WO2013146143A1 - 海水脱硫酸化処理装置及び海水排煙脱硫システム - Google Patents

海水脱硫酸化処理装置及び海水排煙脱硫システム Download PDFInfo

- Publication number

- WO2013146143A1 WO2013146143A1 PCT/JP2013/056128 JP2013056128W WO2013146143A1 WO 2013146143 A1 WO2013146143 A1 WO 2013146143A1 JP 2013056128 W JP2013056128 W JP 2013056128W WO 2013146143 A1 WO2013146143 A1 WO 2013146143A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- seawater

- upstream

- weir

- desulfurization

- oxidation

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/14—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols by absorption

- B01D53/1456—Removing acid components

- B01D53/1481—Removing sulfur dioxide or sulfur trioxide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D19/00—Degasification of liquids

- B01D19/0005—Degasification of liquids with one or more auxiliary substances

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/46—Removing components of defined structure

- B01D53/48—Sulfur compounds

- B01D53/50—Sulfur oxides

- B01D53/507—Sulfur oxides by treating the gases with other liquids

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/72—Treatment of water, waste water, or sewage by oxidation

- C02F1/74—Treatment of water, waste water, or sewage by oxidation with air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23J—REMOVAL OR TREATMENT OF COMBUSTION PRODUCTS OR COMBUSTION RESIDUES; FLUES

- F23J15/00—Arrangements of devices for treating smoke or fumes

- F23J15/02—Arrangements of devices for treating smoke or fumes of purifiers, e.g. for removing noxious material

- F23J15/04—Arrangements of devices for treating smoke or fumes of purifiers, e.g. for removing noxious material using washing fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2252/00—Absorbents, i.e. solvents and liquid materials for gas absorption

- B01D2252/10—Inorganic absorbents

- B01D2252/103—Water

- B01D2252/1035—Sea water

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2101/00—Nature of the contaminant

- C02F2101/10—Inorganic compounds

- C02F2101/101—Sulfur compounds

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2103/00—Nature of the water, waste water, sewage or sludge to be treated

- C02F2103/08—Seawater, e.g. for desalination

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2103/00—Nature of the water, waste water, sewage or sludge to be treated

- C02F2103/18—Nature of the water, waste water, sewage or sludge to be treated from the purification of gaseous effluents

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2301/00—General aspects of water treatment

- C02F2301/04—Flow arrangements

- C02F2301/043—Treatment of partial or bypass streams

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23J—REMOVAL OR TREATMENT OF COMBUSTION PRODUCTS OR COMBUSTION RESIDUES; FLUES

- F23J2215/00—Preventing emissions

- F23J2215/20—Sulfur; Compounds thereof

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23J—REMOVAL OR TREATMENT OF COMBUSTION PRODUCTS OR COMBUSTION RESIDUES; FLUES

- F23J2217/00—Intercepting solids

- F23J2217/50—Intercepting solids by cleaning fluids (washers or scrubbers)

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23J—REMOVAL OR TREATMENT OF COMBUSTION PRODUCTS OR COMBUSTION RESIDUES; FLUES

- F23J2900/00—Special arrangements for conducting or purifying combustion fumes; Treatment of fumes or ashes

- F23J2900/15041—Means for absorbing SOx using seawater

Definitions

- the present invention relates to wastewater treatment of flue gas desulfurization devices applied to power plants such as coal-fired, crude oil-fired, and heavy oil-fired, and more particularly, wastewater of exhaust gas desulfurization devices that use the seawater method (used seawater).

- the present invention relates to a drainage water channel and a seawater flue gas desulfurization system of a seawater desulfurization apparatus that introduces a gas into an aeration apparatus.

- combustion exhaust gas (hereinafter referred to as “exhaust gas”) discharged from a boiler is sulfur such as sulfur dioxide (SO 2 ) contained in the exhaust gas.

- SO 2 sulfur dioxide

- SOx oxide

- the flue gas desulfurization apparatus (hereinafter referred to as “seawater flue gas desulfurization apparatus”) employing the seawater method is a desulfurization system that uses seawater as an absorbent.

