WO2012043818A1 - 合わせガラス用中間膜及び合わせガラス - Google Patents

合わせガラス用中間膜及び合わせガラス Download PDFInfo

- Publication number

- WO2012043818A1 WO2012043818A1 PCT/JP2011/072615 JP2011072615W WO2012043818A1 WO 2012043818 A1 WO2012043818 A1 WO 2012043818A1 JP 2011072615 W JP2011072615 W JP 2011072615W WO 2012043818 A1 WO2012043818 A1 WO 2012043818A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- laminated glass

- polyvinyl acetal

- acetal resin

- mol

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/10761—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer containing vinyl acetal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10009—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets

- B32B17/10036—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets comprising two outer glass sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/22—Layered products comprising a layer of synthetic resin characterised by the use of special additives using plasticisers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/0008—Organic ingredients according to more than one of the "one dot" groups of C08K5/01 - C08K5/59

- C08K5/0016—Plasticisers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/03—3 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/10—Properties of the layers or laminate having particular acoustical properties

- B32B2307/102—Insulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/08—Cars

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/10—Trains

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/12—Ships

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/18—Aircraft

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24942—Structurally defined web or sheet [e.g., overall dimension, etc.] including components having same physical characteristic in differing degree

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31551—Of polyamidoester [polyurethane, polyisocyanate, polycarbamate, etc.]

- Y10T428/31627—Next to aldehyde or ketone condensation product

- Y10T428/3163—Next to acetal of polymerized unsaturated alcohol [e.g., formal butyral, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31855—Of addition polymer from unsaturated monomers

- Y10T428/31909—Next to second addition polymer from unsaturated monomers

Definitions

- the present invention relates to an interlayer film for laminated glass used for laminated glass such as automobiles and buildings, and more specifically, an interlayer film for laminated glass containing a polyvinyl acetal resin and a plasticizer, and the interlayer film for laminated glass. It relates to the laminated glass used.

- Laminated glass is superior in safety even if it is damaged by an external impact and the amount of glass fragments scattered is small. For this reason, the said laminated glass is widely used for a motor vehicle, a rail vehicle, an aircraft, a ship, a building, etc.

- the laminated glass is manufactured by sandwiching an intermediate film between a pair of glass plates.

- Patent Document 1 discloses that 100 parts by weight of a polyvinyl acetal resin having an acetalization degree of 60 to 85 mol% and at least one of alkali metal salts and alkaline earth metal salts.

- a sound insulation layer containing 0.001 to 1.0 part by weight of a metal salt and 30 parts by weight or more of a plasticizer is disclosed. This sound insulation layer can be used as a single layer as an intermediate film or laminated with other layers as a multilayer intermediate film.

- the sound insulating property in the relatively high frequency range of the laminated glass is not sufficient, and hence the sound insulating property is inevitably lowered due to the coincidence effect.

- the sound insulation properties at around 20 ° C. of this laminated glass may not be sufficient.

- the coincidence effect means that when a sound wave is incident on the glass plate, the transverse wave propagates on the glass surface due to the rigidity and inertia of the glass plate, and the transverse wave and the incident sound resonate. This is a phenomenon that occurs.

- the sound insulating property in the vicinity of 20 ° C. of the laminated glass can be increased to some extent. it can.

- the multilayer interlayer film has the sound insulating layer, foaming may occur in the laminated glass using the multilayer interlayer film.

- An object of the present invention is to provide an interlayer film for laminated glass that can enhance the sound insulation of the obtained laminated glass, and a laminated glass using the interlayer film for laminated glass. Is to provide.

- a limited object of the present invention is to use an interlayer film for laminated glass that can obtain a laminated glass that not only has high sound insulation but also suppresses the occurrence of foaming and the growth of foam, and the interlayer film for laminated glass. It is to provide laminated glass.

