WO2020004221A1 - 冷凍サイクル装置 - Google Patents

冷凍サイクル装置 Download PDFInfo

- Publication number

- WO2020004221A1 WO2020004221A1 PCT/JP2019/024496 JP2019024496W WO2020004221A1 WO 2020004221 A1 WO2020004221 A1 WO 2020004221A1 JP 2019024496 W JP2019024496 W JP 2019024496W WO 2020004221 A1 WO2020004221 A1 WO 2020004221A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- evaporator

- refrigerant

- upstream

- downstream

- heat exchanger

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B1/00—Compression machines, plants or systems with non-reversible cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B39/00—Evaporators; Condensers

- F25B39/02—Evaporators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B5/00—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B5/00—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity

- F25B5/04—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity arranged in series

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D7/00—Heat-exchange apparatus having stationary tubular conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall

- F28D7/10—Heat-exchange apparatus having stationary tubular conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall the conduits being arranged one within the other, e.g. concentrically

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F9/00—Casings; Header boxes; Auxiliary supports for elements; Auxiliary members within casings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F9/00—Casings; Header boxes; Auxiliary supports for elements; Auxiliary members within casings

- F28F9/26—Arrangements for connecting different sections of heat-exchange elements, e.g. of radiators

Definitions

- the disclosure in this specification relates to a refrigeration cycle device.

- the refrigerant used for the refrigeration cycle is required to have good refrigerant characteristics such as environmental load and cooling capacity.

- a refrigerant using a mixed refrigerant obtained by mixing different types of refrigerants instead of using a single refrigerant is known.

- the mixed refrigerant obtained by mixing the high-boiling refrigerant and the low-boiling refrigerant evaporates in the evaporator, and the high-boiling refrigerant becomes a non-azeotropic mixed refrigerant that evaporates later. There are cases.

- Patent Document 1 In order to reduce the bias of the temperature distribution, in Patent Document 1, in a heat exchanger for a non-azeotropic mixed refrigerant, a constricted portion having a reduced flow path cross-sectional area is provided at an intermediate portion of a pipe of the heat exchanger. . With this configuration, the temperature of the refrigerant that rises toward the outlet side when there is no constricted portion is made substantially uniform or decreases toward the outlet side by the constricted portion, thereby reducing the temperature distribution bias.

- One object of the disclosure is to provide a refrigeration cycle apparatus in which a non-azeotropic mixed refrigerant uses a refrigeration cycle in which the unevenness of the temperature distribution in the entire evaporator is reduced.

- the refrigeration cycle apparatus disclosed herein is a refrigeration cycle apparatus that includes a compressor, a condenser, a decompression device, an evaporator, and an internal heat exchanger, and performs cooling by circulating a non-azeotropic mixed refrigerant.

- the evaporator is provided with an upstream heat exchange section that exchanges heat between the non-azeotropic mixed refrigerant flowing inside and the external fluid flowing outside, and is provided downstream of the upstream heat exchange section in the flow of the non-azeotropic mixed refrigerant.

- a heat exchange unit having a non-azeotropic mixed refrigerant flowing inside and a downstream heat exchange unit for exchanging heat with an external fluid flowing outside, and the internal heat exchanger is upstream after flowing out of the pressure reducing device.

- the refrigerant whose temperature has risen by flowing through the upstream heat exchange section and the refrigerant before flowing into the upstream heat exchange section are mixed using the internal heat exchanger. Can be heat exchanged.

- the temperature in the downstream heat exchange section is reduced as compared with the case where the internal heat exchanger is not provided, and the upstream heat

- the temperature of the exchange section and the temperature of the downstream heat exchange section can be made close to each other. Therefore, in the refrigeration cycle using the non-azeotropic mixed refrigerant, it is possible to provide a refrigeration cycle apparatus in which the deviation of the temperature distribution in the entire evaporator is reduced.

- FIG. 5 is a configuration diagram illustrating a flow of a refrigerant in a cross section of the internal heat exchanger along a line VV in FIG. 4. It is a perspective view showing the evaporator of a 3rd embodiment. It is an exploded view showing a flow of a refrigerant in an evaporator of a 3rd embodiment. It is a perspective view showing an internal heat exchanger of a 4th embodiment. It is an exploded view showing a flow of a refrigerant in an internal heat exchanger of a 4th embodiment.

- the refrigeration cycle device 1 is a device that generates cold or warm heat using a refrigerant.

- the refrigeration cycle device 1 is used, for example, as a part of a vehicle air-conditioning system that is mounted on a vehicle and cools or heats a vehicle compartment.

- the refrigeration cycle device 1 can be widely applied to devices such as a home air conditioner and a server cooling device other than the vehicle air conditioning system.

- the refrigeration cycle apparatus 1 includes a compressor 2, a condenser 3, a decompression device 4, an evaporator 30, and an internal heat exchanger 50.

- the refrigeration cycle apparatus 1 includes a refrigerant flow path 20 that connects the components and provides a flow path through which the non-azeotropic mixed refrigerant circulates.

- a non-azeotropic mixed refrigerant is used as the refrigerant.

- the non-azeotropic mixed refrigerant is a mixture of refrigerants having different boiling points, and is a refrigerant whose composition changes due to a change in the gas-liquid ratio of each refrigerant due to heat exchange.

- the boiling point of the non-azeotropic mixed refrigerant changes due to the composition change.

- the refrigerant having the lower boiling point evaporates first, whereby the composition of the non-azeotropic mixed refrigerant changes, and the boiling point of the refrigerant as a whole gradually increases during the evaporation process.