- a desulfurization tower (absorption tower) having a cylindrical shape or a rectangular shape such as a substantially cylindrical shape

- the seawater is used as an absorbing liquid to make a wet-based gas-liquid contact. Is generated to remove sulfur oxides.

- the desulfurized seawater (spent seawater) used as the absorbent in the desulfurization tower described above is, for example, a part of the water channel when drained by flowing in a long water channel (Seawater Oxidation Treatment System; SOTS) with an open top.

- SOTS Seawater Oxidation Treatment System

- seawater desulfurization requires an enormous amount of seawater, a compact seawater desulfurization device is desired.

- an object of the present invention is to provide a seawater desulfation treatment apparatus and a seawater flue gas desulfurization system that achieve a compact system.

- the first invention of the present invention for solving the above-described problem is an acidic desulfurization containing sulfurous acid (H 2 SO 3 ) produced by seawater desulfurization of, for example, sulfur oxide in boiler exhaust gas by a seawater desulfurization apparatus.

- H 2 SO 3 sulfurous acid

- a seawater desulfation treatment apparatus comprising an oxidation / aeration tank for performing water quality recovery treatment with diluted seawater and air, and having an upstream weir formed on the inlet side in the longitudinal direction of the oxidation / aeration tank A main flow path into which the diluted seawater is introduced; an upstream mixing section that is formed on the upstream side of the upstream weir, and that mixes with the diluted seawater while introducing the acidic desulfurized seawater; and the oxidation / aeration tank A sub-flow path for supplying diluted seawater that is diverted from the upstream side of the upstream-side mixing section and that is deoxidized and aerated in the oxidation / aeration tank. It is in the desulfation treatment equipment.

- a downstream side weir is formed on the outlet side in the longitudinal direction of the oxidation / aeration tank and secures the volume of the water quality recovery seawater to a predetermined amount or more together with the upstream side weir It exists in the seawater desulfation processing apparatus characterized by this.

- the diluted seawater that is provided downstream of the downstream weir and bypasses the sub-flow path is mixed with water quality recovery seawater on the downstream side of the downstream weir. It exists in the seawater desulfation processing apparatus characterized by having the downstream mixing part which carries out post-dilution.

- the fourth invention is the seawater desulfation treatment apparatus according to the first invention, wherein an opening is formed in the upstream weir.

- the seawater desulfation apparatus according to the second aspect, wherein the openings of the upstream weir and the downstream weir are variable.

- the sixth invention is the seawater desulfation treatment apparatus according to the second invention, wherein heights of the upstream weir and the downstream weir are adjustable.

- the seventh invention is the seawater desulfation treatment apparatus according to the first invention, wherein the upstream weir is multistage, and the height thereof is lowered as going downstream.

- a flue gas desulfurization absorption tower in which exhaust gas and desulfurization seawater are brought into gas-liquid contact to desulfurize sulfur oxide (SO x ) in the gas to sulfurous acid (H 2 SO 3 ), 7.

- the seawater desulfation treatment apparatus according to any one of 7 is provided, and the pumped seawater is branched into diluted seawater and desulfurization seawater, and desulfurization is performed in the flue gas desulfurization absorption tower using the branched desulfurization seawater.

- the acidic desulfurized seawater is introduced into the upstream mixing portion of the seawater desulfation treatment apparatus, and the diluted seawater is supplied to the main flow path and the sub flow path of the seawater desulfation treatment apparatus at a predetermined ratio.

- the seawater flue gas desulfurization system which is characterized by introducing.

- the acidic desulfurized seawater from the desulfurization apparatus is introduced into the upstream side mixing section, and predilution mixing is ensured by the diluted seawater in this section.

- the reliably mixed acidic desulfurized seawater passes over the upstream weir and flows into the oxidation / aeration tank, so that it is aerated in the oxidation / aeration tank, and the oxidation / aeration process is performed reliably.

- the acidic desulfurized seawater that has been reliably oxidized and aerated is subjected to final dilution with diluted seawater bypassed by the secondary flow path, and then discharged into the sea as discharged seawater.

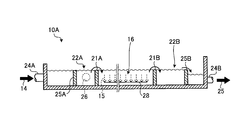

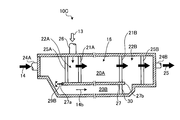

- FIG. 1 is a schematic diagram of a seawater desulfation treatment apparatus according to the present embodiment.

