WO2015002029A1 - 熱電変換素子 - Google Patents

熱電変換素子 Download PDFInfo

- Publication number

- WO2015002029A1 WO2015002029A1 PCT/JP2014/066694 JP2014066694W WO2015002029A1 WO 2015002029 A1 WO2015002029 A1 WO 2015002029A1 JP 2014066694 W JP2014066694 W JP 2014066694W WO 2015002029 A1 WO2015002029 A1 WO 2015002029A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- thermoelectric conversion

- region

- electrode

- dopant

- conversion element

- Prior art date

Links

- 238000006243 chemical reaction Methods 0.000 title claims abstract description 199

- 239000002019 doping agent Substances 0.000 claims abstract description 83

- 239000000463 material Substances 0.000 claims description 55

- -1 salt compound Chemical class 0.000 claims description 40

- 150000001875 compounds Chemical class 0.000 claims description 26

- 239000002253 acid Substances 0.000 claims description 16

- 230000001678 irradiating effect Effects 0.000 claims description 9

- 239000011368 organic material Substances 0.000 claims description 5

- 239000010410 layer Substances 0.000 description 78

- 239000000758 substrate Substances 0.000 description 18

- 239000000969 carrier Substances 0.000 description 16

- 229920001940 conductive polymer Polymers 0.000 description 16

- 239000006185 dispersion Substances 0.000 description 15

- 239000002904 solvent Substances 0.000 description 14

- 239000000203 mixture Substances 0.000 description 13

- 238000000034 method Methods 0.000 description 11

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 9

- 239000004065 semiconductor Substances 0.000 description 8

- 229910052751 metal Inorganic materials 0.000 description 7

- 239000002184 metal Substances 0.000 description 7

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 6

- 229910052809 inorganic oxide Inorganic materials 0.000 description 6

- 229910021392 nanocarbon Inorganic materials 0.000 description 6

- 239000000126 substance Substances 0.000 description 6

- 230000015572 biosynthetic process Effects 0.000 description 5

- 238000000576 coating method Methods 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 5

- 239000002245 particle Substances 0.000 description 5

- ZCYVEMRRCGMTRW-UHFFFAOYSA-N 7553-56-2 Chemical compound [I] ZCYVEMRRCGMTRW-UHFFFAOYSA-N 0.000 description 4

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 4

- 229910021393 carbon nanotube Inorganic materials 0.000 description 4

- 239000002041 carbon nanotube Substances 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- 229910052740 iodine Inorganic materials 0.000 description 4

- 239000011630 iodine Substances 0.000 description 4

- 229920006255 plastic film Polymers 0.000 description 4

- 239000002985 plastic film Substances 0.000 description 4

- 229920000642 polymer Polymers 0.000 description 4

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 3

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 3

- RWSOTUBLDIXVET-UHFFFAOYSA-N Dihydrogen sulfide Chemical class S RWSOTUBLDIXVET-UHFFFAOYSA-N 0.000 description 3

- IAZDPXIOMUYVGZ-UHFFFAOYSA-N Dimethylsulphoxide Chemical compound CS(C)=O IAZDPXIOMUYVGZ-UHFFFAOYSA-N 0.000 description 3

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 3

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 125000005626 carbonium group Chemical group 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- XMBWDFGMSWQBCA-UHFFFAOYSA-N hydrogen iodide Chemical class I XMBWDFGMSWQBCA-UHFFFAOYSA-N 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 239000007769 metal material Substances 0.000 description 3

- 239000000178 monomer Substances 0.000 description 3

- 239000002086 nanomaterial Substances 0.000 description 3

- 230000005855 radiation Effects 0.000 description 3

- 229910052709 silver Inorganic materials 0.000 description 3

- 239000004332 silver Substances 0.000 description 3

- RFFLAFLAYFXFSW-UHFFFAOYSA-N 1,2-dichlorobenzene Chemical compound ClC1=CC=CC=C1Cl RFFLAFLAYFXFSW-UHFFFAOYSA-N 0.000 description 2

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- 229920001342 Bakelite® Polymers 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 2

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 2

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 2

- KKEYFWRCBNTPAC-UHFFFAOYSA-N Terephthalic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 description 2

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 150000007513 acids Chemical class 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 150000003863 ammonium salts Chemical class 0.000 description 2

