WO2017150177A1 - ケース体およびこれを備えたルーバー装置 - Google Patents

ケース体およびこれを備えたルーバー装置 Download PDFInfo

- Publication number

- WO2017150177A1 WO2017150177A1 PCT/JP2017/005343 JP2017005343W WO2017150177A1 WO 2017150177 A1 WO2017150177 A1 WO 2017150177A1 JP 2017005343 W JP2017005343 W JP 2017005343W WO 2017150177 A1 WO2017150177 A1 WO 2017150177A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- case

- motor

- arm

- link

- lock piece

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B5/00—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them

- F16B5/07—Joining sheets or plates, e.g. panels, to one another or to strips or bars parallel to them by means of multiple interengaging protrusions on the surfaces, e.g. hooks, coils

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/08—Air-flow control members, e.g. louvres, grilles, flaps or guide plates

- F24F13/10—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers

- F24F13/14—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers built up of tilting members, e.g. louvre

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K7/00—Arrangements for handling mechanical energy structurally associated with dynamo-electric machines, e.g. structural association with mechanical driving motors or auxiliary dynamo-electric machines

- H02K7/10—Structural association with clutches, brakes, gears, pulleys or mechanical starters

- H02K7/116—Structural association with clutches, brakes, gears, pulleys or mechanical starters with gears

Definitions

- the present invention relates to a case body and a louver device including the same.

- an arm that supports a wind direction plate (louver 5) along an arcuate cam surface (guide surface 322e) provided in a case (second cases 312 and 322).

- a louver device (louver device 1) is disclosed in which an arm is reciprocated between a retracted position and an advanced position by sliding a cam follower portion (arc portions 213, 223) of a second louver support member 22). ing.

- the louver device of Patent Document 1 moves the arm that supports the wind direction plate to the forward position, and rotates the wind direction plate away from the air conditioner body. Therefore, in the louver device of Patent Document 1, the arm is easily touched by the user's eyes, and the arm is required to have high design.

- the locking portions of these case members are provided at positions that are visible to the user. And there exists a subject that this exposed latching part impairs the design property of an arm.

- the louver device of Patent Document 1 when the arm is moved to the forward movement position, the load of the arm and the wind direction plate is applied to the base end portion of the arm and the case (the first fixed body 31 and the second fixed body 32). It is necessary to support only in the vicinity of the opening.

- one of the arms (first louver support member 21) is provided with a motor (second motor 81) for rotating the wind direction plate at the tip thereof, and further the wind pressure received by the wind direction plate. Also increase the load.

- second motor 81 for rotating the wind direction plate at the tip thereof, and further the wind pressure received by the wind direction plate.

- the problem to be solved by the present invention is to provide a case body whose design property is improved by providing a locking portion of the case member invisible from the outside, and a wind direction plate including the case body.

- Another object of the present invention is to provide a louver device capable of supporting the load of an arm in a distributed manner.

- a case body of the present invention includes a first case member and a second case member that are fitted to each other, and an inner surface of the first case member has a distal end with the inner surface as a base end.

- a lock piece that is a protrusion protruding inside the first case member is formed, and a lock hole that is a through hole that engages with the lock piece is formed in the second case member,

- the thickness of the lock piece in the fitting direction of the first case member to the second case member is formed so that the distal end side is thinner than the proximal end side, and the lock piece extends from the proximal end to the distal end.

- the length is a length penetrating the lock hole when the first case member and the second case member are fitted together.

- the lock piece is set to a size that does not penetrate the lock hole. This is because if the lock piece penetrates the lock hole, the tip of the lock piece may damage the contents in the case. Since the lock hole of the present invention is arranged inside the case body rather than the lock piece, for example, when the contents in the case are approaching the vicinity of the lock hole, the displacement of the lock hole to the inside of the case is limited. The If a hook with a normal height is used in this situation, the tip of the lock piece rides on the edge of the lock hole, and the case body may not be locked no matter how much the case body is fitted.

- the lock piece of the present invention is intentionally set to a length (height) penetrating the lock hole, the amount of deformation of the first case member when fitting the case body is increased, and the lock piece is locked. It will be strongly pressed against the hole. Furthermore, since the lock piece of the present invention is shaped so that the tip is thinner than the base end, the tip of the lock piece is easily bent. As a result, the case body of the present invention can avoid the problem that the lock piece easily enters the lock hole and the case body is not locked even when the displacement of the lock hole to the inside of the case is restricted. ing.

- the first case member is elastic in the height direction of the lock piece. It is preferably made of a flexible material that can be deformed.

- the first case member is preferably made of a resin material.

- a spacer member that is housed together with the motor in the case of the case body and fixes the position of the motor in the case, and the direction along the axial direction of the motor is a vertical direction in the case.

- the spacer member fixes the vertical position of the motor in the case by pressing the end surface on the output shaft side of the motor, and the motor is cylindrical from the end surface along the outer peripheral surface of the output shaft.

- the spacer member has a bearing fixing hole that is a through hole into which the bearing portion of the motor is press-fitted, and the outer peripheral surface of the motor in the case is formed in the spacer member.

- a gap is preferably provided around the periphery.

- the motor has a high molding accuracy in the space inside the motor case, it is expected that errors on the outer surface of the motor case will appear larger than the inner surface due to variations in the thickness of the individual motor case. Therefore, when positioning the motor inside the case body, for example, by supporting the outer peripheral surface of the motor case, the motor may not fit in the case body, or the motor may rattle on the contrary.

- the case body of this configuration is provided with a separate spacer member for positioning the motor in the case, and the vertical position of the motor in the case is fixed using the spacer member, and the error is smaller than the outer peripheral surface of the motor case.