- the boiling point is lowest on the inlet side of the heat exchanger where the refrigerant evaporates, and is highest on the outlet side. Therefore, in the heat exchanger in which the refrigerant is appropriately evaporated, a temperature gradient tends to be generated such that the temperature on the inlet side of the heat exchanger is the lowest and the temperature gradually increases toward the outlet side.

- the compressor 2 is a device that compresses a gaseous refrigerant into a state of high temperature and high pressure.

- the condenser 3 is a device that condenses the gaseous refrigerant compressed by the compressor 2 into a liquid.

- the condenser 3 functions as a heat exchanger that radiates heat of the refrigerant to the surroundings in the process of condensing the refrigerant and heats the periphery of the condenser 3.

- the decompression device 4 is a device that lowers the pressure of the refrigerant to facilitate evaporation from liquid to gas.

- the evaporator 30 is a device for evaporating the liquid refrigerant decompressed by the decompression device 4 into a gas.

- the evaporator 30 is a heat exchanger that cools the periphery of the evaporator 30 by removing heat from the surrounding external fluid in the process of evaporating the refrigerant.

- the external fluid is, for example, air.

- the internal heat exchanger 50 is a device that exchanges heat between the refrigerants flowing through the refrigeration cycle device 1.

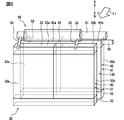

- the evaporator 30 is configured by arranging two heat exchangers, an upstream evaporator 31 and a downstream evaporator 41, side by side.

- Each of the upstream evaporator 31 and the downstream evaporator 41 is a multi-flow type heat exchanger including a plurality of pipes in which refrigerant flows.

- the upstream evaporator 31 is located upstream of the downstream evaporator 41 in the flow of the refrigerant sent from the compressor 2.

- the upstream evaporator 31 includes an upper tank part 32 and a lower tank part 33.

- the upper tank part 32 and the lower tank part 33 face each other.

- the inside of the upper tank section 32 is partitioned into two independent areas of a first upper tank section 32a and a second upper tank section 32b.

- An upstream core section 35 is provided between the upper tank section 32 and the lower tank section 33.

- the upstream core portion 35 includes a plurality of flat tubes having a plurality of paths formed therein, and corrugated fins provided between the flat tubes.

- the upstream core portion 35 is divided into two regions, a first core portion 35a and a second core portion 35b.

- the first core portion 35a is provided between the first upper tank portion 32a and the lower tank portion 33.

- the second core 35b is provided between the second upper tank 32b and the lower tank 33.

- the upstream core section 35 provides an upstream heat exchange section of the evaporator 30.

- the downstream evaporator 41 includes an upper tank part 42 and a lower tank part 43.

- the upper tank part 42 and the lower tank part 43 face each other.

- the inside of the upper tank section 42 is partitioned into two independent areas, a first upper tank section 42a and a second upper tank section 42b.

- a downstream outlet pipe 49 is connected to the second upper tank portion 42b, and functions as an outlet for allowing the refrigerant to flow out of the evaporator 30.

- a downstream core part 45 is provided between the upper tank part 42 and the lower tank part 43.

- the downstream core portion 45 includes a plurality of flat tubes having a plurality of paths formed therein, and corrugated fins provided between the flat tubes.

- the downstream core portion 45 is divided into two regions, a first core portion 45a and a second core portion 45b.

- the first core portion 45a is provided between the first upper tank portion 42a and the lower tank portion 43.

- the second core portion 45b is provided between the second upper tank portion 42b and the lower tank portion 43.

- the downstream core part 45 provides a downstream heat exchange part of the evaporator 30.

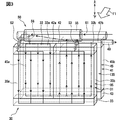

- the internal heat exchanger 50 is a double-pipe heat exchanger including an inner pipe 51 and an outer pipe 55 provided outside the inner pipe 51.

- the internal heat exchanger 50 includes an upstream inlet pipe 52 that communicates the inner pipe 51 with the first upper tank 32a of the upstream evaporator 31.

- the internal heat exchanger 50 includes an upstream outlet pipe 53 that communicates the outer pipe 55 with the second upper tank portion 32b of the upstream evaporator 31.

- the internal heat exchanger 50 includes a downstream inlet pipe 56 that communicates the outer pipe 55 with the first upper tank portion 42a of the downstream evaporator 41.

- the internal heat exchanger 50 is located above the evaporator 30 so as to straddle the upper tank 32 of the upstream evaporator 31 and the upper tank 42 of the downstream evaporator 41. In other words, the internal heat exchanger 50 is integrally provided irremovably from the evaporator 30.

- the upstream core section 35 of the upstream evaporator 31 and the downstream core section 45 of the downstream evaporator 41 provide a core section 135 of the evaporator 30.

- the evaporator 30 performs heat exchange between the air and the refrigerant in the core section 135.

- the upstream core portion 35 of the upstream evaporator 31 is located more leeward of the air flow shown in the arrow F1 direction than the downstream core portion 45 of the downstream evaporator 41. Therefore, in the evaporator 30, the air is further cooled in the upstream core section 35 after being cooled in the downstream core section 45.

- the core part 135 provides a heat exchange part of the evaporator 30.

- the air provides an external fluid flowing outside the evaporator 30.

- the external fluid is not limited to gaseous air, but may be liquid water or the like.