- 150000001450 anions Chemical group 0.000 description 2

- 239000003963 antioxidant agent Substances 0.000 description 2

- 229910052799 carbon Inorganic materials 0.000 description 2

- 239000002134 carbon nanofiber Substances 0.000 description 2

- MVPPADPHJFYWMZ-UHFFFAOYSA-N chlorobenzene Chemical compound ClC1=CC=CC=C1 MVPPADPHJFYWMZ-UHFFFAOYSA-N 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- JHIVVAPYMSGYDF-UHFFFAOYSA-N cyclohexanone Chemical compound O=C1CCCCC1 JHIVVAPYMSGYDF-UHFFFAOYSA-N 0.000 description 2

- 238000001035 drying Methods 0.000 description 2

- 230000005670 electromagnetic radiation Effects 0.000 description 2

- 230000005251 gamma ray Effects 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- 239000010931 gold Substances 0.000 description 2

- 229910021389 graphene Inorganic materials 0.000 description 2

- 239000012760 heat stabilizer Substances 0.000 description 2

- 229910010272 inorganic material Inorganic materials 0.000 description 2

- 239000011147 inorganic material Substances 0.000 description 2

- RBTARNINKXHZNM-UHFFFAOYSA-K iron trichloride Chemical compound Cl[Fe](Cl)Cl RBTARNINKXHZNM-UHFFFAOYSA-K 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical class C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000002070 nanowire Substances 0.000 description 2

- 239000003960 organic solvent Substances 0.000 description 2

- 239000007800 oxidant agent Substances 0.000 description 2

- 239000004014 plasticizer Substances 0.000 description 2

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 2

- 229920006289 polycarbonate film Polymers 0.000 description 2

- 229920006267 polyester film Polymers 0.000 description 2

- 239000011112 polyethylene naphthalate Substances 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 229920001721 polyimide Polymers 0.000 description 2

- 238000010248 power generation Methods 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 150000003623 transition metal compounds Chemical class 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- JWZZKOKVBUJMES-UHFFFAOYSA-N (+-)-Isoprenaline Chemical compound CC(C)NCC(O)C1=CC=C(O)C(O)=C1 JWZZKOKVBUJMES-UHFFFAOYSA-N 0.000 description 1

- MIOPJNTWMNEORI-GMSGAONNSA-N (S)-camphorsulfonic acid Chemical compound C1C[C@@]2(CS(O)(=O)=O)C(=O)C[C@@H]1C2(C)C MIOPJNTWMNEORI-GMSGAONNSA-N 0.000 description 1

- OCJBOOLMMGQPQU-UHFFFAOYSA-N 1,4-dichlorobenzene Chemical compound ClC1=CC=C(Cl)C=C1 OCJBOOLMMGQPQU-UHFFFAOYSA-N 0.000 description 1

- 125000001140 1,4-phenylene group Chemical group [H]C1=C([H])C([*:2])=C([H])C([H])=C1[*:1] 0.000 description 1

- VTFXHGBOGGGYDO-UHFFFAOYSA-N 2,4-bis(dodecylsulfanylmethyl)-6-methylphenol Chemical compound CCCCCCCCCCCCSCC1=CC(C)=C(O)C(CSCCCCCCCCCCCC)=C1 VTFXHGBOGGGYDO-UHFFFAOYSA-N 0.000 description 1

- OLFNXLXEGXRUOI-UHFFFAOYSA-N 2-(benzotriazol-2-yl)-4,6-bis(2-phenylpropan-2-yl)phenol Chemical compound C=1C(N2N=C3C=CC=CC3=N2)=C(O)C(C(C)(C)C=2C=CC=CC=2)=CC=1C(C)(C)C1=CC=CC=C1 OLFNXLXEGXRUOI-UHFFFAOYSA-N 0.000 description 1

- 229920003026 Acene Polymers 0.000 description 1

- XTHFKEDIFFGKHM-UHFFFAOYSA-N Dimethoxyethane Chemical compound COCCOC XTHFKEDIFFGKHM-UHFFFAOYSA-N 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 229910021578 Iron(III) chloride Inorganic materials 0.000 description 1

- BZLVMXJERCGZMT-UHFFFAOYSA-N Methyl tert-butyl ether Chemical compound COC(C)(C)C BZLVMXJERCGZMT-UHFFFAOYSA-N 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- 239000004696 Poly ether ether ketone Substances 0.000 description 1

- 229920001609 Poly(3,4-ethylenedioxythiophene) Polymers 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- UCKMPCXJQFINFW-UHFFFAOYSA-N Sulphide Chemical compound [S-2] UCKMPCXJQFINFW-UHFFFAOYSA-N 0.000 description 1

