WO2014136839A1 - 非接触電力供給装置 - Google Patents

非接触電力供給装置 Download PDFInfo

- Publication number

- WO2014136839A1 WO2014136839A1 PCT/JP2014/055632 JP2014055632W WO2014136839A1 WO 2014136839 A1 WO2014136839 A1 WO 2014136839A1 JP 2014055632 W JP2014055632 W JP 2014055632W WO 2014136839 A1 WO2014136839 A1 WO 2014136839A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- coil

- power supply

- primary coil

- supply device

- contact power

- Prior art date

Links

- 238000004804 winding Methods 0.000 claims abstract description 21

- 229910000859 α-Fe Inorganic materials 0.000 claims description 15

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 7

- 229910052782 aluminium Inorganic materials 0.000 claims description 7

- 239000003990 capacitor Substances 0.000 description 8

- 230000000694 effects Effects 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000004907 flux Effects 0.000 description 2

- 230000020169 heat generation Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000010355 oscillation Effects 0.000 description 2

- 239000004593 Epoxy Substances 0.000 description 1

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical group [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000002500 effect on skin Effects 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000012886 linear function Methods 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

Images

Classifications

-

- H02J5/005—

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L53/00—Methods of charging batteries, specially adapted for electric vehicles; Charging stations or on-board charging equipment therefor; Exchange of energy storage elements in electric vehicles

- B60L53/10—Methods of charging batteries, specially adapted for electric vehicles; Charging stations or on-board charging equipment therefor; Exchange of energy storage elements in electric vehicles characterised by the energy transfer between the charging station and the vehicle

- B60L53/12—Inductive energy transfer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L53/00—Methods of charging batteries, specially adapted for electric vehicles; Charging stations or on-board charging equipment therefor; Exchange of energy storage elements in electric vehicles

- B60L53/30—Constructional details of charging stations

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F38/00—Adaptations of transformers or inductances for specific applications or functions

- H01F38/14—Inductive couplings

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J50/00—Circuit arrangements or systems for wireless supply or distribution of electric power

- H02J50/10—Circuit arrangements or systems for wireless supply or distribution of electric power using inductive coupling

- H02J50/12—Circuit arrangements or systems for wireless supply or distribution of electric power using inductive coupling of the resonant type

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J50/00—Circuit arrangements or systems for wireless supply or distribution of electric power

- H02J50/70—Circuit arrangements or systems for wireless supply or distribution of electric power involving the reduction of electric, magnetic or electromagnetic leakage fields

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0029—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with safety or protection devices or circuits

- H02J7/00308—Overvoltage protection

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60M—POWER SUPPLY LINES, AND DEVICES ALONG RAILS, FOR ELECTRICALLY- PROPELLED VEHICLES

- B60M7/00—Power lines or rails specially adapted for electrically-propelled vehicles of special types, e.g. suspension tramway, ropeway, underground railway

- B60M7/003—Power lines or rails specially adapted for electrically-propelled vehicles of special types, e.g. suspension tramway, ropeway, underground railway for vehicles using stored power (e.g. charging stations)

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J2310/00—The network for supplying or distributing electric power characterised by its spatial reach or by the load

- H02J2310/40—The network being an on-board power network, i.e. within a vehicle

- H02J2310/48—The network being an on-board power network, i.e. within a vehicle for electric vehicles [EV] or hybrid vehicles [HEV]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/7072—Electromobility specific charging systems or methods for batteries, ultracapacitors, supercapacitors or double-layer capacitors

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02T90/10—Technologies relating to charging of electric vehicles

- Y02T90/12—Electric charging stations

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02T90/10—Technologies relating to charging of electric vehicles

- Y02T90/14—Plug-in electric vehicles

Definitions

- the present invention relates to a non-contact power supply device that has a primary coil and a resonance coil and a secondary coil that are arranged at a distance from the primary coil, and that transmits power from the primary coil to the secondary coil in a non-contact manner.

- the present invention relates to a non-contact power supply apparatus that increases the power supply efficiency from the primary coil to the secondary coil.

- a primary coil and a secondary coil are arranged with a gap, and a resonance capacitor is connected to the secondary side.

- a non-contact power feeding device that provides a resonance coil (tertiary coil) and supplies power from the primary coil to the secondary coil.

- a feeding line arranged along a traveling path is used as a primary side, and a pickup coil wound around an iron core provided on a ground moving body is used as a secondary side to resonate with an output terminal of the pickup coil.