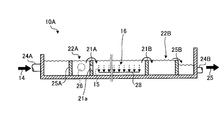

- FIG. 2 is a schematic diagram of another seawater desulfation treatment apparatus according to the present embodiment.

- 3 is a cross-sectional view taken along line AA in FIG.

- FIG. 4 is a cross-sectional view taken along line AA of FIG. 1 according to another embodiment.

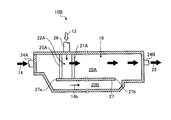

- FIG. 5 is a schematic diagram of another seawater desulfation treatment apparatus according to the present embodiment.

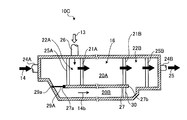

- FIG. 6A is a schematic diagram of another seawater desulfation treatment apparatus according to the present embodiment.

- FIG. 6B is a schematic diagram of another seawater desulfation treatment apparatus according to the present embodiment.

- FIG. 7 is a schematic view of another seawater desulfation treatment apparatus according to the present embodiment.

- FIG. 1 is a schematic diagram of a seawater desulfation treatment apparatus according to the present embodiment.

- FIG. 2 is a schematic diagram of another seawater desulfation treatment apparatus according to the present

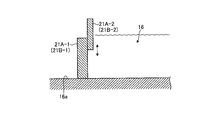

- FIG. 8 is a schematic view of the movable weir of the present embodiment.

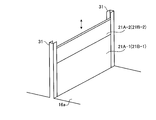

- FIG. 9A is a schematic diagram of the movable weir of the present embodiment.

- FIG. 9-2 is a schematic view of the movable weir of the present embodiment.

- FIG. 10 is a schematic view of a modified example of the weir according to the present embodiment.

- FIG. 11 is a schematic view of a seawater flue gas desulfurization system including the seawater desulfation treatment apparatus shown in FIG.

- FIG. 12 is a graph showing the relationship between the distance between the oxidation / aeration tank and the pH of the seawater.

- FIGS. 1 and 3 are schematic views of a seawater desulfation treatment apparatus according to the present embodiment.

- 3 and 4 are sectional views taken along line AA in FIGS.

- or FIG. 7 is the schematic of the other seawater desulfation processing apparatus which concerns on a present Example.

- a seawater desulfation treatment apparatus 10A according to the present embodiment is generated by desulfurizing, for example, sulfur oxides in boiler exhaust gas using a seawater desulfurization apparatus (not shown).

- a seawater desulfation treatment apparatus comprising an oxidation / aeration tank 16 for performing water quality recovery treatment on acidic desulfurized seawater 13 containing sulfurous acid (H 2 SO 3 ) using diluted seawater 14 and air 15, which is an oxidation / aeration tank 16 has an upstream weir 21A formed on the inlet side in the longitudinal direction, and is formed on the upstream side of the main flow path 20A into which the diluted seawater 14 is introduced and the upstream weir 21A, while introducing the acid desulfurized seawater 13 Acid desulfurized seawater (aerated seawater) detoured from the upstream side of the upstream mixing unit 22A for mixing with the diluted seawater 14 and upstream of the upstream mixing unit 22A of the oxidation / aeration tank 16 and oxidized and aerated in the oxidation / aeration tank 16 13) after A sub-passage 20B for supplying dilution seawater 14 dilution is made comprises a

- reference numeral 24 ⁇ / b> A denotes a diluted seawater introduction passage

- 24 ⁇ / b> B denotes a discharge seawater discharge passage

- 27 denotes a partition that separates the main flow path 20 ⁇ / b> A and the sub flow path 20 ⁇ / b> B.

- an inlet weir 25A and an outlet weir 25B are provided on the upstream side of the upstream weir 21A and the downstream side of the downstream weir 21B, respectively.

- a section sandwiched between the upstream side of the upstream weir 21A and the inlet weir 25A is the upstream mixing section 22A, and a section sandwiched between the downstream weir 21B and the outlet weir 25B is the downstream mixing section 22B.

- An acid desulfurized seawater introduction passage 26 through which the acid desulfurized seawater 13 is introduced is provided on the side wall of the upstream mixing unit 22A. Then, the acidic desulfurized seawater 13 is introduced into the upstream mixing portion 22A through the acidic desulfurized seawater introduction passage 26, and predilution mixing is reliably performed by the diluted seawater 14 in this section.

- the desulfurized seawater is supplied to the flue gas desulfurization absorption tower using a liquid feed pump (not shown).

- the desulfurized seawater can be installed in a section of the upstream mixing unit 22A. Further, it may be installed on the upstream side of the diluted seawater introduction passage 24A.

- the diluted seawater 14b in which a part of the diluted seawater 14 is detoured by the sub-channel 20B is post-diluted into the acid-desulfurized seawater (aerated seawater) 13 which is introduced into the downstream side mixing unit 22B and oxidized and aerated here. Finished dilution is performed, and then discharged into the sea as discharged seawater 25.

- An aeration pipe 28 for diffusing air is installed at the bottom of the oxidation / aeration tank 16, but this oxidation / aeration area is reliably divided by the upstream weir 21A and the downstream weir 21B. Oxidative aeration of the acidic desulfurized seawater 13 with a predetermined volume of seawater is ensured.

- the lateral width of the flow path is narrowed on the introduction side of the diluted seawater 14 and the discharge side of the discharged seawater 25, but the present invention is limited to this.

- the width may be the same as the total width of the main flow path 20A and the sub flow path 20B.

- the amount of absorbed SO 2 in the exhaust gas that absorbs sulfur oxide in the exhaust gas ( ⁇ S) is supplied to the main channel seawater amount (total seawater amount (F T ) ⁇ subchannels introduced into the main channel 20A.

- the value ( ⁇ ) divided by the amount of seawater (F B )) to be controlled is in the range of 0.5 to 1.3.

- 0.5 ⁇ ( ⁇ S / (F T ⁇ F B )) ⁇ ⁇ 1.3

- F T is the total seawater volume

- the amount of absorbed SO 2 ( ⁇ S) is 70,000 gmol / h and the total amount of seawater is 100,000 m 3 / h

- the dilution supplied to the secondary flow path 20B The amount of seawater in the seawater 14b may be 30,000 m 3 / h.

- the absorption SO 2 ( ⁇ S) changes (rises) unexpectedly.

- an opening 21 a may be provided in a part of the upstream weir 21 ⁇ / b> A so that the mixed seawater promotes the inflow into the oxidation / aeration tank 16.

- the opening area of the opening 21a may be variable, and the cross-sectional area of the flow path may be adjusted.

- an upstream mixing unit 22A and a downstream mixing unit 22B are provided on the upstream side and the downstream side of the oxidation / aeration tank 16, respectively.

- the present invention is not limited to this, and only the upstream mixing unit 22A may be provided as in the seawater desulfation treatment apparatus 10B shown in FIG.

- the flow rate of the diluted seawater 14b supplied to the sub-channel 20B can be adjusted by a pump (not shown), but the seawater desulfation treatment shown in FIG.

- the movable sluice 29A provided on the partition inlet side 27a of the partition wall 27 as in the device 10C, the distribution amount of the diluted seawater 14 can be adjusted.

- the movable sluice 29 has a guide portion 29a and is movable in the vertical direction.

- the sub-channel weir 30 may be installed in the sub-channel 20B, and the flow rate of the diluted seawater 14b passing through the sub-channel 20B may be adjusted.

- the movable sluice that is movable in the vertical direction as shown in FIG. 6A is not limited to the movable sluice, which is movable in the vertical direction.

- the seawater desulfation treatment apparatus 10C shown in FIG. It is also possible to adjust the distribution amount of the diluted seawater 14 by providing a rotating sluice 29B that rotates and adjusting the degree of opening and closing.

- diluted seawater 14b is introduced from the partition wall outlet side 27b after passing through the partition wall 27, and the final dilution is performed.

- the present invention is not limited to this, and an opening 27c may be provided in the partition wall 27 as in the seawater desulfation apparatus 10D shown in FIG.

- a part of the diluted seawater 14b supplied to the auxiliary flow path 20B through the opening 27c may be introduced into the oxidation / aeration tank 16 to dilute the oxidized / aerated aeration seawater.

- a part means the remaining seawater which has secured a necessary amount in the downstream mixing unit 22B.

- FIG. 12 shows the relationship between the distance between the oxidation / aeration tank and the pH of the seawater.

- the horizontal axis indicates the distance from the inlet of the oxidation / aeration tank 16, and the vertical axis indicates the pH of the seawater.

- the pH of the graph rapidly increases as the distance increases, indicating a portion where the downstream mixing unit 22 is mixing with the diluted seawater 14 b bypassed by the sub-flow path 20 ⁇ / b> B.

- the “solid line” indicates a case where the amount of bypass is small and ⁇ is small, and the pH at the oxidation tank inlet is high, but the pH drop due to oxidation of sulfurous acid is small.

- the weir of the downstream side weir 21B is a movable weir and can be adjusted by adjusting its height.

- an opening may be provided in the downstream weir 21B, and the opening may be made variable to adjust the flow passage cross-sectional area of the opening.

- FIG. 8 is a schematic view of the movable weir of the present embodiment. As shown in FIG. 8, this movable weir is connected to the foundation wall 21A-1 (21B-1) erected from the bottom 16a of the oxidation / aeration tank 16 and the foundation wall 21A-1 (21B-1). The movable wall 21A-2 (21B-2) can be moved up and down freely. In addition, since the movable weir of the downstream side weir 21B is the same, a code

- FIGS. 9-1 and 9-2 are schematic views of other movable weirs in this embodiment.

- the movable weir shown in FIG. 9-1 includes a pair of U-shaped guide members 31 erected from the bottom 16a of the oxidation / aeration tank 16, and an upstream weir that is movable in the vertical direction within the guide member 31. 21A (downstream dam 21B) is inserted, and the flow rate is adjusted as necessary.

- the movable weir shown in FIG. 9-2 includes a pair of U-shaped guide members 31 erected from the bottom portion 16a of the oxidation / aeration tank 16, and a single piece movable in the guide member 31 in the vertical direction.

- the movable upstream weir 21A is divided into two parts (21A-1, 21A-2) and inserted, and the movable amount is adjusted so that the flow rate is adjusted as necessary. Note that only the upper weir 21A-2 may be movable by fixing the lower weir 21A-1.

- the movable weir of the downstream side weir 21B is the same, a code

- the volume in the oxidation / aeration tank 16 can be arbitrarily changed.

- FIG. 10 is a schematic diagram of another modification of the weir according to the present embodiment.

- a plurality of upstream weirs 21 ⁇ / b> A installed on the upstream side of the oxidation / aeration tank 16 toward the downstream side of the flow of the diluted seawater 14 (three in this embodiment) 21 ⁇ / b > A 1 , 21 ⁇ / b > A 2 , 21A 3 is erected, and the height of the weir is gradually decreased from the upstream side weir 21A 1 to the downstream side weir 21A 3 so that it falls as a waterfall 33.

- the height of the weir is gradually decreased from the upstream side weir 21A 1 to the downstream side weir 21A 3 so that it falls as a waterfall 33.

- innumerable fine air bubbles 34 are generated in the seawater falling in the waterfall, increasing the seawater surface area in contact with the air, and the entrainment effect is exerted, making it easy to absorb external air in the oxidation / aeration tank 16. I am doing so.

- FIG. 11 is a schematic view of a seawater flue gas desulfurization system including the seawater desulfation treatment apparatus shown in FIG.

- the seawater flue gas desulfurization system 100 includes a flue gas desulfurization absorption tower 102 that causes gas-liquid contact between the exhaust gas 101 and the seawater 14a for desulfurization to desulfurize SO 2 to sulfurous acid (H 2 SO 3 ).

- a seawater desulfurization treatment apparatus 10A provided on the downstream side of the flue gas desulfurization absorption tower 102 and provided with an oxidation / aeration tank 16 for diluting and mixing the acidic desulfurized seawater 13 containing sulfur with the diluted seawater 14.

- the seawater pumped from the ocean is branched into diluted seawater 14 and desulfurization seawater 14a, and desulfurized in the flue gas desulfurization absorption tower 102 using the branched desulfurization seawater 14a, and then the acidic desulfurization seawater.

- reference numeral 110 is a condenser for cooling seawater

- L 1 is a seawater pumping passage

- L 2 is a diluted seawater supply passage

- L 3 is a seawater supply passage for desulfurization

- L 4 is an exhaust gas supply passage

- L 5 is acidic.

- Desulfurized seawater supply passages P 1 and P 2 are seawater pumps.

- desulfurization seawater 14a supplied through the desulfurization seawater supply passage L 3 is injected upward from the aeration tube 102a, and the injected desulfurization seawater 14a and the exhaust gas 101 was To make SO 2 in the exhaust gas 101 absorbed in seawater.

- the acidic desulfurized seawater 13 that has absorbed sulfur in the flue gas desulfurization absorption tower 102 is stored at the bottom of the flue gas desulfurization absorption tower 102, and then the seawater desulfation treatment apparatus provided on the downstream side of the flue gas desulfurization absorption tower 102.

- the upstream mixing section 22A of 10A is introduced via the acid desulfurization seawater supply passage L 5, wherein securely mixed with diluted seawater 14 supplied from the dilution seawater supply passage L 2 is made.

- the mixed and diluted acidic desulfurized seawater 13 is introduced into the oxidation / aeration tank 16 provided on the downstream side of the upstream mixing unit 22A beyond the upstream weir 21A.

- air supplied from an oxidation air blower (not shown) is supplied through the air diffuser 102 a, and the quality of the acid desulfurized seawater 13 is recovered.

- the diluted seawater 14b which is separately bypassed in the downstream side mixing section 22B beyond the downstream weir 21B, is introduced into the diluted seawater 14b from the partition wall outlet side 27b, and post-dilution is performed to complete the final dilution. Thereafter, it is discharged to the sea as discharged seawater 25 through the discharged seawater discharge passage 24B.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Environmental & Geological Engineering (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- General Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Organic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Water Supply & Treatment (AREA)

- Biomedical Technology (AREA)

- Treating Waste Gases (AREA)

- Gas Separation By Absorption (AREA)

- Physical Water Treatments (AREA)

- Treatment Of Water By Oxidation Or Reduction (AREA)

- Chimneys And Flues (AREA)

- Degasification And Air Bubble Elimination (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN8034DEN2014 IN2014DN08034A (zh) | 2012-03-30 | 2013-03-06 | |

| CN201380016309.3A CN104203839B (zh) | 2012-03-30 | 2013-03-06 | 海水脱硫氧化处理装置及海水排烟脱硫系统 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012082417A JP2013208605A (ja) | 2012-03-30 | 2012-03-30 | 海水脱硫酸化処理装置及び海水排煙脱硫システム |

| JP2012-082417 | 2012-03-30 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013146143A1 true WO2013146143A1 (ja) | 2013-10-03 |

Family

ID=49259414

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/056128 WO2013146143A1 (ja) | 2012-03-30 | 2013-03-06 | 海水脱硫酸化処理装置及び海水排煙脱硫システム |

Country Status (7)

| Country | Link |

|---|---|

| JP (1) | JP2013208605A (zh) |

| CN (1) | CN104203839B (zh) |

| IN (1) | IN2014DN08034A (zh) |

| MY (1) | MY174385A (zh) |

| SA (1) | SA113340422B1 (zh) |

| TW (1) | TW201348147A (zh) |

| WO (1) | WO2013146143A1 (zh) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3132839A1 (en) | 2015-08-20 | 2017-02-22 | General Electric Technology GmbH | Seawater flue gas desulfurization absorber system |

| EP3144281A1 (en) | 2015-09-17 | 2017-03-22 | General Electric Technology GmbH | Integrated air distributor arrangement for effluent seawater treatment basin |

| US9630864B2 (en) | 2015-06-17 | 2017-04-25 | General Electric Technology Gmbh | Seawater plant with inclined aeration and mixed auto recovery |

| WO2017069044A1 (ja) * | 2015-10-21 | 2017-04-27 | 月島機械株式会社 | 硫黄吸収溶液の処理装置及び処理方法 |

| CN108218050A (zh) * | 2018-03-23 | 2018-06-29 | 东方电气集团东方锅炉股份有限公司 | 一种海水烟气脱硫后酸性海水的水质恢复装置及恢复方法 |

| CN111718018A (zh) * | 2020-07-17 | 2020-09-29 | 中国华电科工集团有限公司 | 一种强制流动的海水脱硫系统曝气池 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3020465B1 (en) * | 2014-11-14 | 2017-08-02 | Doosan Lentjes GmbH | A flue gas purification device |

| JP2016215092A (ja) * | 2015-05-15 | 2016-12-22 | 三菱日立パワーシステムズ株式会社 | 海水脱硫排水の水質改質装置及び海水排煙脱硫システム |

| CN105498502A (zh) * | 2016-01-29 | 2016-04-20 | 北京博奇电力科技有限公司 | 一种海水脱硫曝气工艺控制方法 |

| CN106115888A (zh) * | 2016-08-23 | 2016-11-16 | 中国能源建设集团广东省电力设计研究院有限公司 | 燃煤电厂海水脱硫系统后排水余能回收利用系统 |

| JP2019141817A (ja) * | 2018-02-23 | 2019-08-29 | 三菱日立パワーシステムズ株式会社 | 水処理槽及び脱硫装置 |

| CN110862138A (zh) * | 2019-11-30 | 2020-03-06 | 上海鲲谷环保科技有限公司 | 一种湿式氧化反应系统 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007125474A (ja) * | 2005-11-01 | 2007-05-24 | Nippon Kankyo Kikaku Kk | 海水による排ガス脱硫方法及び排ガス脱硫装置 |

| WO2009008184A1 (ja) * | 2007-07-10 | 2009-01-15 | Mitsubishi Heavy Industries, Ltd. | 流体の混合流路構造及び混合方法 |

| JP2010162510A (ja) * | 2009-01-19 | 2010-07-29 | Ihi Corp | 海水脱硫装置 |

| WO2010113335A1 (ja) * | 2009-03-31 | 2010-10-07 | 三菱重工業株式会社 | 酸化槽、海水処理装置及び海水脱硫システム |

| JP2012115764A (ja) * | 2010-11-30 | 2012-06-21 | Mitsubishi Heavy Ind Ltd | 海水脱硫装置の排水水路及び海水排煙脱硫システム |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1045173C (zh) * | 1995-12-22 | 1999-09-22 | 武汉晶源环境工程有限公司 | 曝气法海水烟气脱硫方法及一种曝气装置 |

| CN1884124A (zh) * | 2006-07-12 | 2006-12-27 | 陈玉乐 | 工业烟气海水脱硫海水恢复装置 |

| JP5259964B2 (ja) * | 2007-02-28 | 2013-08-07 | 三菱重工業株式会社 | 海水排煙脱硫システム |

-

2012

- 2012-03-30 JP JP2012082417A patent/JP2013208605A/ja active Pending

-

2013

- 2013-03-06 WO PCT/JP2013/056128 patent/WO2013146143A1/ja active Application Filing

- 2013-03-06 CN CN201380016309.3A patent/CN104203839B/zh not_active Expired - Fee Related

- 2013-03-06 MY MYPI2014702693A patent/MY174385A/en unknown

- 2013-03-06 IN IN8034DEN2014 patent/IN2014DN08034A/en unknown

- 2013-03-27 SA SA113340422A patent/SA113340422B1/ar unknown

- 2013-03-29 TW TW102111598A patent/TW201348147A/zh unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007125474A (ja) * | 2005-11-01 | 2007-05-24 | Nippon Kankyo Kikaku Kk | 海水による排ガス脱硫方法及び排ガス脱硫装置 |

| WO2009008184A1 (ja) * | 2007-07-10 | 2009-01-15 | Mitsubishi Heavy Industries, Ltd. | 流体の混合流路構造及び混合方法 |

| JP2010162510A (ja) * | 2009-01-19 | 2010-07-29 | Ihi Corp | 海水脱硫装置 |

| WO2010113335A1 (ja) * | 2009-03-31 | 2010-10-07 | 三菱重工業株式会社 | 酸化槽、海水処理装置及び海水脱硫システム |

| JP2012115764A (ja) * | 2010-11-30 | 2012-06-21 | Mitsubishi Heavy Ind Ltd | 海水脱硫装置の排水水路及び海水排煙脱硫システム |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9630864B2 (en) | 2015-06-17 | 2017-04-25 | General Electric Technology Gmbh | Seawater plant with inclined aeration and mixed auto recovery |

| EP3132839A1 (en) | 2015-08-20 | 2017-02-22 | General Electric Technology GmbH | Seawater flue gas desulfurization absorber system |

| EP3144281A1 (en) | 2015-09-17 | 2017-03-22 | General Electric Technology GmbH | Integrated air distributor arrangement for effluent seawater treatment basin |

| WO2017069044A1 (ja) * | 2015-10-21 | 2017-04-27 | 月島機械株式会社 | 硫黄吸収溶液の処理装置及び処理方法 |

| CN108218050A (zh) * | 2018-03-23 | 2018-06-29 | 东方电气集团东方锅炉股份有限公司 | 一种海水烟气脱硫后酸性海水的水质恢复装置及恢复方法 |

| CN111718018A (zh) * | 2020-07-17 | 2020-09-29 | 中国华电科工集团有限公司 | 一种强制流动的海水脱硫系统曝气池 |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201348147A (zh) | 2013-12-01 |

| MY174385A (en) | 2020-04-15 |

| CN104203839A (zh) | 2014-12-10 |

| SA113340422B1 (ar) | 2015-08-16 |

| IN2014DN08034A (zh) | 2015-05-01 |

| CN104203839B (zh) | 2016-04-13 |

| JP2013208605A (ja) | 2013-10-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2013146143A1 (ja) | 海水脱硫酸化処理装置及び海水排煙脱硫システム | |

| WO2016186038A1 (ja) | 海水脱硫排水の水質改質装置及び海水排煙脱硫システム | |

| JP5259964B2 (ja) | 海水排煙脱硫システム | |

| JP2012115764A (ja) | 海水脱硫装置の排水水路及び海水排煙脱硫システム | |

| WO2013118683A1 (ja) | 脱硫海水処理システム | |

| JP6313945B2 (ja) | 海水脱硫用散気装置及びそれを備えた海水脱硫装置、並びに水質改善方法 | |

| CN204073811U (zh) | 海水排烟脱硫系统及发电系统 | |

| JP5166791B2 (ja) | 排煙脱硫装置 | |

| JP2008200621A (ja) | 排煙脱硫装置 | |

| JP5437151B2 (ja) | 排煙脱硫装置及びこれを備えた酸素燃焼装置と方法 | |

| CN101342455B (zh) | 一种喷淋旋流组合脱硫装置 | |

| JP5186396B2 (ja) | 海水脱硫装置 | |

| EP3769835A1 (en) | Flue gas desulfurization device | |

| JP5535861B2 (ja) | エアレーション装置及びこれを備えた海水排煙脱硫装置 | |

| WO2014196458A1 (ja) | 海水脱硫装置及び海水脱硫システム | |

| JP5535823B2 (ja) | エアレーション装置及びこれを備えた海水排煙脱硫装置、エアレーション装置の運転方法 | |

| JP5535817B2 (ja) | エアレーション装置及びこれを備えた海水排煙脱硫装置、エアレーション装置の加湿方法 | |

| JP2012081402A (ja) | エアレーション装置及びこれを備えた海水排煙脱硫装置 | |

| JP5583037B2 (ja) | エアレーション装置及びこれを備えた海水排煙脱硫装置、エアレーション装置の運転方法 | |

| JP6296884B2 (ja) | 排煙脱硫装置 | |

| TW201940435A (zh) | 水處理槽及脫硫裝置 | |

| TWI454429B (zh) | 曝氣裝置及具備其之海水排煙脫硫裝置、曝氣裝置之運轉方法 | |

| JP2012236164A (ja) | エアレーション装置及びこれを備えた海水排煙脱硫装置、エアレーション装置の運転方法 | |

| JP2012239922A (ja) | 海水排煙脱硫装置 | |

| JP2013022512A (ja) | エアレーション装置及び海水排煙脱硫装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13769679 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: IDP00201405888 Country of ref document: ID |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 13769679 Country of ref document: EP Kind code of ref document: A1 |