- 239000004809 Teflon Substances 0.000 description 1

- 229920006362 Teflon® Polymers 0.000 description 1

- STLLXWLDRUVCHL-UHFFFAOYSA-N [2-[1-[2-hydroxy-3,5-bis(2-methylbutan-2-yl)phenyl]ethyl]-4,6-bis(2-methylbutan-2-yl)phenyl] prop-2-enoate Chemical compound CCC(C)(C)C1=CC(C(C)(C)CC)=CC(C(C)C=2C(=C(C=C(C=2)C(C)(C)CC)C(C)(C)CC)OC(=O)C=C)=C1O STLLXWLDRUVCHL-UHFFFAOYSA-N 0.000 description 1

- CGRTZESQZZGAAU-UHFFFAOYSA-N [2-[3-[1-[3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propanoyloxy]-2-methylpropan-2-yl]-2,4,8,10-tetraoxaspiro[5.5]undecan-9-yl]-2-methylpropyl] 3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propanoate Chemical compound CC(C)(C)C1=C(O)C(C)=CC(CCC(=O)OCC(C)(C)C2OCC3(CO2)COC(OC3)C(C)(C)COC(=O)CCC=2C=C(C(O)=C(C)C=2)C(C)(C)C)=C1 CGRTZESQZZGAAU-UHFFFAOYSA-N 0.000 description 1

- IORUEKDKNHHQAL-UHFFFAOYSA-N [2-tert-butyl-6-[(3-tert-butyl-2-hydroxy-5-methylphenyl)methyl]-4-methylphenyl] prop-2-enoate Chemical compound CC(C)(C)C1=CC(C)=CC(CC=2C(=C(C=C(C)C=2)C(C)(C)C)OC(=O)C=C)=C1O IORUEKDKNHHQAL-UHFFFAOYSA-N 0.000 description 1

- BGYHLZZASRKEJE-UHFFFAOYSA-N [3-[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxy]-2,2-bis[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxymethyl]propyl] 3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoate Chemical compound CC(C)(C)C1=C(O)C(C(C)(C)C)=CC(CCC(=O)OCC(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)=C1 BGYHLZZASRKEJE-UHFFFAOYSA-N 0.000 description 1

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 1

- 150000001448 anilines Chemical class 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 239000003849 aromatic solvent Substances 0.000 description 1

- 239000012298 atmosphere Substances 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 125000000751 azo group Chemical group [*]N=N[*] 0.000 description 1

- 239000004637 bakelite Substances 0.000 description 1

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 230000036760 body temperature Effects 0.000 description 1

- 230000005587 bubbling Effects 0.000 description 1

- 239000006229 carbon black Substances 0.000 description 1

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 1

- 239000011852 carbon nanoparticle Substances 0.000 description 1

- 239000003575 carbonaceous material Substances 0.000 description 1

- JJWKPURADFRFRB-UHFFFAOYSA-N carbonyl sulfide Chemical compound O=C=S JJWKPURADFRFRB-UHFFFAOYSA-N 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 229920000547 conjugated polymer Polymers 0.000 description 1

- 230000008094 contradictory effect Effects 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 238000007872 degassing Methods 0.000 description 1

- 230000018044 dehydration Effects 0.000 description 1

- 238000006297 dehydration reaction Methods 0.000 description 1

- 229940117389 dichlorobenzene Drugs 0.000 description 1

- 238000007607 die coating method Methods 0.000 description 1

- SBZXBUIDTXKZTM-UHFFFAOYSA-N diglyme Chemical compound COCCOCCOC SBZXBUIDTXKZTM-UHFFFAOYSA-N 0.000 description 1

- 238000003618 dip coating Methods 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000004821 distillation Methods 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 239000004210 ether based solvent Substances 0.000 description 1

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 150000002240 furans Chemical class 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 239000005453 ketone based solvent Substances 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 150000002605 large molecules Chemical class 0.000 description 1

- 239000011254 layer-forming composition Substances 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 230000000873 masking effect Effects 0.000 description 1

- 238000010907 mechanical stirring Methods 0.000 description 1

- AUHZEENZYGFFBQ-UHFFFAOYSA-N mesitylene Substances CC1=CC(C)=CC(C)=C1 AUHZEENZYGFFBQ-UHFFFAOYSA-N 0.000 description 1

- 125000001827 mesitylenyl group Chemical group [H]C1=C(C(*)=C(C([H])=C1C([H])([H])[H])C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 239000012046 mixed solvent Substances 0.000 description 1