- a resonant circuit is formed by connecting capacitors in parallel.

- a saturable reactor that magnetically saturates and lowers the self-inductance is connected in parallel to the pickup coil.

- a non-contact power feeding device for a ground moving body that regulates an increase in voltage of a pickup coil by increasing a current flowing in a saturable reactor.

- the present invention has been made in view of such circumstances, and efficiently supplies power to a secondary circuit having a resonance circuit (resonance coil) independently of the secondary coil.

- An object of the present invention is to provide a non-contact power supply device in which heat generation and loss of a coil and a resonance coil are reduced.

- a non-contact power supply apparatus includes a primary coil connected to a high-frequency power source, a secondary coil that receives power generated from the primary coil, the primary coil, and the secondary coil.

- a non-contact power supply apparatus having a resonance coil disposed in contact with the secondary coil Each area of the secondary coil and the resonance coil in plan view is equal to or smaller than the area of the primary coil in plan view,

- the primary coil is formed by spirally winding a first litz wire in a planar shape

- the resonant coil is formed by winding a coil in which a second litz wire is spirally wound in a plane in two layers, The next coil was spirally wound in a plane with two third litz wires arranged in parallel.

- a non-contact power supply apparatus is the non-contact power supply apparatus according to the first invention, wherein the first litz wire adjacent to the primary coil has a gap (for example, 1 to 5 mm). Are arranged.

- a non-contact power supply apparatus is the non-contact power supply apparatus according to the first and second aspects of the present invention, wherein the primary coil, the secondary coil, and the resonance coil are in corners in plan view. It is formed in a hollow rectangle (rectangle or square) having roundness.

- a contactless power supply apparatus is the contactless power supply apparatus according to the third aspect of the present invention, wherein the contactless power supply apparatus is for charging a battery of a work vehicle moving in a factory.

- the primary coil is disposed along a path of the work vehicle, and the secondary coil and the resonance coil are mounted on the work vehicle.

- a contactless power supply apparatus is the contactless power supply apparatus according to the fourth and fifth aspects of the present invention.

- a contactless power supply apparatus is the contactless power supply apparatus according to any of the first to sixth aspects of the present invention, wherein the primary coil has a plurality of rod-like shapes crossing the winding of the primary coil on the back surface of the primary coil.

- a ferrite core is provided.

- the rod-shaped ferrite core is preferably rectangular in cross section.

- a contactless power supply device is the contactless power supply device according to the seventh aspect of the invention, wherein the plate-shaped ferrite core has a plate thickness of 3 on the back surface of the rod-shaped ferrite core.

- An aluminum plate of ⁇ 10 mm is provided.

- the litz wire is used for the primary coil, the secondary coil, and the resonance coil, the skin effect hardly occurs even when a high frequency flows, and therefore, the power loss is reduced. It becomes an efficient non-contact power supply device. Moreover, since the area of each of the secondary coil and the resonance coil is equal to or smaller than the area of the primary coil in plan view, the leakage magnetic flux is reduced and efficient power supply can be performed. And since the resonance coil is formed by winding two layers of coils in which a litz wire is spirally wound in a plane, it can be formed compactly by increasing the number of turns.

- the litz wires are arranged at intervals in the primary coil, the cooling effect is increased and the interference between the litz wires is also reduced.

- the primary coil, secondary coil, and resonance coil are rectangular in shape with rounded corners, a wider area can be secured according to the width and travel of work vehicles, automobiles, etc., and transmission efficiency is improved. To do.

- the rod-shaped ferrite core when the rod-shaped ferrite core is disposed on the back surface of the primary coil, the leakage magnetic flux generated by the primary coil can be reduced, power loss can be reduced, and transmission efficiency can be increased. Further, when an aluminum plate having a thickness of 3 to 10 mm is provided on the back surface of the rod-shaped ferrite core, the primary coil and the rod-shaped ferrite core can be assembled on or below the aluminum plate, and can be used as a support member for the primary coil. Works effectively.

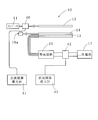

- (A) is a side view of the primary coil used for the non-contact power supply apparatus which concerns on one Example of this invention

- (B) is the top view. It is the layout of the non-contact electric power supply apparatus which tested in order to confirm an effect.

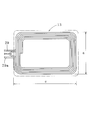

- (A) is a side view of the resonance coil of the non-contact power supply device

- (B) is a plan view. It is a top view of the secondary coil of the non-contact electric power supply apparatus.