- the spacer member has a fixed circumferential angle and radial position in the case, and the motor is a motor having a support shaft that is a rod-like body extending perpendicularly from the end surface. Is formed with a support shaft fixing hole, which is a through hole into which the support shaft of the motor is press-fitted, and the motor has the bearing portion of the motor in the bearing fixing hole of the spacer member. It is preferable that the circumferential angle and the radial position in the case are fixed by press-fitting each of the support shafts into the support shaft fixing holes of the spacer member.

- a louver device of the present invention includes a first drive source, a link mechanism that swings by the drive force of the first drive source, and a fixing portion that can accommodate the link mechanism.

- the link mechanism includes an arm member having the case body according to any one of claims 1 to 5, and a plurality of the support members that support the arm member and reciprocate the arm member in the extending direction and the storing direction.

- the link members include a drive link driven by the first drive source, and a driven link that follows the operation of the drive link via the arm member.

- the drive link has a distal end side connected to the arm member, a proximal end side connected to the first drive source directly or via another member, and the driven link has a distal end side connected to the arm member.

- Proximal side The is coupled to the fixed portion, the extending direction side end portion of the arm member, characterized in that the wind direction plate is a plate-shaped member is pivotally connected.

- the load of the wind direction plate and the arm member can be distributed to each link member by reciprocating the arm member that opens and closes the wind direction plate by the link mechanism. As a result, it is possible to prevent the stress supporting the load from concentrating on only a part, and to reduce the size of the entire apparatus.

- the link mechanism is a four-bar link mechanism having the arm member as an intermediate link, and the driven link is disposed on the extension direction side with respect to the drive link.

- the link mechanism a four-bar link

- the reciprocating movement of the arm member by the link mechanism can be realized with a minimum number of parts.

- the driven link does not need to be connected to the first drive source, there are fewer restrictions on the arrangement location than the drive link. Therefore, by disposing the driven link closer to the extending direction of the arm member than the driving link, the driven link can be disposed at the end of the extending direction side of the device, and the arm member is supported farther. Is possible.

- a second drive source is disposed at a side end portion of the arm member in the extending direction, and the wind direction plate is rotatable within a predetermined angle range by a drive force of the second drive source. Is preferred.

- Rotating the wind direction plate by the second drive source provided at the side end portion in the extending direction of the arm member enables more complicated operation of the wind direction plate, and the degree of freedom of wind direction control can be increased.

- the second drive source is preferably a stepping motor.

- the stepping motor can rotate in both forward and reverse directions, and the rotation angle can be calculated from the number of steps. Therefore, it is not necessary to separately perform feedback control using a rotary encoder or the like in order to detect the arrangement angle of the wind direction plate at that time. Thereby, the number of parts in the whole apparatus can be reduced and the apparatus can be downsized.

- the design of the case body can be improved, and the load of the wind direction plate and the arm can be dispersed and supported.

- louver device is a device that is installed at a blower opening of an air conditioner (not shown) and controls the air direction.

- width direction means the X direction shown in the coordinate axis display of FIG. 1

- front-back direction means the Y direction shown in the coordinate axis display

- vertical direction means the same coordinate axis table.

- FIG. 1 is an external perspective view showing an example of an arrangement configuration of a louver device.

- one common wind direction plate 91 is also referred to as two louver devices 10, 10 ′ and one support unit 70 (hereinafter collectively referred to as “louver device 10 etc.”). ).

- the two louver devices 10 and 10 ' are the same device, and the configuration of the louver device 10 described below is also the configuration of the louver device 10'.

- These louver devices 10 and the like are all arranged behind the wind direction plate 91 (on the side of the air conditioner casing not shown).

- the louver devices 10 and 10 ′ are arranged in the vicinity of both ends in the longitudinal direction of the wind direction plate 91, and the support unit 70 is arranged at substantially the center in the longitudinal direction.

- Arm connection pieces 911 and 912 which are connecting portions with the louver device 10 and the like are formed on the surface of the wind direction plate 91 facing the louver device 10 and the like.

- the wind direction plate 91 is supported by the arms 42 and 72 by coupling the arm connection pieces 911 and 912 to the wind direction plate connection portions 262 and 721 provided on the arms 42 and 72 of the louver device 10 and the like.

- the arms 42 and 72 operate integrally.

- the louver device 10, 10 ' is a drive device that opens and closes and rotates the wind direction plate 91 by the driving force of the drive source provided in the louver device 10, 10'.

- the support unit 70 is an auxiliary unit that supports the wind direction plate 91 following the operation of the louver devices 10, 10 ′. Even when the length of the wind direction plate 91 in the longitudinal direction is short, or when only the both ends of the wind direction plate 91 are supported by the louver devices 10 and 10 ′, the wind direction plate 91 has a rigidity that does not cause deflection due to its own weight. In some cases, the support unit 70 may be omitted.

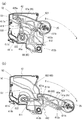

- FIG. 2 is an exploded perspective view showing the internal structure of the louver device 10 (and the louver device 10 ′).

- the louver device 10 includes a first motor 20 (first drive source) that is a stepping motor, a link mechanism 40 that swings by the driving force of the first motor 20, and a link mechanism 40 that decelerates the rotation of the first motor 20. And a case 50 (fixed portion) that accommodates the link mechanism 40 and the reduction gear train 30.

- the link mechanism 40 includes two link members 41 and an arm 42 (arm member) supported by these link members 41 and reciprocating in an extension direction A and a storage direction B (see FIG. 6) described later. ing.

- the link member 41 includes a drive link 411 driven by the first motor 20 and a driven link 412 that follows the operation of the drive link 411 via the arm 42.

- the link mechanism 40 constitutes a four-bar linkage mechanism in which the case 50 is a fixed link and the arm 42 is an intermediate link.

- the case 50 includes a first case half 51 that can be disassembled in the width direction X, a second case half 52, and an intermediate plate 53.