- 239000002808 molecular sieve Substances 0.000 description 1

- QUAMTGJKVDWJEQ-UHFFFAOYSA-N octabenzone Chemical compound OC1=CC(OCCCCCCCC)=CC=C1C(=O)C1=CC=CC=C1 QUAMTGJKVDWJEQ-UHFFFAOYSA-N 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- QQVIHTHCMHWDBS-UHFFFAOYSA-N perisophthalic acid Natural products OC(=O)C1=CC=CC(C(O)=O)=C1 QQVIHTHCMHWDBS-UHFFFAOYSA-N 0.000 description 1

- 125000000843 phenylene group Chemical group C1(=C(C=CC=C1)*)* 0.000 description 1

- 150000004714 phosphonium salts Chemical class 0.000 description 1

- NBIIXXVUZAFLBC-UHFFFAOYSA-N phosphoric acid Substances OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 1

- 239000003495 polar organic solvent Substances 0.000 description 1

- 229920000301 poly(3-hexylthiophene-2,5-diyl) polymer Polymers 0.000 description 1

- 229920003223 poly(pyromellitimide-1,4-diphenyl ether) Polymers 0.000 description 1

- 229920003050 poly-cycloolefin Polymers 0.000 description 1

- 229920001707 polybutylene terephthalate Polymers 0.000 description 1

- 229920002530 polyetherether ketone Polymers 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 229920006389 polyphenyl polymer Polymers 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 1

- 150000003233 pyrroles Chemical class 0.000 description 1

- 150000003254 radicals Chemical class 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 150000005082 selenophenes Chemical class 0.000 description 1

- 238000007086 side reaction Methods 0.000 description 1

- URGAHOPLAPQHLN-UHFFFAOYSA-N sodium aluminosilicate Chemical compound [Na+].[Al+3].[O-][Si]([O-])=O.[O-][Si]([O-])=O URGAHOPLAPQHLN-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000000527 sonication Methods 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 125000001424 substituent group Chemical group 0.000 description 1

- KKEYFWRCBNTPAC-UHFFFAOYSA-L terephthalate(2-) Chemical compound [O-]C(=O)C1=CC=C(C([O-])=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-L 0.000 description 1

- CXWXQJXEFPUFDZ-UHFFFAOYSA-N tetralin Chemical compound C1=CC=C2CCCCC2=C1 CXWXQJXEFPUFDZ-UHFFFAOYSA-N 0.000 description 1

- 150000003577 thiophenes Chemical class 0.000 description 1

- 238000001132 ultrasonic dispersion Methods 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N10/00—Thermoelectric devices comprising a junction of dissimilar materials, i.e. devices exhibiting Seebeck or Peltier effects

- H10N10/80—Constructional details

- H10N10/85—Thermoelectric active materials

- H10N10/856—Thermoelectric active materials comprising organic compositions

Definitions

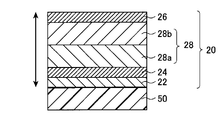

- the dopant doping average in the first region which is a half region of the thermoelectric conversion layer on one electrode side is half the region of the thermoelectric conversion layer on the other electrode side. It is characterized by being larger than the average dopant doping rate in a certain second region. That is, the present invention is characterized in that the average density of the number of dopants in the first region, that is, the number density is larger than the average density of the dopants in the second region, and the amount of dopant in the first region is increased. More than the amount of dopant in the second region.

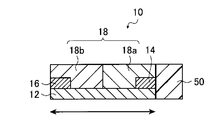

- the thermoelectric conversion element 10 includes a first electrode 14 and a second electrode 16 that are laminated at spaced positions on the substrate 12, and further, the first electrode 14 and the second electrode 16.

- a thermoelectric conversion layer 18 is laminated on the substrate 12 so as to cover the electrode 16.

- the first electrode 14 and the second electrode 16 constitute an electrode pair.

- the thermoelectric conversion layer 18 has two regions, the first region 18a and the second region 18b, having different doping rates, that is, dopant densities, in the direction from the first electrode 14 to the second electrode 16. Do it.

- the first region 18a and the second region 18b are substantially the same size.

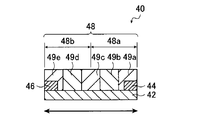

- the first region 48a side which is the first electrode 44 side, which has a high dopant content

- the second region 48b side which is the second electrode 46 side with a small amount

- This increases the number of carriers on the high-temperature part side, increases the difference in the number of carriers with the low-temperature part side, and can increase the difference more than the difference in the number of carriers due to the temperature.

