WO2018037773A1 - マットレスずれ止め具、および寝台装置 - Google Patents

マットレスずれ止め具、および寝台装置 Download PDFInfo

- Publication number

- WO2018037773A1 WO2018037773A1 PCT/JP2017/025953 JP2017025953W WO2018037773A1 WO 2018037773 A1 WO2018037773 A1 WO 2018037773A1 JP 2017025953 W JP2017025953 W JP 2017025953W WO 2018037773 A1 WO2018037773 A1 WO 2018037773A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- bed

- mattress

- fitted

- short

- restriction

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C20/00—Head -, foot -, or like rests for beds, sofas or the like

- A47C20/04—Head -, foot -, or like rests for beds, sofas or the like with adjustable inclination

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C21/00—Attachments for beds, e.g. sheet holders, bed-cover holders; Ventilating, cooling or heating means in connection with bedsteads or mattresses

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C21/00—Attachments for beds, e.g. sheet holders, bed-cover holders; Ventilating, cooling or heating means in connection with bedsteads or mattresses

- A47C21/02—Holders for loose bed elements, e.g. sheet holders; bed cover holders

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/002—Beds specially adapted for nursing; Devices for lifting patients or disabled persons having adjustable mattress frame

- A61G7/015—Beds specially adapted for nursing; Devices for lifting patients or disabled persons having adjustable mattress frame divided into different adjustable sections, e.g. for Gatch position

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61G—TRANSPORT, PERSONAL CONVEYANCES, OR ACCOMMODATION SPECIALLY ADAPTED FOR PATIENTS OR DISABLED PERSONS; OPERATING TABLES OR CHAIRS; CHAIRS FOR DENTISTRY; FUNERAL DEVICES

- A61G7/00—Beds specially adapted for nursing; Devices for lifting patients or disabled persons

- A61G7/05—Parts, details or accessories of beds

Definitions

- the present invention relates to a mattress slip stopper and a bed apparatus.

- a mattress slip stopper for example, as shown in Patent Document 1 below, a mattress slip stopper that regulates horizontal displacement of a mattress on a bed is known.

- the present invention has been made in view of the above-described circumstances, and an object of the present invention is to provide a mattress slip stopper and a bed apparatus that can reliably regulate the horizontal displacement of the mattress with respect to the bed.

- An aspect according to the present invention is a mattress displacement stopper that restricts the displacement of the mattress on the bed, and a longitudinal restriction portion that regulates the displacement of the mattress in the longitudinal direction of the bed;

- a short-side restricting portion that restricts displacement of the mattress in the short-side direction, and a relative position between the long-side restricting portion and the short-side restricting portion is fixed.

- the relative position between the long restricting portion and the short restricting portion is fixed, the external force from the mattress along one of the long direction and the short direction is applied to the long restricting portion and the short restricting portion. It can be received not only by any one of the hand regulating portions but also by the other. For this reason, even when the external force transmitted from the mattress is large, the external force can be reliably received by the mattress slip stopper. Thereby, the horizontal displacement of the mattress with respect to the bed can be reliably controlled. Further, the relative position between the long restriction part and the short restriction part is fixed.

- one mattress slip stopper can effectively effect the displacement in both the longitudinal direction and the short direction of the bed with respect to the bed. Can be regulated. Thereby, the number of parts can be reduced.

- the longitudinal restriction portion and the short side restriction portion may be integrally formed.

- the long restriction portion and the short restriction portion are integrally formed, there is no need to provide a member for connecting the long restriction portion and the short restriction portion to each other, and the mattress misalignment stopper can be strengthened with a simple configuration. Can be formed.

- the mattress slip stopper is firmly attached to the bed as compared with the configuration in which only one is attached to the bed. Can be attached to.

- a bed apparatus includes the bed and the mattress slip prevention device according to any one of (1) to (3) above.

- the mattress detent tool is attached to the bed as compared with the configuration in which only one is attached to the bed. Can be firmly attached.

- the 1st to-be-fitted part and the 2nd to-be-fitted part which each of a 1st attachment part and a 2nd attachment part fit are provided in the bed apparatus, the mattress deviation stopper to the bed apparatus is provided. Mounting can be performed easily.