- the flow of the refrigerant in the evaporator 30 for each of the three parts of the evaporator 30, the upstream evaporator 31, the internal heat exchanger 50, and the downstream evaporator 41, is shown below.

- the arrows indicated by solid lines indicate the flow of the refrigerant before flowing out of the upstream evaporator 31.

- the arrows indicated by the two-dot chain lines indicate the flow of the refrigerant after flowing out of the upstream evaporator 31.

- the refrigerant whose pressure has been reduced by the pressure reducing device 4 and whose temperature has decreased passes through the inner pipe 51 and flows into the upstream evaporator 31 from the upstream inlet pipe 52. At this time, the refrigerant exchanges heat with the refrigerant flowing through the outer tube 55 while passing through the inner tube 51.

- the flow of the refrigerant in the upstream evaporator 31 will be described below.

- the refrigerant spreads inside the first upper tank part 32a and flows down the first core part 35a from above.

- the refrigerant flows into the lower tank portion 33 communicating with the first core portion 35a, and spreads inside the lower tank portion 33.

- the refrigerant flows out of the lower tank portion 33, flows upward from the bottom through the second core portion 35b, and flows into the second upper tank portion 32b.

- the refrigerant that has flowed into the second upper tank portion 32b passes through the upstream outlet pipe 53 and flows out of the upstream evaporator 31.

- the refrigerant exchanges heat with external air in the process of flowing through the first core portion 35a and the second core portion 35b.

- the refrigerant having a low boiling point among the refrigerants forming the non-azeotropic mixed refrigerant evaporates more actively than the refrigerant having a high boiling point.

- the composition of the refrigerant changes due to this evaporation, and the refrigerant after flowing out of the second core portion 35b has a higher boiling point than the refrigerant before flowing into the first core portion 35a.

- the flow of the refrigerant in the internal heat exchanger 50 will be described below.

- the refrigerant flowing out of the upstream evaporator 31 flows from the upstream outlet pipe 53 into the outer pipe 55.

- the refrigerant moves in a state of being in contact with the outer surface of the inner tube 51 by flowing through the outer tube 55.

- the refrigerant and the refrigerant flowing through the inner tube 51 exchange heat, and flow out of the internal heat exchanger 50 through the downstream inlet tube 56.

- the refrigerant flows in a gas-liquid two-phase state.

- the refrigerant flowing through the inner tube 51 is in a gas-liquid two-phase state in which the ratio of the liquid phase is large

- the refrigerant flowing through the outer tube 55 is in a gas-liquid two-phase state in which the ratio of the gas phase is large.

- the refrigerant flowing through the inner pipe 51 and the refrigerant flowing through the outer pipe 55 exchange heat. That is, the low-temperature refrigerant flowing through the inner pipe 51 is heated by the high-temperature refrigerant flowing through the outer pipe 55, and the temperature rises.

- the high-temperature refrigerant flowing through the outer pipe 55 is cooled by the low-temperature refrigerant flowing through the inner pipe 51, and its temperature is reduced.

- the temperature of the refrigerant flowing into the upstream evaporator 31 and the temperature of the refrigerant flowing into the downstream evaporator 41 become substantially equal.

- the heat exchange using the internal heat exchanger 50 eliminates the temperature gradient of the refrigerant.

- the temperature difference between the refrigerant flowing into the upstream evaporator 31 and the refrigerant flowing into the downstream evaporator 41 may be reduced by the internal heat exchanger 50, and the temperature gradient of the refrigerant does not need to be completely eliminated. .

- the flow of the refrigerant in the downstream evaporator 41 will be described below.

- the refrigerant spreads inside the first upper tank portion 42a and flows down the first core portion 45a from above.

- the refrigerant flows into the lower tank portion 43 communicating with the first core portion 45a, and spreads inside the lower tank portion 43.

- the refrigerant flows out of the lower tank portion 43, flows upward from below through the second core portion 45b, and flows into the second upper tank portion 42b.

- the refrigerant flowing into the second upper tank portion 42b flows out of the downstream evaporator 41 through the downstream outlet pipe 49.

- the refrigerant exchanges heat with external air in the process of flowing through the first core portion 45a and the second core portion 45b.

- the refrigerants forming the non-azeotropic mixed refrigerant not only the refrigerant having a small boiling point and a low boiling point but also the refrigerant having a high boiling point which has not been evaporated very much in the upstream evaporator 31 is actively evaporated.

- the proportion of the refrigerant having a high boiling point in the liquid phase in the entire refrigerant increases.

- the refrigerant flowing into the upstream evaporator 31 and the refrigerant flowing into the downstream evaporator 41 exchange heat using the internal heat exchanger 50.

- the internal heat exchanger 50 when used, the temperature gradient generated by the characteristics of the non-azeotropic mixed refrigerant is eliminated by heat exchange between the refrigerants, and the temperature of the refrigerant flowing into the downstream evaporator 41 is increased by the upstream evaporation.

- the temperature is substantially equal to the temperature of the refrigerant flowing into the vessel 31.

- the temperature gradient generated due to the characteristics of the non-azeotropic mixed refrigerant is not eliminated, and the temperature of the refrigerant flowing into the downstream evaporator 41 is reduced by the refrigerant flowing into the upstream evaporator 31.

- the temperature becomes higher than the temperature. Therefore, the temperature distribution between the upstream evaporator 31 and the downstream evaporator 41 can be made substantially the same by using the internal heat exchanger 50, and the entire evaporator 30 can be compared with the case where the internal heat exchanger 50 is not used. The resulting bias in the temperature distribution can be reduced.

- the cooling performance of the evaporator 30 will be reduced. Assuming that the lowest refrigerant temperature at which frost formation does not occur in the evaporator 30 is 0 ° C., the state in which the refrigerant temperature on the inlet side where the temperature is most likely to decrease in the evaporator 30 is 0 ° C. This is the state with the highest cooling performance.

- the temperature of the refrigerant on the outlet side is 5 ° C.

- the average temperature of the evaporator 30 is 2.5 ° C.

- the temperature of the refrigerant on the outlet side is 10 ° C., so that the average temperature of the evaporator 30 is 5 ° C. Therefore, as the temperature gradient in the entire evaporator 30 is smaller, the average temperature in the evaporator 30 can be reduced, and the cooling performance of the evaporator 30 can be improved. That is, by reducing the temperature gradient in the entire evaporator 30 using the internal heat exchanger 50, frost formation in the evaporator 30 can be prevented and the cooling performance of the evaporator 30 can be improved.

- the internal heat exchanger 50 that exchanges heat between non-azeotropic mixed refrigerants is provided.

- the internal heat exchanger 50 flows out of the pressure reducing device 4 until it flows into the upstream core 35 of the upstream evaporator 31 and flows out of the upstream core 35 of the upstream evaporator 31.

- the refrigerant is extracted in the course of flowing through the core portion 135, exchanges heat with the refrigerant before flowing into the core portion 135, and then returns to the core portion 135 again.

- the refrigerant whose temperature has risen by flowing through a part of the evaporator 30 is cooled by the low-temperature refrigerant before flowing into the evaporator 30, and the cooled and lowered refrigerant is returned to the evaporator 30 again.

- the temperature gradient of the refrigerant in the entire evaporator 30 can be reduced, it is easy to exhibit high cooling performance in a state where frost formation on the evaporator 30 is prevented.

- the disadvantage of using the non-azeotropic mixed refrigerant as the refrigerant is reduced, and the optimal refrigerant is selected from various refrigerants including the non-azeotropic mixed refrigerant according to the application, and the refrigerant is used for the refrigeration cycle apparatus 1. Can be used.

- the internal heat exchanger 50 is provided integrally with the evaporator 30. For this reason, the piping through which the evaporator 30 and the internal heat exchanger 50 communicate and the refrigerant flows can be shortened. Therefore, the refrigeration cycle apparatus 1 is easily reduced in size.

- the internal heat exchanger 50 is provided in the upper tank 32 of the upstream evaporator 31 and the upper tank 42 of the downstream evaporator 41. Therefore, the inlet and outlet of the refrigerant in the evaporator 30 and the internal heat exchanger 50 can be adjacent to each other. Therefore, the piping through which the evaporator 30 communicates with the internal heat exchanger 50 and in which the refrigerant flows is shortened, and the refrigeration cycle apparatus 1 is easily reduced in size.

- the internal heat exchanger 50 is provided in the upper tank portion 32 of the upstream evaporator 31 and the upper tank portion 42 of the downstream evaporator 41 at positions avoiding the core 135 through which air passes. For this reason, the internal heat exchanger 50 does not deteriorate the pressure loss when air flows in the evaporator 30.

- the internal heat exchanger 50 is a double pipe having an inner pipe 51 and an outer pipe 55. Therefore, it is possible to suppress the refrigerant flowing through the inner pipe 51 from being heated by exchanging heat with the air around the internal heat exchanger 50. Therefore, even when the temperature of the air around the internal heat exchanger 50 is high, it is easy to supply a low-temperature refrigerant to the evaporator 30.

- a refrigerant having a large liquid phase ratio before flowing into the upstream evaporator 31 flows into the outer tube 55, and a refrigerant having a large gas phase ratio flowing out from the upstream evaporator 31 flows into the inner tube 51. Is also good.

- the upstream core section 35 which is the upstream heat exchange section is located downstream of the air flow downstream of the downstream core section 45 which is the downstream heat exchange section.

- the upstream core portion 35 of the upstream evaporator 31 into which the lowest-temperature refrigerant decompressed by the decompression device 4 flows is located more leeward of the air flow than the downstream core portion 45 of the downstream evaporator 41. .

- the air exchanged in the evaporator 30 performs heat exchange in the downstream core portion 45 of the downstream evaporator 41 and then heat exchange in the upstream core portion 35 of the upstream evaporator 31 where the temperature tends to decrease.

- the cooling can be performed so that the temperature of the air is gradually decreased in the order of the downstream evaporator 41 and the upstream evaporator 31 from the windward to the leeward.

- Cooling of the refrigerant flowing out of the upstream core portion 35 is performed by heat exchange between the refrigerant and the refrigerant before flowing into the upstream core portion 35. Therefore, the refrigerant flowing out of the upstream core portion 35 does not become lower in temperature than the refrigerant before flowing into the upstream core portion 35. Therefore, frost formation on the downstream core portion 45 is more easily prevented than in the case where the temperature of the refrigerant flowing out of the upstream core portion 35 is reduced by using the pressure reducing device.

- the outer tube 55 may be provided spirally along the inner tube 51. According to this, the flow of the refrigerant in the outer pipe 55 can be substantially uniformly exchanged with the entire circumference of the inner pipe 51. For this reason, it is possible to reduce a decrease in the heat exchange efficiency in the internal heat exchanger 50 due to the refrigerant flowing unevenly to a specific portion of the outer tube 55.

- the cooling capacity of the upstream evaporator 31 and that of the downstream evaporator 41 may be different. For example, of the cooling capacity of the entire evaporator 30, two-thirds may be covered by the upstream evaporator 31, and the remaining third may be covered by the downstream evaporator 41. According to this, the size of the upstream evaporator 31 and the downstream evaporator 41 can be set freely. Further, the cooling capacity may be adjusted by using different types of heat exchangers, such as using the upstream evaporator 31 as a multi-flow type heat exchanger and the downstream evaporator 41 as a fin tube type heat exchanger. Good.

- Internal fins may be provided inside the inner pipe 51 and the outer pipe 55 to promote heat exchange between the refrigerant passing through the inner pipe 51 and the refrigerant passing through the outer pipe 55. Further, instead of forming the internal heat exchanger 50 as a double pipe composed of the inner pipe 51 and the outer pipe 55, the path of the refrigerant flowing into the upstream evaporator 31 by dividing the inside of the pipe up and down and the downstream evaporator Alternatively, a path for the refrigerant flowing into 41 may be formed.

- This embodiment is a modified example based on the preceding embodiment.

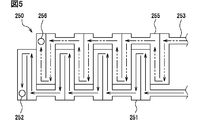

- the internal heat exchanger 250 is not a double tube, but has a structure in which refrigerant flow paths are alternately arranged.

- the internal heat exchanger 250 is a heat exchanger including an upstream pipe 251 and a downstream pipe 255.

- the upstream pipe 251 is a pipe through which the refrigerant before flowing into the upstream evaporator 31 flows.

- the downstream pipe 255 is a pipe through which the refrigerant flows after flowing out of the upstream evaporator 31 and before flowing into the downstream evaporator 41.

- the internal heat exchanger 250 is located above the evaporator 30 so as to straddle the upper tank 32 of the upstream evaporator 31 and the upper tank 42 of the downstream evaporator 41. In other words, the internal heat exchanger 250 is integrally provided so as not to be detachable from the evaporator 30.

- the internal heat exchanger 250 includes an upstream inlet pipe 252 that connects the upstream pipe 251 and the first upper tank 32a of the upstream evaporator 31.

- the second upper tank portion 32b of the upstream evaporator 31 and the downstream pipe 255 of the internal heat exchanger 250 are communicated by using a communication pipe 253.

- FIG. 5 shows a configuration when the horizontal cross section of the internal heat exchanger 250 is viewed from the top downward.

- the arrows indicated by solid lines indicate the flow of the refrigerant before flowing out of the upstream evaporator 31.

- the arrows indicated by the two-dot chain lines indicate the flow of the refrigerant after flowing out of the upstream evaporator 31.

- the internal heat exchanger 250 includes a downstream inlet pipe 256 that communicates the downstream pipe 255 with the first upper tank portion 32a of the downstream evaporator 41.

- the upstream pipe 251 and the downstream pipe 255 are provided in a meandering manner in contact with each other.

- the refrigerant whose pressure has been reduced by the pressure reducing device 4 and whose temperature has decreased flows inside the upstream pipe 251 and flows into the upstream evaporator 31 from the upstream inlet pipe 252.

- the refrigerant flowing into the upstream evaporator 31 exchanges heat with air and evaporates. This evaporation changes the composition of the non-azeotropic refrigerant mixture, thereby increasing the temperature of the refrigerant.

- the refrigerant flowing out of the upstream evaporator 31 passes through the communication pipe 253 and flows into the downstream pipe 255 in a state where the temperature is higher than that of the refrigerant flowing through the upstream pipe 251, flows inside the downstream pipe 255, and flows into the downstream inlet. It flows into the downstream evaporator 41 from the pipe 256.

- the internal heat exchanger 250 is configured by contacting the upstream pipe 251 and the downstream pipe 255 at a plurality of locations. Therefore, the refrigerant flowing through the upstream pipe 251 and the refrigerant flowing through the downstream pipe 255 easily exchange heat. Therefore, by the heat exchange between the refrigerants using the internal heat exchanger 250, the temperature difference between the refrigerants is eliminated, and the temperature gradient of the evaporator 30 is easily eliminated.

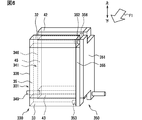

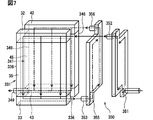

- the internal heat exchanger 350 is a plate-type heat exchanger, and is provided on the side plates 336 and 346.

- the evaporator 330 is composed of two heat exchangers, an upstream evaporator 331 and a downstream evaporator 341.

- Each of the upstream evaporator 331 and the downstream evaporator 341 is a multi-flow type heat exchanger having a plurality of pipes in which refrigerant flows.

- the upstream evaporator 331 is located upstream of the downstream evaporator 341 in the flow of the refrigerant sent from the compressor 2.

- the upstream evaporator 331 includes the upper tank part 32 and the lower tank part 33.

- the upper tank part 32 and the lower tank part 33 face each other, and an upstream core part 35 is provided between the upper tank part 32 and the lower tank part 33.

- the upstream core section 35 includes a plurality of flat tubes having a plurality of paths formed therein, and corrugated fins provided between the flat tubes.

- the upstream core section 35 provides an upstream heat exchange section for the evaporator 330.

- a side plate 336 for reinforcement is provided on the outermost side of the upstream core portion 35. The side plate 336 is provided over the upper tank part 32 and the lower tank part 33.

- the downstream evaporator 341 includes an upper tank part 42 and a lower tank part 43.

- the upper tank section 42 and the lower tank section 43 face each other, and a downstream core section 45 is provided between the upper tank section 42 and the lower tank section 43.

- the downstream core portion 45 includes a plurality of flat tubes having a plurality of paths formed therein, and corrugated fins provided between the flat tubes.

- the downstream outlet pipe 349 is connected to the lower tank portion 43.

- the downstream outlet pipe 349 functions as an outlet through which the refrigerant flows out of the evaporator 330.

- the downstream core section 45 provides a downstream heat exchange section of the evaporator 330.

- a side plate 346 for reinforcement is provided at the outermost side of the downstream core portion 45.

- the side plate 346 is provided over the upper tank part 42 and the lower tank part 43.

- the internal heat exchanger 350 includes an upstream plate 351 and a downstream plate 355.

- the upstream plate 351 and the downstream plate 355 each have a cavity formed therein, and constitute a refrigerant path so that the refrigerant flowing into the cavity spreads and flows over the entire cavity.

- the internal heat exchanger 350 is a plate-type heat exchanger in which the upstream plate 351 and the downstream plate 355 are overlapped in a state where they are in heat exchange with each other.

- the internal heat exchanger 350 includes an upstream inlet pipe 352 that connects the upstream plate 351 and the upper tank 32 of the upstream evaporator 331.

- the internal heat exchanger 350 includes an upstream outlet pipe 353 that communicates the downstream plate 355 with the lower tank 33 of the upstream evaporator 331.

- the internal heat exchanger 350 includes a downstream inlet pipe 356 that connects the downstream plate 355 and the upper tank section 42 of the downstream evaporator 341.

- the internal heat exchanger 350 is provided integrally with the evaporator 330 so as not to be detachable.

- arrows indicated by solid lines indicate the flow of the refrigerant before flowing out of the upstream evaporator 331.

- the arrow indicated by the two-dot chain line indicates the flow of the refrigerant after flowing out of the upstream evaporator 331.

- the refrigerant whose pressure has been reduced by the pressure reducing device 4 and whose temperature has decreased passes through the upstream plate 351 and flows into the upstream evaporator 331 from the upstream inlet pipe 352. At this time, the refrigerant exchanges heat with the refrigerant flowing through the downstream plate 355 while passing through the upstream plate 351.

- the refrigerant exchanges heat with outside air in the process of flowing through the upstream core section 35.

- the refrigerant having a low boiling point among the refrigerants forming the non-azeotropic mixed refrigerant evaporates more actively than the refrigerant having a high boiling point. Therefore, the refrigerant after flowing out of the upstream core portion 35 has a higher boiling point than the refrigerant before flowing into the upstream core portion 35.

- the flow of the refrigerant in the internal heat exchanger 350 will be described below.

- the refrigerant flowing out of the upstream evaporator 331 flows into the downstream plate 355 from the upstream outlet pipe 353.

- the refrigerant moves through the downstream plate 355 while being in contact with the outer surface of the upstream plate 351.

- the refrigerant and the refrigerant flowing through the upstream plate 351 exchange heat, and flow out of the internal heat exchanger 350 through the downstream inlet pipe 356.

- the refrigerant flows in a gas-liquid two-phase state.

- the refrigerant flowing in the upstream plate 351 is in a gas-liquid two-phase state in which the proportion of the liquid phase is large

- the refrigerant flowing in the downstream plate 355 is in a gas-liquid two-phase state in which the proportion of the gas phase is large.

- the refrigerant flowing through the upstream plate 351 and the refrigerant flowing through the downstream plate 355 exchange heat. That is, the low-temperature refrigerant flowing through the upstream plate 351 is heated by the high-temperature refrigerant flowing through the downstream plate 355, and the temperature rises.

- the high-temperature refrigerant flowing through the downstream plate 355 is cooled by the low-temperature refrigerant flowing through the upstream plate 351, and the temperature is reduced.

- the temperature of the refrigerant flowing into the upstream evaporator 331 and the temperature of the refrigerant flowing into the downstream evaporator 341 become substantially equal.

- the heat exchange using the internal heat exchanger 350 reduces the temperature gradient of the refrigerant.

- the refrigerant exchanges heat with external air in the process of flowing through the downstream core 45.

- the refrigerants forming the non-azeotropic mixed refrigerant not only the refrigerant having a small boiling point and a low proportion but also the refrigerant having a high boiling point which has not been evaporated very much in the upstream evaporator 331 is actively evaporated.

- the refrigerant flowing into the upstream evaporator 331 and the refrigerant flowing into the downstream evaporator 341 are heat-exchanged by using the internal heat exchanger 350. Therefore, the temperature distribution between the upstream evaporator 331 and the downstream evaporator 341 can be made almost the same, and the bias of the temperature distribution generated in the entire evaporator 330 can be reduced as compared with the case where the internal heat exchanger 350 is not used. Can be.

- the internal heat exchanger 350 is provided on the side plate 336 of the upstream evaporator 331 and the side plate 346 of the downstream evaporator 341. For this reason, the internal heat exchanger 350 is reinforced by the side plates 336, 346. Therefore, it is easy to prevent the internal heat exchanger 350 from being deformed or the like so that the heat cannot be appropriately exchanged between the refrigerants.

- the internal heat exchanger 350 is provided on the side plates 336 and 346 at positions avoiding the upstream core portion 35 and the downstream core portion 45 through which air passes. For this reason, the internal heat exchanger 350 does not deteriorate the pressure loss when air flows in the evaporator 330.