- an interlayer film for laminated glass having a one-layer structure or a laminated structure of two or more layers, comprising a first layer containing a polyvinyl acetal resin and a plasticizer, the first layer

- An interlayer film for laminated glass is provided in which the degree of acetylation of the polyvinyl acetal resin contained in the layer exceeds 30 mol%.

- the interlayer film for laminated glass according to the present invention may be a single-layer interlayer film for laminated glass composed of only the first layer, or may be a multilayer interlayer film for laminated glass including the first layer. Good.

- the interlayer film for laminated glass having a laminated structure of two or more layers, the second layer disposed on the first surface side of the first layer. are further provided.

- the second layer contains a polyvinyl acetal resin

- the degree of acetylation of the polyvinyl acetal resin contained in the second layer is the above-mentioned

- the degree of acetylation of the polyvinyl acetal resin contained in one layer is lower.

- the degree of acetylation of the polyvinyl acetal resin contained in the second layer is 30 mol% or less.

- the second layer includes the polyvinyl acetal resin and a plasticizer, and the above-mentioned amount relative to 100 parts by weight of the polyvinyl acetal resin in the second layer.

- the plasticizer content is less than the plasticizer content relative to 100 parts by weight of the polyvinyl acetal resin in the first layer.

- the second layer is laminated on the first surface of the first layer.

- the interlayer film for laminated glass has a laminated structure of two or more layers, and is laminated on the first surface of the first layer, And a second layer containing a polyvinyl acetal resin and a plasticizer is further provided, and the content of the plasticizer with respect to 100 parts by weight of the polyvinyl acetal resin in the first layer is 50 parts by weight or more.

- the hydroxyl content of the polyvinyl acetal resin in the first layer is lower than the hydroxyl content of the polyvinyl acetal resin in the second layer, and the hydroxyl content of the polyvinyl acetal resin in the first layer

- the difference between the content and the hydroxyl content of the polyvinyl acetal resin in the second layer is 9.2 mol% or less

- the polyvinyl acetal resin in the first layer When the difference between the hydroxyl group content and the hydroxyl group content of the polyvinyl acetal resin in the second layer is more than 8.5 mol% and 9.2 mol% or less, the first The degree of acetylation of the polyvinyl acetal resin in the layer is 8 mol% or less.

- the polyvinyl acetal resin in the first layer contains a high molecular weight component having an absolute molecular weight of 1,000,000 or more, and in the first layer.

- the proportion of the high molecular weight component in the polyvinyl acetal resin is 7.4% or more, or the polyvinyl acetal resin in the first layer includes a high molecular weight component having a polystyrene equivalent molecular weight of 1 million or more, And the ratio of the said high molecular weight component to the said polyvinyl acetal resin in the said 1st layer is 9% or more.

- the glass transition temperature of the resin film is Tg. (Tg + 80) Ratio of elastic modulus G ′ (Tg + 80) at (Tg + 80) ° C. to elastic modulus G ′ (Tg + 30) at (Tg + 30) ° C. (G ′ (Tg + 80) / G ′ (Tg + 30)) Is 0.65 or more.

- the polyvinyl acetal resin in the first layer is obtained by acetalizing a polyvinyl alcohol resin having an average degree of polymerization exceeding 3000. .

- an interlayer film for laminated glass having a laminated structure of three or more layers, which is disposed on the first surface side of the first layer. And a third layer disposed on the second surface side opposite to the first surface of the first layer.

- the third layer contains a polyvinyl acetal resin, and the degree of acetylation of the polyvinyl acetal resin contained in the third layer is The degree of acetylation of the polyvinyl acetal resin contained in one layer is lower.

- the degree of acetylation of the polyvinyl acetal resin contained in the third layer is 30 mol% or less.

- the third layer contains a polyvinyl acetal resin and a plasticizer, and the plastic with respect to 100 parts by weight of the polyvinyl acetal resin in the third layer.

- the content of the agent is less than the content of the plasticizer with respect to 100 parts by weight of the polyvinyl acetal resin in the first layer.