- the direction in which the first attachment portion is fitted to the first fitted portion and the direction in which the second attachment portion is fitted to the second fitted portion are different from each other. For this reason, the direction in which the first attachment portion is removed from the first fitted portion and the direction in which the second attachment portion is removed from the second fitted portion are different from each other. Therefore, even if an external force is unexpectedly applied to the mattress slip stopper, the fitting between the first attachment portion and the first fitted portion and the fitting between the second attachment portion and the second fitted portion are not performed. Simultaneous release can be suppressed.

- the horizontal displacement of the mattress with respect to the bed can be reliably regulated.

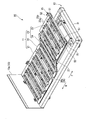

- FIG. 1 It is a perspective view of the bed apparatus concerning one embodiment of the present invention. It is a side view of the bed apparatus shown in FIG. It is a top view of the bed apparatus shown in FIG. It is a bottom view of the bed apparatus shown in FIG. It is a disassembled perspective view of the bed apparatus shown in FIG. 1, and is a view showing a state where a bottom is removed. It is a perspective view which shows a leg raising state in the bed apparatus shown in FIG. It is a side view of the bed apparatus shown in FIG. It is an expansion perspective view of the principal part in the bed apparatus shown in FIG. It is an expansion perspective view of the mattress slip stopper of the bed apparatus shown in FIG.

- the mattress slip stopper 15 and the bed apparatus 10 will be described below with reference to FIGS.

- the bed apparatus 10 can be used, for example, in a medical environment (including a care environment) or a general home.

- an arrow H indicates a direction that becomes the head side H when the person (user) sleeps

- an arrow F indicates a direction that becomes the foot side F when the person sleeps.

- the horizontal direction orthogonal to the front-rear direction which is the direction of arrows H and F, may be referred to as the left-right direction.

- the front-rear direction and the left-right direction are both directions along the horizontal direction.

- the bed apparatus 10 includes a bed 11, a support frame 12, a board 13, and a drive mechanism 14.

- the bed apparatus 10 is a so-called electric bed that uses electric power as a power source.

- the bed 11 is longer in the front-rear direction than in the left-right direction when viewed in plan.

- the longitudinal direction of the bed 11 is the front-rear direction, and the short direction of the bed 11 is the left-right direction.

- a mattress (not shown) is disposed on the bed 11.

- a user lies on the bed 11 through the mattress.

- the bed 11 includes a back bottom 21, a waist bottom 22, and a leg bottom 23. These back bottom 21, waist bottom 22 and leg bottom 23 are arranged in this order from the head side H to the foot side F.

- the back bottom 21 supports the back of the user.

- the waist bottom 22 supports the user's waist.

- the leg bottom 23 supports a user's leg.

- the leg bottom 23 includes a knee bottom 24 and a foot bottom 25. The knee bottom 24 and the foot bottom 25 are arranged in this order from the head side H to the foot side F.

- the knee bottom 24 supports the waist from the user's knee.

- the foot bottom 25 supports the foot tip from the user's knee.

- the support frame 12 supports the bed 11.

- the support frame 12 receives the loads of the bed 11 and the users on the bed 11.

- the support frame 12 includes a main frame 31 and a grounding portion 32.

- the main frame 31 supports the bed 11.

- the main frame 31 has a rectangular shape in plan view.

- the main frame 31 includes an outer frame portion 33 and an inner frame portion 34.

- the outer frame portion 33 forms the outer peripheral edge portion of the main frame 31 and is disposed on the outer peripheral edge portion of the support frame 12.

- the outer frame portion 33 is formed in a C-shape that opens toward the head side H in plan view.

- the outer frame portion 33 includes a first frame member 35 and a second frame member 36.

- the first frame member 35 extends in the left-right direction.

- the first frame member 35 is disposed at the end on the foot side F of the support frame 12.

- the second frame member 36 extends in the front-rear direction.

- the second frame member 36 is provided with a pair at intervals in the left-right direction.

- the second frame member 36 extends from the left and right ends of the first frame member 35 toward the head side H along the front-rear direction.

- the second frame member 36 is fixed to the first frame member 35 so as not to move.

- the first frame member 35 and the second frame member 36 are connected to each other to form a corner portion of the outer frame portion 33.