- (A)-(C) is a wave form diagram which shows the operation state of the non-contact electric power supply apparatus, respectively.

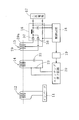

- a non-contact power supply apparatus 10 includes a primary coil 12 connected to a high-frequency power source 11 composed of an inverter (preferably 8 to 50 kHz), A secondary coil 13 that receives electric power generated from the primary coil 12, and a resonance coil 14 that is disposed between the primary coil 12 and the secondary coil 13 in contact with or close to the secondary coil 13.

- a high-frequency power source 11 composed of an inverter (preferably 8 to 50 kHz)

- a secondary coil 13 that receives electric power generated from the primary coil 12

- a resonance coil 14 that is disposed between the primary coil 12 and the secondary coil 13 in contact with or close to the secondary coil 13.

- a rectifier circuit 16 is connected to the secondary coil 13, and the output of the secondary coil 13 is converted into a direct current and supplied to a secondary battery 17 as a load.

- the DC voltage and current rectified by the rectifier circuit 16 are detected and input to the control circuit 18.

- the control circuit 18 performs digital processing and supplies it to the switching element circuit 20 via the photocoupler 19.

- an on signal and an off signal that are classified by the duty ratio are generated to increase or decrease the current flowing through the resonance coil 14.

- a capacitor 22 and a resistor 23 are connected to the resonance coil 14 in series. This state is shown in FIG. 6C.

- the switching element circuit 20 is turned off and only the resistor 23 is connected in series to the resonance coil 14, but in the period t1, the switching element circuit is connected. 20 is turned on, and another resistor is added in parallel to the resistor 23. Therefore, the resonance current can be controlled by changing the length ratio between t1 and t2.

- the current passing through the rectifier circuit 16 is detected by detecting the output current of the rectifier circuit 16 and feeding it back to the resonant coil 14. Can be made constant (or below a certain value). Further, the output voltage of the rectifier circuit 16 can be controlled to a predetermined value or less by detecting and feeding back the output voltage of the rectifier circuit 16 by the control circuit 18. In addition, when the secondary battery 17 is close to the completion of charging, the voltage increases, and this can be detected and the charging current can be reduced or reduced to zero.

- 6A shows the output voltage of the high frequency power supply 11

- FIG. 6B shows the current flowing through the resonance coil 14.

- the resonance coil 14 is provided with a resonance capacitor 18 a in series so that the current flowing through the resonance coil 14 resonates with the oscillation frequency f of the high-frequency power source (inverter) 11.

- the resonance frequency f1 formed by the resonance coil 14 and the capacitor 18a can be adjusted to (0.9 to 1.05) f by adjusting the capacitor 18a.

- the primary coil 12 attached to a fixed object for example, fixed to the building or arranged along the path of the work vehicle

- a vehicle driven by the secondary battery 17 for example, a work vehicle moving in the factory.

- the secondary coil 13 and the resonance coil 14 that are mounted on will be described.

- the areas of the secondary coil 13 and the resonance coil 14 in plan view are equal to or smaller than the area of the primary coil 12 in plan view, and the primary coil 12 preferably covers the resonance coil 14. .

- the secondary coil 13 and the resonance coil 14 in a plan view have a rectangular shape with rounded corners (having roundness), and are arranged with the same shape and area.

- the secondary coil 13 and the resonance coil 14 in plan view have widths a and b in the range of 350 to 600 mm and lengths c and d in the range of 350 to 650 mm in FIGS. Is in range.

- the width e of the primary coil 12 made of a hollow rectangle whose corners are arcuate in plan view is in the range of 350 to 600 mm, and is long.

- the thickness f is in the range of 350 to 800 mm.

- the length refers to the length in the traveling direction of the vehicle (that is, the length along the passage of the vehicle), and the width refers to the length in the direction orthogonal to the length (that is, the length along the width of the passage). .

- the primary coil 12 is formed by spirally winding a first litz wire 25 in a planar shape

- the resonant coil 14 is formed by winding coils 27 and 28 spirally wound in a plane on a second litz wire 26 in two layers.

- the secondary coil 13 is formed and two third litz wires 29 and 29a are arranged in parallel and spirally wound in a planar shape.