- the third layer is laminated on the second surface of the first layer.

- the laminated glass according to the present invention includes a first laminated glass constituent member, a second laminated glass constituent member, and an intermediate film sandwiched between the first and second laminated glass constituent members.

- the interlayer film is an interlayer film for laminated glass constructed according to the present invention.

- the interlayer film for laminated glass according to the present invention includes a first layer containing a polyvinyl acetal resin and a plasticizer, and the degree of acetylation of the polyvinyl acetal resin contained in the first layer is 30 mol. Therefore, the sound insulation of the laminated glass using the interlayer film for laminated glass according to the present invention can be improved.

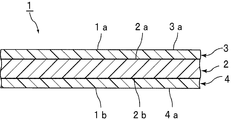

- FIG. 1 is a partially cutaway cross-sectional view schematically showing an interlayer film for laminated glass according to an embodiment of the present invention.

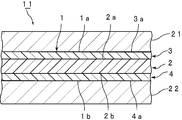

- FIG. 2 is a partially cutaway cross-sectional view schematically showing an example of laminated glass using the interlayer film for laminated glass shown in FIG.

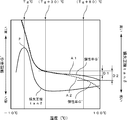

- FIG. 3 shows a loss tangent tan ⁇ when the viscoelasticity of the resin film is measured by using a resin film containing polyvinyl acetal resin contained in the first layer and triethylene glycol di-2-ethylhexanoate. It is a figure for demonstrating the relationship between temperature, and the relationship between elastic modulus G 'and temperature.

- FIG. 1 schematically shows a laminated glass using an interlayer film for laminated glass according to an embodiment of the present invention in a partially cutaway sectional view.

- the intermediate film 1 shown in FIG. 1 is a multilayer intermediate film.

- the intermediate film 1 is used to obtain a laminated glass.

- the intermediate film 1 is an intermediate film for laminated glass.

- the intermediate film 1 is opposite to the first layer 2, the second layer 3 disposed on the first surface 2 a side of the first layer 2, and the first surface 2 a of the first layer 2.

- a third layer 4 disposed on the second surface 2b side.

- the second layer 3 is laminated on the first surface 2 a of the first layer 2.

- the third layer 4 is laminated on the second surface 2 b of the first layer 2.

- the first layer 2 is an intermediate layer and mainly functions as a sound insulation layer.

- the second and third layers 3 and 4 are protective layers, and are surface layers in this embodiment.

- the first layer 2 is disposed between the second and third layers 3 and 4.

- the first layer 2 is sandwiched between the second and third layers 3 and 4. Therefore, the intermediate film 1 has a multilayer structure in which the second layer 3, the first layer 2, and the third layer 4 are laminated in this order.

- first layer 2 and the second layer 3 and between the first layer 2 and the third layer 4 may be laminated between the first layer 2 and the second layer 3 and between the first layer 2 and the third layer 4, respectively. It is preferable that the first layer 2 and the second layer 3 and the first layer 2 and the third layer 4 are directly laminated, respectively.

- the other layer include a layer containing a thermoplastic resin such as polyvinyl acetal resin, and a layer containing polyethylene terephthalate.

- the first layer 2 includes a polyvinyl acetal resin having a degree of acetylation exceeding 30 mol% and a plasticizer.

- the second layer 3 preferably includes a polyvinyl acetal resin, and preferably includes a polyvinyl acetal resin and a plasticizer.

- the second layer 3 includes, for example, a polyvinyl acetal resin having a degree of acetylation of 30 mol% or less and a plasticizer.

- the third layer 4 preferably includes a polyvinyl acetal resin, and preferably includes a polyvinyl acetal resin and a plasticizer.

- the 3rd layer 4 contains the polyvinyl acetal resin whose acetylation degree is 30 mol% or less, and a plasticizer, for example.