- the thermoelectromotive force can be improved. Therefore, thermoelectric characteristics can be improved and conversion efficiency can be improved.

- thermoelectric conversion layer which the thermoelectric conversion element of this invention has will not be specifically limited if a dopant is contained.

- the thermoelectric conversion layer contains at least a thermoelectric conversion material and a dopant.

- the thermoelectric conversion layer may contain a polymer material or an inorganic material.

- the solvent is preferably degassed in advance.

- the dissolved oxygen concentration in the solvent is preferably 10 ppm or less.

- Examples of the degassing method include a method of irradiating ultrasonic waves under reduced pressure, a method of bubbling an inert gas such as argon, and the like.

- the solvent is preferably dehydrated in advance.

- the amount of water in the solvent is preferably 1000 ppm or less, and more preferably 100 ppm or less.

- a dehydration method a known method such as a method using molecular sieve or distillation can be used.

- the solvent may be used in an appropriate amount depending on the kind of the material, but is preferably 90 to 99.99% by mass, more preferably 95 to 99.95% by mass with respect to the total mass of the solution. 98 to 99.9% by mass is more preferable.

- the film forming method is not particularly limited.

- known coating methods such as spin coating, extrusion die coating, blade coating, bar coating, screen printing, stencil printing, roll coating, curtain coating, spray coating, dip coating, and inkjet method. Can be used.

- coating a drying process is performed as needed.

- the solvent can be volatilized and dried by blowing hot air.

- the prepared chloroform solution of dispersion B is affixed with a Teflon (registered trademark) frame on the substrate on which the electrodes are formed, and the solution is poured into the frame and dried on a hot plate at 60 ° C. for 1 hour. After drying, the frame was removed, and a conductive film having a thickness of about 1.1 ⁇ m was formed. After that, half of the film formed using an ultraviolet irradiation machine (ECS-401GX manufactured by Eye Graphics Co., Ltd.) is irradiated with ultraviolet light at a light amount of 200 mJ / cm 2 , so that only the half region, ie, the first region is doped.

- ECS-401GX ultraviolet irradiation machine

Landscapes

- Compositions Of Macromolecular Compounds (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-138831 | 2013-07-02 | ||

| JP2013138831A JP2015012261A (ja) | 2013-07-02 | 2013-07-02 | 熱電変換素子 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015002029A1 true WO2015002029A1 (ja) | 2015-01-08 |

Family

ID=52143608

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/066694 WO2015002029A1 (ja) | 2013-07-02 | 2014-06-24 | 熱電変換素子 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP2015012261A (ru) |

| WO (1) | WO2015002029A1 (ru) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6704577B2 (ja) * | 2015-02-23 | 2020-06-03 | 国立大学法人 奈良先端科学技術大学院大学 | カーボンナノチューブ−ドーパント組成物複合体の製造方法およびカーボンナノチューブ−ドーパント組成物複合体 |

| JP2021019032A (ja) * | 2019-07-18 | 2021-02-15 | 株式会社テックスイージー | 熱電素子及びその製造方法 |

| JP2021111664A (ja) * | 2020-01-08 | 2021-08-02 | 国立大学法人鳥取大学 | 熱電変換素子及びその製造方法並びに熱電変換デバイス |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3564860A (en) * | 1966-10-13 | 1971-02-23 | Borg Warner | Thermoelectric elements utilizing distributed peltier effect |

| WO2006043514A1 (ja) * | 2004-10-18 | 2006-04-27 | Meidensha Corporation | ペルチェ素子又はゼーベック素子の構造及びその製造方法 |

| WO2007097059A1 (ja) * | 2006-02-22 | 2007-08-30 | Murata Manufacturing Co., Ltd. | 熱電変換モジュールおよびその製造方法 |

| US20100193000A1 (en) * | 2007-06-21 | 2010-08-05 | Peter Prenninger | Thermoelectric generator for converting thermal energy into electrical energy |

| WO2013065631A1 (ja) * | 2011-10-31 | 2013-05-10 | 富士フイルム株式会社 | 熱電変換材料及び熱電変換素子 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1074986A (ja) * | 1996-06-27 | 1998-03-17 | Natl Aerospace Lab | 熱電変換素子、π型熱電変換素子対および熱電変換モジュールの各製造方法 |

| JP2010278191A (ja) * | 2009-05-28 | 2010-12-09 | Konica Minolta Holdings Inc | 熱電変換素子 |

| CN103477397B (zh) * | 2011-03-28 | 2016-07-06 | 富士胶片株式会社 | 导电性组合物、使用所述组合物的导电性膜及其制造方法 |