- the thickness of the first to third litz wires 25, 26, 29, and 29a is determined by the flowing current, but when charging the secondary battery 17 of the vehicle in the factory, for example, 100A specification (diameter is about 8). It is preferable to employ those having a thickness of ⁇ 9 mm and 14-22 SQ.

- a plurality of rod-shaped ferrite cores 31 cross about the winding (the first litz wire 25) of the primary coil 12 and are approximately 10 to It is provided at intervals of 50 mm.

- the rod-shaped ferrite core 31 completely covers the winding and protrudes further inside and outside. This prevents the magnetic field generated by the primary coil 12 from leaking to the back side of the primary coil 12 as much as possible.

- a gap S is provided between adjacent windings of the primary coil 12, that is, the first litz wire 25, to prevent interference between the first litz wires 25 as much as possible.

- the gap S is, for example, about 2 to 5 mm.

- the primary coil 12 is fixed on an insulating plate (for example, a glass epoxy substrate) 33, a rod-shaped ferrite core 31 is provided on the back of the insulating plate 33, and an aluminum plate 35 of 3 to 10 mm (preferably 5 to 8 mm) is provided on the back. Is provided.

- the aluminum plate 35 reinforces the entire primary coil 12 through the rod-shaped ferrite core 31 and can be screwed to the ceiling, wall, etc. of the building.

- the secondary coil 13 is formed by winding two litz wires 29, 29 a (third litz wire) or in parallel with each other, winding one litz wire 29, 29a is connected and used as an intermediate tap, and the rectifier circuit 16 by the two diodes 37 and 38 is comprised.

- the primary coil 12 has a width e of 400 mm, a length f of 600 mm (see FIG. 1), and the first litz wire 25 having a diameter of 8 to 9 mm is 10 turns by planar spiral winding. .

- a resonance coil 14 is disposed immediately below the primary coil 12, and a secondary coil 13 is disposed in contact with the resonance coil 14.

- the interval between the resonance coil 14 and the primary coil 12 was 50 mm.

- the planar dimensions of the resonance coil 14 and the secondary coil 13 were the same, the widths a and b were 400 mm, and the length was 600 mm.

- the resonance coil 14 is formed by winding a second litz wire (diameter 8 to 9 mm) 26 for eight turns and connecting the coils 27 and 28 in series to form two layers.

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Computer Networks & Wireless Communication (AREA)

- Mechanical Engineering (AREA)

- Transportation (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Current-Collector Devices For Electrically Propelled Vehicles (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

- Charge And Discharge Circuits For Batteries Or The Like (AREA)

- Coils Of Transformers For General Uses (AREA)

Abstract

Description

更に、大電力を非接触で供給すると、抵抗損及び渦電流損による一次コイルの発熱が大きくなり、共振コイルに流れる電流も増大し、共振コイルが過剰に発熱を起こすと共に、共振回路に存在する抵抗によって電力消費が発生するという問題がある。

平面視した前記二次コイル及び前記共振コイルのそれぞれの面積は、平面視した前記一次コイルの面積と同等又は小さくなって、

前記一次コイルは、第1のリッツ線を平面状に螺旋巻きして形成され、前記共振コイルは第2のリッツ線を平面状に螺旋巻きしたコイルを直列2層巻きして形成され、前記二次コイルは第3のリッツ線を2本並列に並べて平面状に螺旋巻きした。

第3の発明に係る非接触電力供給装置は、第1、第2の発明に係る非接触電力供給装置において、前記一次コイル、前記二次コイル及び前記共振コイルは、平面視して角部に丸みを有する中抜きの矩形(長方形又は正方形)に形成されている。

また、二次コイル及び共振コイルのそれぞれの面積は、平面視した一次コイルの面積と同等又は小さくなっているので、漏洩磁束が減少し、効率のよい電力供給ができる。

そして、共振コイルはリッツ線を平面状に螺旋巻きしたコイルを直列2層巻きして形成されているので、巻き数を増やしてコンパクトに形成できる。

更に、一次コイル、二次コイル及び共振コイルの形状を角部に丸みを有する矩形とした場合は、作業車、自動車等の幅、走行に合わせて、より広い面積を確保でき、伝送効率が向上する。

更に、棒状フェライトコアの背面に板厚が3~10mmのアルミ板を設けた場合は、一次コイル及び棒状フェライトコアをこのアルミ板の上又は下に組み立てることができ、一次コイルの支持部材としても有効に働く。