- the second frame member 36 is welded (fixed) to the first frame member 35.

- a curtain plate 37 is attached to the outer frame portion 33.

- the curtain 37 covers the outer frame 33 from the side.

- the curtain plate 37 includes a first curtain plate 38, a second curtain plate 39, and a square curtain plate 40.

- the first curtain plate 38 covers the first frame member 35 from the side.

- the second curtain plate 39 covers the second frame member 36 from the side.

- the corner curtain plate 40 covers the corner portion.

- the inner frame portion 34 is disposed inside the outer frame portion 33 in plan view.

- the inner frame portion 34 includes a horizontal member 41 and a vertical member 42.

- the horizontal member 41 extends in the left-right direction.

- the horizontal member 41 connects the pair of left and right second frame members 36 in the left-right direction.

- a pair of front and rear members 41 are arranged.

- the horizontal member 41 is fixed to the second frame member 36 so as not to move.

- the horizontal member 41 is welded (fixed) to the second frame member 36.

- the vertical member 42 extends in the front-rear direction.

- the vertical member 42 connects the pair of front and rear horizontal members 41 in the front-rear direction.

- a pair of vertical members 42 are arranged in the left-right direction.

- the end portion on the head side H of the vertical member 42 is disposed at the same position in the front-rear direction as the end portion on the head side H of the second frame member 36.

- the vertical member 42 is fixed to the horizontal member 41 so as not to move.

- the vertical member 42 is welded (fixed) to the horizontal member 41.

- the grounding unit 32 is grounded on the ground plane.

- a pair of grounding portions 32 are disposed in the left-right direction, and a pair of left and right grounding portions 32 are disposed in the front-rear direction.

- a total of four grounding portions 32 are provided.

- the grounding portion 32 is connected to the vertical member 42.

- the support frame 12 supports a part (movable bottom) of the bed 11 so as to be rotatable around a rotation shaft 26 extending in the left-right direction.

- the bed apparatus 10 is a so-called gatch bed.

- the waist bottom 22 is fixed to the support base 12, and the back bottom 21 and the leg bottom 23 are rotatably connected to the waist bottom 22.

- the rotation shaft 26 includes a first rotation shaft 26 a that connects the back bottom 21 and the waist bottom 22, and a second rotation shaft 26 b that connects the leg bottom 23 and the waist bottom 22.

- the knee bottom 24 and the foot bottom 25 are connected so as to be rotatable around a bending shaft 27 extending in the left-right direction. Therefore, when the leg bottom 23 rotates around the second rotation shaft 26b and the bed apparatus 10 enters the leg-raised state, the leg bottom 23 bends so that the bending shaft 27 protrudes.

- a leg stay 43 is rotatably connected to the leg bottom 23.

- the foot stay 43 holds the leg bottom 23 in a raised state.

- the foot bottom 25 extends parallel to the horizontal direction.

- the foot stay 43 is formed in a long shape extending in the front-rear direction.

- the first end 43a and the second end 43b of the foot stay 43 are rotatably fixed to the foot bottom 25 and the main frame 31, respectively.

- the first end 43a of the foot stay 43 is fixed to the foot bottom 25 so that it cannot be detached.

- the second end 43b of the foot stay 43 is detachably fixed to the main frame 31.

- the board 13 is disposed at an end portion in the front-rear direction of the support frame 12.

- the board 13 is formed in a plate shape whose front and back faces in the front-rear direction.

- the board 13 includes a head board 13 a located on the head side H of the support frame 12.

- the head board 13 a is fixed to the end portion on the head side H of the vertical member 42.

- the drive mechanism 14 is attached to the support frame 12.

- a plurality of drive mechanisms 14 are provided.

- the plurality of drive mechanisms 14 are disposed below the bed 11.

- the drive mechanism 14 moves at least a part of the bed 11 and the support frame 12.

- the drive mechanism 14 is a linear actuator that expands and contracts in the front-rear direction.

- the drive mechanism 14 includes a first drive mechanism 14 a that rotates the back bottom 21 and a second drive mechanism 14 b that rotates the leg bottom 23. Both ends of the first drive mechanism 14a in the front-rear direction are attached to the main frame 31 and the back link 44, respectively.