- the compositions of the first layer 2 and the second and third layers 3 and 4 are preferably different.

- the composition of the second layer 3 and the third layer 4 may be the same or different.

- the main feature of this embodiment is that the first layer 2 containing a polyvinyl acetal resin and a plasticizer is provided, and the degree of acetylation of the polyvinyl acetal resin contained in the first layer 2 is 30 mol%. It is to exceed.

- This embodiment is particularly characterized in that the degree of acetylation of the polyvinyl acetal resin contained in the first layer 2 is quite high and exceeds 30 mol%. Thereby, the sound insulation of the laminated glass using the intermediate film 1 can be improved.

- the first layer 2 containing a polyvinyl acetal resin having an acetylation degree exceeding 30 mol% can enhance sound insulation in a temperature range of 20 to 30 ° C.

- a laminated glass used for a fuel vehicle using an internal combustion engine is particularly required to have sound insulation in a relatively low frequency range.

- the laminated glass used in a fuel vehicle using an internal combustion engine has high sound insulation in a high frequency range.

- the high sound-insulation property in a high frequency region is calculated

- the inventors have also found that the first layer 2 containing a polyvinyl acetal resin having an acetylation degree exceeding 30 mol% can effectively and sufficiently enhance the sound insulation in a high frequency range of the laminated glass. .

- second and third layers 3 and 4 are laminated on both surfaces of the first layer 2.

- the second layer is preferably disposed on the first surface side of the first layer, and the second layer is preferably laminated on the first surface of the first layer.

- the second layer may be disposed only on the first surface side of the first layer, and the third layer may not be disposed on the second surface side of the first layer.

- it is preferable that the second layer is disposed on the first surface side of the first layer, and the third layer is disposed on the second surface side of the first layer.

- the third layer is laminated on the second surface of the first layer.

- the interlayer film for laminated glass having a multilayer structure with improved sound insulation has a problem that foaming is likely to occur in the laminated glass.

- the present inventors have found that in the interlayer film for laminated glass having a multilayer structure, the plasticizer migrates between the respective layers, and as a result, a layer having a high plasticizer content is formed.

- the plasticizer migrates from the second and third layers to the first layer, and as a result, the plasticizer content in the first layer increases.

- foaming is likely to occur in the laminated glass using the interlayer film for laminated glass. It has also been found that once foaming occurs, foaming grows with the resulting foam as a nucleus.

- the content of the plasticizer with respect to 100 parts by weight of the polyvinyl acetal resin in the first layer 2 is 50 parts by weight or more, and the first layer

- the hydroxyl group content of the polyvinyl acetal resin in 2 is lower than the hydroxyl group content of the polyvinyl acetal resin in the second layer 3, and the hydroxyl group content of the polyvinyl acetal resin in the first layer 2.

- the difference between the hydroxyl group content of the polyvinyl acetal resin in the second layer 3 (hereinafter sometimes referred to as a content difference (1-2)) is 9.2 mol% or less, and

- the difference (content ratio difference (1-2)) between the hydroxyl group content of the polyvinyl acetal resin in the first layer 2 and the hydroxyl group content of the polyvinyl acetal resin in the second layer 3 is 8. 5 models %, Greater to or less than 9.2 mol% is preferably acetylation degree of the polyvinyl acetal resin in the first layer 2 is not more than 8 mol%.

- the content difference (1-2) may be more than 8.5 mol% and 9.2 mol% or less, and may be 8.5 mol% or less.

- the hydroxyl group content of the polyvinyl acetal resin in the first layer 2 is lower than the hydroxyl group content of the polyvinyl acetal resin in the third layer 4, and the polyvinyl acetal in the first layer 2.

- the difference between the hydroxyl group content of the resin and the hydroxyl group content of the polyvinyl acetal resin in the third layer 4 was 9.2 mol.

- the acetylation degree of the polyvinyl acetal resin in the first layer 2 is preferably 8 mol% or less.

- the content difference (1-3) is 8.5 mol% or less

- the content difference (1-2) exceeds 8.5 mol% and is 9.2 mol% or less.

- the degree of acetylation of the polyvinyl acetal resin in the first layer 2 is preferably 8 mol% or less.

- the content difference (1-3) exceeds 8.5 mol%, may be 9.2 mol% or less, and may be 8.5 mol% or less.

- the present inventors have controlled the content of each hydroxyl group of the polyvinyl acetal resin in the first to third layers as described above.

- the occurrence of foaming and the growth of foaming in the laminated glass can be sufficiently suppressed. Since the migration of the plasticizer can be suppressed and the occurrence of foaming and the growth of foaming in the laminated glass can be sufficiently suppressed, the content of the plasticizer in each layer, particularly the content of the plasticizer in the first layer 2 is increased. be able to. For this reason, the sound insulation of a laminated glass can be improved further.

- content of the said plasticizer with respect to 100 weight part of the said polyvinyl acetal resin in the 1st layer 2 is content of the said plasticizer with respect to 100 weight part of the said polyvinyl acetal resin in the 2nd, 3rd layers 3 and 4.

- the amount is larger than the amount, foaming tends to occur more easily. Furthermore, once foaming occurs, the generated foam becomes a nucleus and the foam tends to grow.

- the content of each hydroxyl group of the polyvinyl acetal resin in the first to third layers as described above, the occurrence of foaming and the growth of foam in the laminated glass can be sufficiently suppressed.

- the preferred lower limit of the difference from the content of each hydroxyl group in the acetal resin is 0.1 mol%, more preferred lower limit is 1 mol%, still more preferred.

- the lower limit is 2 mol%, the preferred upper limit is 8.5 mol%, the more preferred upper limit is 7.8 mol%, the still more preferred upper limit is 7 mol%, and the particularly preferred upper limit is 5.6 mol%.

- the hydroxyl group content of the polyvinyl acetal resin in the first layer 2 and the above in the second and third layers 3 and 4 The difference from the content of each hydroxyl group in the polyvinyl acetal resin (content difference (1-2) and content difference (1-3)) is preferably 5 mol% or less, more preferably 4.5 mol% or less, more More preferably, it is 4 mol% or less, More preferably, it is 3.5 mol% or less.

- the polyvinyl acetal resin in the first layer 2 contains a high molecular weight component having an absolute molecular weight of 1,000,000 or more (hereinafter sometimes referred to as a high molecular weight component X), or in the first layer 2

- the polyvinyl acetal resin preferably contains a high molecular weight component (hereinafter sometimes referred to as a high molecular weight component Y) having a molecular weight of polystyrene equivalent (hereinafter sometimes referred to as a molecular weight y) of 1,000,000 or more.

- the high molecular weight components X and Y are polyvinyl acetal resins.

- the proportion of the high molecular weight component X in the polyvinyl acetal resin in the first layer 2 is 7.4% or more, or the high molecular weight component in the polyvinyl acetal resin in the first layer 2

- the proportion of Y is preferably 9% or more.

- the polyvinyl acetal resin in the first layer 2 contains the high molecular weight component X having an absolute molecular weight of 1 million or more in the specific ratio, it is possible to suppress foaming from occurring in the laminated glass. Even when the polyvinyl acetal resin in the first layer 2 contains the high molecular weight component Y having a molecular weight y of 1,000,000 or more in the above specific ratio, foaming of the laminated glass can be suppressed.

- the ratio of the high molecular weight component X in the polyvinyl acetal resin in the first layer 2 is the high molecular weight component X in the peak area of the polyvinyl acetal resin component obtained when measuring the absolute molecular weight. Is defined as a value expressed as a percentage (%).

- the proportion of the high molecular weight component Y in the polyvinyl acetal resin in the first layer 2 is the high molecular weight component in the peak area of the polyvinyl acetal resin component obtained when measuring the polystyrene equivalent molecular weight.

- the area ratio of the area corresponding to Y is defined as a value expressed as a percentage (%).

- compositions of the second and third layers 3 and 4 are preferably different from the composition of the first layer 2.

- the polyvinyl acetal resin in the second and third layers 3 and 4 contains the high molecular weight component X having an absolute molecular weight of 1 million or more, and occupies the polyvinyl acetal resin in the second and third layers 3 and 4.

- the ratio of the high molecular weight component X may be 7.4% or more, the high molecular weight component Y having a molecular weight y of 1,000,000 or more is included, and the polyvinyl in the second and third layers 3 and 4

- the proportion of the high molecular weight component Y in the acetal resin may be 9% or more.

- a high molecular weight component having an absolute molecular weight of 1 million or more in the polyvinyl acetal resin in the first layer 2 The preferable lower limit of the ratio of X is 8%, the more preferable lower limit is 8.5%, the still more preferable lower limit is 9%, the particularly preferable lower limit is 9.5%, and the most preferable lower limit is 10%.

- the ratio of the high molecular weight component X is preferably 11% or more, more preferably 12% or more, and still more preferably 14 because the sound insulation of the laminated glass can be further enhanced and the generation of foaming and the growth of foaming can be further suppressed. % Or more, particularly preferably 16% or more.

- the upper limit of the ratio of the high molecular weight component X is not particularly limited, the preferable upper limit is 40%, the more preferable upper limit is 30%, and the further preferable upper limit is 25%.

- the polyvinyl acetal resin in the first layer 2 contains a high molecular weight component Y having a molecular weight y of 1,000,000 or more, it accounts for the polyvinyl acetal resin in the first layer 2 containing the high molecular weight component Y.

- the preferable lower limit of the proportion of the high molecular weight component Y having a molecular weight y of 1,000,000 or more is 10%, the more preferable lower limit is 11%, the still more preferable lower limit is 11.5%, and the particularly preferable lower limit is 12%.

- the ratio of the high molecular weight component Y is preferably 12.5% or more, more preferably 13.5% or more, since the sound insulation of the laminated glass can be further enhanced and the occurrence of foaming and the growth of foaming can be further suppressed. More preferably, it is 14% or more, particularly preferably 15% or more, and most preferably 18% or more.

- the upper limit of the proportion of the high molecular weight component Y is not particularly limited, but the preferable upper limit is 40%, the more preferable upper limit is 30%, and the further preferable upper limit is 25%. When the proportion of the high molecular weight component Y is not less than the above lower limit, the sound insulating properties of the laminated glass can be further enhanced, and the generation of foam and the growth of foam can be further suppressed.

- the resin film A containing 100 parts by weight of the polyvinyl acetal resin contained in the first layer 2 and 60 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) as a plasticizer, the resin film

- Tg glass transition temperature

- Tg + 30 glass transition temperature

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) to the elastic modulus G ′ (Tg + 30) at ° C. is preferably 0.65 or more.

- the glass transition temperature of the resin film B is Tg (° C.)

- the ratio of the elastic modulus G ′ (Tg + 80) at Tg + 80) ° C. to the elastic modulus G ′ (Tg + 30) at (Tg + 30) ° C. is 0.65 or more. Is also preferable.

- the first layer 2 is used as the resin film B, and the first layer 2 itself is the resin film B.

- the resin film B is the first layer 2 and includes the polyvinyl acetal resin and the plasticizer in a weight ratio in the first layer 2.

- the elastic modulus is It is more preferable to measure G ′ (Tg + 80) and elastic modulus G ′ (Tg + 30).

- the present inventors have found that the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) according to Test Method A or Test Method B is It was also found that the occurrence of foaming and the growth of foaming in the laminated glass can be sufficiently suppressed by being 0.65 or more. Even if there is much content of the said plasticizer in the 1st layer 2, since generation

- the second and third layers 3 and 4 are laminated on both surfaces of the first layer 2 configured so that the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is 0.65 or more.