図2、図5に示すように、本発明の一実施例に係る非接触電力供給装置10は、インバータ(8~50kHzのものが好ましい)からなる高周波電源11に接続される一次コイル12と、一次コイル12から発生する電力を受ける二次コイル13と、一次コイル12と二次コイル13の間で、二次コイル13に当接又は近接して配置された共振コイル14とを有する。

また、整流回路16の出力電圧を制御回路18によって検出し、フィードバックすることによって、整流回路16の出力電圧を一定値以下に制御できる。なお、二次電池17が充電完了に近くなった場合、電圧が上昇するので、これを検知して充電電流を減らすか0にすることもできる。

なお、図6(A)は高周波電源11の出力電圧を、(B)は共振コイル14を流れる電流を示す。

また、共振コイル14には直列には共振用コンデンサー18aが設けられて、高周波電源(インバータ)11の発振周波数fに、共振コイル14を流れる電流を共振させるようにしている。なお、コンデンサー18aを調整して、共振コイル14とコンデンサー18aによって形成される共振周波数f1を(0.9~1.05)fとすることもできる。

一方、図1(A)、(B)に示すように、平面視して角部が円弧状となった中抜きの矩形からなる一次コイル12の幅eは350~600mmの範囲にあり、長さfは350~800mmの範囲にある。

なお、長さは車両の進行方向に対する長さ(即ち車両の通路に沿った長さ)を、幅は長さに直交する方向の長さ(即ち、通路の幅に沿った長さ)をいう。

一次コイル12の隣り合う巻線、即ち第1のリッツ線25の間には隙間Sが設けられ、第1のリッツ線25同士の干渉を極力防止している。隙間Sは例えば2~5mm程度である。

図2に示すように、一次コイル12は幅eが400mm、長さfが600mm(図1参照)で、直径が8~9mmの第1のリッツ線25を平面状螺旋巻きで10ターンとした。

共振コイル14は第2のリッツ線(直径8~9mm)26を8ターン巻いて、このコイル27、28を直列に接続して2層としている。

図2に示すように、一次コイル12の手前側に端子ボックス40を設けて、交流積算電力計41を接続し、整流回路16の出力側に端子ボックス42を設けて直流積算電力計43を接続して測定した結果、交流側の電力が4.591kw、直流側の電力が3.504kwであった。従って、単純に効率(η)を計算すると、76%となるが、実際は一次コイル12と二次コイル13との隙間を調整すると、70~90%程度まで可能になる。なお、高周波電源の発振周波数は10kHzであった。

本発明は前記した実施例に限定されるものではなく、本発明の要旨を変更しない範囲でその構成を変更することもできる。

例えば、この実施例では一次コイルに一次側共振コイルを設けていないが、必要によって設けることもできる。この場合、一次側共振コイルで電力を消費するので、効率が落ちると思われるが、一次コイルと二次コイルの間隔を離すことができる。

Claims (8)

- 高周波電源に接続される一次コイルと、前記一次コイルから発生する電力を受ける二次コイルと、前記一次コイルと前記二次コイルの間で、前記二次コイルに当接して配置された共振コイルとを有する非接触電力供給装置において、

平面視した前記二次コイル及び前記共振コイルのそれぞれの面積は、平面視した前記一次コイルの面積と同等又は小さくなって、

前記一次コイルは、第1のリッツ線を平面状に螺旋巻きして形成され、前記共振コイルは第2のリッツ線を平面状に螺旋巻きしたコイルを直列2層巻きして形成され、前記二次コイルは第3のリッツ線を2本並列に並べて平面状に螺旋巻きしたことを特徴とする非接触電力供給装置。 - 請求項1記載の非接触電力供給装置において、前記一次コイルの隣り合う前記第1のリッツ線は隙間を有して配置されていることを特徴とする非接触電力供給装置。

- 請求項1又は2記載の非接触電力供給装置において、前記一次コイル、前記二次コイル及び前記共振コイルは、平面視して角部に丸みを有する中抜きの矩形に形成されていることを特徴とする非接触電力供給装置。

- 請求項3記載の非接触電力供給装置において、該非接触電力供給装置は工場内を移動する作業車の電池を充電するためのものであって、前記一次コイルは前記作業車の通路に沿って配置され、前記二次コイル及び前記共振コイルは前記作業車に搭載されることを特徴とする非接触電力供給装置。