- the back upper link 44 supports the back bottom 21 from below.

- Both ends of the second drive mechanism 14b in the front-rear direction are attached to the main frame 31 and the above-knee link 45, respectively.

- the above-knee link 45 supports the leg bottom 23 from below.

- the second drive mechanism 14b is operated, the above-knee link 45 is rotated and the leg bottom 23 is in a leg-raised state.

- the bed 11 is provided with a mattress slip stopper 15 that regulates a horizontal displacement of a mattress (not shown) placed on the bed 11.

- a mattress slip stopper 15 that regulates a horizontal displacement of a mattress (not shown) placed on the bed 11.

- the head side H along the front-rear direction may be referred to as the front

- the foot side F may be referred to as the rear.

- the mattress slip stopper 15 is attached to each corner located at the rear end of the bed 11.

- the mattress misalignment stop 15 extends along the left-right direction, and extends along the front-rear direction in the horizontal direction, and a longitudinal restriction portion 51 that restricts the displacement of the mattress in the front-rear direction. And a short-side restricting portion 52 that restricts the displacement of.

- the long side restricting part 51 and the short side restricting part 52 are connected to each other and have an L shape in a top view. That is, the relative position between the long restriction part 51 and the short restriction part 52 is fixed.

- the size of the longitudinal regulating portion 51 along the left-right direction is larger than the size of the short-side regulating portion 52 along the front-rear direction.

- the long restriction portion 51 and the short restriction portion 52 are integrally formed of a synthetic resin material.

- a connecting portion 53 between the longitudinal regulating portion 51 and the short-side regulating portion 52 is formed in a curved shape protruding toward the outside of the bed apparatus 10.

- the longitudinal regulation part 51 and the short regulation part 52 may be integrally formed with a metal material or other materials.

- the longitudinal restricting portion 51 extends along the left-right direction, extends along the up-down direction, the first side wall portion 51a whose front and back faces in the front-rear direction, and the first side wall portion 51a extending forward from the lower end edge of the first side wall portion 51a. 1 bottom wall part 51b.

- the first side wall 51a gradually extends forward as it goes upward.

- the rear end portion of the first bottom wall portion 51b is formed in a curved shape that protrudes rearward.

- a first attachment piece 51c extending forward is formed at the outer end portion on the side opposite to the connection portion 53 side in the left-right direction.

- the connection portion 53 side is referred to as an outer side

- the first attachment piece 51c side is referred to as an inner side.

- the first attachment piece 51c gradually extends downward as it goes forward.

- the longitudinal restriction portion 51 is provided with a first attachment portion 51d that is fitted to a first fitted portion 11a provided on the bed 11 so as to be integrally formed.

- the first attachment portion 51d extends along the left-right direction, has a C-shape when viewed from the left-right direction, and is formed in a concave shape that opens toward the rear.

- the upper end part of the 1st attaching part 51d and the front-end edge of the 1st attaching piece 51c are connected.

- the short-side restricting portion 52 extends along the front-rear direction, extends along the up-down direction, and has a second side wall portion 52a whose front and back faces in the left-right direction, and an inner side in the left-right direction from the lower edge of the second side wall portion 52a. And a second bottom wall portion 52b extending toward the bottom.

- the second side wall portion 52a gradually extends inward in the left-right direction as it goes upward.

- the outer end of the second bottom wall 52b in the left-right direction is formed in a curved surface that protrudes outward in the left-right direction.

- the short-side restricting portion 52 is provided with a second attachment portion 52d that is fitted to a second fitted portion 11b provided on the bed 11 so as to be integrally formed.

- the second attachment portion 52d is formed in a convex shape that protrudes downward from the lower surface of the second bottom wall portion 52b and extends in the front-rear direction.

- a fitting portion 52e that protrudes inward in the left-right direction is formed at the lower end of the second attachment portion 52d.

- the fitting portion 52e is disposed over a portion excluding both end portions in the front-rear direction of the second attachment portion 52d.

- the second attachment portion 52d is disposed at the inner end in the left-right direction of the second bottom wall portion 52b.

- connection part 53 includes a connection wall part 53a that connects the first side wall part 51a and the second side wall part 52a to each other, a connection bottom wall part 53b that connects the first bottom wall part 51b and the second bottom wall part 52b to each other, It has.