- the internal heat exchanger 350 is provided in the evaporator 330 so as to connect the upper tank sections 32 and 42 and the lower tank sections 33 and 43. For this reason, the internal heat exchanger 350 can fulfill the function of the side plates 336 and 346 in the evaporator 330. Therefore, of the side plates 336 and 346 provided on both sides, one side plate 336 and 346 can be the same component as the internal heat exchanger 350.

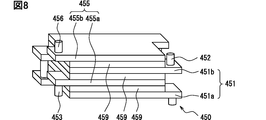

- the internal heat exchanger 450 is a stacked heat exchanger, and is configured integrally with the cold storage material 459.

- the internal heat exchanger 450 includes an upstream plate 451, a downstream plate 455, and a cold storage material 459.

- the upstream plate 451 and the downstream plate 455 have a cavity formed therein, and constitute a refrigerant path such that the refrigerant flowing into the inside spreads and flows as a whole.

- the upstream plate 451 includes two parts, a first upstream plate 451a and a second upstream plate 451b.

- the first upstream plate 451a and the second upstream plate 451b are connected by a pipe.

- the downstream plate 455 is composed of two parts, a first downstream plate 455a and a second downstream plate 455b.

- the first downstream plate 455a and the second downstream plate 455b are connected by a pipe.

- the first upstream plate 451a is provided with an upstream inlet pipe 452 connected to the upstream evaporator 31 and functioning as a refrigerant inlet of the upstream evaporator 31.

- the first downstream plate 455a includes an upstream outlet pipe 453 connected to the upstream evaporator 31 and functioning as a refrigerant outlet of the upstream evaporator 31.

- the second downstream plate 455b includes a downstream inlet pipe 456 that is connected to the downstream evaporator 41 and functions as a refrigerant inlet of the downstream evaporator 41.

- the internal heat exchanger 450 has a state in which the upstream plate 451 and the downstream plate 455 are alternately stacked, and the cold storage material 459 is sandwiched between the upstream plate 451 and the downstream plate 455 one by one. More specifically, from one surface to the opposite surface of the internal heat exchanger 450, the first upstream plate 451a, the cold storage material 459, the first downstream plate 455a, the cold storage material 459, the second upstream plate 451b, the cold storage material 459 and the second downstream plate 455b.

- the arrangement order of the components constituting the laminated internal heat exchanger 450 is not limited to the above-described configuration.

- the cold storage material 459 may be arranged at the outermost side and laminated.

- the cold storage material 459 is wound so as to cover the stacked upstream plate 451 and downstream plate 455 from the outside, and the internal heat exchanger 450 is provided. May be configured.

- arrows indicated by solid lines indicate the flow of the refrigerant before flowing out of the upstream evaporator 31.

- the arrows indicated by the two-dot chain lines indicate the flow of the refrigerant after flowing out of the upstream evaporator 31.

- the refrigerant whose pressure has been reduced by the pressure reducing device 4 and whose temperature has decreased flows into the first upstream plate 451a, spreads inside, and flows into the second upstream plate 451b through the pipe.

- the refrigerant that has flowed into the second upstream plate 451b spreads inside the second upstream plate 451b, and then flows through the upstream inlet pipe 452 toward the upstream evaporator 31 to flow out of the internal heat exchanger 450. I do.

- the refrigerant flowing through the upstream evaporator 31 passes through the upstream outlet pipe 453, flows into the first downstream plate 455a, spreads inside, and flows through the pipe into the second downstream plate 455b.

- the refrigerant that has flowed into the second downstream plate 455b spreads inside the second downstream plate 455b, and then flows through the downstream inlet pipe 456 toward the downstream evaporator 41 to flow out of the internal heat exchanger 450. I do.

- the non-azeotropic mixed refrigerants exchange heat with each other via the regenerator material 459 in the process of flowing through the internal heat exchanger 450. That is, the refrigerant having a low temperature flowing through the upstream plate 451 and the cold storage material 459 perform heat exchange, and the cold storage material 459 is cooled to decrease the temperature and increase the temperature of the refrigerant.

- the refrigerant having a high temperature flowing through the downstream plate 455 and the cold storage material 459 perform heat exchange, and the refrigerant flowing through the downstream plate 455 is cooled, so that the temperature of the refrigerant decreases and the temperature of the cold storage material 459 increases. That is, a temperature gradient caused by a change in the composition of the azeotropic mixed refrigerant can be reduced.

- the temperature of the cold storage material 459 that has exchanged heat with the refrigerant does not necessarily change. That is, a latent heat storage material that stores a change in heat exchanged by heat exchange with the refrigerant using a state change between the solid and the liquid of the cool storage material 459 may be used. By using a latent heat storage material, both the sensible heat and the latent heat can be stored, so that the size of the cold storage material 459 can be easily reduced.

- the internal heat exchanger 450 is a stacked heat exchanger in which the upstream plate 451 and the downstream plate 455 are stacked. Therefore, the heat exchange efficiency of the internal heat exchanger 450 can be easily adjusted by changing the number of stacked plates forming the internal heat exchanger 450.

- the internal heat exchanger 450 includes the cold storage material 459, and the refrigerant and the cold storage material 459 perform heat exchange. Therefore, it is easy for the internal heat exchanger 450 to maintain the refrigerant at an appropriate temperature by using the cold storage material 459. In other words, when the temperature of the refrigerant is too high, the refrigerant is cooled by the cold storage material 459, and when the temperature of the refrigerant is too low, the refrigerant is heated by the cold storage material 459. Therefore, the temperature of the refrigerant flowing into the upstream core portion 35 and the temperature of the refrigerant flowing into the downstream core portion 45 are appropriately managed, and a desired cooling performance can be easily obtained in the evaporator 30.