- 請求項4記載の非接触電力供給装置において、前記二次コイルの出力は整流されて前記電池に充電され、この充電電流の調整は、前記共振コイルに流れる電流を制御して行うことを特徴とする非接触電力供給装置。

- 請求項4又は5記載の非接触電力供給装置において、1)前記一次コイル、前記二次コイル、及び前記共振コイルの前記通路の幅に沿った寸法は、それぞれ平面視して350~600mmの範囲にあり、2)前記一次コイルの前記通路に沿った長さは平面視して350~800mmの範囲にあり、3)前記二次コイル及び前記共振コイルの前記通路に沿った長さは、350~650mmの範囲にあることを特徴とする非接触電力供給装置。

- 請求項1~6のいずれか1項に記載の非接触電力供給装置において、前記一次コイルの背面には、該一次コイルの巻線を交差して複数の棒状フェライトコアが設けられていることを特徴とする非接触電力供給装置。

- 請求項7記載の非接触電力供給装置において、前記棒状フェライトコアの背面には、前記一次コイル及び該棒状フェライトコアを保持する板厚が3~10mmのアルミ板が設けられていることを特徴とする非接触電力供給装置。

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201611078801.5A CN106505643B (zh) | 2013-03-06 | 2014-03-05 | 非接触电力供给装置 |

| CN201480001919.0A CN104488170A (zh) | 2013-03-06 | 2014-03-05 | 非接触电力供给装置 |

| US14/416,743 US9716386B2 (en) | 2013-03-06 | 2014-03-05 | Contactless power supply system |

| EP14760172.8A EP2879273A4 (en) | 2013-03-06 | 2014-03-05 | CONTACTLESS ENERGY SUPPLY DEVICE |

| JP2014546214A JP5707543B2 (ja) | 2013-03-06 | 2014-03-05 | 非接触電力供給装置 |

| KR1020157001610A KR20150023837A (ko) | 2013-03-06 | 2014-03-05 | 비접촉 전력 공급 장치 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013044743 | 2013-03-06 | ||

| JP2013-044743 | 2013-03-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014136839A1 true WO2014136839A1 (ja) | 2014-09-12 |

Family

ID=51491348

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/055632 WO2014136839A1 (ja) | 2013-03-06 | 2014-03-05 | 非接触電力供給装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9716386B2 (ja) |

| EP (1) | EP2879273A4 (ja) |

| JP (2) | JP5707543B2 (ja) |

| KR (1) | KR20150023837A (ja) |

| CN (2) | CN106505643B (ja) |

| MY (1) | MY172772A (ja) |

| WO (1) | WO2014136839A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017187611A1 (ja) * | 2016-04-28 | 2017-11-02 | 三菱電機エンジニアリング株式会社 | 無線電力伝送装置及び受信装置 |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014002876A1 (de) * | 2014-03-05 | 2015-09-10 | Supa Wireless Gmbh | Anordnung für eine induktive Energieübertragung |

| US9929606B2 (en) * | 2015-05-11 | 2018-03-27 | Qualcomm Incorporated | Integration of positioning antennas in wireless inductive charging power applications |

| JP6706623B2 (ja) | 2015-09-24 | 2020-06-10 | 株式会社Fuji | 非接触給電システム |

| CN109074937B (zh) * | 2016-07-13 | 2020-09-08 | 日本制铁株式会社 | 电感调整装置 |

| US10144302B2 (en) | 2016-09-23 | 2018-12-04 | Qualcomm Incorporated | Twisted wire for power charging |

| JP6776889B2 (ja) * | 2016-12-27 | 2020-10-28 | 株式会社ダイフク | 搬送台車 |

| KR101806764B1 (ko) | 2017-02-13 | 2017-12-07 | 동원건설산업 주식회사 | 무선충전 급전장치용 리츠 와이어 단말부 보호 브라켓 |

| FR3065121B1 (fr) * | 2017-04-06 | 2020-10-02 | Dcns | Systeme de transmission d'energie electrique sans contact notamment pour drone |

| DE102017109818A1 (de) * | 2017-05-08 | 2018-11-08 | Liebherr-Verzahntechnik Gmbh | Ladeportal |

| JP6505820B1 (ja) * | 2017-12-18 | 2019-04-24 | 昭和電線ケーブルシステム株式会社 | 非接触給電装置およびコイル |

| EP3786985B1 (en) | 2019-08-28 | 2023-06-07 | Delta Electronics (Thailand) Public Co., Ltd. | Resonating inductor for wireless power transfer |

