WO2012137378A1 - 熱安定性、柔軟性に優れる不織布 - Google Patents

熱安定性、柔軟性に優れる不織布 Download PDFInfo

- Publication number

- WO2012137378A1 WO2012137378A1 PCT/JP2011/075207 JP2011075207W WO2012137378A1 WO 2012137378 A1 WO2012137378 A1 WO 2012137378A1 JP 2011075207 W JP2011075207 W JP 2011075207W WO 2012137378 A1 WO2012137378 A1 WO 2012137378A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- nonwoven fabric

- fiber

- less

- flexibility

- woven fabric

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4282—Addition polymers

- D04H1/4291—Olefin series

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/514—Backsheet, i.e. the impermeable cover or layer furthest from the skin

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/005—Synthetic yarns or filaments

- D04H3/007—Addition polymers

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/08—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating

- D04H3/16—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the method of strengthening or consolidating with bonds between thermoplastic filaments produced in association with filament formation, e.g. immediately following extrusion

Definitions

- the present invention relates to a non-woven fabric made of polyolefin fibers excellent in processability suitable for top sheets, back sheets or side gathers of absorbent articles used for sanitary materials.

- the degree of adhesion of nonwoven fabric fibers is increased to suppress dimensional changes by increasing the thermal bonding temperature, increasing the bonding pressure, increasing the embossed area ratio, etc.

- the texture of a nonwoven fabric will become hard by making the adhesion degree high even if which method is used. That is, the conventional means for improving the thermal stability of the nonwoven fabric has a problem that the flexibility is inferior for use in sanitary materials, and it is very difficult to achieve both flexibility and thermal stability of the nonwoven fabric. .

- Patent Document 1 describes that a propylene / ethylene random copolymer is used and the ethylene content is set to a specific narrow range in order to achieve both flexibility and thermal stability.

- Patent Document 2 describes a method of increasing the thermal bonding temperature to lower the thermal shrinkage rate.

- the method described in Patent Document 2 makes the texture of the nonwoven fabric hard and is not preferable for use as a sanitary material.

- the problem to be solved by the present invention is a nonwoven fabric suitable for top sheets, back sheets or side gather parts of absorbent articles used for sanitary materials, having high thermal stability, excellent flexibility, and good workability. Is to provide.

- the inventors have made the crystallite size of the polyolefin-based fiber constituting the nonwoven fabric a specific size and the bending flexibility of the nonwoven fabric within a specific range.

- the film bonding process can suppress changes in width and wrinkles due to the effect of heat when applying the hot melt agent, curving of the nonwoven fabric, etc., and heat sealing in the heat sealing process, which is a subsequent process

- the present inventors have found that changes in width and wrinkles due to the influence of heat from the roller, generation of wrinkles, bending of the nonwoven fabric, and the like can be suppressed, and the present invention has been completed.

- the present inventors set the crystallite size within a specific range by setting the fiber temperature at the inlet of the traction device and the traction air wind speed within a predetermined range in the production process of the nonwoven fabric, thereby providing high thermal stability and flexibility.

- the present inventors have found that a non-woven fabric that can be suitably used for sanitary materials and that is excellent in workability and has good workability has been obtained, and has led to the present invention.

- a nonwoven fabric comprising polyolefin fibers, wherein the polyolefin fibers have a crystallite size of 15 nm or more and 50 nm or less, and the bending flexibility of the nonwoven fabric is 5 mm or more and 100 mm or less.

- the non-woven fabric of the present invention is a non-woven fabric composed of polyolefin fibers, and the polyolefin fiber has a crystallite size of 15 nm to 50 nm and a flexural flexibility of 5 mm to 100 mm, while maintaining flexibility.

- the property is also good.

- the crystallite size is large, the crystal part rigidly suppresses the movement of the molecule and can suppress the contraction.

- the nonwoven fabric of this invention is a nonwoven fabric which is excellent in the workability suitable for the top sheet, back sheet, or side gather part of the absorbent article used for a sanitary material by having the said structure.

- polyolefin fibers constituting the nonwoven fabric of the present invention include fibers made of a resin such as polyethylene, polypropylene, and copolymers of these monomers and other ⁇ -olefins.

- a resin such as polyethylene, polypropylene, and copolymers of these monomers and other ⁇ -olefins.