- connection wall 53a and the connection bottom wall 53b a portion located outside the bed apparatus 10 is formed in a curved surface shape protruding toward the outside of the bed apparatus 10. The relative position between the long restriction part 51 and the short restriction part 52 is fixed by the connection wall part 53a and the connection bottom wall part 53b.

- the leg bottom 25 of the bed 11 is formed with a plurality of vent holes 11c penetrating the leg bottom 25 in the vertical direction along the horizontal direction.

- the first fitted portion 11a is formed on the inner peripheral surface of the vent hole 11c.

- the first fitted portion 11a is formed at the lower end of the inner peripheral surface of the vent hole 11c.

- the inner peripheral surface of the vent hole 11c is inclined so as to gradually increase as the inner diameter of the vent hole 11c increases from below to above.

- the 1st to-be-fitted part 11a is formed in the convex shape which protrudes toward the front, and is extended along the left-right direction.

- the vertical size of the first fitted portion 11a is smaller than the opening width in the vertical direction of the first attachment portion 51d.

- the second fitted portion 11 b is formed on a bottom edge 25 b made of synthetic resin, which is separately provided at both ends in the left-right direction of the foot bottom 25 of the bed 11.

- the 2nd to-be-fitted part 11b is a long hole which is formed in the concave shape opened upwards on the upper surface of the bottom edge 25b, and extends along the front-back direction.

- the first fitting portion 11a is fitted in the first fitting portion 51d

- the second fitting portion 52d is fitted in the second fitting portion 11b

- the fitting direction between 51d and the first fitted portion 11a is different from the fitting direction between the second attachment portion 52d and the second fitted portion 11b.

- the 1st attaching part 51d may be formed in the concave shape opened toward one direction

- the 2nd attaching part 52d is formed in the convex shape protruded toward one direction. May be.

- the back bottom 21, the waist bottom 22, and the leg bottom 23 each include a main body portion that is located at the center in the left-right direction and a bottom edge that is located at an end portion in the left-right direction of the main body portion. ing.

- the first fitted portion 11a is formed on the body portion 25a of the foot bottom 25 of the leg bottom 23, and the second fitted portion 11b is formed on the bottom edge 25b of the foot bottom 25, respectively.

- the mattress slip stopper 15 is disposed above the corner of the rear end of the bed 11.

- the mattress misalignment stopper 15 is moved downward so that the second attachment portion 52d of the short-side restricting portion 52 is inserted into the second fitted portion 11b.

- the mattress is prevented from slipping in a state in which the longitudinal restriction portion 51 is rotated forward about the connection portion 53 and elastically deformed so that the first attachment portion 51d is inserted into the vent hole 11c.

- the tool 15 is moved downward.

- the second bottom wall portion 52b comes into contact with the bottom edge 25b, and the longitudinal restriction portion 51 is restored and deformed rearward, and the first fitted portion 11a is fitted into the opening of the first mounting portion 51d. .

- the relative position between the long restriction part 51 and the short restriction part 52 is fixed. For this reason, the external force from the mattress along one of the front-rear direction and the left-right direction is not received by only one of the long restriction part 51 and the short restriction part 52, but is also received by the other. It becomes possible. Therefore, even when the external force transmitted from the mattress is large, the external force can be reliably received by the mattress slip stopper 15. Thereby, the horizontal displacement of the mattress with respect to the bed 11 can be reliably regulated.

- the relative position between the long restriction part 51 and the short restriction part 52 is fixed. Therefore, for example, by attaching the mattress slip stopper 15 to the corner of the mattress placement portion in the bed 11, the mattress slip stopper 15 can be displaced in both the front-rear direction and the left-right direction with respect to the bed 11. Can be effectively controlled, and the number of parts can be reduced.

- the long restriction part 51 and the short restriction part 52 are integrally formed. Therefore, there is no need to provide a member for connecting the long restriction part 51 and the short restriction part 52 to each other, and the mattress misalignment stopper 15 can be firmly formed with a simple configuration.