| PL243920B1 (pl) * | 2021-10-15 | 2023-10-30 | Siec Badawcza Lukasiewicz Inst Tele I Radiotechniczny | Układ zasilania indukcyjnego z izolacją wysokonapięciową |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3442937B2 (ja) | 1996-08-26 | 2003-09-02 | 日立機電工業株式会社 | 地上移動体の非接触給電装置 |

| JP4318742B1 (ja) | 2008-10-06 | 2009-08-26 | 有限会社日本テクモ | 非接触電力供給装置 |

| JP2010016235A (ja) * | 2008-07-04 | 2010-01-21 | Panasonic Electric Works Co Ltd | 平面コイル |

| JP2010273441A (ja) * | 2009-05-20 | 2010-12-02 | Nippon Tekumo:Kk | 非接触電力供給装置 |

| JP2012120410A (ja) * | 2010-12-03 | 2012-06-21 | Fujitsu Ten Ltd | 受電装置、送電装置、及び無線電力伝送システム |

| JP2012249401A (ja) * | 2011-05-27 | 2012-12-13 | Nissan Motor Co Ltd | 非接触給電装置 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU4093393A (en) * | 1993-05-03 | 1994-11-21 | Peter Bruce Clark | Power collector for inductive power transfer |

| JP2009158598A (ja) | 2007-12-25 | 2009-07-16 | Panasonic Electric Works Co Ltd | 平面コイル及びこれを用いた非接触電力伝送機器 |

| EP2394346B1 (en) | 2009-02-05 | 2020-10-21 | Auckland UniServices Limited | Inductive power transfer apparatus |

| JP5471283B2 (ja) | 2009-10-19 | 2014-04-16 | Tdk株式会社 | ワイヤレス給電装置、ワイヤレス受電装置およびワイヤレス電力伝送システム |

| JP2011229202A (ja) | 2010-04-15 | 2011-11-10 | Panasonic Corp | 無線電力伝送用コイル |

| CN101854086A (zh) * | 2010-04-30 | 2010-10-06 | 中山大学 | 一种高品质因数的无线能量传输设备 |

| US20110309689A1 (en) | 2010-06-17 | 2011-12-22 | Semiconductor Energy Laboratory Co., Ltd. | Electric power transmitting device, electric power receiving device, and power supply method using electric power transmitting and receiving devices |

| EP2587629A1 (en) * | 2010-06-28 | 2013-05-01 | Showa Aircraft Industry Co., Ltd. | Non-contact electric power feeding device |

| JP5653137B2 (ja) | 2010-08-31 | 2015-01-14 | キヤノン株式会社 | 給電装置及び方法 |

| JP4982598B2 (ja) * | 2010-09-07 | 2012-07-25 | 株式会社東芝 | 無線電力伝送システム、該システムの送電装置および受電装置 |

| WO2012040548A1 (en) | 2010-09-26 | 2012-03-29 | Access Business Group International Llc | Selectively controllable electromagnetic shielding |

| JP4835786B1 (ja) | 2010-12-01 | 2011-12-14 | パナソニック株式会社 | 非接触充電モジュール及び非接触充電機器 |

| US8800738B2 (en) | 2010-12-28 | 2014-08-12 | Tdk Corporation | Wireless power feeder and wireless power receiver |

| US9035500B2 (en) * | 2011-03-01 | 2015-05-19 | Tdk Corporation | Wireless power feeder, wireless power receiver, and wireless power transmission system, and coil |

| US9136728B2 (en) * | 2011-04-28 | 2015-09-15 | Medtronic, Inc. | Implantable medical devices and systems having inductive telemetry and recharge on a single coil |

| WO2012157115A1 (ja) | 2011-05-19 | 2012-11-22 | トヨタ自動車株式会社 | 受電装置およびそれを備える車両、給電設備、ならびに給電システム |

| KR101339486B1 (ko) * | 2012-03-29 | 2013-12-10 | 삼성전기주식회사 | 박막 코일 및 이를 구비하는 전자 기기 |

-

2014

- 2014-03-05 US US14/416,743 patent/US9716386B2/en active Active

- 2014-03-05 JP JP2014546214A patent/JP5707543B2/ja active Active

- 2014-03-05 EP EP14760172.8A patent/EP2879273A4/en not_active Withdrawn

- 2014-03-05 KR KR1020157001610A patent/KR20150023837A/ko not_active Application Discontinuation