- polypropylene fiber it is preferable to use polypropylene fiber because it is strong and difficult to break during use, and is excellent in dimensional stability during production of sanitary materials.

- Polypropylene may be a polymer synthesized by a general Ziegler-Natta catalyst or a polymer synthesized by a single site active catalyst typified by metallocene.

- ⁇ -olefins are those having 3 to 10 carbon atoms, such as propylene, 1-butene, 1-pentene, 1-hexane, 4-methyl-1-pentene, and 1-octene. Can be mentioned. These may be used alone or in combination of two or more.

- polyolefin fiber polyethylene terephthalate fiber, polybutylene terephthalate fiber, polyethylene naphthalate fiber, polyester fiber such as copolymer polyester, nylon-6 fiber, nylon-66 fiber, polyamide fiber such as copolymer nylon, polylactic acid Biodegradable fibers such as polybutylene succinate and polyethylene succinate may be used alone or in combination of two or more. It is preferable to use one kind alone.

- a core-sheath fiber having a polyolefin resin as a surface layer may be used.

- the fiber shape may be not only a normal circular fiber but also a specially shaped fiber such as a crimped fiber or a deformed fiber.

- the main component is homopolypropylene.

- the lower limit of MFR is 20 g / 10 minutes or more, preferably more than 30 g / 10 minutes, more preferably more than 40 g / 10 minutes, and still more preferably more than 53 g / 10 minutes.

- the upper limit is 100 g / 10 min or less, preferably 85 g / 10 min or less, more preferably 70 g / 10 min or less, still more preferably less than 65 g / 10 min.

- MFR is measured according to JIS-K7210 “Testing methods for plastic-thermoplastic melt mass flow rate (MFR) and melt volume flow rate (MVR)”, test temperature 230 ° C., test load 2.16 kg. I went and asked.

- the polyolefin fiber constituting the nonwoven fabric of the present invention may contain a nucleating agent, a flame retardant, an inorganic filler, a pigment, a colorant, a heat stabilizer, an antistatic agent and the like.

- the joining means for producing a nonwoven fabric by joining polyolefin fibers include a partial thermocompression bonding method, a hot air method, a joining method using a molten component (hot melt agent) method, and various other methods. Therefore, the partial thermocompression bonding method is preferable.

- the area ratio of thermocompression bonding in the partial thermocompression bonding of the nonwoven fabric of the present invention is 3% or more and 40% or less, preferably 4% or more and 25% or less, more preferably 4% or more and 20%, from the viewpoint of strength retention and flexibility. Or less, more preferably 5% or more and 15% or less.

- the partial thermocompression treatment of the present invention can be carried out by an ultrasonic method or by passing a web between heated embossing rolls, whereby the front and back are integrated, for example, pinpoint shape, elliptical shape, diamond shape

- a floating pattern such as a rectangular shape is scattered all over the nonwoven fabric. From the viewpoint of productivity, it is preferable to use a heated embossing roll.

- the average single yarn fineness of the polyolefin fibers constituting the nonwoven fabric of the present invention is preferably 0.5 dtex or more and 3.5 dtex or less, more preferably 0.7 dtex or more and 3.2 dtex or less, further preferably 0.9 dtex or more. 2.8 dtex or less. From the viewpoint of spinning stability, it is preferably 0.5 dtex or more, and the finer the fineness, the higher the strength and flexibility of the nonwoven fabric because the number of bonding points of the yarn increases. Since it is mainly used for sanitary materials, it is preferably 3.5 dtex or less from the viewpoint of the strength of the nonwoven fabric.

- the basis weight of the nonwoven fabric of the present invention is 8 g / m 2 or more and 40 g / m 2 or less, preferably 10 g / m 2 or more and 30 g / m 2 or less, more preferably 10 g / m 2 or more and 25 g / m 2 or less, and still more preferably. Is 10 g / m 2 or more and less than 23 g / m 2 .

- the crystallite size of the nonwoven fabric of the present invention is 15 nm or more and 50 nm or less, preferably more than 20 nm and 50 nm or less, more preferably 25 nm or more and 40 nm or less. If the crystallite size is 15 nm or more, the thermal stability is good, and the crystallite size is 50 nm or less from the viewpoint of the flexibility of the nonwoven fabric used for the sanitary material.