-

2013

- 2013-07-02 JP JP2013138831A patent/JP2015012261A/ja active Pending

-

2014

- 2014-06-24 WO PCT/JP2014/066694 patent/WO2015002029A1/ja active Application Filing

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3564860A (en) * | 1966-10-13 | 1971-02-23 | Borg Warner | Thermoelectric elements utilizing distributed peltier effect |

| WO2006043514A1 (ja) * | 2004-10-18 | 2006-04-27 | Meidensha Corporation | ペルチェ素子又はゼーベック素子の構造及びその製造方法 |

| WO2007097059A1 (ja) * | 2006-02-22 | 2007-08-30 | Murata Manufacturing Co., Ltd. | 熱電変換モジュールおよびその製造方法 |

| US20100193000A1 (en) * | 2007-06-21 | 2010-08-05 | Peter Prenninger | Thermoelectric generator for converting thermal energy into electrical energy |

| WO2013065631A1 (ja) * | 2011-10-31 | 2013-05-10 | 富士フイルム株式会社 | 熱電変換材料及び熱電変換素子 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015012261A (ja) | 2015-01-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Jin et al. | Synthesis of freestanding PEDOT: PSS/PVA@ Ag NPs nanofiber film for high-performance flexible thermoelectric generator | |

| Chen et al. | High-performance transparent and stretchable all-solid supercapacitors based on highly aligned carbon nanotube sheets | |

| Sun et al. | Developing polymer composite materials: carbon nanotubes or graphene? | |

| Liang et al. | Initiating a stretchable, compressible, and wearable thermoelectric generator by a spiral architecture with ternary nanocomposites for efficient heat harvesting | |

| Li et al. | Electromagnetic interference (EMI) shielding of single-walled carbon nanotube epoxy composites | |

| Giri et al. | In situ synthesis of cobalt doped polyaniline modified graphene composites for high performance supercapacitor electrode materials | |

| JP6110818B2 (ja) | 熱電変換材料、熱電変換素子ならびにこれを用いた熱電発電用物品およびセンサー用電源 | |

| JP6205333B2 (ja) | 熱電変換モジュール | |

| Kausar et al. | Effectiveness of polystyrene/carbon nanotube composite in electromagnetic interference shielding materials: a review | |

| WO2014010454A1 (ja) | 熱電変換素子及びこれを用いた熱電変換材料 | |

| Cho et al. | Recent developments of the solution-processable and highly conductive polyaniline composites for optical and electrochemical applications | |

| Kausar | Contemporary applications of carbon black-filled polymer composites: An overview of essential aspects | |

| JP2013211212A (ja) | 積層電極とその製造方法およびそれ用いた光電変換素子 | |

| Seki et al. | Freestanding bilayers of drop-cast single-walled carbon nanotubes and electropolymerized poly (3, 4-ethylenedioxythiophene) for thermoelectric energy harvesting | |

| WO2017154823A1 (ja) | 熱電変換素子、熱電変換素子の製造方法、熱電変換モジュール、および、熱電変換モジュールの製造方法 | |

| Ube et al. | Fabrication of well-isolated graphene and evaluation of thermoelectric performance of polyaniline–graphene composite film | |

| Kausar | Polymeric nanocomposites reinforced with nanowires: Opening doors to future applications | |

| WO2015002029A1 (ja) | 熱電変換素子 | |

| Karakoti et al. | Tailoring the electrochemical performance of PEDOT: PSS via incorporation of spray dryer processed graphene oxide | |

| Lu et al. | Aniline-pyrrole copolymer/SWCNT thermoelectric composites from electrochemical polymerization | |

| JP6771844B2 (ja) | 熱電変換層、熱電変換層形成用組成物、熱電変換素子、熱電変換モジュール | |

| Mardi et al. | Enhanced thermoelectric properties of poly (3-hexylthiophene) through the Incorporation of aligned carbon nanotube forest and chemical treatments | |

| WO2014119468A1 (ja) | 熱電変換材料、熱電変換素子並びにこれを用いた熱電発電用物品及びセンサー用電源 | |

| JP6535106B2 (ja) | 熱電変換層、熱電変換素子および熱電変換層形成用組成物 | |

| WO2014119470A1 (ja) | 熱電変換材料、熱電変換素子並びにこれを用いた熱電発電用物品及びセンサー用電源 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14820389 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 14820389 Country of ref document: EP Kind code of ref document: A1 |