- 2014-03-05 MY MYPI2015700226A patent/MY172772A/en unknown

- 2014-03-05 CN CN201611078801.5A patent/CN106505643B/zh not_active Expired - Fee Related

- 2014-03-05 CN CN201480001919.0A patent/CN104488170A/zh active Pending

- 2014-03-05 WO PCT/JP2014/055632 patent/WO2014136839A1/ja active Application Filing

-

2015

- 2015-01-16 JP JP2015006904A patent/JP6154835B2/ja active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3442937B2 (ja) | 1996-08-26 | 2003-09-02 | 日立機電工業株式会社 | 地上移動体の非接触給電装置 |

| JP2010016235A (ja) * | 2008-07-04 | 2010-01-21 | Panasonic Electric Works Co Ltd | 平面コイル |

| JP4318742B1 (ja) | 2008-10-06 | 2009-08-26 | 有限会社日本テクモ | 非接触電力供給装置 |

| JP2010273441A (ja) * | 2009-05-20 | 2010-12-02 | Nippon Tekumo:Kk | 非接触電力供給装置 |

| JP2012120410A (ja) * | 2010-12-03 | 2012-06-21 | Fujitsu Ten Ltd | 受電装置、送電装置、及び無線電力伝送システム |

| JP2012249401A (ja) * | 2011-05-27 | 2012-12-13 | Nissan Motor Co Ltd | 非接触給電装置 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2879273A4 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017187611A1 (ja) * | 2016-04-28 | 2017-11-02 | 三菱電機エンジニアリング株式会社 | 無線電力伝送装置及び受信装置 |

| JPWO2017187611A1 (ja) * | 2016-04-28 | 2018-05-10 | 三菱電機エンジニアリング株式会社 | 無線電力伝送装置及び受信装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US9716386B2 (en) | 2017-07-25 |

| US20150207332A1 (en) | 2015-07-23 |

| JP5707543B2 (ja) | 2015-04-30 |

| CN104488170A (zh) | 2015-04-01 |

| CN106505643A (zh) | 2017-03-15 |

| EP2879273A4 (en) | 2016-04-27 |

| JP6154835B2 (ja) | 2017-06-28 |

| JP2015136287A (ja) | 2015-07-27 |

| KR20150023837A (ko) | 2015-03-05 |

| JPWO2014136839A1 (ja) | 2017-02-16 |

| MY172772A (en) | 2019-12-12 |

| EP2879273A1 (en) | 2015-06-03 |

| CN106505643B (zh) | 2019-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6154835B2 (ja) | 非接触電力供給装置 | |

| JP2015136287A5 (ja) | ||

| JP6371364B2 (ja) | 非接触電力供給装置 | |

| US10002708B2 (en) | Coil unit and wireless power transmission device | |

| US10014105B2 (en) | Coil unit and wireless power transmission device | |

| WO2012108432A1 (ja) | 非接触給電装置 | |

| US11043845B2 (en) | Power feeding device and wireless power transmission device | |

| JP2010093902A (ja) | 非接触電力供給装置 | |

| JP2010040699A (ja) | 非接触給電装置 | |

| JP2014230474A (ja) | 非接触給電システム | |

| JP6358098B2 (ja) | 給電装置および非接触電力伝送装置 | |

| JP5384195B2 (ja) | 非接触電力供給装置 | |

| JP6354437B2 (ja) | 非接触給電装置 | |

| Matsumoto et al. | Wireless power transfer system with passive boost topology for AGVs | |

| JP5250867B2 (ja) | 誘導受電回路 | |

| JP2014128048A (ja) | 高周波電圧発生装置及び受給電システム | |

| US9991749B2 (en) | Coil unit, wireless power feeding device, wireless power receiving device, and wireless power transmission device | |

| JP2018196230A (ja) | 移動体用ワイヤレス給電システム | |

| JP2018166394A (ja) | 誘導給電装置 | |

| JP6424710B2 (ja) | 非接触電力伝送用コイルおよび非接触電力伝送装置 | |

| JP2006287987A (ja) | 無接触給電設備の2次側受電回路 | |

| JP2005102378A (ja) | 誘導受電回路 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 2014546214 Country of ref document: JP Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14760172 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20157001610 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14416743 Country of ref document: US |

|

| REEP | Request for entry into the european phase |

Ref document number: 2014760172 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2014760172 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: IDP00201500518 Country of ref document: ID |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |