WO2014054649A1 - Article absorbant - Google Patents

Article absorbant Download PDFInfo

- Publication number

- WO2014054649A1 WO2014054649A1 PCT/JP2013/076727 JP2013076727W WO2014054649A1 WO 2014054649 A1 WO2014054649 A1 WO 2014054649A1 JP 2013076727 W JP2013076727 W JP 2013076727W WO 2014054649 A1 WO2014054649 A1 WO 2014054649A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- acid

- chain hydrocarbon

- fiber

- hydrocarbon moiety

- top sheet

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15804—Plant, e.g. involving several steps

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/51104—Topsheet, i.e. the permeable cover or layer facing the skin the top sheet having a three-dimensional cross-section, e.g. corrugations, embossments, recesses or projections

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/51113—Topsheet, i.e. the permeable cover or layer facing the skin comprising an additive, e.g. lotion or odour control

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/84—Accessories, not otherwise provided for, for absorbent pads

- A61F13/8405—Additives, e.g. for odour, disinfectant or pH control

Definitions

- the present invention relates to an absorbent article.

- Patent Documents 1 to 4 As a top sheet of an absorbent article, a non-woven fabric having an uneven surface and a method for producing the same are known (Patent Documents 1 to 4).

- an object of this invention is to provide the absorbent article which has the improved menstrual blood transfer property from a top sheet to an absorber, and can reduce the menstrual blood remaining on a top sheet.

- the present invention provides a liquid-permeable top sheet having a skin contact surface, a liquid-impermeable back sheet having a non-skin contact surface, the top sheet, and the back sheet.

- An absorbent article comprising an absorbent body provided therebetween, wherein the top sheet intersects the first direction and the first direction at least in the excretory opening contact region of the skin contact surface.

- the absorbent article is provided with a blood slipperiness imparting agent having a mass% and a weight average molecular weight of less than 1,000.

- an absorbent article that has improved menstrual blood transfer from the top sheet to the absorbent body and can reduce menstrual blood remaining on the top sheet.

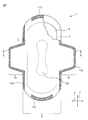

- FIG. 1 is a partially broken plan view of a sanitary napkin according to an embodiment of the absorbent article of the present invention.

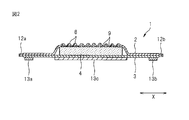

- 2 is a cross-sectional view taken along line AA in FIG.

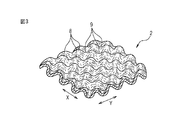

- FIG. 3 is a partial perspective view of a top sheet provided in the sanitary napkin shown in FIG. 1.

- 4A is a partially enlarged cross-sectional view of the top sheet shown in FIG. 3

- FIG. 4B is a diagram showing fiber orientations at the top of the convex portion and the bottom of the concave portion shown in FIG. 4A.

- FIG. 4C is a development view of the convex side wall and the concave side wall shown in FIG.

- FIG. 5 is a diagram illustrating a manufacturing process of the top sheet shown in FIG. FIG.

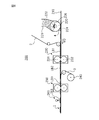

- FIG. 6 is a diagram for explaining a manufacturing process of the sanitary napkin shown in FIG.

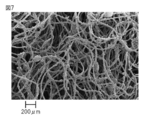

- FIG. 7 is an electron micrograph of the skin contact surface of the top sheet in a sanitary napkin in which the top sheet contains tri-C2L oil fatty acid glycerides.

- FIG. 8 is a photomicrograph of menstrual blood with or without a blood slipping agent.

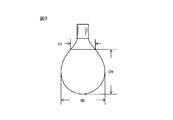

- FIG. 9 is a diagram for explaining a method of measuring the surface tension.

- An absorbent article according to the present invention is provided between a liquid-permeable top sheet having a skin contact surface, a liquid-impermeable back sheet having a non-skin contact surface, and the top sheet and the back sheet.

- An absorbent article comprising the absorbent body, wherein the top sheet has a first direction and a second direction intersecting the first direction at least in the excretory opening contact region of the skin contact surface.

- a plurality of concave portions each having a bottom portion and a concave portion side wall portion extending from the bottom portion, and the convex side wall portion extending from the top portion. Having a fiber orientation along the direction, and the recess side wall portion is a fiber along its extending direction. It has a tropism, wherein at least the convex portion of the excretory opening contact region, kinematic viscosity at 40 ° C. of 0.01 to 80 mm 2 / s, water holding percentage of 0.01 to 4.0 mass%,

- the absorbent article is coated with a blood slipperiness-imparting agent having a weight average molecular weight of less than 1,000.

- the absorbent article according to the present invention when menstrual blood excreted from the wearer reaches the excretory opening contact region, it slides down together with the blood slipperiness-imparting agent present in the convex portion, passes through the top sheet, and becomes an absorbent body. Transition. Therefore, the absorbent article according to the present invention has improved menstrual blood transfer from the top sheet to the absorbent body, and can reduce menstrual blood remaining on the top sheet. For this reason, the sticky feeling of the skin contact surface of the top sheet is prevented, and the smooth feeling is maintained. The effect of such a blood slipperiness-imparting agent is exerted irrespective of changes in menstrual blood discharge (that is, whether menstrual blood discharged at a time is large or small). .

- the convex side wall portion extends from the top of the convex portion toward the bottom of the concave portion, and the concave side wall portion starts from the bottom of the concave portion at the top of the convex portion. It extends towards. Therefore, the convex side wall portion has a fiber orientation along the extending direction, that is, the direction from the top of the convex portion toward the bottom of the concave portion, and the concave side wall portion is in the extending direction, that is, the concave portion. It has fiber orientation along the direction from the bottom toward the top of the convex portion.

- menstrual blood excreted from the wearer easily slides along the extending direction of the convex side wall portion and the concave side wall portion together with the blood slipperiness imparting agent.

- menstrual blood excreted from the wearer does not spread in the surface direction of the top sheet, but easily moves in the thickness direction of the top sheet (that is, to the absorber).

- the convex side wall portion and the concave side wall portion have fiber orientation along each extending direction, and therefore the fiber orientation in the thickness direction of the top sheet is large, resulting from this.

- the top sheet has high compression deformation and compression recovery properties (cushioning properties). Therefore, even if the absorbent article is compressed, liquid return (rewetting back) from the absorbent body hardly occurs. Moreover, since the cushioning property of a top sheet is high, it gives a wearer good comfort.

- the skin contact surface of the top sheet has an uneven shape, the contact area between the wearer's skin and the top sheet is small, and the surface direction of the top sheet through the space in the recess is reduced. Good air permeability. Therefore, it is difficult to give the wearer stuffiness and itching.

- the fiber density at the top of the convex portion is lower than the fiber density at the bottom of the concave portion. Since the liquid is likely to move from the lower fiber density (the top of the convex portion in aspect 1) to the higher (the bottom of the concave part in aspect 1), the absorbent article according to aspect 1 has the effect of the blood slipperiness-imparting agent. In combination with the above, it has improved menstrual transfer from the top sheet to the absorbent body.

- the fiber density at the top of the convex portion is higher than the fiber density at the bottom of the concave portion.

- the liquid is less likely to move from the higher fiber density (the top of the convex part in aspect 2) to the lower (the bottom of the concave part in aspect 2), but the absorbent article according to aspect 2 has the effect of the blood slipperiness-imparting agent. Therefore, it has the improved menstrual blood transfer property from a top sheet to an absorber. Therefore, the effect of the blood slipperiness-imparting agent is significant in the absorbent article according to aspect 2.

- the convex side wall part and / or the concave side wall part have portions having different fiber orientations.

- Aspect 3 can be combined with Aspect 1 or Aspect 2.

- the fiber orientation in the thickness direction at the bottom of the recess is smaller than the fiber orientation in the thickness direction at the sidewall of the recess.

- menstrual blood is easy to transfer to a thickness direction (namely, to an absorber), without accumulating in a recessed part side wall part.

- the fiber orientation in a recessed part changes to the direction perpendicular

- Aspect 4 can be combined with one of Aspects 1 to 3, or two or more aspects that can be arranged side by side.

- the number of fiber fusion points at the top of the convex portion is smaller than the number of fiber fusion points at the bottom of the concave portion.

- the touch of a top sheet is favorable.

- Aspect 5 can be combined with one of aspects 1 to 4 or two or more aspects that can be arranged side by side.

- the constituent fibers of the top sheet are heat-sealed.

- corrugated shape of a top sheet is maintained by the heat sealing

- Aspect 6 can be combined with one of aspects 1 to 5 or two or more aspects that can be arranged side by side.

- the top sheet contains heat-extensible heat-extensible fibers. Due to the thermal elongation of the heat-extensible fibers, effective uneven shaping is possible. Moreover, the heat

- the IOB of the blood slipperiness imparting agent is an IOB of 0.00 to 0.60.

- Aspect 8 can be combined with one of Aspects 1 to 7, or two or more aspects that can be juxtaposed.

- the blood slipperiness imparting agent includes the following (i) to (iii): (I) hydrocarbons, (Ii) from (ii-1) a hydrocarbon moiety and (ii-2) a carbonyl group (—CO—) and an oxy group (—O—) inserted between the CC single bonds of the hydrocarbon moiety.

- the hydrocarbon moiety A compound having one or a plurality of the same or different groups selected from the group consisting of a carboxyl group (—COOH) and a hydroxyl group (—OH), which replaces a hydrogen atom; Selected from the group consisting of any combination thereof (in the compound (ii) or (iii), when two or more oxy groups are inserted, each oxy group is not adjacent) ).

- Aspect 9 can be combined with one of aspects 1 to 8 or two or more aspects that can be arranged side by side.

- the blood slipperiness imparting agent includes the following (i ′) to (iii ′): (I ′) hydrocarbon, (Ii ′) (ii′-1) a hydrocarbon moiety and (ii′-2) a carbonyl bond (—CO—), an ester bond (—COO) inserted between the C—C single bonds of the hydrocarbon moiety.

- Aspect 10 can be combined with one of Aspects 1-9 or two or more aspects that can be juxtaposed.

- the blood slipperiness imparting agent includes the following (A) to (F): (A) (A1) a compound having a chain hydrocarbon moiety and 2 to 4 hydroxyl groups substituting hydrogen atoms in the chain hydrocarbon moiety, (A2) a chain hydrocarbon moiety, and the chain An ester with a compound having one carboxyl group for substituting a hydrogen atom in the hydrocarbon moiety, (B) (B1) a compound having a chain hydrocarbon moiety and 2 to 4 hydroxyl groups substituting for hydrogen atoms in the chain hydrocarbon moiety, (B2) a chain hydrocarbon moiety, and the chain An ether with a compound having one hydroxyl group replacing a hydrogen atom of the hydrocarbon moiety, (C) (C1) a carboxylic acid, a hydroxy acid, an alkoxy acid or an oxo acid containing a chain hydrocarbon moiety and 2 to 4 carboxyl groups replacing the hydrogen atom of the chain

- Aspect 11 can be combined with one of Aspects 1 to 10 or two or more aspects that can be juxtaposed.

- the blood slipperiness imparting agent is (a 1 ) an ester of a chain hydrocarbon tetraol and at least one fatty acid, (a 2 ) a chain carbonization.

- An ester of hydrogen triol and at least one fatty acid (a 3 ) an ester of a chain hydrocarbon diol and at least one fatty acid, and (b 1 ) a chain hydrocarbon tetraol and at least one aliphatic monohydric alcohol.

- the blood slipperiness imparting agent has a vapor pressure of 0.00 to 0.01 Pa at 1 atm and 40 ° C.

- Aspect 13 can be combined with one of Aspects 1-12 or two or more aspects that can be juxtaposed.

- the kind and application of the absorbent article of the present invention are not particularly limited.

- the absorbent article include sanitary products and sanitary products such as sanitary napkins and panty liners, and these may be used for humans and non-human animals such as pets.

- the liquid to be absorbed by the absorbent article is not particularly limited, but is mainly liquid excrement such as menstrual blood.

- an embodiment of the absorbent article of the present invention will be described based on the drawings, taking a sanitary napkin as an example.

- a sanitary napkin 1 according to an embodiment of the absorbent article of the present invention includes a liquid-permeable top sheet 2, a liquid-impermeable back sheet 3, and a top sheet 2. And an absorbent body 4 provided between the back sheets 3.

- the X-axis direction corresponds to the width direction of the sanitary napkin 1

- the Y-axis direction corresponds to the longitudinal direction of the sanitary napkin 1

- the plane direction extending in the X-axis Y-axis direction corresponds to the plane direction of the sanitary napkin 1.

- the sanitary napkin 1 is worn for the purpose of absorbing liquid excretion such as menstrual blood.

- the top sheet 2 is worn on the skin side of the wearer, and the back sheet 3 is worn on the clothes (underwear) side of the wearer.

- Liquid excreta such as menstrual blood passes through the top sheet 2 to reach the absorber 4 and is absorbed and held by the absorber 4. Leakage of liquid excretion absorbed and held by the absorber 4 is prevented by the back sheet 3.

- the top sheet 2 and the back sheet 3 are joined at their longitudinal ends by seal portions 11 a and 11 b to form a main body portion 6, and end portions in the width direction are sealed portions 12 a. , 12b and substantially rectangular wings 7a, 7b extending in the width direction from the main body 6 are formed.

- the shape of the main body portion 6 can be adjusted as appropriate within a range suitable for the wearer's body, underwear, etc. Examples of the shape of the main body portion 6 include a substantially rectangular shape, a substantially oval shape, and a generally saddle shape. .

- the total length in the longitudinal direction of the main body 6 is usually 100 to 500 mm, preferably 150 to 350 mm.

- the total length in the width direction of the main body 6 is usually 30 to 200 mm, preferably 40 to 180 mm.

- Examples of the bonding mode by the seal portions 11a, 11b, 12a, and 12b include embossing, ultrasonic waves, hot-melt adhesives, and the like. In order to increase the bonding strength, two or more bonding modes may be combined (for example, embossing is performed after bonding with a hot-melt adhesive).

- embossing for example, a method of embossing by passing the top sheet 2 and the back sheet 3 together between an embossing roll having a patterned convex portion and a flat roll (a method called a so-called round seal), etc. Is mentioned.

- the emboss pattern include a lattice pattern, a staggered pattern, and a wavy pattern.

- the hot melt adhesive for example, styrene-ethylene-butadiene-styrene (SEBS), styrene-butadiene-styrene (SBS), styrene-isoprene-styrene (SIS), or the like, or linear Pressure-sensitive adhesives or heat-sensitive adhesives mainly composed of olefins such as low density polyethylene; water-soluble polymers (for example, polyvinyl alcohol, carboxymethyl cellulose, gelatin, etc.) or water-swellable polymers (for example, polyvinyl acetate, poly And water sensitive adhesives such as sodium acrylate).

- the method for applying the adhesive include spiral coating, coater coating, curtain coater coating, and summit gun coating.

- adhesive portions 13 a and 13 b are provided on the clothing side of the backsheet 3 that forms the wing portions 7 a and 7 b, and on the clothing side of the backsheet 3 that forms the main body portion 6, An adhesive portion 13c is provided.

- the sanitary napkin 1 is obtained by attaching the adhesive part 13c to the crotch part of the underwear, bending the wing parts 7a and 7b to the outer surface side of the underwear, and attaching the adhesive parts 13a and 13b to the crotch part of the underwear. Stablely fixed to underwear.

- Examples of the adhesive contained in the adhesive portions 13a, 13b, and 13c include styrene-ethylene-butylene-styrene block copolymers, styrene-butylene polymers, styrene-butylene-styrene block copolymers, and styrene-isobutylene- Styrene polymers such as styrene copolymers; tackifiers such as C5 petroleum resins, C9 petroleum resins, dicyclopentadiene petroleum resins, rosin petroleum resins, polyterpene resins, terpene phenol resins; trifresyl phosphate, phthalic acid Examples include monomer plasticizers such as dibutyl and dioctyl phthalate; polymer plasticizers such as vinyl polymer and polyester.

- the top sheet 2 is a sheet through which liquid excretion such as menstrual blood can pass.

- One surface (upper surface in FIG. 2) of the top sheet 2 is a skin contact surface with which the wearer's skin comes into contact, and the other surface (lower surface in FIG. 2) is an absorption on which the absorber 4 is disposed. It is a body placement surface.

- the top sheet 2 examples include a non-woven fabric, a synthetic resin film in which liquid permeation holes are formed, and a laminate of a synthetic resin film and a non-woven fabric, and a non-woven fabric is preferable.

- a nonwoven fabric an air through nonwoven fabric, a heat bond nonwoven fabric, a spun bond nonwoven fabric, a melt blown nonwoven fabric, a spunlace nonwoven fabric, a needle punch nonwoven fabric, etc. are mentioned, for example.

- the top sheet 2 contains a heat-fusible fiber as a constituent fiber.

- the constituent fibers of the top sheet 2 are heat-sealed by melting and solidifying the heat-fusible fibers, whereby the uneven shape of the top sheet 2 is maintained. Further, when the sanitary napkin 1 is used, it is difficult for fibers to fall out and fluff from the top sheet 2.

- the heat-fusible fiber examples include a heat-fusible fiber made of a thermoplastic resin such as polyolefin, polyester, or polyamide.

- a thermoplastic resin such as polyolefin, polyester, or polyamide.

- the polyolefin include, for example, linear low density polyethylene (LLDPE), low density polyethylene (LDPE), medium density polyethylene (MDPE), high density polyethylene (HDPE), polypropylene, polybutylene, and copolymers based on these (for example, Ethylene-vinyl acetate copolymer (EVA), ethylene-ethyl acrylate copolymer (EEA), ethylene-acrylic acid copolymer (EAA), ethylene-propylene random copolymer (EP)), and the like.

- LLDPE linear low density polyethylene

- LDPE low density polyethylene

- MDPE medium density polyethylene

- HDPE high density polyethylene

- EVA Ethylene-vinyl acetate copolymer

- Polyethylene particularly HDPE, is preferred because it has a relatively low softening point of around 100 ° C. and is excellent in heat workability, and has low rigidity and a supple feel.

- the polyester include linear or branched carbon atoms of up to 20 including polyethylene terephthalate (PET), polytrimethyl terephthalate (PTT), polybutylene terephthalate (PBT), polylactic acid, and polyglycolic acid. And polyesters such as polyhydroxyalkanoic acid, copolymers based on these, and copolymerized polyesters obtained by copolymerizing alkylene terephthalate as a main component with a small amount of other components. Since it has elastic resilience, it is possible to construct fibers and nonwoven fabrics having high cushioning properties, and PET is preferred from the economical point of being obtained industrially at a low cost.

- the polyamide include 6-nylon and 6,6-nylon.

- the fiber diameter of the heat-fusible fiber is usually 5 to 100 ⁇ m, preferably 10 to 40 ⁇ m, and the fineness of the heat-fusible fiber is usually 0.5 to 10 dtex, preferably 1 to 5 dtex.

- the content of the conductive fiber is usually 10 to 100% by mass, preferably 50 to 100% by mass, based on the entire constituent fibers of the top sheet 2.

- the top sheet 2 preferably contains a thermally stretchable fiber as a constituent fiber. Due to the thermal elongation of the heat-extensible fibers, effective uneven shaping is possible. Moreover, the heat

- the heat-extensible fiber may be a fiber whose actual fiber length is elongated by heat treatment (for example, a fiber whose actual fiber length is elongated due to a change in the crystalline state of the resin). Fibers that do not elongate but have an apparent fiber length (for example, crimped fibers in which the apparent fiber length is elongated by releasing the crimps such as zigzag, ⁇ , and spiral) It may be.

- the heat-extensible fibers include two types of resins having different melting points or softening points (resins having a relatively high melting point or softening point are called “high melting point resins”, and resins having a relatively low melting point are “low melting point resins”. And a two-component heat-extensible composite fiber in which a low melting point resin is continuously present in the length direction on at least a part of the fiber surface.

- the high-melting point resin is a component that develops heat extensibility

- the low melting point resin is a component that develops heat-fusibility

- the heat-extensible composite fiber is heated at a temperature lower than the melting point of the high-melting point resin component. It is extensible.

- the kind of the high melting point resin and the low melting point resin is not particularly limited as long as it has fiber forming ability.

- the melting point difference or softening point difference between the high melting point resin and the low melting point resin is usually 20 ° C. or higher, preferably 25 ° C. or higher.

- the melting point of the high melting point resin and the low melting point resin for example, the melting point measured by the following method is used. Using a differential scanning calorimeter (for example, DSC6200, manufactured by Seiko Instruments Inc.), a finely cut fiber sample (for example, 2 mg sample) was subjected to thermal analysis at a heating rate of 10 ° C./min to melt each resin. The peak temperature is measured and the measured melting peak temperature is defined as the melting point. When the melting point of the resin cannot be clearly measured by this method, the temperature at which the resin is fused to such an extent that the fiber fusing point strength can be measured as the temperature at which the molecular flow of the resin begins, is used as the softening point. Used for.

- a differential scanning calorimeter for example, DSC6200, manufactured by Seiko Instruments Inc.

- the orientation index of the high melting point resin and the low melting point resin can be appropriately adjusted depending on the type of the resin.

- the orientation index is usually 60% or less, preferably 40% or less, and more preferably 25% or less.

- polyester is used as the high melting point resin

- the orientation index is usually 25% or less, preferably 20% or less, more preferably 10% or less.

- the orientation index of the low melting point resin is usually 5% or more, preferably 15% or more, and more preferably 30% or more.

- the orientation index of the high melting point resin and the low melting point resin is an index of the degree of orientation of the polymer chain of the resin constituting the fiber, and is calculated by the following formula.

- Orientation index (%) X / Y ⁇ 100 [Wherein, X is the value of birefringence of the resin in the heat-extensible conjugate fiber, and Y is the value of intrinsic birefringence of the resin. ]

- the birefringence (X in the above formula) of the resin in the heat-extensible composite fiber is measured, for example, with a polarizing plate attached to an interference microscope and polarized light in a direction parallel to and perpendicular to the fiber axis.

- the immersion liquid for example, a standard refraction liquid manufactured by Cargille is used.

- the refractive index of the immersion liquid is measured by, for example, an Abbe refractometer. From the interference fringe image of the composite fiber obtained by the interference microscope, a known method (for example, Journal of the Fiber Society, “Fiber structure formation in high-speed spinning of core-sheath type composite fiber”, Vol. 51, No. 9, No. 408). Page, 1995), the refractive index in the direction parallel and perpendicular to the fiber axis is obtained, and the birefringence which is the difference between the two is calculated.

- the intrinsic birefringence of the resin (Y in the above formula) is the birefringence in a state where the polymer polymer chains are perfectly oriented, and the value is, for example, the first edition of “Plastic material in molding process”, and the attached surface molding process. It is described in typical plastic materials used (edited by the Japan Society for Plastic Processing), Sigma Publishing, published on February 10, 1998.

- the thermal elongation rate of the heat-stretchable composite fiber at a temperature 10 ° C. higher than the melting point or softening point of the low-melting resin is preferably 0.5 to 20%, more preferably 3 to 20%, still more preferably 7.5 to 20%.

- the thermal elongation rate for example, the thermal elongation rate measured by the following method is used.

- a thermomechanical analyzer TMA-50 manufactured by Shimadzu Corp.

- TMA-50 was mounted with parallel fibers arranged at a distance of 10 mm between chucks, and a constant load of 0.025 mN / tex was applied at a heating rate of 10 ° C./min. Raise the temperature.

- the change in the elongation rate of the fiber at that time was measured, and the elongation rate at the melting point or softening point of the low melting point resin and the elongation rate at a temperature 10 ° C. higher than the melting point or softening point of the low melting point resin were read.

- the thermal elongation rate for example, the thermal elongation rate measured by the following method is used.

- a thermomechanical analyzer TMA-50 manufactured by Shimadzu Corp.

- the reason why the thermal elongation rate is measured in the above temperature range is that, when the fiber intersection is heat-sealed, the temperature range is higher than the melting point or softening point of the low-melting resin and up to about 10 ° C. Is usually adopted.

- the heat-extensible conjugate fiber can take the form of a core-sheath type (concentric type, eccentric type), a side-by-side type, or the like.

- the sheath component and the core component can be composed of a low melting point resin and a high melting point resin, respectively.

- the core component include polypropylene (PP), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), and the like.

- the sheath component when the core component is PP include polyethylene (PE) such as high density polyethylene (HDPE), low density polyethylene (LDPE), and linear low density polyethylene (LLDPE), and an ethylene propylene copolymer. , Polystyrene and the like.

- the sheath component when the core component is PET, PBT, and the like include PP and copolymer polyester.

- the ratio (weight ratio) of the low-melting point resin to the high-melting point resin in the heat-stretchable composite fiber can be appropriately adjusted in consideration of the heat-stretchability, heat-fusibility, mechanical properties, etc. of the fiber. 90 to 90:10, preferably 20:80 to 80:20, and more preferably 50:50 to 70:30.

- the thickness of the heat-extensible composite fiber can be adjusted to, for example, 1.0 to 10 dtex (particularly 1.7 to 8.0 dtex).

- the fiber length of the heat-extensible composite fiber is, for example, about 30 to 70 mm. Can be adjusted.

- a heat-extensible conjugate fiber having a desired thermal elongation rate can be produced, for example, by subjecting a spun conjugate fiber to a heat treatment or a crimping treatment without performing a drawing treatment.

- the conditions of the heat treatment applied to the composite fiber after spinning can be appropriately adjusted according to the types of the high melting point resin and the low melting point resin constituting the composite fiber.

- the heating temperature is usually 50 to 120 ° C., preferably 70 to 100 ° C.

- the heating time is usually 10 ° C. It is ⁇ 500 seconds, preferably 20 to 200 seconds.

- the heating medium include hot air and infrared rays.

- Examples of the crimping treatment performed on the spun composite fiber include mechanical crimping.

- the crimp may be in either a two-dimensional or three-dimensional manner, or a three-dimensional manifested crimp seen in an eccentric core-sheath composite fiber, side-by-side composite fiber, or the like. It may be.

- the mechanical crimping involves heat, the heating process and the crimping process are performed simultaneously.

- the fiber may be slightly stretched in the crimping process, but such stretching is not included in the stretching process.

- the drawing treatment usually means a drawing operation with a draw ratio of about 2 to 6 times performed on an undrawn yarn.

- the top sheet 2 may contain fibers other than heat-fusible fibers and heat-extensible fibers.

- fibers other than the heat-fusible fiber and the heat-extensible fiber include natural fibers (wool, cotton, etc.), regenerated fibers (rayon, acetate, etc.), inorganic fibers (glass fiber, carbon fiber, etc.), and the like.

- the content of the other fibers can be appropriately adjusted, but is usually 95% by weight or less, preferably 80% by weight or less of the top sheet 2.

- the skin contact surface of the top sheet 2 has a large number of convex portions 8 and concave portions 9, and the skin contact surface of the top sheet 2 has an uneven shape. . Since the skin contact surface of the top sheet 2 is uneven, the contact area between the wearer's skin and the top sheet 2 is small, and the air permeability in the surface direction of the top sheet 2 through the space in the recess 9 is good. is there. Therefore, it is difficult to give the wearer stuffiness and itching.

- the convex portion 8 and the concave portion 9 are formed on substantially the entire absorber arrangement region including the excretory opening abutting region 20 in the skin contact surface of the top sheet 2. 9 should just be formed in the excretion opening

- FIG. The absorber arrangement region is a region where the absorber 4 overlaps the top sheet 2 when the absorber 4 is projected onto the top sheet 2.

- the excretion opening contact area 20 is an area where the wearer's excretion opening (for example, small labia, large labia, etc.) abuts when the sanitary napkin 1 is worn.

- the excretory opening contact region 20 is a region surrounded by a dotted line in FIG. 1, and is set at substantially the center of the absorber arrangement region. The position, area, and the like of the excretion opening contact region 20 can be adjusted as appropriate.

- the excretory opening contact area 20 may be set as an area substantially the same as the area where the excretion opening actually contacts, or may be set as a larger area, but liquid excrement such as menstrual blood From the viewpoint of preventing leakage to the outside, it is preferably set as a region larger than the region where the excretion port actually contacts.

- the excretion opening contact region 20 has a length of usually 50 to 200 mm, preferably 70 to 150 mm, and a width of usually 10 to 80 mm, preferably 20 to 50 mm.

- the excretory opening contact area 20 is set as a virtual area, but may be set as a visually recognizable area.

- Visual recognition includes, for example, coloring of the excretory opening contact region 20 and formation of a recess (for example, a recess formed by a heat embossing process) extending continuously or intermittently along the periphery of the excretion opening contact region 20. Etc. are possible.

- substantially the entire excretory opening contact region 20 has a kinematic viscosity at 40 ° C. of 0.01 to 80 mm 2 / s, a water retention of 0.01 to 4.0% by mass, and a weight average molecular weight.

- the blood slipperiness imparting agent which is less than 1,000 is applied. Refer to the separate item for details of the blood slipperiness-imparting agent.

- the blood slipperiness imparting agent is applied to substantially the entire excretory opening contact region 20, but the blood slipperiness imparting agent is at least the convex portion 8 (particularly convex in the excretion port contact region 20. It only has to be applied to the top 81) of the part 8.

- the blood slipperiness imparting agent is applied to at least the convex portion 8 in the excretory opening contact region 20, it is applied to a portion other than the convex portion 8 (for example, the concave portion 9).

- it may be applied to a region other than the excretion opening contact area 20 (for example, a peripheral area of the excretion opening contact area 20) on the skin contact surface.

- the blood slipperiness-imparting agent can be applied to substantially the entire skin contact surface or substantially the entire absorber arrangement region.

- the blood slipperiness imparting agent When the blood slipperiness imparting agent is applied to at least the convex portion 8 (particularly, the top portion 81 of the convex portion 8) in the excretory opening contact region 20, the following effects are exhibited.

- menstrual blood excreted from the wearer reaches the excretory opening contact region 20, it slides down into the concave portion 9 together with the blood slipperiness imparting agent present in the convex portion 8, passes through the top sheet 2, and shifts to the absorber 4. . Therefore, the sanitary napkin 1 has improved menstrual blood transfer from the top sheet 2 to the absorbent body 4, and can reduce menstrual blood remaining on the top sheet 2. For this reason, the sticky feeling of the skin contact surface of the top sheet 2 is prevented, and a smooth feeling is maintained. The effect of such a blood slipperiness-imparting agent is exerted irrespective of changes in menstrual blood discharge (that is, whether menstrual blood discharged at a time is large or small). .

- the convex side wall 82 extends from the top 81 of the convex 8 toward the bottom 91 of the concave portion 9, and the concave side wall 92 starts from the bottom 91 of the concave 9.

- the convex side wall 82 has a fiber orientation along the extending direction, that is, the direction from the top 81 of the convex 8 toward the bottom 91 of the concave 9, and the concave side 92 is extended. It has fiber orientation along the direction, that is, the direction from the bottom 91 of the concave portion 9 to the top 81 of the convex portion 8.

- menstrual blood excreted from the wearer easily slides along the extending direction of the convex side wall portion 82 and the concave side wall portion 92 together with the blood slipperiness imparting agent.

- menstrual blood excreted from the wearer does not spread in the surface direction of the top sheet 2 and easily moves in the thickness direction of the top sheet 2 (that is, to the absorber 4).

- lubricity imparting agent exhibits effectively. Is done.

- the effect of the blood slipperiness imparting agent can be enhanced by applying the blood slipperiness imparting agent to the concave portion 9 in addition to the convex portion 8.

- lubricity imparting agent acts also as a lubrication agent and reduces the friction between fibers, the suppleness of the whole top sheet 2 can be improved.

- the sanitary napkin 1 is different from known absorbent articles including skin care compositions, lotion compositions, etc., and does not require components such as emollients and immobilizing agents. It can be applied to the sheet 2.

- the basis weight of the blood slipperiness imparting agent is usually about 1 to 30 g / m 2 , preferably about 2 to 20 g / m 2 , more preferably about 3 to 10 g / m 2 .

- the basis weight of the blood slipperiness-imparting agent is less than about 1 g / m 2 , menstrual blood tends to remain in the top sheet 2, while when the basis weight of the blood slipperiness-imparting agent exceeds about 30 g / m 2 , The sticky feeling during wearing tends to increase.

- the basis weight of the blood slipperiness imparting agent can be measured, for example, by the following method.

- (1) The range to be measured of the top sheet is cut out with a sharp blade, for example, a cutter blade, so as not to change its thickness as much as possible, and a sample is obtained.

- (2) The area of the sample: SA (m 2 ) and the mass: SM 0 (g) are measured.

- (3) The sample is stirred for at least 3 minutes in a solvent capable of dissolving the blood lubricity-imparting agent, such as ethanol, acetone, etc., and the blood lubricity-imparting agent is dissolved in the solvent.

- a solvent capable of dissolving the blood lubricity-imparting agent such as ethanol, acetone, etc.

- the sample is filtered on the filter paper whose mass has been measured, and the sample is thoroughly washed with a solvent on the filter paper.

- the sample on the filter paper is dried in an oven at 60 ° C.

- the mass of the filter paper and the sample is measured, and the mass of the filter paper is subtracted therefrom to calculate the mass of the sample after drying: SM 1 (g).

- the basis weight BBS (g / m 2 ) of the blood slipperiness-imparting agent is calculated based on the following formula.

- BBS (g / m 2 ) [SM 0 (g) ⁇ SM 1 (g)] / SA (m 2 )

- a plurality of samples are collected from a plurality of absorbent articles so that the total area of the samples exceeds 100 cm 2 , the experiment is repeated a plurality of times, and an average value thereof is adopted.

- the blood slipperiness-imparting agent is preferably applied so as not to block the gaps between the fibers of the topsheet 2.

- the blood slipperiness imparting agent adheres to the surface of the fiber of the top sheet 2 in the form of droplets or particles, or covers the surface of the fiber.

- the blood slipperiness-imparting agent is preferably coated so that its surface area becomes large. Thereby, the contact area of a blood slipperiness

- the surface area can be increased by reducing the particle size.

- Examples of the method for applying the blood slipperiness-imparting agent include a method using a coating apparatus (for example, a non-contact type coater such as a spiral coater, curtain coater, spray coater, dip coater, contact type coater, etc.).

- a coating apparatus for example, a non-contact type coater such as a spiral coater, curtain coater, spray coater, dip coater, contact type coater, etc.

- a preferred coating apparatus is a non-contact type coater.

- the blood slipperiness imparting agent can be applied as a coating liquid containing a volatile solvent, for example, an alcohol solvent, an ester solvent, an aromatic solvent, or the like, if desired.

- a volatile solvent for example, an alcohol solvent, an ester solvent, an aromatic solvent, or the like.

- the blood slipperiness-imparting agent is, for example, a control seam HMA (Hot Melt Adhesive) as it is in the case of a liquid at room temperature or heated to lower the viscosity and heated to be liquefied in the case of a solid at room temperature. ) Can be applied by gun. By increasing the air pressure of the control seam HMA gun, it is possible to apply a particulate blood slipping agent. In addition, the application quantity of a blood slipperiness

- a control seam HMA Hot Melt Adhesive

- the blood slipperiness-imparting agent may be applied when the top sheet 2 is produced, or may be applied on the production line of the sanitary napkin 1. From the viewpoint of suppressing capital investment, it is preferable to apply a blood slipperiness-imparting agent in the production line of the sanitary napkin 1, and further suppress the blood slipperiness-imparting agent from dropping and contaminating the line. Therefore, it is preferable to apply the blood slipperiness imparting agent immediately downstream of the production line, specifically, immediately before the product is enclosed in the individual package.

- the convex part 8 has protruded to the skin contact surface side (upper side in FIG. 2) of the top sheet 2, and the recessed part 9 has the absorber arrangement

- the convex portions 8 and the concave portions 9 are alternately arranged in the first direction and the second direction intersecting with the first direction.

- the first direction is an arbitrary direction in the skin contact surface of the top sheet 2

- the second direction is a direction that intersects the first direction in the skin contact surface of the top sheet 2.

- the first direction is the X direction

- the second direction is the Y direction

- the angle at which the first direction and the second direction intersect is 90 °.

- the first direction, the second direction, and the angle at which the first direction and the second direction intersect are not limited to the present embodiment, and can be changed as appropriate.

- the angle at which the first direction and the second direction intersect is preferably 30 to 90 °.

- the convex portions 8 and the concave portions 9 are alternately arranged in the X direction and the Y direction to form a row, and adjacent convex portions in the rows in the X direction and the Y direction.

- the recesses 9 are positioned between the eight recesses 8 (that is, four recesses 9 are positioned around one protrusion 8).

- the convex portions 8 are arranged so as to be shifted by a half pitch, so that when the top sheet 2 is viewed in plan, the arrangement pattern of the convex portions 8 is a staggered pattern.

- the concave portions 9 are arranged so as to be shifted by a half pitch, so that when the top sheet 2 is viewed in plan, the arrangement pattern of the concave portions 9 is a staggered pattern.

- the arrangement pattern of the convex part 8 and the recessed part 9 is not limited to this embodiment, It can change suitably.

- the number of concave portions 9 positioned around one convex portion 8 and the number of convex portions 8 positioned around one concave portion 9 can be appropriately selected.

- the height of the convex portion 8 is usually 0.2 to 15 mm, preferably 0.5 to 5 mm, the width (X direction) is usually 1 to 20 mm, preferably 2 to 10 mm, and the length (Y direction). ) Is usually 1 to 20 mm, preferably 2 to 10 mm, and the interval between the convex portions 8 (width or length of the concave portion 9) is usually 1 to 20 mm, preferably 2 to 10 mm.

- the convex part 8 has a top part 81 and a convex part side wall part 82 extending from the top part 81, and the concave part 9 is a bottom part 91 and a concave part side wall part 92 extending from the bottom part 91. And have.

- the external shape of the convex portion 8 and the concave portion 9 is hemispherical, the cross-sectional view shape is arched, and the planar view shape is circular.

- the external shape of the convex part 8 is a shape when the convex part 8 is seen from the skin contact surface of the top sheet 2

- the external shape of the concave part 9 is the concave part 9 from the absorber arrangement surface of the top sheet 2. It is the shape when seen.

- the shape of the convex part 8 and the recessed part 9 is not limited to this embodiment, It can change into another shape. Examples of other external shapes include cone shapes such as a cone, a truncated cone, a pyramid, a truncated pyramid, and an oblique cone. Examples of other planar shapes include an elliptical shape, a rectangular shape, and a polygonal shape. Can be mentioned.

- the inside of the convex part 8 is hollow.

- a ridge-shaped connecting portion may be formed between the adjacent convex portions 8 and between the adjacent concave portions 9.

- the internal spaces of the adjacent convex portions 8 may or may not communicate with each other through this connecting portion.

- the convex portion side wall portion 82 When the skin contact surface side of the top sheet 2 is set to the upper side and the absorber arrangement surface side is set to the lower side, the convex portion side wall portion 82 has a tapered shape whose diameter gradually increases downward. Has a tapered shape with a diameter gradually increasing upward.

- the convex side wall portion 82 extends downward from the top portion 81, and the lower end portion thereof is continuous with the upper end portion of the concave side wall portion 92 extending upward from the bottom portion 91. That is, the convex side wall 82 extends in the direction from the top 81 to the bottom 91, and the concave side wall 92 extends in the direction from the bottom 91 to the top 81. Accordingly, the extending direction of the convex side wall 82 is a direction from the top 81 to the bottom 91, and the extending direction of the concave side wall 92 is a direction from the bottom 91 to the top 81.

- the shape of the convex side wall portion 82 and the concave side wall portion 92 is not limited to the shape of the present embodiment, and can be changed to other shapes. Examples of other shapes include a cylindrical shape and a rectangular tube shape.

- the convex side wall portion 82 has fiber orientation along the extending direction (that is, the direction from the top portion 81 to the bottom portion 91), and the concave side wall portion 92 is extended in the extending direction (that is, from the bottom portion 91 to the top portion). Fiber orientation along the direction toward 81).

- the convex side wall portion 82 and the concave side wall portion 92 are developed, the convex side wall portion 82 has a fiber orientation OR along its extending direction D 82.

- the recess side wall portion 92 has a fiber orientation OR 92 along the extending direction D 92 thereof.

- the convex side wall 82 has a radial fiber orientation that converges toward the top 81

- the concave side wall 92 is a radial fiber that converges toward the bottom 91.

- the convex side wall portion 82 and the concave side wall portion 92 have fiber orientation along the respective extending directions, whereby the fiber orientation in the thickness direction of the top sheet 2 is increased.

- the compression deformation property and compression recovery property (cushion property) of No. 2 are improved. Therefore, even if the sanitary napkin 1 is compressed, liquid return (rewetting back) from the absorbent body 4 hardly occurs. Moreover, since the cushioning property of the top sheet 2 is high, the wearer is given good comfort.

- the convex side wall portion 82 and the concave side wall portion 92 have substantially the same fiber orientation throughout the circumferential direction, but have portions with different fiber orientations. It may be.

- the convex part side wall part 82 and the concave part side wall part 92 may have a part in which the fiber orientation before uneven forming is maintained.

- the fiber orientation before the uneven shaping is maintained even after the uneven shaping.

- the portions having different fiber orientations have, for example, fiber orientations along a direction orthogonal to the extending direction of the convex side wall portions 82 or the concave side wall portions 92.

- the fibers are usually heat-sealed in a state where the fibers are oriented in the MD direction, the fibers are formed on the convex side wall portions 82 and the concave side wall portions 92 in the MD direction cross section. Although oriented in the extending direction of the side wall 92, the fibers are oriented in the direction perpendicular to the extending directions of the convex side wall 82 and the concave side wall 92 in the cross section in the CD direction.

- Fiber orientation is a concept consisting of the orientation angle and orientation strength of the fiber, and can be measured, for example, by the following method.

- the sample is allowed to stand so that the skin contact surface of the top sheet is positioned on the upper side.

- a microscope for example, a scanning electron microscope such as JCM-5100 manufactured by JEOL Ltd.

- an enlarged image is taken from a direction perpendicular to the measurement surface of the sample, printed, and transparent PET property Trace the fiber on the sheet.

- the enlarged image is an image enlarged to a magnification capable of measuring 10 or more fibers, and the enlargement magnification is, for example, 50 to 300 times.

- the image is taken into a personal computer, and the image is binarized by using a NexusNewQube (stand-alone version) image processing software manufactured by Nexus Corporation.

- the orientation angle is the angle at which the fibers are most oriented

- the orientation strength is the strength at that orientation angle. It shows that the fiber is orientating in the extending direction of a convex part side wall part or a recessed part side wall part, so that an orientation angle is near 90 degrees. Moreover, it shows that the direction of a fiber has gathered, so that orientation strength is large.

- the case where the orientation strength is 1.05 or more is assumed to be oriented. The measurement is repeated several times (for example, 3 to 5 times), and the average value is calculated.

- the fiber orientation at the top 81 of the convex portion 8 is different from the fiber orientation at the bottom 91 of the concave portion 9. That is, the fiber orientation OR 81 at the top 81 of the convex portion 8 is along the thickness direction, but the fiber orientation OR 91 at the bottom 91 of the concave portion 9 is not along the thickness direction. Along the direction perpendicular to the thickness direction.

- the orientation angle is preferably 50 ° to 130 °, and the orientation strength is preferably 1.05 or more.

- the orientation angle is preferably 0 ° to 50 ° or 130 ° to 180 °, and the orientation strength is preferably less than 1.05.

- the fiber orientation in the thickness direction at the bottom 91 of the recess 9 is preferably smaller than the fiber orientation in the thickness direction at the recess side wall 92. Thereby, menstrual blood easily moves in the thickness direction (that is, to the absorbent body 4) without accumulating in the recess side wall portion 92.

- the fiber orientation in the recessed part 9 changes in a direction perpendicular to the thickness direction as the absorber 4 is approached, whereby a gradient occurs in the fiber orientation, and menstrual blood is easily transmitted and diffused.

- the orientation angle of the recess side wall portion 92 is preferably 50 ° to 130 °, and the orientation strength is preferably 1.05 or more.

- the orientation angle of the bottom 91 of the recess 9 is preferably 0 ° to less than 50 ° or 130 ° to 180 °, and the orientation strength is preferably less than 1.05.

- the relationship between the fiber orientation OR 81 at the top 81 of the convex portion 8 and the fiber orientation OR 91 at the bottom 91 of the concave portion 9 is preferably OR 81 > OR 91 .

- the top part 81 of the convex part 8 has the compressive deformation property and compression recovery property (flexibility) superior to the bottom part 91 of the concave part 9.

- the fiber orientation in the skin contact surface side portion and the fiber orientation in the absorbent body placement surface side portion are substantially equal. That is, it is preferable that radial fiber orientation toward the bottom portion 91 of the recess 9 exists in both the skin contact surface side portion and the absorber arrangement surface side portion. Thereby, the compression deformability and the compression recovery property (flexibility) of the bottom 91 of the recess 9 are improved, and the bottom 91 of the recess 9 is not easily crushed.

- the fiber density of the top part 81 of the convex part 8 may be smaller or larger than the fiber density of the bottom part 91 of the concave part 9. Since the liquid easily moves from the lower fiber density to the higher fiber density according to the density gradient, when the fiber density at the top 81 of the convex portion 8 is smaller than the fiber density at the bottom 91 of the concave portion 9, the sanitary napkin 1 is Combined with the action and effect of the blood slipperiness-imparting agent, it has improved menstrual blood transfer from the top sheet 2 to the absorber 4.

- the liquid is less likely to move from the higher fiber density to the lower fiber density

- the fiber density at the top 81 of the convex portion 8 is smaller than the fiber density at the bottom 91 of the concave portion 9

- menstrual blood migration is less than the fiber density.

- the sanitary napkin 1 has an improved menstrual transfer property from the top sheet 2 to the absorbent body 4 due to the action effect of the blood slipperiness imparting agent. Therefore, the effect of the blood slipperiness imparting agent is remarkable when the fiber density of the top portion 81 of the convex portion 8 is larger than the fiber density of the bottom portion 91 of the concave portion 9.

- the fiber density of the top portion 81 of the convex portion 8 is larger than the fiber density of the bottom portion 91 of the concave portion 9, the followability of the uneven shape of the top sheet 2 to the wearer's skin becomes good, so the wearer Good comfort when rearranging and walking.

- the fiber density can be measured, for example, by the following method.

- the cut surface of the top sheet 2 is magnified and observed using a microscope (for example, a scanning electron microscope such as JCM-5100 manufactured by JEOL Ltd.).

- the magnification is adjusted to a magnification (for example, 150 to 500 times) at which 30 to 60 fiber cross sections can be measured.

- the fiber density (lines / mm 2 ) is calculated based on the number of fiber cross sections and the visual field area where the number of fiber cross sections is measured. Perform measurements at several locations (for example, 3 to 5 locations) and calculate the average value.

- the fiber density of the top portion 81 of the convex portion 8 measured in this way is preferably 30 to 150 pieces / mm 2 , more preferably 60 to 100 pieces / mm 2 , and the fiber density of the bottom portion 91 of the concave portion 9 is The number is preferably 150 to 600 / mm 2 , more preferably 300 to 550 / mm 2 .

- the fiber amount of the top part 81 of the convex part 8 and the fiber amount of the bottom part 91 of the recessed part 9 are substantially equal. Thereby, compression deformation property and compression recovery property improve. In addition, changes in feel and breakage due to fiber unevenness are less likely to occur.

- the fiber amount can be measured, for example, by the following method. Using a microscope (for example, Keyence digital microscope VHX-1000), the measurement site is enlarged. The enlargement magnification is, for example, 10 to 100 times. The thickness of the top of the convex part (T 81 in FIG. 4A) and the thickness of the bottom of the concave part (T 91 in FIG.

- the fiber density of the skin contact surface side portion of the top portion 81 of the convex portion 8 is smaller than the fiber density of the absorber arrangement surface side portion. Thereby, compression deformation property and compression recovery property improve.

- the fiber density of the skin contact surface side portion of the top portion 81 of the convex portion 8 is preferably 10 to 50 fibers / mm 2 , more preferably 15 to 30 fibers / mm 2 , and the fiber density in the absorber arrangement surface side portion. Is preferably 20 to 100 / mm 2 , more preferably 45 to 70 / mm 2 .

- the ratio of the fiber density of the absorber placement surface side portion to the fiber density of the skin contact surface side portion is preferably about 2 to 5 times. Thereby, compression deformation property and compression recovery property improve.

- the number of fiber fusion points at the top portion 81 of the convex portion 8 is preferably smaller than the number of fiber fusion points at the bottom portion 91 of the concave portion 9. Thereby, the touch of the top sheet 2 becomes favorable.

- the number of fiber fusion points is calculated by counting the number of fiber fusion points per unit area (1 mm 2 ).

- the number of fiber fusion points at the top 81 of the convex portion 8 is preferably 30 to 130 pieces / mm 2 , more preferably 50 to 100 pieces / mm 2 .

- the number of fiber fusion points at the bottom 91 of the recess 9 is preferably 250 to 500 / mm 2 , more preferably 300 to 450 / mm 2 .

- the thickness T 81 of the top portion 81 of the convex portion 8 is usually 0.1 to 5 mm, preferably 0.3 to 2.5 mm

- the thickness T 82 of the convex side wall portion 82 is usually 0.1 to 5 mm, preferably Is 0.3 to 2.5 mm

- the thickness T 91 of the bottom 91 of the recess 9 is usually 0.1 to 5 mm, preferably 0.3 to 2.5 mm

- the thickness T 92 of the recess side wall 92 is The thickness is usually 0.1 to 5 mm, preferably 0.3 to 2.5 mm. It is preferable that the relationship between the thicknesses of the respective parts is T 81 > T 82 and T 92 > T 91 .

- the thickness of the top sheet 2 under a load of 3 gf / cm 2 is usually 0.2 to 20 mm, preferably 0.5 to 10 mm.

- the basis weight (average value of the entire sheet) of the top sheet 2 is usually 10 to 100 g / m 2 , preferably 20 to 50 g / m 2 .

- the presence / absence and degree of the fiber density gradient of the top sheet 2 contains a colored liquid (for example, a pigment).

- a colored liquid for example, a pigment

- (Liquid) is dropped, and the color density after dropping can be evaluated. That is, the dark part can be evaluated as a part with a large liquid migration amount, that is, a part with a relatively high fiber density, and the light color part has a small liquid migration amount, that is, a fiber density. It can be evaluated as a relatively small portion.

- the top sheet 2 may be hydrophilized.

- the hydrophilic treatment include coating of the surface of the top sheet 2 with a hydrophilic agent, addition of a hydrophilic agent to a component, corona treatment, plasma treatment, and the like.

- the lipophilic region derived from the blood slipping agent and the hydrophilic region derived from the hydrophilic agent coexist sparsely in the top sheet 2, and menstrual blood is in the top sheet 2. It slips down from the convex part 8 of this, and it becomes easy to transfer to an absorber.

- the back sheet 3 is a sheet through which liquid excretion such as menstrual blood cannot permeate, and can prevent leakage of liquid excretion absorbed by the absorber 4.

- One surface (upper surface in FIG. 2) of the back sheet is an absorber arrangement surface on which the absorber 4 is arranged, and the other surface (lower surface in FIG. 2) is a non-skin contact surface (this embodiment). Then, the wearer's clothes (underwear) are in contact with each other).

- the backsheet 3 preferably has moisture permeability in addition to liquid impermeability in order to reduce stuffiness when worn.

- backsheet 3 examples include waterproof nonwoven fabric, synthetic resin (eg, polyethylene, polypropylene, polyethylene terephthalate, etc.) film, and composite sheet of nonwoven fabric and synthetic resin film (eg, nonwoven fabric such as spunbond and spunlace). And a composite film in which a breathable synthetic resin film is bonded), an SMS nonwoven fabric in which a melt-blown nonwoven fabric having high water resistance is sandwiched between strong spunbond nonwoven fabrics, and the like.

- synthetic resin eg, polyethylene, polypropylene, polyethylene terephthalate, etc.

- composite sheet of nonwoven fabric and synthetic resin film eg, nonwoven fabric such as spunbond and spunlace

- SMS nonwoven fabric in which a melt-blown nonwoven fabric having high water resistance is sandwiched between strong spunbond nonwoven fabrics, and the like.

- the absorber 4 contains an absorbent material that absorbs liquid excreta such as menstrual blood.

- the absorbent material contained in the absorber 4 is not particularly limited as long as it can absorb and retain liquid excretion such as menstrual blood.

- Examples of the absorbent material include a water-absorbing fiber and a highly water-absorbing material (for example, a highly water-absorbing resin and a highly water-absorbing fiber).

- the absorber 4 includes additives such as an antioxidant, a light stabilizer, an ultraviolet absorber, a neutralizer, a nucleating agent, an epoxy stabilizer, a lubricant, an antibacterial agent, a flame retardant, an antistatic agent, a pigment, and a plasticizer. You may contain as needed.

- water-absorbing fibers include wood pulp obtained from softwood or hardwood (for example, mechanical pulp such as groundwood pulp, refiner ground pulp, thermomechanical pulp, chemithermomechanical pulp; kraft pulp, sulfide pulp, alkaline pulp, etc. Chemical pulp; semi-chemical pulp, etc.]; mercerized pulp or crosslinked pulp obtained by chemically treating wood pulp; non-wood pulp such as bagasse, kenaf, bamboo, hemp, cotton (eg cotton linter); rayon, fibril Examples include regenerated cellulose such as rayon; semi-synthetic cellulose such as acetate and triacetate, but pulverized pulp is preferred because it is low in cost and easy to mold.

- wood pulp obtained from softwood or hardwood for example, mechanical pulp such as groundwood pulp, refiner ground pulp, thermomechanical pulp, chemithermomechanical pulp; kraft pulp, sulfide pulp, alkaline pulp, etc. Chemical pulp; semi-chemical pulp, etc.]; mercerized pulp or crosslinked pulp obtained by chemically treating wood pulp;

- the superabsorbent material examples include starch, cellulose, and synthetic polymer superabsorbent materials.

- starch-based or cellulose-based superabsorbent material examples include starch-acrylic acid (salt) graft copolymers, saponified starch-acrylonitrile copolymers, and crosslinked products of sodium carboxymethyl cellulose.

- Synthetic polymers examples include polyacrylates, polysulfonates, maleic anhydrides, polyacrylamides, polyvinyl alcohols, polyethylene oxides, polyaspartates, polyglutamates , Polyalginate-based, starch-based, and cellulose-based superabsorbent resins (Superabsorbent Polymer: SAP), and the like. Resins are preferred.

- shape of the superabsorbent material include particulates, fibers, and scales. In the case of particulates, the particle size is preferably 50 to 1000 ⁇ m, more preferably 100 to 600 ⁇ m. .

- the absorbent body 4 contains a highly water-absorbing material (for example, highly water-absorbing resin, highly water-absorbing fiber, etc.), the content of the highly water-absorbing material is usually 5 to 80% by mass, preferably 10%. It is ⁇ 60 mass%, more preferably 20 to 40 mass%.

- a highly water-absorbing material for example, highly water-absorbing resin, highly water-absorbing fiber, etc.

- the absorber 4 may contain silver, copper, zinc, silica, activated carbon, aluminosilicate compound, zeolite or the like. Thereby, functions, such as a deodorizing property, antibacterial property, and an endothermic effect, can be provided to an absorber.

- the thickness, basis weight, etc. of the absorbent body 4 can be appropriately adjusted according to the characteristics (for example, absorbency, strength, lightness, etc.) that the sanitary napkin 1 should have.

- the thickness of the absorber 4 is usually 0.1 to 15 mm, preferably 1 to 10 mm, more preferably 2 to 5 mm, and the basis weight is usually 20 to 1000 g / m 2 , preferably 50 to 800 g / m 2 , 100 to 500 g / m 2 is preferable.

- the thickness, basis weight, etc. of the absorber 4 may be constant throughout the absorber 4 or may be partially different.

- the absorbent body 4 is preferably in a form having a core containing an absorbent material and a core wrap covering the core.

- the core wrap is not particularly limited as long as it has liquid permeability and absorber retention.

- Examples of the core wrap include a nonwoven fabric, a woven fabric, a synthetic resin film in which liquid permeation holes are formed, and a net-like sheet having a mesh.

- a wet method using pulverized pulp as a main material A tissue molded with is preferred.

- the sanitary napkin 1 may include a second sheet disposed between the top sheet 2 and the absorbent body 4 in addition to the top sheet 2.

- the blood slipperiness imparting agent may be applied to the second sheet.

- the second sheet is not particularly limited as long as liquid excretion such as menstrual blood can permeate, and the thickness, basis weight, density, etc. of the second sheet are appropriately adjusted within a range where liquid excretion such as menstrual blood can permeate. can do.

- Examples of the second sheet include a nonwoven fabric, a woven fabric, a synthetic resin film in which liquid permeation holes are formed, and a net-like sheet having a mesh.

- Examples of the nonwoven fabric include air-through nonwoven fabric, spunbond nonwoven fabric, point bond nonwoven fabric, spunlace nonwoven fabric, needle punched nonwoven fabric, melt blown nonwoven fabric, and combinations thereof (for example, SMS).

- natural fibers wool, cotton, etc.

- regenerated fibers rayon, acetate, etc.

- inorganic fibers glass fibers, carbon fibers, etc.

- synthetic resin fibers polyethylene, polypropylene, polybutylene, ethylene-vinyl acetate copolymer, Polyolefins such as ethylene-ethyl acrylate copolymer, ethylene-acrylic acid copolymer, ionomer resin; polyesters such as polyethylene terephthalate, polybutylene terephthalate, polytrimethylene terephthalate, polylactic acid; De), and the like.

- Nonwoven fabrics include core / sheath fibers, side-by-side fibers, island / sea fibers, etc .; hollow fibers; flat fibers, Y-shaped fibers, C-shaped fibers, etc .; latent crimps or manifestations Crimped three-dimensional crimped fibers; split fibers that are split by a physical load such as water flow, heat, and embossing may be mixed.

- the manufacturing method which concerns on this embodiment cuts out the process (process 1) of laminating an absorber, the process of laminating a top sheet (process 2), the process of laminating a back sheet (process 3), and a sanitary napkin.

- a manufacturing apparatus 200 shown in FIG. 6 is used, including a step (step 4) and a step (step 5) of applying a blood slipperiness-imparting agent to a sanitary napkin.

- Step 1 On the peripheral surface of the suction drum 220 that rotates in the transport direction MD, recesses 224 are formed at a required pitch in the circumferential direction as a mold for filling the absorbent material 222.

- the suction unit 226 acts on the recess 224, and the absorber material 222 supplied from the material supply unit 221 is sucked into the recess 224 by vacuum.

- the material supply unit 221 is formed so as to cover the suction drum 220, and the material supply unit 221 supplies the absorber material 222 to the recess 224 by air conveyance, and the absorber 4 is formed in the recess 224.

- the absorber 4 formed in the recess 224 is transferred onto the carrier sheet 210 that proceeds in the transport direction MD.

- the top sheet 2 is laminated on the absorber 4 to form a laminate LB1.

- the manufacturing method of the top sheet 2 is mentioned later.

- a pressing groove is formed in the laminated body LB1 as necessary.

- the compressed groove is formed by the embossing device 230.

- the embossing device 230 includes an upper roll 231 having a convex portion (not shown) provided on the outer peripheral surface, and a lower roll 232 having a smooth outer peripheral surface.

- the convex portion of the upper roll 231 is formed so as to correspond to the shape of the compressed groove, the arrangement pattern, and the like.

- the laminated body LB1 passes between the upper roll 231 and the lower roll 232 of the embossing device 230, the laminated body LB1 is compressed in the thickness direction, and a compressed groove is formed in the laminated body LB1.

- the compressed groove is formed, for example, in the periphery of the excretory opening contact area 20, the peripheral area of the peripheral area of the excretion opening contact area 20, or the like in the top sheet 2.

- the top sheet 2 is integrated with the absorbent body 4 by forming the compressed grooves.

- the pressing groove forming step by the embossing device 230 is omitted when it is not necessary.

- Step 3 The back sheet 3 supplied from the back sheet roll 240 is laminated on the lower surface (opposite side of the top sheet 2) of the laminated body LB2 via an adhesive layer to form the laminated body LB3.

- the laminated body LB2 and the laminated body LB3 are the same.

- Step 4 The laminate LB3 is cut using the cutter 250, and a sanitary napkin is cut out.

- the blood slipperiness imparting agent 261 is applied to the top sheet 2 of the sanitary napkin using the spray 260 to form a blood slipperiness imparting agent layer on the surface of the top sheet 2.

- the blood slipperiness-imparting agent layer is formed at least in the excretion opening contact region 20 in the skin contact surface of the top sheet 2.

- the blood slipperiness-imparting agent is applied after cutting out the sanitary napkin, but it may be applied at any stage before cutting out, or it may be applied in the top sheet manufacturing process. Good. In order to prevent the blood slipperiness-imparting agent applied during production from flowing down, it is preferable to apply the blood slipperiness-imparting agent immediately downstream of the manufacturing process, for example, immediately before packaging a sanitary napkin.

- the manufacturing method of the sanitary napkin 1 can include, in addition to steps 1 to 5, a step of forming the seal portions 7a, 7b, 8a, 8b, a step of forming the adhesive portions 9a, 9b, 9c, and the like.

- the conveyor belt 110 rotates in the conveying direction MD while being supported by the upper rollers 111a and 111b and the lower rollers 111c and 111d.

- a plurality of protrusions 112 are formed on the web conveyance surface of the conveyor belt 110, and the web conveyance surface is uneven. Further, a plurality of vent holes (not shown) are formed on the web conveyance surface of the conveyor belt 110.

- the protrusion 112 has a tapered shape whose diameter gradually decreases toward the tip, and the tip has a rounded shape.

- the height of the protrusion 112 is, for example, 0.5 to 20 mm. If the height of the projection 112 is too low, the uneven shaping on the fiber web 50 may be insufficient, while if too high, the projection 112 may penetrate the fiber web 50 when hot air is blown. . From this viewpoint, the height of the protrusion 112 is preferably 1 to 10 mm.

- the pitch of the protrusions 112 in the MD direction is 1 to 20 mm, and the pitch in the direction perpendicular to the MD direction (CD direction) is 1 to 20 mm.

- the CD direction coincides with the width direction of the fiber web 50.

- the opening ratio (total area of the air holes / surface area of the conveyor belt 110) of the air holes (not shown) is preferably 20 to 45%, more preferably 25 to 40%. If the opening ratio is too low, the uneven shaping on the fiber web 50 may be insufficient, while if it is too high, the fiber web 50 will enter the vent hole when hot air is blown, and it will be difficult to peel off from the conveyor belt 110.

- the conveyor belt 110 which is supported by the rollers 111a to 111d and rotates, supports the fiber web 50 by the protrusions 112 formed on the conveying surface thereof and conveys it in the MD direction.

- a pair of drive rolls 151 and 152 are provided on the upstream side of the conveyor belt 110.

- the drive rolls 151 and 152 supply the fiber web 50 manufactured by the card machine to the conveyor belt 110.

- a tension detector (not shown) and the peripheral speed V1 of the driving rolls 151 and 152 are controlled based on the magnitude of the tension detected by the tension detector.

- a control unit (not shown). The controller adjusts the peripheral speed V1 of the drive rolls 151 and 152 relative to the peripheral speed V2 of the conveyor belt 110 based on the detection output of the tension detector. Thereby, the tension of the fiber web 50 supplied to the first nozzle 120 is adjusted to a desired tension.

- the control unit increases the circumferential speed V1 of the drive rolls 151 and 152 to the first nozzle 120 than the circumferential speed V2 of the conveyor belt.

- the tension of the fiber web 50 is reduced.

- the control unit makes the peripheral speed V1 of the drive rolls 151 and 152 smaller than the peripheral speed V2 of the conveyor belt 110, and causes the first nozzle 120 to The tension of the supplied fiber web 50 is increased.

- the peripheral speed V1 of the drive rolls 151 and 152 which is relatively adjusted, is the speed of the roll surface, and the peripheral speed V2 of the conveyor belt 110 is the speed of the web conveyance surface.

- the manufacturing apparatus 100 sprays the 1st nozzle 120 which performs the 1st air through process by spraying the 1st heating fluid H1 in order toward MD direction, and the 2nd heating fluid H2.

- a second nozzle 130 that performs the second air-through process and a third nozzle 140 that sprays the third heating fluid H3 and performs the third air-through process are provided.