-linking agents, epoxy cross-linking agents, metal chelate cross-linking agents and aziridine cross-linking agents. These may be used alone or in combination of two or more.

- the cross-linking agent is preferably a type of cross-linking agent that is mixed after the production of the acrylic polymer to proceed the cross-linking reaction, and an isocyanate-based cross-linking agent and an epoxy-based cross-linking agent that are highly reactive with the acrylic polymer are used. More preferably.

- Examples of the above-mentioned isocyanate-based cross-linking agent include tolylene diisocyanate, triphenylmethane isocyanate, naphthylene-1,5-diisocyanate, hexamethylene diisocyanate, diphenylmethane diisocyanate, xylylene diisocyanate, and trimethylolpropane-modified tolylene diisocyanate. These may be used alone or in combination of two or more. Among these, tolylene diisocyanate, which is a trifunctional polyisocyanate compound, adducts of these trimethylolpropanes, and triphenylmethane isocyanate are particularly preferable.

- a gel fraction value for measuring the insoluble matter after the adhesive layer is immersed in toluene for 24 hours is used.

- the gel fraction of the adhesive layer is appropriately selected depending on the intended purpose without any limitation, but it is preferably 10% by weight to 70% by weight, more preferably 25% by weight to 65% by weight, and 35% by weight. % To 60% by weight is more preferable for obtaining an adhesive layer having good cohesiveness and adhesiveness.

- the gel fraction refers to the value measured by the following method.

- the pressure-sensitive adhesive resin containing the above-mentioned pressure-sensitive adhesive resin and, if necessary, the above-mentioned additive is further coated so as to have a thickness after drying of 50 ⁇ m, and dried at 100° C. for 3 minutes, and then at 40° C. What was aged for 2 days was cut into a 50 mm square and used as a sample.

- the weight (G1) of the sample before being immersed in toluene was measured in advance, and the toluene-insoluble content of the sample after being immersed in the toluene solution at 23° C. for 24 hours was separated by filtering with a 300 mesh wire mesh.

- the weight (G2) of the residue after drying at 110° C. for 1 hour is measured, and the gel fraction is obtained according to the following formula (4).

- the weight (G3) of the conductive fine particles in the sample is calculated from the weight (G1) of the sample and the composition of the pressure-sensitive adhesive composition.

- Gel fraction (% by weight) (G2-G3)/(G1-G3) ⁇ 100 Formula (4)

- the rubber-based pressure-sensitive adhesive resin is not particularly limited, and a rubber material that can be generally used as a pressure-sensitive adhesive resin such as a synthetic rubber-based pressure-sensitive adhesive resin or a natural rubber-based pressure-sensitive adhesive resin, and a tackifying resin if necessary. And the like containing the additive.

- the rubber material examples include block copolymers of polyaromatic vinyl compounds and conjugated diene compounds; styrene-isoprene copolymers, styrene-isoprene-styrene copolymers, styrene-butadiene-styrene copolymers, styrene.

- examples thereof include styrene-based resins such as ethylene-butylene copolymer and styrene-ethylene-propylene copolymer. These may be used alone or in combination of two or more.

- the styrene-based resin is preferable, and it is more preferable to use two or more kinds of the styrene-based resins in combination, since the adhesive sheet can have excellent adhesive properties and holding power, and the styrene-isoprene copolymer It is particularly preferable to use the combination of the polymer and the styrene-isoprene-styrene copolymer.

- the styrene-based resin may have, for example, a single structure having a linear structure, a branched structure, or a multi-branched structure, or a mixture of different structures.

- the pressure-sensitive adhesive sheet can be provided with excellent adhesive performance.

- a structure having a branched structure or a multi-branched structure with a styrene block arranged at the terminal of the molecule can have a pseudo cross-linking structure and can give excellent cohesive force, and thus can give high holding power. it can. For this reason, it is preferable that the styrene-based resin is mixed and used according to the required characteristics.

- the styrene resin it is preferable to use one having a structural unit represented by the following chemical formula (1) in the range of 10% by weight to 80% by weight based on the total weight of the styrene resin, It is more preferable to use the one having a range of 12% to 60% by weight, further preferable to use the one having a range of 15% to 40% by weight, and the range of 17% to 35% by weight. It is particularly preferable to use one that has. Thereby, excellent adhesiveness and heat resistance can be obtained.

- the styrene-isoprene copolymer and the styrene-isoprene-styrene copolymer are used in combination as the styrene-based resin, the styrene-isoprene copolymer and the styrene-isoprene-styrene copolymer are combined.

- the content of the styrene-isoprene copolymer with respect to the total weight is preferably 0% by weight to 80% by weight, more preferably 0% by weight to 77% by weight, and 0% by weight to 75% by weight. It is more preferable that the amount is 0% to 70% by weight.

- the adhesive sheet can have both excellent adhesive performance and thermal durability.

- the styrene-isoprene copolymer it is preferable to use one having a weight average molecular weight measured by gel permeation chromatography (GPC) in terms of standard polystyrene in the range of 10,000 to 800,000. The range of 30,000 to 500,000 is more preferable, and the range of 50,000 to 300,000 is more preferable.

- GPC gel permeation chromatography

- the weight average molecular weight of the styrene-isoprene copolymer is within the above-mentioned preferred range, heat fluidity and compatibility at the time of solvent dilution can be ensured, so that the workability in the manufacturing process is good and the heat durability is good. It is preferable because the pressure-sensitive adhesive sheet having the above can be obtained.

- the measurement of the weight average molecular weight of the styrene-isoprene copolymer by the GPC method is a standard polystyrene conversion value measured using a GPC device (SC-8020, manufactured by Tosoh Corporation), and the measurement conditions are It is as follows.

- the method for producing the styrene-isoprene copolymer is not particularly limited and may be appropriately selected from conventionally known production methods. For example, a method of sequentially polymerizing a styrene block and an isoprene block by anion living polymerization method. And so on.

- the method for producing the styrene-isoprene-styrene copolymer is not particularly limited and may be appropriately selected from conventionally known production methods.

- a styrene block and an isoprene block are sequentially polymerized by an anion living polymerization method.

- a method of producing a block copolymer having a living active terminal and then reacting it with a coupling agent to produce a coupled block copolymer are sequentially polymerized by an anion living polymerization method.

- a method of producing a block copolymer having a living active terminal and then reacting it with a coupling agent to produce a coupled block copolymer are sequentially polymerized by an anion living polymerization method.

- the method for producing the mixture of the styrene-isoprene copolymer and the styrene-isoprene-styrene copolymer is not particularly limited and may be appropriately selected from conventionally known production methods. And a method of mixing the styrene-isoprene copolymer produced in (3) and the styrene-isoprene-styrene copolymer.

- a method for producing a mixture of the styrene-isoprene copolymer and the styrene-isoprene-styrene copolymer it is also possible to produce the mixture simultaneously in one polymerization step.

- a styrene monomer is polymerized in a polymerization solvent using an anionic polymerization initiator to form a polystyrene block having a living active terminal. ..

- isoprene is polymerized from the living active end of the polystyrene block to obtain a styrene-isoprene diene block copolymer having a living active end.

- a part of the styrene-isoprene diene block copolymer having a living active terminal is reacted with a coupling agent to form a coupled styrene-isoprene-styrene block copolymer.

- the rest of the styrene-isoprene diene block copolymer having a living active end is deactivated with a polymerization terminator to obtain a styrene-isoprene diene block copolymer.

- a polymerization terminator to obtain a styrene-isoprene diene block copolymer.

- the tackifying resin contained in the rubber-based pressure-sensitive adhesive resin is not particularly limited and may be appropriately selected depending on the purpose, but it is preferable to use a tackifying resin having a softening point of 80° C. or higher. This makes it possible to obtain the pressure-sensitive adhesive sheet having excellent initial adhesiveness and thermal durability.

- the tackifying resin is preferably solid at room temperature (23° C.), and specific examples thereof include C 5 petroleum resin, C 9 petroleum resin, C 5 /C 9 petroleum resin, alicyclic ring.

- Examples thereof include petroleum resins such as group petroleum resins, polymerized rosin resins, terpene resins, rosin resins, terpene-phenol resins, styrene resins, coumarone-indene resins, xylene resins, and phenol resins. These may be used alone or in combination of two or more. Among these, it is preferable to use the C 5 petroleum resin and the polymerized rosin resin in combination as the tackifying resin in order to achieve both excellent initial adhesiveness and thermal durability.

- the petroleum resin is easily compatible with the structural unit represented by the chemical formula (1) that constitutes the styrene resin, and as a result, the initial adhesive strength and thermal durability of the pressure-sensitive adhesive sheet are further improved. You can

- Examples of the C 5 petroleum resin include Escoletz 1202, Escoletz 1304, Escoletz 1401 (all manufactured by ExxonMobil), Wing Tack 95 (manufactured by Goodyear Tire and Rubber Company), Quinton K100, Quinton R100, Examples include Quinton F100 (above, manufactured by Nippon Zeon Co., Ltd.), PicoTac 95, PicoPale 100 (manufactured by Rika Hercules Co., Ltd.) and the like.

- Examples of the C 9 petroleum resin include Nisseki Neopolymer L-90, Nisseki Neopolymer 120, Nisseki Neopolymer 130, Nisseki Neopolymer 140, Nisseki Neopolymer 150, Nisseki Neopolymer 170S and Nisseki Neopolymer 170S.

- Stone Neopolymer 160 Nisseki Neopolymer E-100, Nisseki Neopolymer E-130, Nisseki Neopolymer 130S, Nisseki Neopolymer S (above, JX Nikko Nisseki Energy Co., Ltd.), Petcoal (registered trademark) (Manufactured by Tosoh Corporation) and the like.

- C 5 series/C 9 series petroleum resin a copolymer of the C 5 series petroleum resin and the C 9 series petroleum resin can be used, and for example, Escoletz 2101 (manufactured by ExxonMobil), Quinton G115 (manufactured by Nippon Zeon Co., Ltd.), HercoTack 1149 (manufactured by Rika Hercules Co., Ltd.) and the like can be used.

- the alicyclic petroleum resin can be obtained by hydrogenating the C 9 petroleum resin, and examples thereof include Escoletz 5300 (manufactured by ExxonMobil), Alcon P-100 (manufactured by Arakawa Chemical Industry Co., Ltd.), Rigalite R101 (manufactured by Rika Hercules Co., Ltd.) and the like can be mentioned.

- the amount of the tackifying resin used is not particularly limited and may be appropriately selected depending on the intended purpose. It is 0% by weight to 100% by weight based on the total amount of the components constituting the rubber-based adhesive resin. Is preferably used in the range of 0% by weight to 70% by weight, more preferably 0% by weight to 50% by weight, still more preferably 0% by weight to 30% by weight. It is particularly preferable to use the above range.

- the tackifier resin in the preferred range, it is easy to achieve both excellent elongation at break and thermal durability of the pressure-sensitive adhesive sheet while increasing the interfacial adhesion between the pressure-sensitive adhesive layer and the base material layer. Become.

- the amount of the tackifying resin having a softening point of 80° C. or higher is appropriately selected depending on the intended purpose without any limitation, but it is 3% by weight to 100% by weight based on the total amount of the styrene resin. %, preferably in the range of 5% to 80% by weight, and more preferably in the range of 5% to 80% by weight. It is particularly preferable in order to obtain the pressure-sensitive adhesive sheet having both excellent heat durability.

- a tackifying resin having a softening point of ⁇ 5° C. or lower can be used in combination with the tackifying resin having a softening point of 80° C. or higher. ..

- the tackifying resin having a softening point of ⁇ 5° C. or lower is not particularly limited and may be appropriately selected from the known tackifying resins according to the purpose, but a tackifying resin that is liquid at room temperature is used. Preferably.

- the tackifying resin having a softening point of ⁇ 5° C. or lower include process oil, liquid rubber such as polyester and polybutene. These may be used alone or in combination of two or more. Among these, it is preferable to use polybutene as the tackifying resin having a softening point of ⁇ 5° C. or lower in order to exhibit even more excellent initial adhesiveness.

- the tackifying resin having a softening point of ⁇ 5° C. or lower is preferably used in the range of 0% by weight to 40% by weight, and the range of 0% by weight to 30% by weight based on the total amount of the tackifying resin. It is more preferable to use.

- the tackifying resin having a softening point of ⁇ 5° C. or lower is preferably used in the range of 0% by weight to 40% by weight, and 0% by weight to 30% by weight based on the total amount of the styrene resin. It is more preferable to use it within the range since the initial adhesive strength can be improved, good adhesion can be achieved, and sufficient thermal durability can be obtained.

- the weight ratio of the tackifying resin having a softening point of 80° C. or higher and the tackifying resin having a softening point of ⁇ 5° C. or lower is not particularly limited and may be appropriately selected depending on the purpose.

- the weight of the tackifying resin having a point of 80° C. or higher/the weight of the tackifying resin having a softening point of ⁇ 5° C. or lower], and the softening point of the tackifying resin having a softening point of ⁇ 5° C. or lower is 80° C.

- the above tackifying resin in a weight ratio range of 5 to 50, and it is preferable to use it in a range of 10 to 30 to achieve both excellent initial adhesiveness and excellent holding power. It is more preferable for obtaining an adhesive sheet.

- the weight ratio of the styrene resin and the tackifying resin is not particularly limited and may be appropriately selected depending on the purpose, but is represented by [styrene resin/tackifying resin]

- the weight ratio of the styrene resin to the resin is preferably in the range of 0.5 to 10.0, and is used in the range of 0.6 to 9.0 to improve the initial adhesive strength. It is more preferable because it is possible to obtain excellent thermal durability.

- the weight ratio [styrene resin/tackifier resin] is larger than 1 to prevent peeling due to the repulsive force of the pressure-sensitive adhesive sheet when the pressure-sensitive adhesive sheet is attached to a curved surface portion of an adherend ( It is preferable in terms of resistance to repulsion.

- the other components in the pressure-sensitive adhesive layer are not particularly limited and can be appropriately selected within a range that does not impair the properties of the pressure-sensitive adhesive sheet.

- UV absorbers fillers, polymerization inhibitors, surface modifiers, antistatic agents, defoamers, viscosity modifiers, light stabilizers, weather stabilizers, heat stabilizers, antioxidants, leveling agents, organic pigments, Additives such as inorganic pigments, pigment dispersants, plasticizers, softeners, flame retardants, metal deactivators, silica beads, organic beads; inorganic fillers such as silicon oxide, aluminum oxide, titanium oxide, zirconia, antimony pentoxide Agents and the like. These may be used alone or in combination of two or more. The content of the other components in the pressure-sensitive adhesive layer can be appropriately selected within a range that does not impair the characteristics of the pressure-sensitive adhesive sheet.

- the pressure-sensitive adhesive layer is not particularly limited as long as it is arranged on the surface of the base material layer, and can be appropriately selected according to the purpose of use, and is arranged on only one surface of the base material layer. It may be arranged on both surfaces, but it is preferably arranged on both surfaces.

- the 25% elongation stress of the pressure-sensitive adhesive layer is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 0.04 MPa to 0.4 MPa, more preferably 0.05 MPa to 0.1 MPa.

- the 25% elongation stress of the pressure-sensitive adhesive layer is within the above-mentioned preferred range, it is possible to obtain a suitable adhesive strength as the pressure-sensitive adhesive sheet, and it is possible to relatively easily peel off even when stretched and peeled.

- the pressure-sensitive adhesive sheet is formed when a load is generated in the shearing direction of the pressure-sensitive adhesive sheet while fixing hard adherends to each other.

- the force required to extend the pressure-sensitive adhesive sheet may become excessive when the pressure-sensitive adhesive sheet is peeled off.

- the adhesive layer was punched out into a dumbbell shape with a marked line length of 20 mm and a width of 10 mm, and a Tensilon tensile tester (model: RTF) was used under the conditions of a measurement atmosphere of 23° C. and 50% RH. -1210, manufactured by A&D Co., Ltd.) is used to indicate the stress value measured when stretched by 25% by pulling in the length direction at a pulling rate of 300 mm/min.

- the stress at break of the adhesive layer is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 0.5 MPa to 2.1 MPa, more preferably 1.0 MPa to 2.1 MPa.

- the stress at break of the pressure-sensitive adhesive layer is within the preferred range, it is possible to prevent the pressure-sensitive adhesive sheet from being torn even when the pressure-sensitive adhesive sheet is stretched and peeled off, so that the pressure-sensitive adhesive sheet is elongated. Since the load of is not excessive, the re-peeling work by peeling can be facilitated.

- the pressure-sensitive adhesive sheet may be torn when stretched and peeled off, and if it exceeds 2.1 MPa, the pressure-sensitive adhesive sheet may be broken. When it is attempted to re-stretch by stretching, it may not be able to be sufficiently stretched and re-stripping may be impossible.

- the force required for stretching and deforming the pressure-sensitive adhesive sheet also depends on the thickness of the pressure-sensitive adhesive sheet, and for example, stretching the pressure-sensitive adhesive sheet with a large thickness of the pressure-sensitive adhesive sheet and high stress at breakage Even if peeling is attempted, it may not be possible to sufficiently stretch and it may not be possible to peel again.

- the stress at break of the pressure-sensitive adhesive layer was obtained by punching the pressure-sensitive adhesive layer into a dumbbell shape having a marked line length of 20 mm and a width of 10 mm under a measurement atmosphere of 23° C. and 50% RH under a Tensilon tensile tester (model: RTF-1210). (Manufactured by A&D Co., Ltd.) is used to indicate the stress value measured at the time of breaking by pulling in the length direction at a pulling speed of 300 mm/min.

- the elongation at break of the adhesive layer is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 450% to 1,300%, more preferably 500% to 1,200%, and 600 % To 1,100% is more preferable.

- the elongation at break of the pressure-sensitive adhesive layer was obtained by punching the pressure-sensitive adhesive layer into a dumbbell shape having a marked line length of 20 mm and a width of 10 mm under a measurement atmosphere of 23° C.

- the average thickness of the adhesive layer is appropriately selected depending on the intended purpose without any limitation, but it is preferably 5 ⁇ m to 150 ⁇ m, more preferably 20 ⁇ m to 120 ⁇ m, and even more preferably 40 ⁇ m to 110 ⁇ m. It is more preferable that the thickness is 50 ⁇ m to 100 ⁇ m.