- the internal heat exchanger 450 may be arranged at a position away from the evaporator 30. According to this, since the position of the internal heat exchanger 450 can be freely designed, the degree of design freedom can be increased. This is particularly useful when it is necessary to arrange each component of the refrigeration cycle apparatus 1 in a limited space, such as when the refrigeration cycle apparatus 1 is mounted on a vehicle.

- the evaporator 30 divides the upstream core part 35 into two parts, the first core part 35a and the second core part 35b, has been described as an example, the number of divisions such as three divisions or four divisions may be increased. .

- the number of divisions of the downstream core section 45 is not limited to two as in the case of the upstream core section 35.

- the disclosure in this specification is not limited to the illustrated embodiment.

- the disclosure embraces the illustrated embodiments and variations thereon based on those skilled in the art.

- the disclosure is not limited to the combination of parts and / or elements shown in the embodiments.

- the disclosure can be implemented in various combinations.

- the disclosure may have additional parts that can be added to the embodiments.

- the disclosure encompasses embodiments that omit parts and / or elements.

- the disclosure encompasses the replacement or combination of parts and / or elements between one embodiment and another.

- the disclosed technical scope is not limited to the description of the embodiments.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

- Details Of Heat-Exchange And Heat-Transfer (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018123436A JP7115069B2 (ja) | 2018-06-28 | 2018-06-28 | 冷凍サイクル装置 |

| JP2018-123436 | 2018-06-28 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020004221A1 true WO2020004221A1 (ja) | 2020-01-02 |

Family

ID=68987107

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/024496 Ceased WO2020004221A1 (ja) | 2018-06-28 | 2019-06-20 | 冷凍サイクル装置 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP7115069B2 (enExample) |

| WO (1) | WO2020004221A1 (enExample) |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000055525A (ja) * | 1998-08-17 | 2000-02-25 | Samsung Electronics Co Ltd | 冷蔵庫用冷凍サイクル装置 |

| JP2003302188A (ja) * | 2002-04-11 | 2003-10-24 | Denso Corp | 熱交換器 |

| JP2010216778A (ja) * | 2009-03-19 | 2010-09-30 | Hitachi Appliances Inc | 冷凍サイクル装置 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6323313B2 (ja) * | 2014-11-27 | 2018-05-16 | 株式会社デンソー | 蒸発器ユニット |

| JP6341099B2 (ja) * | 2015-01-14 | 2018-06-13 | 株式会社デンソー | 冷媒蒸発器 |

-

2018

- 2018-06-28 JP JP2018123436A patent/JP7115069B2/ja active Active

-

2019

- 2019-06-20 WO PCT/JP2019/024496 patent/WO2020004221A1/ja not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000055525A (ja) * | 1998-08-17 | 2000-02-25 | Samsung Electronics Co Ltd | 冷蔵庫用冷凍サイクル装置 |

| JP2003302188A (ja) * | 2002-04-11 | 2003-10-24 | Denso Corp | 熱交換器 |

| JP2010216778A (ja) * | 2009-03-19 | 2010-09-30 | Hitachi Appliances Inc | 冷凍サイクル装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP7115069B2 (ja) | 2022-08-09 |

| JP2020003147A (ja) | 2020-01-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100905995B1 (ko) | 공기 조화 장치 | |

| US8616012B2 (en) | Evaporator for a refrigeration circuit | |

| CN101592411B (zh) | 冷冻循环装置 | |

| JP6580451B2 (ja) | 熱交換機 | |

| JP6042026B2 (ja) | 冷凍サイクル装置 | |

| US9951996B2 (en) | Refrigerant evaporator | |

| US20160054038A1 (en) | Heat exchanger and refrigeration cycle apparatus | |

| JP5975971B2 (ja) | 熱交換器及び冷凍サイクル装置 | |

| JPWO2018029784A1 (ja) | 熱交換器及びこの熱交換器を備えた冷凍サイクル装置 | |

| CN105705898A (zh) | 具有相变材料的热能储存组合件 | |

| US20220412610A1 (en) | Cooling module using solid refrigerant and cooling system using solid refrigerant | |

| WO2018154957A1 (ja) | 冷凍サイクル装置 | |

| WO2007034744A1 (ja) | 空気調和装置 | |

| JP5526494B2 (ja) | 冷凍装置 | |

| WO2020004221A1 (ja) | 冷凍サイクル装置 | |

| JP2009133530A (ja) | 熱交換器及びそれを用いてなるヒートポンプ給湯機 | |

| CN212378292U (zh) | 空调换热系统和回热器 | |

| CN116438413A (zh) | 制冷循环装置 | |

| JP2017036900A (ja) | 放熱器およびそれを用いた超臨界圧冷凍サイクル | |

| JP2002228299A (ja) | 複合型熱交換器 | |

| US11820199B2 (en) | Heat exchanger | |

| WO2018168698A1 (ja) | 熱交換装置および熱交換方法 | |

| JP2005009808A (ja) | 空気調和機の熱交換器。 | |

| EP3795928A1 (en) | Refrigeration cycle device | |

| JPH09329372A (ja) | 冷却機能付配管継手 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19826815 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19826815 Country of ref document: EP Kind code of ref document: A1 |