- the first case half 51, the second case half 52, and the intermediate plate 53 are integrated by being connected by a set screw 59.

- the link mechanism 40 is disposed in a space defined by the first case half 51 and the middle plate 53, and the reduction gear train 30 is disposed in a space defined by the second case half 52 and the middle plate 53.

- the first motor 20 is disposed outside the bottom surface (surface orthogonal to the width direction X) of the second case half 52 and is fixed to the second case half 52 by a set screw 29.

- a portion corresponding to the position of the pinion gear 21 of the first motor 20 has a covered cylindrical shape protruding toward the opening side (inside the case 50) of the second case half 52.

- the pinion cover part 521 is provided.

- the pinion cover portion 521 is open on the pinion gear 21 side, and the pinion gear 21 is accommodated inside the pinion cover portion 521.

- the pinion cover part 521 is provided with a window part 521a which is an opening partly cut off in the circumferential direction, and the pinion gear 21 housed in the pinion cover part 521 has a part of its tooth part. Is exposed to the inside of the second case half 52 from the window 521a.

- the reduction gear train 30 is a composite gear train that includes a large-diameter gear portion and a small-diameter gear portion, respectively. Each gear member of the reduction gear train 30 is rotatably supported by a support shaft 36 erected between the second case half 52 and the intermediate plate 53.

- the reduction gear train 30 sequentially transmits the rotation of the pinion gear 21 of the first motor 20 from the large diameter gear portion to the small diameter gear portion, thereby reducing the rotation of the pinion gear 21 and transmitting it to the gear portion 411c of the drive link 411. To do.

- the arm 42 can be reciprocated using a general output motor.

- a through hole 411b penetrating in the width direction X is formed in the base end portion (base end side) of the drive link 411 constituting the link mechanism 40, and the support shaft erected in the second case half 52 By inserting 522 into the through hole 411b, the base end portion of the drive link 411 is rotatably supported by the case 50.

- a gear portion 411c extending toward the reduction gear train 30 side is provided at the base end portion of the drive link 411.

- a cutout portion 533 through which the gear portion 411c is inserted is formed at a portion corresponding to the position of the gear portion 411c in the intermediate plate 53.

- the gear portion 411 c is inserted through the notch portion 533, thereby penetrating the intermediate plate 53 and meshing with the final gear of the reduction gear train 30.

- the driving force of the first motor 20 is transmitted to the drive link 411 via the reduction gear train 30 and the gear portion 411c.

- the driven link 412 of the link mechanism 40 is provided with a substantially cylindrical shaft body 412b whose axis is parallel to the width direction X at the base end portion (base end side). Bearings 513 and 523 which are circular through holes penetrating in the width direction X are formed at portions corresponding to the positions of the shaft bodies 412 b in the first case half 51 and the second case half 52.

- the driven link 412 is rotatably supported by the case 50 by fitting the shaft body 412b to the bearings 513 and 523.

- the “base end” of the link member 41 (drive link 411, driven link 412) in the present invention is a fixed joint, that is, fixed to a predetermined position and allowed to rotate, but in the vertical direction Z and the front-rear direction Y.

- the “tip” refers to a free joint, that is, an end that is allowed to rotate and swing.

- the base ends of the drive link 411 and the driven link 412 are both supported by the case 50, but these base ends need not necessarily be supported by the case 50.

- a member (fixed part) whose position is fixed such as a housing of an air conditioner (not shown), can support the base end part rotatably, and is deformed by the load of the arm 42 and the wind direction plate 91

- the case 50 can be substituted if it is a member having such a degree of rigidity that it does not.

- FIG. 3 is an exploded perspective view showing the internal structure of the arm 42.

- the arm 42 includes an arm case 42 a that is a case body of the arm 42.

- the arm case 42a includes a first arm half 421 that is a first case member fitted in the width direction X, and a second arm half 422 that is a second case member.

- a hook portion 426 and a lock hole 427 are provided at the ends of the first arm half body 421 and the second arm half body 422 on the extending direction A side to lock the fitted end portions, respectively.

- the first arm half 421 and the second arm half 422 are fixed by the hook portion 426 and the lock hole 427 and the three set screws 429.

- a motor chamber 43 in which the second motor 25 that is the second drive source is accommodated is provided at the end portion in the extending direction A side of the arm case 42a and in the vicinity thereof.

- the second motor 25 is a stepping motor that rotates the wind direction plate 91 within a predetermined angle range.

- a pinion gear 261 is attached to the output shaft 253 of the second motor 25 where the D cut is applied.

- a wind direction plate connecting portion 262 is rotatably supported on a support shaft 252 (described later) that is fixed to the second motor 25 so as not to move and extends parallel to the axial direction of the output shaft 253.

- the rotation of the pinion gear 261 is decelerated via the gear portion 262 a of the wind direction plate connecting portion 262 and transmitted to the wind direction plate connecting portion 262.

- the relative positional relationship of the wind direction plate connecting portion 262 with respect to the output shaft 253 is kept constant. I'm leaning.

- the meshing accuracy of the pinion gear 261 and the gear portion 262a of the wind direction plate connecting portion 262 is increased, and noises due to rattling of these gear members and a decrease in component life are suppressed.

- a circular opening 422a penetrating in the width direction X is formed at a portion of the second arm half 422 constituting the motor chamber 43, and the wind direction plate connecting portion 262 is connected to the outside of the arm case 42a from the opening 422a. Is exposed. Thereby, the wind direction plate connection part 262 of the arm 42 and the arm connection piece 911 of the wind direction plate 91 can be coupled.

- a corrugated rib 423 is provided in a portion closer to the storage direction B than the motor chamber 43, and the rigidity of the arm case 42 a is enhanced by the rib 423.

- a part of the rib 423 also serves as an arm-side contact portion 67 of the second swing restricting portion 65 described later.

- FIG. 8 is a diagram for explaining a structure for handling the lead wire 93 of the second motor 25.

- the lead wire 93 connected to the connector 259 of the second motor 25 is drawn into the case 50 through a gap provided above the rib 423 inside the arm 42.

- the lead wire 93 drawn into the case 50 passes through the upper side of the drive link 411 and is drawn into the guide piece 532 formed on the rear side (left side in FIG. 8) of the intermediate plate 53 and guided to the guide piece 532. It is pulled out of the louver device 10 from the outlet 54.

- the outlet 54 is an opening defined by the first case half 51 and the second case half 52.

- a spacer member 27 that fixes the position of the second motor 25 in the motor chamber 43 is accommodated together with the second motor 25.

- the spacer member 27 includes a substantially disc-shaped flat plate portion 271 and a pair of side plate portions 272 extending from the periphery of the flat plate portion 271 to the second motor 25 side.

- the pair of side plate portions 272 are formed at positions and ranges that are line-symmetrical at the periphery of the flat plate portion 271.

- the direction along the axial direction of the second motor 25 is the vertical direction inside the motor chamber 43 (the first arm half 421 side is “down”, the second arm half is The body 422 side is referred to as “upper.”

- “upper” and “lower” refer to the same vertical direction

- the flat plate portion 271 of the spacer member 27 Is placed on the upper surface 251 that is the end surface of the second motor 25 on the output shaft 253 side, and the upper surface 251 is pressed downward to fix the vertical position of the second motor 25 in the motor chamber 43.

- the pair of side plate portions 272 are not in contact with the inner peripheral surface of the second arm half 422 and the outer peripheral surface 25a of the second motor 25, and a gap is provided between them. Further, the outer peripheral surface 25a of the second motor 25 and the inner peripheral surface 43a of the motor chamber 43 are not in contact with each other, and a gap is provided between them.

- Two substantially cylindrical anti-rotation sleeves 273 extending toward the second arm half 422 are formed on the surface of the flat plate portion 271 of the spacer member 27 on the second arm half 422 side.

- Each anti-rotation sleeve 273 is provided with a slit in a part of its circumferential direction, so that it can be elastically deformed radially outward.

- a detent pin 424 which is a protrusion fitted to each detent sleeve 273, is formed at a position corresponding to the position where each detent sleeve 273 is formed. Yes.

- the spacer member 27 is fitted in the rotation-preventing pin 424 and the rotation-preventing sleeve 273 so that the spacer member 27 has a circumferential angle and a radial position in the motor chamber 43 (a position in a direction perpendicular to the vertical direction. The same applies to the above).

- a bearing portion 251 a extending in a cylindrical shape from the upper surface 251 along the outer peripheral surface of the output shaft 253 is formed, and at a position corresponding to the position where the bearing portion 251 a is formed in the flat plate portion 271.

- a support shaft 252, which is a rod-like body extending perpendicularly from the upper surface 251, is fixed to the upper surface 251 of the second motor 25 so as not to move, and at a position corresponding to the position where the support shaft 252 is formed in the flat plate portion 271.

- a support shaft fixing hole 271b which is a through hole into which the support shaft 252 is press-fitted, is formed. As described above, the position and angle of the spacer member 27 in the motor chamber 43 are fixed.

- the second motor 25 has a bearing portion 251 a that is press-fitted into the bearing fixing hole 271 a of the spacer member 27 and a support shaft 252 that is press-fitted into the support shaft fixing hole 271 b of the spacer member 27.

- the circumferential angle and the radial position in the motor chamber 43 are fixed. That is, the absolute position of the second motor 25 in the motor chamber 43 is fixed.

- the motor has a high molding accuracy in the space inside the motor case, it is expected that the outer surface of the motor case has a larger error than the inner surface due to variations in the thickness of the individual motor case. Therefore, when positioning the motor inside the case body, for example, by supporting the outer peripheral surface of the motor case, the motor may not fit in the case body, or on the contrary, the motor may rattle. .

- the motor chamber 43 of the present embodiment covers the spacer member 27 separately provided in the motor chamber 43 on the upper surface 251 of the second motor 25 while providing a gap around the outer peripheral surface 25a of the second motor 25, thereby reducing the molding error.

- the second motor 25 is absorbed while absorbing an error appearing on the outer surface of the second motor 25. It is possible to suppress noise and a decrease in component life due to 25 rattles.

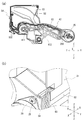

- FIG. 12 is an explanatory diagram of a locking structure of the arm case 42a using the hook portion 426 and the lock hole 427.

- FIG. 12A is a plan view of the arm 42 as viewed from the second arm half body 422 side

- FIG. 12B is a cross-sectional view in the CC direction of FIG. 12A

- FIG. 12C is FIG. It is an enlarged view of the part enclosed with the broken line D of b).

- the hook portion 426 is a protruding portion with the distal end protruding inside the motor chamber 43 with the inner peripheral surface 43 a of the motor chamber 43 of the first arm half 421 as the base end.

- the second arm half 422 has a tongue-like stopper portion 422c at a position corresponding to the position where the hook portion 426 is formed, and the stopper portion 422c has a lock that is a through hole that engages with the hook portion 426.

- a hole 427 is formed.

- the hook portion 426 and the lock hole 427 are a pair of lock pieces and a lock hole that latch the end portion on the extending direction A side of the arm case 42a. Since the hook portion 426 and the lock hole 427 are arranged inside the arm case 42a, they are concealed from the outside, and the design of the arm case 42a is enhanced.

- the hook portion 426 in the fitting direction of the first arm half body 421 and the second arm half body 422 (in the width direction X in the present embodiment) is formed so that the distal end side is thinner than the proximal end side. ing. More specifically, the hook portion 426 is formed as a tapered surface 426a whose surface corresponding to the upper surface of the hook portion 426 in FIG. 12C gradually decreases from the base end toward the tip end.

- a tapered surface on which the tapered surface 426a of the hook portion 426 rides when the first arm half body 421 and the second arm half body 422 are fitted is formed at the distal end portion of the stopper portion 422c.

- the first arm half body 421 is elastically deformed in the height direction of the hook portion 426 by about the height of the hook portion 426. It is made of a resin material capable of.

- the height of the hook portion 426 in this embodiment is a height that penetrates the lock hole 427.

- the lock piece is set to a size that does not penetrate the lock hole. This is because if the lock piece penetrates the lock hole, the tip of the lock piece may damage the contents in the case.

- the lock hole 427 of this embodiment is disposed inside the motor chamber 43 with respect to the hook portion 426. Further, the outer peripheral surface 25a of the motor 25 approaches the vicinity of the stopper portion 422c in which the lock hole 427 is formed, and the displacement of the lock hole 427 into the motor chamber 43 is limited.

- the tip of the lock piece rides on the edge of the lock hole, and the case body may not be locked no matter how much the case body is fitted.

- the hook portion 426 of the present embodiment is intentionally set to a height penetrating the lock hole 427, the amount of deformation of the first arm half 421 when the arm case 42a is fitted increases, and the hook portion 426 is strongly pressed against the lock hole 427. Furthermore, since the hook portion 426 of the present embodiment is shaped so that the tip thickness is thinner than the base end thereof, the tip of the hook portion 426 is easily bent.

- the hook portion 426 is easily pushed into the lock hole 427 while the displacement of the lock hole 427 (stopper portion 422c) into the motor chamber 43 is limited. It is possible to avoid the problem that the arm case 42a is not locked.

- FIG. 4 is a transparent view showing the meshing structure of the reduction gear train 30.

- the tooth part shown by the dotted line in FIG. 4 represents the gear part on the rear side of the figure of each gear member.

- the tooth part of the pinion gear 21 exposed from the window part 521a of the pinion cover part 521 meshes with the large-diameter gear part of the first reduction gear 31 constituting the reduction gear train 30. Thereafter, the small-diameter gear portion of the first reduction gear 31 is the large-diameter gear portion of the second reduction gear 32, the small-diameter gear portion of the second reduction gear 32 is the large-diameter gear portion of the third reduction gear 33, and the third reduction gear.

- the small-diameter gear portion 33 is in mesh with the large-diameter gear portion of the fourth reduction gear 34, and the small-diameter gear portion of the fourth reduction gear 34 is in mesh with the large-diameter gear portion of the fifth reduction gear 35.

- the small-diameter gear portion of the fifth reduction gear 35 meshes with the gear portion 411c of the drive link 411. Thereby, the rotation of the first motor 20 is decelerated and transmitted to the drive link 411.

- the first reduction gear 31 is a torque limiter mechanism that suppresses transmission torque by consuming excess torque by idling when torque exceeding a predetermined threshold is applied.

- a gear member having an overload protection mechanism As the predetermined threshold torque, an appropriate margin value is appropriately added to the upper limit value of the torque that can actually be transmitted to the first reduction gear 31 during the normal operation of the louver device 10, and a torque that can be determined to be highly likely to be abnormal. You only have to set it.

- FIG. 5 is an external perspective view of the first reduction gear 31 (FIG. 5A) and a cross-sectional view in the AA direction of the first reduction gear 31 shown in FIG. 5A (FIG. 5B).

- “upper” and “lower” refer to the upper and lower sides in FIGS. 5A and 5B

- “plan view” refers to the first reduction gear. A line-of-sight direction in which the first reduction gear 31 is looked down from above 31.

- the first reduction gear 31 is composed of an upper small-diameter gear portion 311 and a lower large-diameter gear portion 312 made of different members.

- the small-diameter gear portion 311 and the large-diameter gear portion 312 are supported by a common shaft portion 314 and can rotate independently of each other.

- a coil spring 313 is disposed between the small-diameter gear portion 311 and the large-diameter gear portion 312 in a state of being compressed in the vertical direction.

- the small-diameter gear portion 311 is moved upward by the coil spring 313, and the large-diameter gear portion 312. Is biased downward.

- the small-diameter gear portion 311 is urged upward by the coil spring 313 coming into contact with the lower surface thereof, and is moved upward by a flange portion 314a extending radially outward from the vicinity of the upper end of the shaft portion 314. It has been stopped.

- positioned is formed in planar view cross shape.

- the large-diameter gear portion 312 is press-fitted into the shaft portion 314, and a metal plate 315, which is an annular flat plate member, is coaxially disposed on the upper surface and the lower surface thereof.

- the large-diameter gear portion 312 is urged downward through the metal plate 315 when the coil spring 313 contacts the metal plate 315 disposed on the upper surface side of the large-diameter gear portion 312. Further, the metal plate 315 disposed on the lower surface side of the large diameter gear portion 312 is placed on the upper surface of the enlarged diameter portion 314b formed in the vicinity of the lower end of the shaft portion 314. The downward movement of the large-diameter gear portion 312 is locked by the portion 314b.

- the large-diameter gear portion 312 is pressed against the enlarged-diameter portion 314b by the urging force of the coil spring 313.

- the large-diameter gear portion 312 rotates around the shaft portion 314 in the circumferential direction due to the frictional resistance caused by press-fitting into the shaft portion 314 and the frictional resistance caused by being pressed against the enlarged-diameter portion 314b by the coil spring 313. To do.

- the first reduction gear 31 has the above-described configuration, the first reduction gear 31 and the smaller diameter gear portion 311 (and the shaft portion 314) are larger than the smaller diameter gear portion 311 within the torque range in which the shaft portion 314 and the large diameter gear portion 312 can be rotated by the frictional resistance.

- the diameter gear portion 312 rotates integrally in the circumferential direction, and when a torque exceeding the frictional resistance is applied, either the small diameter gear portion 311 (and the shaft portion 314) or the large diameter gear portion 312 idles.

- the reduction gear train 30 includes the first reduction gear 31 provided with the torque limiter mechanism, for example, during the hold of the first motor 20, the wind direction plate 91 is manually opened and closed by the user, and the reduction gear train 30 and the link mechanism. Even when an unexpected external force such as 40 is applied to the power transmission member of the first motor 20, it is possible to prevent the step-out of the first motor 20 and damage to the power transmission member. Further, for example, in the initialization operation of the first motor 20, the first motor 20 is intentionally moved toward the initial position of the drive link 411 in order to synchronize the recognition angle of the first motor 20 and the actual arrangement angle of the drive link 411. Even in the case of a step out of several steps, it is possible to reduce damage and abnormal noise of the power transmission member.

- the first reduction gear 31 meshes with the pinion gear 21 of the first motor 20.

- the torque limiter mechanism of the present invention operates when a torque larger than the transmission torque during normal operation is applied. Therefore, if a torque limiter mechanism is provided on a gear member (for example, the fifth reduction gear 35) having a large transmission torque during normal operation, a protective effect can be obtained only when a greater external force (torque) is applied.

- a torque limiter mechanism By providing the first speed reduction gear 31 having the smallest transmission torque in the speed reduction gear train 30 with the torque limiter mechanism, the torque limiter mechanism can be operated quickly with respect to an abnormality.

- FIG. 6 is an explanatory view showing the reciprocating motion of the arm 42 by the link mechanism 40.

- 6A shows a state where the arm 42 has moved to the limit in the storage direction B

- FIG. 6B shows a state where the arm 42 has moved to the limit in the extending direction A.

- the link mechanism 40 includes two link members 41 (a drive link 411 and a driven link 412), and is reciprocated in the extending direction A and the storage direction B supported by the link members 41. And an arm 42.

- the drive link 411 is formed with a circular through hole 411a penetrating in the width direction X at the tip.

- the support shaft 421a of the arm 42 By inserting the support shaft 421a of the arm 42 into the through hole 411a, the distal end portion of the drive link 411 and the arm 42 are rotatably connected to each other. Further, as described above, the base end portion of the drive link 411 can rotate to the case 50 by inserting the support shaft 522 of the second case half 52 into the through hole 411b formed in the base end portion. It is supported by.

- the gear portion 411 c formed at the base end portion of the drive link 411 meshes with the fifth reduction gear 35 of the reduction gear train 30.

- the driven link 412 is arranged on the extending direction A side with respect to the drive link 411.

- a circular through hole 412a penetrating in the width direction X is formed at the distal end of the driven link 412, and the support shaft 421b of the arm 42 is inserted into the through hole 412a, whereby the distal end of the driven link 412 is formed.

- the arm 42 are rotatably connected to each other.

- the base end portion of the driven link 412 is attached to the case 50 by fitting the shaft body 412b to the bearings 513 and 523 of the first case half 51 and the second case half 52. It is rotatably supported.

- the drive link 411 when the first motor 20 is rotated in the CW direction, the drive link 411 is also rotated in the CW direction, and the arm 42 is moved in the extending direction A.

- the arm 42 is also CCW. The arm 42 moves in the storage direction B.

- the load of the wind direction plate 91 and the arm 42 can be distributed to each link member 41 (the drive link 411 and the driven link 412). As a result, it is possible to prevent the stress supporting the load from being concentrated on only a part, and the entire apparatus is downsized. Further, since the sliding portion of the link mechanism 40 is almost only the joint portion, the sliding resistance accompanying the reciprocating motion of the arm 42 is relatively small.

- a stepping motor is used as the first motor 20 of the present embodiment.

- the stepping motor can rotate in both forward and reverse directions, and the rotation angle can be calculated from the number of steps. Therefore, it is not necessary to separately perform feedback control using a rotary encoder or the like in order to detect the arrangement angle of the drive link 411 at that time. Thereby, reduction of the number of parts in the whole apparatus and size reduction of the apparatus are achieved.

- the first drive source of the present invention is not necessarily a stepping motor, and other motors can be used as long as the motor can rotate in both forward and reverse directions. However, in that case, as described above, a position detecting means such as feedback control may be required separately.

- ribs 511 that support the link member 41 from the width direction X (the axial direction of the indirect portion of each link member) on the surface of the first case half 51 and the intermediate plate 53 on the link mechanism 40 side.

- ribs 531 are formed.

- the rib 511 and the rib 531 are linearly extending ribs protruding toward the link mechanism 40 along the rotation trajectory of each link member 41, and each link member 41 is slidably in contact with the rib 511 and the rib 531. Yes.

- each link member 41 Supporting each link member 41 with a linear rib prevents rattling in the width direction X of the link mechanism 40 and reduces sliding resistance with each link member 41.

- the louver device 10 is provided with a swing restricting portion that is a pair of locking portions that restrict the swingable range of the link mechanism 40 by abutting each other when the link mechanism 40 swings to a predetermined position. Yes.

- a swing restricting portion that is a pair of locking portions that restrict the swingable range of the link mechanism 40 by abutting each other when the link mechanism 40 swings to a predetermined position.

- two types of swing restricting portions are provided.

- FIG. 7 is an explanatory view showing the structure of the first swing restricting portion 60.

- 7A shows a state where the arm 42 has moved to the limit in the storage direction B

- FIG. 7B shows a state where the arm 42 has moved to the limit in the extending direction A.

- the 1st case half 51 of FIG. 7 is transparently displayed by the broken line.

- the first swing restricting portion 60 includes a protruding portion 61 formed on the drive link 411 and a contact portion 62 formed on the first case half 51.

- the protrusion 61 is a substantially rectangular tube-like engagement piece that protrudes from the drive link 411 along the width direction X (the axial direction of the indirect portion of the drive link) toward the first case half 51.

- the contact portion 62 is a rib-like engagement piece formed at a position where the link mechanism 40 abuts on the protrusion 61 when the link mechanism 40 swings to a predetermined position. The formation position of the contact portion 62 can be determined as appropriate according to the desired swing range of the link mechanism 40.

- the link mechanism 40 When the link mechanism 40 is swung to a predetermined position, the projection 61 formed on the drive link 411 and the contact portion 62 formed on the first case half 51 are brought into contact with each other, whereby the link The swingable range of the mechanism 40 can be limited to a desired range. Further, when the arm 42 is moved to the limit in the extending direction A side (that is, when the arm 42 is moved to a position where the projecting portion 61 and the contact portion 62 contact each other), the projecting portion 61 and the contact portion 62 are interposed. By supporting the drive link 411 on the first case half 51, the load on the arm 42 and the wind direction plate 91 can be further dispersed.

- the second swing restricting portion 65 is formed from opposed surfaces 66a and 67a of the bent portion 66 of the driven link 412 bent in a substantially L shape toward the inside of the link mechanism 40 and the arm side contact portion 67 of the arm 42. (See FIG. 6).

- the bent portion 66 is bent at an angle with which the facing surfaces 66a and 67a abut when the arm 42 extends to a predetermined position in the extending direction A.

- the bending angle of the bent portion 66 can be appropriately determined according to the desired extension range of the arm 42.

- FIG. 6 (b) shows the arm 42 moved in the extending direction A.

- the extension range of the arm 42 in FIG. 6B is limited by the first swing restricting portion 60, and the second swing restricting portion 65 is not acting.

- the movement of the arm 42 is limited by the contact of the facing surfaces 66a and 67a.

- the driven link 412 supports the arm 42 not only at its connecting portion but also at these facing surfaces 66a and 67a, so that the load of the arm 42 and the wind direction plate 91 can be further dispersed.

- the two types of swing restricting portions are provided, but only one of these swing restricting portions may be provided.

- FIG. 9 is an exploded perspective view showing the internal structure of the support unit 70.

- FIG. 10 is an explanatory view showing the reciprocating motion of the arm 72 by the support unit 70.

- the support unit 70 does not include a drive source, and is an auxiliary unit that supports the wind direction plate 91 following the operation of the louver devices 10, 10 ′.

- the support unit 70 has a case 71 composed of a first case half 711 and a second case half 712 that can be disassembled in the width direction X.

- An arm 72 and a follower link 73 are swingably supported on the case 71.

- the configuration and support structure of the driven link 73 are the same as the driven link 412 of the louver device 10.

- the arm 72 is not provided with a driving source corresponding to the second motor 25 of the louver device 10, and the wind direction plate 91 is rotated by the wind direction plate connecting portion 721 provided at the end portion in the extending direction A side. They are only combined as possible.

- a pin 751 that protrudes along the width direction X toward the second case half 712 is formed at the base end of the arm 72.

- the pin 751 is a cam follower that slides along a curved cam groove 752 provided in the second case half 712.

- the curved shape of the cam groove 752 is the same as the swing locus of the link mechanism 40 of the louver device 10.

- the width of the support unit 70 in the width direction X is smaller than that of the louver devices 10 and 10 ', and the air path of the air conditioner is not blocked.

- the use of the support unit 70 prevents the wind direction plate 91 from being bent by its own weight or wind pressure.

- louver device 11 According to another embodiment of the present invention will be described with reference to the drawings.

- components having the same or the same functions as those of the previous embodiment are denoted by the same reference numerals as those of the previous embodiment, and detailed description thereof is omitted.

- FIG. 11 is an explanatory view showing the reciprocating motion of the arm 42 in the louver device 11.

- 11A shows a state where the arm 42 has moved to the limit in the storage direction B

- FIG. 11B shows a state where the arm 42 has moved to the limit in the extending direction A.

- the louver device 11 is provided with a braking mechanism that brakes the arm 42 by a braking spring 95 that is a coil spring.

- the brake spring 95 in this embodiment is connected to the drive link 411 and the driven link 412, and when the arm 42 moves in the extending direction A, the driven link 412 is urged toward the storage direction B by its elastic force. Thus, the movement of the arm 42 in the extending direction A is braked.

- the arm 42 When moving the arm 42 in the extending direction A, the arm 42 is urged toward the extending direction A by the load of the arm 42 and the wind direction plate 91. In particular, when the wind direction plate 91 is receiving a large amount of wind pressure, the urging force is further increased. This may impair the stability of the opening / closing operation of the wind direction plate 91, may damage the power transmission member of the first motor 20, and may cause the first motor 20 to step out.

- connection target of the brake spring 95 is not limited to the drive link 411 and the driven link 412, and the same effect can be obtained by connecting the case 50 and a part of the link mechanism 40.

- a four-bar linkage mechanism is employed in order to realize the reciprocating movement of the arm member by the link mechanism with a minimum number of parts. More complex operations may be possible.

- first motor first drive source

- second motor second drive source (motor)

- 25a outer peripheral surface motor outer surface

- 251 upper surface 251a bearing portion

- 252 support Shaft 27 spacer member, 271 flat plate portion, 272 side plate portion, 271a bearing fixing hole, 271b support shaft fixing hole, 273 non-rotating sleeve

- 40 link mechanism 41 link member, 411 drive link, 412 driven link, 42 arm (arm Member, intermediate link), 42a arm case (case body), 421 first arm half (first case member), 422 second arm half (second case member), 422c stopper portion, 424 detent pin, 426 Hook part (lock piece), 427 lock hole, 43 motor room, 43a inner peripheral surface (first The inner surface of the over scan member), 50 cases (fixing portion), 91 louver, A extending direction, B housing direction

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Power Engineering (AREA)

- Air-Flow Control Members (AREA)

- Connection Of Motors, Electrical Generators, Mechanical Devices, And The Like (AREA)

- Connection Of Plates (AREA)

- Housings, Intake/Discharge, And Installation Of Fluid Heaters (AREA)

- Air-Conditioning Room Units, And Self-Contained Units In General (AREA)

- Air Filters, Heat-Exchange Apparatuses, And Housings Of Air-Conditioning Units (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201780014331.2A CN108700098B (zh) | 2016-03-04 | 2017-02-14 | 外壳及具有该外壳的导风板装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016042048A JP6727857B2 (ja) | 2016-03-04 | 2016-03-04 | ケース体およびこれを備えたルーバー装置 |

| JP2016-042048 | 2016-03-04 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017150177A1 true WO2017150177A1 (ja) | 2017-09-08 |

Family

ID=59742801

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/005343 Ceased WO2017150177A1 (ja) | 2016-03-04 | 2017-02-14 | ケース体およびこれを備えたルーバー装置 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6727857B2 (enExample) |

| CN (1) | CN108700098B (enExample) |

| WO (1) | WO2017150177A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2019151027A1 (ja) * | 2018-02-02 | 2021-01-28 | 日本ゼオン株式会社 | 積層フィルム及びその製造方法並びに偏光板 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003239920A (ja) * | 2002-02-19 | 2003-08-27 | Seiko Epson Corp | スナップフィットの接合構造及び成形品 |

| JP3468230B2 (ja) * | 2001-06-27 | 2003-11-17 | 株式会社ノーリツ | 浴室暖房機 |

| JP2009210207A (ja) * | 2008-03-05 | 2009-09-17 | Nidec Sankyo Corp | ルーバ装置 |

| JP2014001825A (ja) * | 2012-06-20 | 2014-01-09 | Tokai Rika Co Ltd | 部品の結合構造 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6068897B2 (ja) * | 2012-09-21 | 2017-01-25 | 矢崎総業株式会社 | 係止構造 |

| JP6116396B2 (ja) * | 2013-06-19 | 2017-04-19 | 株式会社ニフコ | 取付具 |

-

2016

- 2016-03-04 JP JP2016042048A patent/JP6727857B2/ja not_active Expired - Fee Related

-

2017

- 2017-02-14 CN CN201780014331.2A patent/CN108700098B/zh active Active

- 2017-02-14 WO PCT/JP2017/005343 patent/WO2017150177A1/ja not_active Ceased

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3468230B2 (ja) * | 2001-06-27 | 2003-11-17 | 株式会社ノーリツ | 浴室暖房機 |

| JP2003239920A (ja) * | 2002-02-19 | 2003-08-27 | Seiko Epson Corp | スナップフィットの接合構造及び成形品 |

| JP2009210207A (ja) * | 2008-03-05 | 2009-09-17 | Nidec Sankyo Corp | ルーバ装置 |

| JP2014001825A (ja) * | 2012-06-20 | 2014-01-09 | Tokai Rika Co Ltd | 部品の結合構造 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2019151027A1 (ja) * | 2018-02-02 | 2021-01-28 | 日本ゼオン株式会社 | 積層フィルム及びその製造方法並びに偏光板 |

| JP7173053B2 (ja) | 2018-02-02 | 2022-11-16 | 日本ゼオン株式会社 | 積層フィルム及びその製造方法並びに偏光板 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108700098B (zh) | 2020-05-05 |

| JP2017155905A (ja) | 2017-09-07 |

| CN108700098A (zh) | 2018-10-23 |

| JP6727857B2 (ja) | 2020-07-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6698382B2 (ja) | ルーバー装置 | |

| US9784384B2 (en) | Damper device | |

| EP2163421B1 (en) | Power seat driving apparatus for vehicle | |

| JP6584894B2 (ja) | ルーバー装置 | |

| US11149827B2 (en) | Linear drive device | |

| US9320161B2 (en) | On-vehicle electronic device | |

| JP2016536546A (ja) | リニア駆動装置、接続部材、排ガス再循環制御バルブ | |

| JP6609150B2 (ja) | ルーバー装置 | |

| EP4043261A1 (en) | Head-up display device | |

| WO2017150177A1 (ja) | ケース体およびこれを備えたルーバー装置 | |

| JP5047980B2 (ja) | レンズ駆動装置 | |

| US9074669B2 (en) | Drive unit | |

| JP4440930B2 (ja) | 扉開閉装置 | |

| KR20190038691A (ko) | 기어조립체 일체형 엑츄에이터장치 | |

| JP7644809B2 (ja) | 車両用ミラー装置 | |

| WO2017057229A1 (ja) | ルーバー装置 | |

| JP6816491B2 (ja) | 車両用窓ガラス昇降装置、移動体駆動装置、及びサンルーフ装置 | |

| US10684473B2 (en) | Angle-adjusting mechanism of head-up display | |

| JP7360928B2 (ja) | ドア開閉装置及びドアチェック装置 | |

| CN110671418B (zh) | 枢轴结构及应用其的壳体 | |

| US20250052105A1 (en) | Vehicle-opening/closing-body driving device | |

| KR102290497B1 (ko) | 밸브 개폐용 액츄에이터 | |

| JP2025012435A (ja) | ステアリング装置 | |

| WO2017169405A1 (ja) | 移動体駆動装置、車両用窓ガラス昇降装置、及びサンルーフ装置 | |

| CN119496332A (zh) | 马达的减震降噪结构 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17759648 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 17759648 Country of ref document: EP Kind code of ref document: A1 |