- the "average thickness of the adhesive layer” means the average thickness of the adhesive layer on one surface of the adhesive sheet. When the pressure-sensitive adhesive sheet has the pressure-sensitive adhesive layer on both sides thereof, the average thickness of the pressure-sensitive adhesive layer on the one surface and the average thickness of the pressure-sensitive adhesive layer on the other surface may be the same or different. However, it is preferable that they have the same thickness.

- the "average thickness of the adhesive layer” means that the adhesive sheet is cut in the length direction at intervals of 100 mm at five locations in the width direction, and in each of the cut surfaces, at an interval of 100 mm in the width direction.

- the total thickness of the adhesive layers at the points is an average value of the total thickness of 25 points measured by using a TH-104 paper/film thickness measuring machine (manufactured by Tester Sangyo Co., Ltd.).

- the method for forming the pressure-sensitive adhesive layer is not particularly limited and can be appropriately selected from known methods according to the purpose.

- at least one surface of the base material layer is a heat press method, Examples thereof include a cast method by extrusion molding, a uniaxial stretching method, a sequential secondary stretching method, a simultaneous biaxial stretching method, an inflation method, a tube method, a calender method, a solution method and the like to form the adhesive layer.

- the cast method by extrusion and the solution method are preferable.

- Examples of the solution method include a method of directly applying a solution containing the pressure-sensitive adhesive composition to the base material layer using a roll coater or the like, a method of forming the pressure-sensitive adhesive layer on a release sheet, and then peeling the solution and using the solution. Can be mentioned.

- the release sheet is not particularly limited and may be appropriately selected depending on the intended purpose.

- Examples thereof include paper such as kraft paper, glassine paper, and fine paper; polyethylene, polypropylene (biaxially oriented polypropylene (OPP), uniaxially oriented).

- Resin film such as polypropylene (CPP) and polyethylene terephthalate (PET); laminated paper in which the paper and the resin film are laminated, silicone on one side or both sides of the paper which is subjected to sealing treatment with clay or polyvinyl alcohol Examples include those that have been subjected to a peeling treatment with a resin or the like. These may be used alone or in combination of two or more.

- the base material layer is not particularly limited and can be appropriately selected from known materials that can be used for the pressure-sensitive adhesive sheet, as long as the characteristics of the pressure-sensitive adhesive sheet are not impaired. It is preferable to contain, and if necessary, other components may be further contained.

- the base material layer may have a single-layer structure or a multi-layer structure having two layers, three layers, or more layers.

- Substrate material examples include styrene-isoprene copolymer, styrene-isoprene-styrene copolymer, styrene-butadiene-styrene copolymer, styrene-ethylene-butylene copolymer, styrene-ethylene-propylene copolymer.

- Styrene resins such as polymers; polyurethane resins such as ester polyurethane and ether polyurethane; polyolefin resins such as polyethylene and polypropylene; polyester resins such as polyethylene terephthalate, polybutylene terephthalate and polyethylene naphthalate; polystyrene; polycarbonate; polymethylpentene Polysulfone; polyetheretherketone; polyethersulfone; polyetherimide; polyimide film; fluorine resin; nylon; acrylic resin and the like. These may be used alone or in combination of two or more, but preferably in combination of two or more.

- the styrene resin and the polyurethane resin are preferable because they easily obtain suitable elongation at break and stress at break, and the styrene resin is more preferable, and the styrene-isoprene copolymer and the styrene-isoprene- It is particularly preferable to use it in combination with a styrene copolymer.

- the styrene-based resin is a resin that exhibits thermoplasticity, it has excellent moldability such as extrusion molding and injection molding, and the base material layer can be easily molded.

- the styrene-based resin easily obtains a particularly excellent elongation at break among the resin group generally called thermoplastic resin, and can be suitably used as a base material of the pressure-sensitive adhesive sheet.

- the ratio of the styrene resin to the total resin component in the base material is preferably 50% to 100%, more preferably 60% to 100%, further preferably 65% to 100%. , 70% to 100% is particularly preferable.

- the ratio of the styrene resin is within the preferable range, it is possible to obtain a base material layer having excellent elongation at break and stress at break.

- the styrene-based resin may have, for example, a single structure having a linear structure, a branched structure, or a multi-branched structure, or a mixture of different structures.

- the styrene-based resin rich in the linear structure can give the base material layer an excellent elongation at break.

- those having a branched structure or a multi-branched structure with a styrene block arranged at the terminal of the molecule can have a pseudo cross-linked structure and can give excellent cohesive force. Therefore, it is preferable that the styrene-based resin is mixed and used according to the required mechanical characteristics.

- the styrene resin it is preferable to use one having the structural unit represented by the chemical formula (1) in the range of 13% by weight to 60% by weight, based on the total weight of the styrene resin. It is more preferable to use the one having the range of 50% by weight to 50% by weight, further preferable to use the one having the range of 15% to 45% by weight, and the range of 15% to 35% by weight. It is particularly preferable to use one.

- the ratio of the structural unit represented by the following chemical formula (1) to the total weight of the styrene-based resin is within the preferable range, the elongation at break and the stress at break can be easily obtained in a preferable range.

- the styrene-isoprene copolymer and the styrene-isoprene-styrene copolymer are used in combination as the styrene-based resin, the styrene-isoprene copolymer and the styrene-isoprene-styrene copolymer are combined.

- the content of the styrene-isoprene copolymer based on the total weight is preferably 0% by weight to 80% by weight, more preferably 0% by weight to 70% by weight, and 0% by weight to 50% by weight. More preferably, it is 0% by weight to 30% by weight.

- the content of the styrene-isoprene copolymer is within the preferable range, it becomes possible to achieve both thermal durability and excellent elongation at break and stress at break.

- the styrene-isoprene copolymer it is preferable to use one having a weight average molecular weight measured by gel permeation chromatography (GPC) in terms of standard polystyrene in the range of 10,000 to 800,000. The range of 30,000 to 500,000 is more preferable, and the range of 50,000 to 300,000 is more preferable.

- GPC gel permeation chromatography

- the weight average molecular weight of the styrene-isoprene copolymer is within the above-mentioned preferred range, heat fluidity and compatibility at the time of solvent dilution can be ensured, so that the workability in the manufacturing process is good and the heat durability is good.

- the substrate layer having has The measurement of the weight average molecular weight of the styrene-isoprene copolymer by the GPC method is the same as the method described in the item of "-rubber adhesive resin-".

- the method for producing the styrene-isoprene copolymer, the styrene-isoprene-styrene copolymer, and the mixture of the styrene-isoprene copolymer and the styrene-isoprene-styrene copolymer is not particularly limited, It can be appropriately selected from conventionally known production methods, and examples thereof include the same method as the method described in the above-mentioned item “—Rubber adhesive resin—”.

- the polyurethane resin is not particularly limited and may be appropriately selected depending on the intended purpose. However, those having a softening point of 40° C. or higher are preferable, and those having a softening point of 50° C. or higher are more preferable.

- the upper limit of the softening point is preferably 100°C or lower.

- the softening point refers to a value measured according to JIS K 2207 (dry bulb type) (hereinafter, the same applies to the softening point).

- a reaction product of a polyol (b1-1) and a polyisocyanate (b1-2) can be preferably used.

- the polyol (b1-1) is appropriately selected depending on the intended purpose without any limitation, and examples thereof include polyester polyol, polyether polyol, polycarbonate polyol, and acrylic polyol. These may be used alone or in combination of two or more. Among these, as the polyol (b1-1), polyester polyol and polyether polyol are preferable because the mechanical properties of the base material layer can be obtained. In the base material layer, polyester polyol is preferably used when heat resistance is required, and polyether polyol is preferably used when water resistance or biodegradation resistance is required.

- polyester polyol examples include polyester obtained by esterification reaction of low molecular weight polyol and polycarboxylic acid, polyester obtained by ring-opening polymerization reaction of cyclic ester compound such as ⁇ -caprolactone, and copolymerization thereof. Examples include polyester.

- Examples of the low molecular weight polyol that can be used for producing the polyester polyol include, for example, ethylene glycol, propylene glycol, 1,4-butanediol, 1,6-hexanediol having a weight average molecular weight of about 50 to 300.

- Aliphatic alkylene glycols such as diethylene glycol, neopentyl glycol and 1,3-butanediol, cyclohexanedimethanol and the like can be used.

- polycarboxylic acid examples include aliphatic dicarboxylic acids such as succinic acid, adipic acid, sebacic acid, and dodecanedicarboxylic acid; aromatic dicarboxylic acids such as terephthalic acid, isophthalic acid, phthalic acid, and naphthalenedicarboxylic acid; Examples thereof include anhydrides and esterified products.

- polyether polyol examples include those obtained by addition-polymerizing alkylene oxide with one or more compounds having two or more active hydrogen atoms as an initiator.

- polycarbonate polyol for example, one obtained by reacting a carbonic acid ester and/or phosgene with a low molecular weight polyol described later can be used.

- Examples of the carbonic acid ester include methyl carbonate, dimethyl carbonate, ethyl carbonate, diethyl carbonate, cyclocarbonate, diphenyl carbonate and the like.

- Examples of the low molecular weight polyol which can react with the carbonic acid ester and/or phosgene that can be used for producing the polycarbonate polyol include, for example, ethylene glycol, diethylene glycol, triethylene glycol, tetraethylene glycol, 1,2-propanediol, 1,3-propanediol, dipropylene glycol, tripropylene glycol, 1,2-butanediol, 1,3-butanediol, 1,4-butanediol, 2,3-butanediol, 1,5-pentanediol, 1,5-hexanediol, 1,6-hexanediol, 2,5-hexanediol, 1,7-heptanediol, 1,8-octanediol, 1,9-nonanediol, 1,10-decanediol, 1 ,11-Undecanedio

- the polyisocyanate (b1-2) is not particularly limited and may be appropriately selected according to the purpose.

- alicyclic polyisocyanate, aliphatic polyisocyanate, aromatic polyisocyanate and the like may be used.

- examples thereof include alicyclic polyisocyanates. These may be used alone or in combination of two or more.

- alicyclic polyisocyanate examples include isophorone diisocyanate, 1,3-bis(isocyanatomethyl)cyclohexane, 4,4′-dicyclohexylmethane diisocyanate, 2,4-methylcyclohexane diisocyanate and 2,6-methylcyclohexane diisocyanate.

- Cyclohexylene diisocyanate methyl cyclohexylene diisocyanate, bis(2-isocyanatoethyl)-4-cyclohexylene-1,2-dicarboxylate, 2,5-norbornane diisocyanate, 2,6-norbornane diisocyanate, dimer acid diisocyanate, Examples thereof include bicycloheptane triisocyanate. These may be used alone or in combination of two or more.

- the method for producing the polyurethane resin (b1) by reacting the polyol (b1-1) with the polyisocyanate (b1-2) is not particularly limited and may be appropriately selected from conventionally known production methods.

- the polyol (b1-1) charged in a reaction vessel is heated under normal pressure or reduced pressure to remove water, and then the polyisocyanate (b1-2) is collectively or divided. Examples include a method of supplying and reacting.

- the reaction condition of the polyol (b1-1) and the polyisocyanate (b1-2) is not particularly limited and may be appropriately selected in consideration of various conditions such as safety, quality and cost.

- the temperature is preferably 70°C to 120°C, and the reaction time is preferably 30 minutes to 5 hours.

- a tertiary amine catalyst or an organometallic catalyst can be used as a catalyst. ..

- the reaction may be carried out in a solvent-free environment or in the presence of an organic solvent.

- the organic solvent is not particularly limited and may be appropriately selected depending on the intended purpose. Examples thereof include ester solvents such as methyl acetate, ethyl acetate, propyl acetate and butyl acetate; acetone, methyl ethyl ketone, methyl butyl ketone and cyclohexanone. And the like; ether solvent such as methyl cellosolve acetate and butyl cellosolve acetate; aromatic hydrocarbon solvent such as toluene and xylene; amide solvent such as dimethylformamide and dimethylacetamide. These may be used alone or in combination of two or more.

- the organic solvent may be removed during the production of the polyurethane resin (b1) or after the production of the polyurethane (b1) by an appropriate method such as heating under reduced pressure or drying under normal pressure.

- the other components in the base material layer are not particularly limited and may be appropriately selected within a range that does not impair the properties of the pressure-sensitive adhesive sheet.

- a tackifying resin for example, a tackifying resin; a polymer component other than the base material; Cross-linking agent, anti-aging agent, ultraviolet absorber, filler, polymerization inhibitor, surface modifier, antistatic agent, defoamer, viscosity modifier, light resistance stabilizer, weather resistance stabilizer, heat resistance stabilizer, antioxidant, Examples include additives such as leveling agents, organic pigments, inorganic pigments, pigment dispersants, silica beads, and organic beads; inorganic fillers such as silicon oxide, aluminum oxide, titanium oxide, zirconia, and antimony pentoxide. These may be used alone or in combination of two or more.

- the content of the other components in the base material layer can be appropriately selected within a range that does not impair the characteristics of the pressure-sensitive adhesive sheet.

- the tackifying resin can be used for the purpose of enhancing the adhesiveness between the pressure-sensitive adhesive layer of the pressure-sensitive adhesive sheet and the base material layer and heat resistance.

- the tackifying resin is not particularly limited and may be appropriately selected depending on the intended purpose, but has a softening point of preferably 80° C. or higher, more preferably 90° C. or higher, more preferably 100° C. or higher. Is more preferable, and one having a temperature of 110° C. or higher is particularly preferable.

- tackifying resin for example, those described in the above item “—Rubber adhesive resin—” can be used, and the preferred embodiments are also the same.

- the antiaging agent is not particularly limited and may be appropriately selected from known ones according to the purpose.

- a phenolic antiaging agent a phosphorus antiaging agent (referred to as “processing stabilizer”). A), an amine anti-aging agent, an imidazole anti-aging agent, and the like. These may be used alone or in combination of two or more.

- the phenolic anti-aging agent, the phosphorus anti-aging agent is preferable, it is possible to effectively improve the heat stability of the material for the substrate, as a result of using them in combination, as a result, This is preferable because it is possible to obtain a pressure-sensitive adhesive sheet that maintains good initial adhesiveness and further has excellent thermal durability.

- the phosphorus-based antiaging agent may slightly change color (yellowing) with time in a high temperature environment, the amount used should be such that the balance between the initial adhesiveness, thermal durability and discoloration prevention. It is preferable to set it in consideration.

- a phenolic compound having a sterically hindering group can be generally used, and a monophenol type, a bisphenol type and a polyphenol type are typical. Specific examples include 2,6-di-t-butyl-4-methylphenol, 2,2'-methylenebis(4-methyl-6-t-butylphenol), 2,2'-methylenebis(4-ethyl-6).

- the amount of the phenol-based antioxidant used is not particularly limited and may be appropriately selected depending on the intended purpose. It is 0.1 to 5 parts by weight per 100 parts by weight of the base material. It is preferable to use it in the range of 0.5 to 3 parts by weight, and it is possible to effectively improve the heat resistance stability of the material for a substrate, and as a result, it is possible to improve the initial stability. It is possible to obtain a pressure-sensitive adhesive sheet that maintains adhesiveness and has further excellent heat durability.

- the stress at 25% elongation of the base material layer is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 0.2 MPa to 10.0 MPa, more preferably 0.2 MPa to 5.0 MPa. , 0.2 MPa to 3.0 MPa are more preferable, and 0.2 MPa to 2.0 MPa are particularly preferable.

- the adhesive strength suitable as the pressure-sensitive adhesive sheet can be obtained, and the adhesive sheet can be peeled off relatively easily even when stretched and peeled. ..

- the pressure-sensitive adhesive sheet is subjected to a load in the shearing direction of the pressure-sensitive adhesive sheet while fixing hard adherends to each other.

- the force necessary for stretching the pressure-sensitive adhesive sheet may become excessive when the pressure-sensitive adhesive sheet is peeled off.

- the base material layer was punched out into a dumbbell shape having a marked line length of 20 mm and a width of 6 mm under a measurement atmosphere of 23° C.

- the stress at break of the base material layer is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 1.5 MPa to 100.0 MPa, more preferably 7.0 MPa to 50.0 MPa, 0.0 MPa to 40.0 MPa is more preferable, and 8.0 MPa to 35.0 MPa is particularly preferable.

- the stress at break of the base material layer is within the preferable range, it is possible to prevent the pressure-sensitive adhesive sheet from being torn even when the pressure-sensitive adhesive sheet is stretched and peeled off, and the pressure-sensitive adhesive sheet is elongated. Since the load for this is not excessive, the re-peeling work by peeling is facilitated.

- the adhesive sheet when the stress at break of the base material layer is less than 1.5 MPa, the adhesive sheet may be torn when the adhesive sheet is stretched and peeled off. When the sheet is stretched to be re-peeled, it may not be able to be sufficiently stretched and re-peeled in some cases.

- the force required for stretching and deforming the pressure-sensitive adhesive sheet also depends on the thickness of the pressure-sensitive adhesive sheet, and for example, stretching the pressure-sensitive adhesive sheet with a large thickness of the pressure-sensitive adhesive sheet and high stress at breakage Even if peeling is attempted, it may not be possible to sufficiently stretch and it may not be possible to peel again.

- the stress at break of the base material layer is obtained by punching out the base material layer into a dumbbell shape having a marked line length of 20 mm and a width of 6 mm under a measurement atmosphere of 23° C. and 50% RH under a Tensilon tensile tester (type: RTF). -1210, manufactured by A&D Co., Ltd.) is used to indicate the stress value measured when the film is ruptured by pulling in the length direction at a tensile speed of 500 mm/min.

- the elongation at break of the base material layer is not particularly limited and may be appropriately selected depending on the intended purpose, but is preferably 200% to 1,300%, more preferably 400% to 1,300%, It is more preferably 700% to 1,300%.

- the elongation at break of the base material layer is 200% or more, even when the pressure-sensitive adhesive sheet is firmly adhered to the adherend, when the pressure-sensitive adhesive sheet is re-peeled, the adherend is attached. The stress for stretching in the horizontal direction to the vertical direction with respect to the surface does not become too large, and even when peeling, the pressure-sensitive adhesive sheet can be easily peeled without excessive stretching.

- the stretching distance in the horizontal direction to the vertical direction with respect to the attaching surface of the adherend becomes too long. Instead, work in a small space is possible.