- both the long restricting portion 51 and the short restricting portion 52 are attached to the bed 11 by the first attaching portion 51d and the second attaching portion 52d, compared to the configuration in which only one is attached to the bed 11, the mattress displacement prevention The tool 15 can be firmly attached to the bed 11. Further, since the first fitted portion 11a and the second fitted portion 11b into which the first attaching portion 51d and the second attaching portion 52d are respectively fitted are provided on the bed 11, the mattress slip stopper 15 Can be easily mounted on the bed 11.

- the direction in which the first attachment portion 51d is fitted into the first fitted portion 11a and the direction in which the second attachment portion 52d is fitted into the second fitted portion 11b are different from each other. For this reason, the direction in which the first attachment portion 51d is removed from the first fitted portion 11a and the direction in which the second attachment portion 52d is removed from the second fitted portion 11b are different from each other. Therefore, even if an external force is unexpectedly applied to the mattress slip stopper 15, the engagement between the first mounting portion 51d and the first fitted portion 11a, and the second mounting portion 52d and the second fitted portion 11b. Can be prevented from being simultaneously released.

- the mattress slip stopper 15 since the mattress slip stopper 15 is provided, the above-described effects can be achieved in the bed apparatus 10.

- the technical scope of the present invention is not limited to the above embodiment, and various modifications can be made without departing from the spirit of the present invention.

- the configuration in which the long-length restricting portion 51 and the short-side restricting portion 52 are integrally formed has been shown, but the present invention is not limited to such an aspect.

- the long restriction part and the short restriction part may be formed separately, and may be connected by a connecting member that connects them to each other.

- the 1st attachment part 51d attached to the bed 11 is provided in the length control part 51, and the 2nd attachment part 52d attached to the bed 11 is provided in the short control part 52.

- the present invention is not limited to such a mode. Only one of the first attachment portion and the second attachment portion may be provided.

- the 1st attaching part 51d and the 2nd attaching part 52d showed the structure fitted to the 1st to-be-fitted part 11a and the 2nd attaching part 52d, it is restricted to such an aspect. I can't.

- the first attachment portion and the second attachment portion may be locked to a part of the bed without being fitted to the first fitted portion and the second attachment portion.

- the fitting direction between the 1st attaching part 51d and the 1st to-be-fitted part 11a and the fitting direction between the 2nd attaching part 52d and the 2nd to-be-fitted part 11b are mutually mutually.

- the present invention is not limited to such a mode.

- the same direction may be sufficient as the fitting direction between a 1st attaching part and a 1st to-be-fitted part, and the fitting direction between a 2nd attaching part and a 2nd to-be-fitted part.

- the horizontal displacement of the mattress with respect to the bed can be reliably regulated.

Landscapes

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Nursing (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Invalid Beds And Related Equipment (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201780031287.6A CN109561764B (zh) | 2016-08-26 | 2017-07-18 | 床垫错位防止件及床装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016-165811 | 2016-08-26 | ||

| JP2016165811A JP6619711B2 (ja) | 2016-08-26 | 2016-08-26 | マットレスずれ止め具、および寝台装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018037773A1 true WO2018037773A1 (ja) | 2018-03-01 |

Family

ID=61245410

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/025953 WO2018037773A1 (ja) | 2016-08-26 | 2017-07-18 | マットレスずれ止め具、および寝台装置 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6619711B2 (zh) |

| CN (1) | CN109561764B (zh) |

| WO (1) | WO2018037773A1 (zh) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD888463S1 (en) * | 2019-03-08 | 2020-06-30 | Shenzhen Shoujia Technology Co., Ltd. | Massage mattress |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS50140714U (zh) * | 1974-05-08 | 1975-11-19 | ||

| WO2016134355A1 (en) * | 2015-02-20 | 2016-08-25 | Levitation Sciences Llc | Adjustable mattress retainer bars |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2260641Y (zh) * | 1996-04-05 | 1997-08-27 | 何和亭 | 台球桌 |

| DE29907771U1 (de) * | 1999-05-03 | 2000-02-10 | Recticel Int Bettsysteme Gmbh | Matratzenhalter |

| JP2006129997A (ja) * | 2004-11-04 | 2006-05-25 | Puroguroobu Japan:Kk | カバー用具保持具 |

| CN201026278Y (zh) * | 2007-05-13 | 2008-02-27 | 赵洪 | 偏瘫病人健身三轮车 |

| CN101779873A (zh) * | 2009-01-20 | 2010-07-21 | 王宏波 | 新型可拆装调节床 |

| CN202324356U (zh) * | 2011-11-15 | 2012-07-11 | 成都市市政工程(集团)有限责任公司 | 用于浇筑板式混凝土的钢筋定位垫块 |

| CN202634955U (zh) * | 2012-04-20 | 2012-12-26 | 深圳市杰美特科技有限公司 | 数码产品保护组件 |

| GB2520660A (en) * | 2012-09-07 | 2015-05-27 | G Form Llc | Protective case and methods of making |

| TWM467391U (zh) * | 2013-07-17 | 2013-12-11 | Quan-Hang Shi | 床墊固定架 |

| KR200477053Y1 (ko) * | 2014-02-10 | 2015-05-04 | 박형진 | 매트리스 고정장치 |

| TW201630500A (zh) * | 2015-02-02 | 2016-08-16 | Ge-Chang Zhang | 具嵌卡式彈性緩衝片之保護套 |

| HK1210366A2 (zh) * | 2015-02-24 | 2016-04-15 | 豪通投資有限公司 | 用於覆蓋床墊的覆蓋單子和覆蓋單子定位系統 |

| CN205338315U (zh) * | 2015-12-28 | 2016-06-29 | 际诺思(厦门)轻工制品有限公司 | 一种床垫防滑结构和床架 |

| CN205432952U (zh) * | 2015-12-28 | 2016-08-10 | 际诺思(厦门)轻工制品有限公司 | 一种床垫防滑装置和床架 |

-

2016

- 2016-08-26 JP JP2016165811A patent/JP6619711B2/ja active Active

-

2017

- 2017-07-18 WO PCT/JP2017/025953 patent/WO2018037773A1/ja active Application Filing

- 2017-07-18 CN CN201780031287.6A patent/CN109561764B/zh active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS50140714U (zh) * | 1974-05-08 | 1975-11-19 | ||

| WO2016134355A1 (en) * | 2015-02-20 | 2016-08-25 | Levitation Sciences Llc | Adjustable mattress retainer bars |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6619711B2 (ja) | 2019-12-11 |

| CN109561764A (zh) | 2019-04-02 |

| CN109561764B (zh) | 2022-05-03 |

| JP2018029889A (ja) | 2018-03-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2016021103A1 (ja) | 動作支援装置 | |

| US8348340B2 (en) | Seat structure | |

| JP5007444B2 (ja) | 背凭れ、及び椅子 | |

| EP2948026B1 (en) | Adjustable bed | |

| US20190307621A1 (en) | Electric bed combining matrress | |

| JP2021506370A (ja) | 調節可能なヘッドサポートを備えるベビーキャリアおよびそのバックル | |

| JP6013371B2 (ja) | 可動式ベッド用マットレス保持システム | |

| JP2015221599A (ja) | 車両用シート | |

| US20220160570A1 (en) | Strength assist device | |

| USD976023S1 (en) | Infant bed sun canopy | |

| WO2018037773A1 (ja) | マットレスずれ止め具、および寝台装置 | |

| KR101440918B1 (ko) | 의자용 팔걸이 | |

| CA2917020C (en) | Patient protective system for an adjustable bed | |

| JP2020014520A (ja) | 安全機能付きアシストスーツ | |

| JP6860638B2 (ja) | 寝台装置 | |

| JP6668179B2 (ja) | 足ボトム支持構造および寝台装置 | |

| JP7044691B2 (ja) | オプション受けおよび身体支持装置 | |

| JP6148905B2 (ja) | 椅子 | |

| JP7032774B2 (ja) | マットレス | |

| WO2018037770A1 (ja) | 寝台装置 | |

| JP2022081643A (ja) | オプション受けおよび身体支持装置 | |

| JP2015202380A (ja) | ベッド | |

| GB2421426A (en) | Mattress elevator restraint | |

| JP6479932B2 (ja) | 寝台装置 | |

| JP3191046U (ja) | 折畳みベッド |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17843260 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 17843260 Country of ref document: EP Kind code of ref document: A1 |