- the nonwoven fabric of the present invention has a desired crystallite size by making the fiber temperature at the inlet of the traction device 30 ° C. or higher, and pulling with a strong traction force at a traction air wind speed of 5000 m / min or more. .

- the fiber temperature is preferably 30 ° C. or higher and 80 ° C. or lower, more preferably 35 ° C. or higher and 70 ° C. or lower.

- the traction air wind speed is preferably 6000 m / min or more and 30000 m / min or less, more preferably 7000 m / min or more and 20000 m / min or less.

- the method for pulling the nonwoven fabric of the present invention is not particularly limited, but in order to obtain a nonwoven fabric having a large crystallite size and excellent thermal stability, a method using a high-speed airflow pulling device using an air jet is preferable, and a rectangular shape is used. The use of a mold traction device is even better.

- the average “flexural flexibility” of the vertical direction and the horizontal direction of the nonwoven fabric of the present invention defined below is 5 mm or more and 100 mm or less, preferably 5 mm or more and 90 mm or less, more preferably 10 mm or more and 80 mm or less.

- the nonwoven fabric is excellent in workability, texture and flexibility.

- the boiling water shrinkage of the nonwoven fabric of the present invention is a suitable method for efficiently transmitting thermal energy and checking the thermal stability of the fiber because hot water surrounds the fiber.

- the boiling water shrinkage of the present invention is preferably 0% or more and 3.0% or less, more preferably 0.1% or more and 2.0% or less, and further preferably 0.1% or more and 1.0% or less. . If the boiling water shrinkage ratio is within this range, the width and wrinkle generation due to heat at the time of applying the hot melt agent or heat sealing is suppressed in the sanitary material production line, and stable processing is possible without breaking.

- the dry heat shrinkage of the nonwoven fabric of the present invention is preferably 0% or more and 5.0% or less at 120 ° C., more preferably 0.1% or more and 3.0% or less, and further preferably 0.2% or more. 1.5% or less. If the dry heat shrinkage rate is in this range, the width and wrinkle generation due to heat at the time of hot melt application and heat sealing are suppressed in the sanitary material production line, and stable processing is possible without breaking. Become.

- a hydrophilizing agent may be applied to the nonwoven fabric of the present invention.

- a hydrophilizing agent in consideration of safety to the human body, safety in the process, etc., nonionic active agents to which ethylene oxides such as higher alcohols, higher fatty acids, alkylphenols are added, alkyl phosphate salts, alkyls

- Anionic active agents such as sulfates are preferably used alone or as a mixture.

- the adhesion amount of the hydrophilizing agent varies depending on the required performance, but usually it is preferably in the range of 0.1% by weight to 1.0% by weight, more preferably 0.15% by weight to 0%. 0.8 wt% or less, more preferably 0.2 wt% or more and 0.6 wt% or less. When the adhesion amount is within this range, the hydrophilic performance as a sanitary material top sheet is satisfied, and the processability is also good.

- an existing method such as a dipping method, a spraying method, a coating (kiss coater, gravure coater) method or the like can be usually employed using a diluted hydrophilizing agent.

- the mixed hydrophilizing agent is preferably applied after being diluted with a solvent such as water.

- a drying process may be required.

- a known method using convection heat transfer, conduction heat transfer, radiant heat transfer, or the like can be employed, and drying by hot air or infrared rays, drying by heat contact, or the like can be used. .

- a softening agent may be applied to the nonwoven fabric of the present invention.

- a softening agent is preferably an ester compound, more preferably an ester compound of a tri- to hexavalent polyol and a monocarboxylic acid.

- the trivalent to hexavalent polyol include trivalent polyols such as glycerin and trimethylolpropane, tetravalent polyols such as pentaerythritol, glucose, sorbitan, diglycerin, and ethylene glycol diglyceryl ether, triglycerin, and trimethylol.

- pentavalent polyols such as propanediglyceryl ether

- hexavalent polyols such as sorbitol, tetraglycerin, and dipentaerythritol.

- Examples of the monocarboxylic acid include alicyclic monocarboxylic acids such as octacarboxylic acid, dodecanoic acid, tetradecanoic acid, octadecanoic acid, docosanoic acid, hexacosanoic acid, octadecenoic acid, docosenoic acid, isooctadecanoic acid, and cyclohexanecarboxylic acid.

- alicyclic monocarboxylic acids such as octacarboxylic acid, dodecanoic acid, tetradecanoic acid, octadecanoic acid, docosanoic acid, hexacosanoic acid, octadecenoic acid, docosenoic acid, isooctadecanoic acid, and cyclohexanecarboxylic acid.

- Aromatic monocarboxylic acids such as carboxylic acid, benzoic acid and methylbenzenecarboxylic acid, hydroxyaliphatic monocarboxylic acids such as hydroxypropionic acid, hydroxyoctadecanoic acid and hydroxyoctadecenoic acid, and sulfur-containing aliphatic monocarboxylic acids such as alkylthiopropionic acid An acid etc. are mentioned.

- the ester compound does not need to be a single component, and may be a mixture of two or more kinds or oils and fats derived from natural products.

- saturated aliphatic monocarboxylic acids or aromatic monocarboxylic acids are preferable because ester compounds containing unsaturated fatty acids are easily oxidized and easily deteriorated during spinning.

- Naturally-derived oils and fats are preferably odorless and stable compared to raw material oils, and therefore, hydrogenated ester compounds are preferably used.

- the ester compound a monocarboxylic acid having a relatively large molecular weight and high lipophilicity is preferable. Due to the high lipophilicity, it enters into the amorphous part of the polyolefin fiber and inhibits crystallization to increase the amorphous region, so that an effect of reducing the bending flexibility can be obtained.

- the melting point of the ester compound is preferably 70 ° C. or higher, more preferably 80 ° C. or higher and 150 ° C. or lower. When the melting point of the ester compound is broad and has a range, the melting point means an average melting point.

- the ester compound may be mixed with other compositions such as an ester compound having a melting point of less than 70 ° C. and other organic compounds.

- the content of the ester compound as the softening agent is preferably 0.3% by weight or more and 5.0% by weight or less with respect to the polyolefin fiber. Even if a small amount of the ester compound is added, the bending flexibility and slipperiness are remarkably improved, and even if the content is increased, the performance improvement corresponding to the content is not seen. Therefore, in consideration of spinnability and smoke generation, the content is preferably 5.0% by weight or less, more preferably 0.5% by weight or more and 3.5% by weight or less, and further preferably 0.5% by weight or more. 0% by weight or less.

- the manufacturing method of the nonwoven fabric of this invention is not specifically limited, Since it is mainly used for a sanitary material, it is preferable that it is a spun bond (S) method from a viewpoint of intensity

- spunbond (S) fibers may be laminated with meltblown (M) fibers, or a structure in which SM, SMS, SMMS, and SMSMS are laminated.

- the spinning temperature of the present invention is 190 ° C or higher and 260 ° C or lower, preferably 200 ° C or higher and 255 ° C or lower, more preferably 205 ° C or higher and 230 ° C or lower, and further preferably 210 ° C or higher and 225 ° C or lower.

- the spinning temperature is 260 ° C. or lower, the occurrence of yarn breakage due to less fouling of the spinneret surface due to the resin decomposition product and lowering of the resin viscosity can be suppressed.

- the spinning temperature is high, the produced nonwoven fabric has an increased bending flexibility due to the influence of the resin decomposition product, and tends to be hard as a nonwoven fabric.

- the spinning temperature is 190 ° C. or higher, the occurrence of yarn breakage due to an increase in the viscosity of the resin can be suppressed, and further, resin leakage due to an increase in the spinneret pressure during spinning can be suppressed.

- the nonwoven fabric of the present invention is not particularly limited as long fibers or short fibers depending on the purpose, but is mainly used for sanitary materials. It is preferable that

- the non-woven fabric of the present invention has a very high thermal stability and can be suitably used for the production of sanitary materials.

- sanitary materials include disposable diapers, sanitary napkins, and incontinence pads, and the top of their surfaces. It is preferably used for seats, outer backsheets, side gathers around the legs, and the like.

- the use of the nonwoven fabric of the present invention is not limited to the above uses, and examples thereof include masks, warmers, tape base fabrics, waterproof sheet base fabrics, patch medicinal base fabrics, first aid base fabrics, packaging materials, wipe products, and medical gowns. It can also be used for bandages, clothing, skin care sheets and the like.

- Average single yarn fineness Except for 10 cm at both ends of the produced nonwoven fabric, a 1 cm square test piece was sampled by dividing into approximately 5 equal parts in the width direction, the fiber diameter was measured 20 points at a time with a microscope, and the fineness was calculated from the average value.

- Weight per unit (g / m 2 ) In accordance with JIS-L1906, five test pieces measuring 20 cm in length and 5 cm in width were arbitrarily sampled and the mass was measured, and the average value was converted into the weight per unit area.

- Boiling water shrinkage (%) Three test pieces each having a length of 25 cm and a width of 25 cm are sampled, and a mark representing the length of 20 cm is accurately placed on each of the three vertical and horizontal specimens. After the sample is immersed in boiling water for 3 minutes in a suitable container, the sample is taken out, drained lightly with a filter paper or the like, held at one end with a clip, suspended at room temperature, and dried. Next, measure the length of 3 points each in the vertical and horizontal directions marked at the beginning. The shrinkage rate in the vertical direction was calculated by the following formula, and the average value was obtained.

- Boiling water shrinkage rate (%) (L ⁇ L ′) / L ⁇ 100 ⁇ In the formula, L: the total length (mm) of the three lines before processing, and L ': the total length (mm) of the three lines after processing. ⁇ .

- Dry heat shrinkage (%) Three test pieces of 25 cm (vertical) ⁇ 25 cm (horizontal) are arbitrarily sampled, and a mark representing the length of 20 cm is accurately placed on each of the three vertical and horizontal specimens.

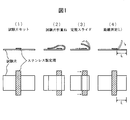

- Flexibility Collect arbitrarily 5 specimens 10 cm wide and 30 cm long from the nonwoven fabric sample (samples are taken so that the measurement direction is 30 cm) and place it on a flat table as shown in FIG. Place a ruler made of stainless steel on the part so as to be orthogonal to the longitudinal direction.

- the ruler preferably has a width of 2.5 cm and a measurement scale of 30 cm (1).

- one end of the test piece is lifted and slowly overlapped with a loop formed on the opposite test piece with the stainless ruler as the boundary (2).

- Crystallite size (nm) Using an XRD analyzer [apparatus: NanoViewer manufactured by Rigaku Corporation, optical system: pinhole collimation (confocal mirror + first slit: 0.4 mm ⁇ + second slit: 0.3 mm ⁇ ), X-ray source: CuK ⁇ ray, 45 kV 60 mA, detection Instrument: Imaging plate, camera length: 80.8 mm]

- XRD analyzer Appatus: NanoViewer manufactured by Rigaku Corporation, optical system: pinhole collimation (confocal mirror + first slit: 0.4 mm ⁇ + second slit: 0.3 mm ⁇ ), X-ray source: CuK ⁇ ray, 45 kV 60 mA, detection Instrument: Imaging plate, camera length: 80.8 mm

- One fiber was set in a cell, X-rays were incident from the direction perpendicular to the fiber axis, and transmitted scattered (diffracted) light was detected. In order to reduce the influence of background scattering, the measurement was performed in

- a crystallite perpendicular to the (040) plane from the diffraction peak width derived from the (040) plane was calculated by the following formula. ⁇ Wherein, K: Scherrer constant (constant depending on crystallite shape and the like: 0.9 is used), ⁇ : X-ray wavelength, ⁇ : half width of peak (full width at half maximum: FWHM) (rad), And b: full width at half maximum of the incident beam (full width at half maximum: FWHM) (rad). ⁇ .

- Example 1 Polypropylene resin with an MFR of 60 g / 10 min (measured at a temperature of 230 ° C. and a load of 2.16 kg according to JIS-K7210) by a spunbond method, nozzle diameter ⁇ 0.4 mm, single-hole discharge rate 0.56 g / min ⁇ Hole

- the fiber is extruded at a spinning temperature of 215 ° C, and the filament group is pulled at a pulling device inlet fiber temperature of 40 ° C and a pulling air wind speed of 17,500 m / min using an air jet high-speed airflow traction device.

- a long fiber web having an average single yarn fineness of 1.1 dtex was prepared.

- the obtained web was passed between a flat roll and an embossing roll (pattern specification: circular with a diameter of 0.425 mm, staggered arrangement, horizontal pitch 2.1 mm, vertical pitch 1.1 mm, crimping area ratio 6.3%).

- the fibers were bonded at a temperature of 135 ° C. and a linear pressure of 35 kgf / cm to obtain a long fiber nonwoven fabric having a basis weight of 17 g / m 2 .

- Example 2 The fiber temperature at the pulling device inlet was 50 ° C., the pulling air wind speed was 15,000 m / min, and a long fiber nonwoven fabric having an average single yarn fineness of 1.5 dtex and a basis weight of 11 g / m 2 was obtained in the same manner as in Example 1.

- Example 3 Single-hole discharge rate of 0.90 g / min ⁇ Hole, fiber temperature at the pulling device inlet is 65 ° C., pulling air wind speed is 12,500 m / min, and the average single yarn fineness is 2.0 dtex and the basis weight is 25 g in the same manner as in Example 1. / M 2 long fiber nonwoven fabric was obtained.

- Example 4 Polypropylene resin with an MFR of 60 g / 10 min (measured at a temperature of 230 ° C. and a load of 2.16 kg according to JIS-K7210) by a spunbond method, nozzle diameter ⁇ 0.48 mm, single hole discharge rate 0.33 g / min ⁇ Hole

- the filament group was extruded at a spinning temperature of 230 ° C., and the filament group was pulled at a pulling device inlet fiber temperature of 40 ° C. and a pulling air wind speed of 6,400 m / min, and extruded toward the moving collection surface.

- a long fiber web having an average single yarn fineness of 1.1 dtex was prepared. Subsequently, the fibers were bonded together in the same manner as in Example 1 to obtain a long fiber nonwoven fabric having a basis weight of 17 g / m 2 .

- Example 5 Single-hole discharge of 0.66 g / min ⁇ Hole, fiber temperature at the pulling device inlet is 60 ° C., pulling air wind speed is 5,500 m / min, and the average single yarn fineness is 2.2 dtex and the basis weight is 20 g as in Example 4. / M 2 long fiber nonwoven fabric was obtained.

- Example 6 The fiber temperature at the pulling device inlet was 50 ° C., the pulling air wind speed was 10,000 m / min, and a long fiber nonwoven fabric with an average single yarn fineness of 2.8 dtex and a basis weight of 18 g / m 2 was obtained in the same manner as in Example 3.

- the obtained non-woven fabric was passed through a corona discharge treatment machine under a discharge amount of 40 W ⁇ min / m 2 (discharge degree: 4.0 W / cm 2 ) in an atmosphere at room temperature of 22 ° C., and a non-woven fabric having a wetting tension of 39 mN / m was obtained. Obtained.

- a polyether-based hydrophilizing agent was applied to the obtained non-woven fabric by a spray method, followed by hot-air drying at 80 ° C. for 5 minutes to obtain a long-fiber non-woven fabric having an agent concentration adhesion amount of 0.3% by weight.

- Example 7 The fiber temperature at the pulling device inlet is 50 ° C., the pulling air wind speed is 12,500 m / min, and the average single yarn fineness is 2.0 dtex and the agent concentration adhesion amount is 15 g / m 2 in the same manner as in Example 6. A non-woven fabric having a long fiber weight was obtained.

- Example 8 The fiber temperature at the pulling device inlet was 60 ° C., the pulling air wind speed was 5,000 m / min, and a long fiber nonwoven fabric having an average single yarn fineness of 2.6 dtex and a basis weight of 17 g / m 2 was obtained in the same manner as in Example 5.

- the obtained non-woven fabric was passed through a corona discharge treatment machine under a discharge amount of 40 W ⁇ min / m 2 (discharge degree: 4.0 W / cm 2 ) in an atmosphere at room temperature of 22 ° C., and a non-woven fabric having a wetting tension of 39 mN / m was obtained. Obtained.

- a polyether-based hydrophilizing agent was applied to the obtained non-woven fabric by a kiss coater method, followed by hot-air drying at 80 ° C. for 5 minutes to obtain a long-fiber non-woven fabric having an agent concentration adhesion amount of 0.3% by weight.

- Example 9 Mixing 1.25% by weight of glycerides of octadecanoic acid (hydrogenated vegetable oils and fats) with a melting point of 86-90 ° C (average melting point of 88 ° C), fiber temperature at the traction device inlet is 40 ° C, and traction air wind speed is 17,500m / As in Example 1, a long fiber nonwoven fabric having an average single yarn fineness of 1.1 dtex and a basis weight of 17 g / m 2 was obtained.

- Example 10 An average monofilament as in Example 1 was mixed with 3.50% by weight of glycerides of octadecanoic acid (hydrogenated vegetable oil and fat), the fiber temperature at the inlet of the traction device was 40 ° C., and the traction air wind speed was 17,500 m / min. A long fiber web having a fineness of 1.1 dtex was prepared. Next, the obtained web was passed between a flat roll and an embossing roll (pattern specification: slanted ridge pattern, pressure bonding area ratio 14%) to bond the fibers at a temperature of 135 ° C. and a linear pressure of 35 kgf / cm, and a basis weight of 15 g. / M 2 long fiber nonwoven fabric was obtained.

- glycerides of octadecanoic acid hydrochloride

- Example 3 The fiber temperature at the pulling device inlet was 40 ° C., the pulling air wind speed was 17,500 m / min, and a long fiber web having an average single yarn fineness of 1.1 dtex was obtained in the same manner as in Example 1.

- the obtained web was passed between a flat roll and an embossing roll (pattern specification: texture pattern, horizontal pitch 2.0 mm, vertical pitch 2.0 mm, crimping area 14.4%), and the temperature was linear pressure at 148 ° C. Was 50 kgf / cm, and a non-woven fabric having a basis weight of 17 g / m 2 was obtained.

- the nonwoven fabric of the present invention has high thermal stability, excellent flexibility, and good workability, it can be suitably used for sanitary material top sheets, back sheets, side gathers, and the like.

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Epidemiology (AREA)

- General Health & Medical Sciences (AREA)

- Biomedical Technology (AREA)

- Veterinary Medicine (AREA)

- Dermatology (AREA)

- Nonwoven Fabrics (AREA)

- Absorbent Articles And Supports Therefor (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

- Laminated Bodies (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201180069808.XA CN103459695B (zh) | 2011-04-06 | 2011-11-01 | 热稳定性、柔软性优异的无纺布 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011084585 | 2011-04-06 | ||

| JP2011-084585 | 2011-04-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012137378A1 true WO2012137378A1 (ja) | 2012-10-11 |

Family

ID=45775735

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/075207 Ceased WO2012137378A1 (ja) | 2011-04-06 | 2011-11-01 | 熱安定性、柔軟性に優れる不織布 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP5818636B2 (enExample) |

| CN (1) | CN103459695B (enExample) |

| MY (1) | MY164201A (enExample) |

| WO (1) | WO2012137378A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019196576A (ja) * | 2018-05-07 | 2019-11-14 | 東レ株式会社 | スパンボンド不織布 |

| US20200240061A1 (en) * | 2017-09-28 | 2020-07-30 | Toray Industries, Inc. | Spunbond nonwoven fabric |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11369313B2 (en) * | 2016-12-13 | 2022-06-28 | Amolifescience Co., Ltd. | Patch-type sensor module |

| JP7172250B2 (ja) * | 2018-02-08 | 2022-11-16 | 東レ株式会社 | スパンボンド不織布 |

| CN110306293B (zh) * | 2019-05-13 | 2021-07-23 | 山东寿光鲁清石化有限公司 | 一种超柔无纺布及制备工艺以及在婴儿尿不湿中的应用 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009138311A (ja) * | 2007-12-10 | 2009-06-25 | Asahi Kasei Fibers Corp | 柔軟性のある長繊維不織布 |

| WO2010024268A1 (ja) * | 2008-09-01 | 2010-03-04 | 三井化学株式会社 | 長繊維不織布 |

| JP2010168715A (ja) * | 2008-12-25 | 2010-08-05 | Kao Corp | 不織布及びその製造方法 |

| JP2010168713A (ja) * | 2008-12-24 | 2010-08-05 | Idemitsu Kosan Co Ltd | 弾性不織布、その製造方法及び繊維製品 |

| WO2011030893A1 (ja) * | 2009-09-14 | 2011-03-17 | 出光興産株式会社 | スパンボンド不織布および繊維製品 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1096157A (ja) * | 1996-09-24 | 1998-04-14 | Mitsui Petrochem Ind Ltd | 柔軟性不織布 |

| JP3662455B2 (ja) * | 1999-11-22 | 2005-06-22 | ユニ・チャーム株式会社 | ポリプロピレン製不織布およびその製造方法 |

| JP2003129364A (ja) * | 2001-10-18 | 2003-05-08 | Ube Nitto Kasei Co Ltd | ポリプロピレン系熱圧着不織布 |

| CN100503911C (zh) * | 2003-01-30 | 2009-06-24 | 陶氏环球技术公司 | 由不混溶聚合物混合物形成的纤维 |

-

2011

- 2011-10-31 JP JP2011239402A patent/JP5818636B2/ja active Active

- 2011-11-01 MY MYPI2013701720A patent/MY164201A/en unknown

- 2011-11-01 WO PCT/JP2011/075207 patent/WO2012137378A1/ja not_active Ceased

- 2011-11-01 CN CN201180069808.XA patent/CN103459695B/zh active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009138311A (ja) * | 2007-12-10 | 2009-06-25 | Asahi Kasei Fibers Corp | 柔軟性のある長繊維不織布 |

| WO2010024268A1 (ja) * | 2008-09-01 | 2010-03-04 | 三井化学株式会社 | 長繊維不織布 |

| JP2010168713A (ja) * | 2008-12-24 | 2010-08-05 | Idemitsu Kosan Co Ltd | 弾性不織布、その製造方法及び繊維製品 |

| JP2010168715A (ja) * | 2008-12-25 | 2010-08-05 | Kao Corp | 不織布及びその製造方法 |

| WO2011030893A1 (ja) * | 2009-09-14 | 2011-03-17 | 出光興産株式会社 | スパンボンド不織布および繊維製品 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20200240061A1 (en) * | 2017-09-28 | 2020-07-30 | Toray Industries, Inc. | Spunbond nonwoven fabric |

| JP2019196576A (ja) * | 2018-05-07 | 2019-11-14 | 東レ株式会社 | スパンボンド不織布 |

| JP7110795B2 (ja) | 2018-05-07 | 2022-08-02 | 東レ株式会社 | スパンボンド不織布 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103459695A (zh) | 2013-12-18 |

| CN103459695B (zh) | 2017-06-13 |

| JP2012021260A (ja) | 2012-02-02 |

| MY164201A (en) | 2017-11-30 |

| JP5818636B2 (ja) | 2015-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6034022B2 (ja) | 不織布積層体 | |

| JP4599366B2 (ja) | メルトフローレートの高い繊維を含有する柔軟で伸張性のある不織布ウェブ | |

| JP6873931B2 (ja) | 柔軟な不織布ウェブを備える物品 | |

| US9345802B2 (en) | Absorbent article with barrier component | |

| JP6714982B2 (ja) | 嵩高性複合長繊維不織布 | |

| EP2270271A1 (en) | High barrier nonwoven | |

| JP5818636B2 (ja) | 熱安定性、柔軟性に優れる不織布 | |

| JP7140803B2 (ja) | 繊維加工剤、及びこれを含有する液透過性不織布 | |

| WO2010151410A1 (en) | Absorbent article with barrier component | |

| CZ2012757A3 (cs) | Netkaná textilie se zlepšeným omakem a mechanickými vlastnostmi | |

| JP5948537B2 (ja) | 柔軟性のある長繊維不織布 | |

| JP5731948B2 (ja) | 熱可塑性不織布 | |

| JP4642063B2 (ja) | 柔軟性のある長繊維不織布 | |

| JP5948541B2 (ja) | ポリプロピレン系不織布 | |

| JP2011084824A (ja) | 繊維用親水化剤及びそれを含有する繊維 | |

| TWI717037B (zh) | 抑制熱熔透印之不織布 | |

| CN114364834A (zh) | 卷曲复合纤维无纺布及其层压制品与物品 | |

| JP2019157306A (ja) | 嵩高柔軟不織布 | |

| JP7028695B2 (ja) | 嵩高柔軟不織布 | |

| CZ2012761A3 (cs) | Netkaná textilie se zlepšeným omakem a mechanickými vlastnostmi |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11863022 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 11863022 Country of ref document: EP Kind code of ref document: A1 |