- the use of the interlayer film 1 for laminated glass can further suppress the generation of foam and the growth of foam in the laminated glass.

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is 0.65 or more, preferably 1.0 or less.

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is 0.65 or more, even if the laminated glass is stored under considerably severe conditions or for a long period of time, the occurrence of foaming and foaming in the laminated glass Can be sufficiently suppressed.

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is not less than the above lower limit and not more than the above upper limit, even if the laminated glass is stored under considerably severe conditions or for a long time, Generation of foaming and growth of foaming can be more effectively suppressed.

- the content of the plasticizer with respect to 100 parts by weight of the polyvinyl acetal resin in the first layer 2 is preferably 40 parts by weight or more.

- the glass transition temperature Tg (° C.) indicates the peak temperature of the loss tangent tan ⁇ obtained from the measurement result obtained by measuring the viscoelasticity.

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is more preferably 0.7 or more, and more preferably 0.95. It is below, More preferably, it is 0.75 or more, More preferably, it is 0.9 or less.

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is preferably 0.65 or more, more preferably 0.66 or more, and further preferably 0.67 or more. Particularly preferably, it is 0.7 or more, preferably 0.82 or less, more preferably 0.8 or less. Further, when the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is 0.82 or less, or 0.8 or less, the intermediate film can be easily formed.

- the intermediate film 1 can be easily formed by an extruder, a method of using a polyvinyl alcohol resin having a relatively high average degree of polymerization when synthesizing the polyvinyl acetal resin in the first layer 2.

- a method of physically cross-linking the molecules of the polyvinyl acetal resin in the first layer 2 is preferable.

- the loss tangent tan ⁇ and the temperature have a relationship as shown in FIG.

- the temperature at the peak P of the loss tangent tan ⁇ is the glass transition temperature Tg.

- the glass transition temperature Tg at the elastic modulus G ′ of the broken line A2 shown in FIG. 3 and the glass transition temperature Tg at the elastic modulus G ′ of the solid line A1 are the same temperature.

- the change amount D1 in the elastic modulus G ′ of the solid line A1 is smaller than the change amount D2 in the elastic modulus G ′ of the broken line A2. Therefore, in FIG.

- the G ′ (Tg + 30) is preferably 200,000 Pa or more.

- G ′ (Tg + 30) is more preferably 220,000 Pa or more, further preferably 230,000 Pa or more, particularly preferably 240,000 Pa or more, preferably 10 million Pa or less, more preferably 5 million Pa or less, particularly preferably It is 1,000,000 Pa or less, most preferably 500,000 Pa or less, and most preferably 300,000 Pa or less.

- production of foaming and growth of foaming in a laminated glass can be suppressed more effectively as said G '(Tg + 30) is more than the said minimum.

- the relationship between the elastic modulus G ′ and the temperature is greatly influenced by the kind of the polyvinyl acetal resin, particularly greatly influenced by the average degree of polymerization of the polyvinyl alcohol resin used for obtaining the polyvinyl acetal resin. It is not greatly affected by the type, and the content of the general plasticizer is not greatly affected by the content of the plasticizer.

- G ′ (Tg + 30)) is not significantly different from the above ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) when 3GO is used.

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) does not greatly differ.

- the above ratio (G ′ (Tg + 80) / G ′) measured using a resin film containing 100 parts by weight of polyvinyl acetal resin and 60 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) as a plasticizer. (Tg + 30)) is not significantly different from the above ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) measured using the first layer 2 itself.

- Both of the above ratios (G ′ (Tg + 80) / G ′ (Tg + 30)) obtained by the above test method A and the above test method B are preferably 0.65 or more.

- the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is more preferably 0.65 or more.

- the said polyvinyl acetal resin in the 1st layer 2 is obtained by acetalizing the polyvinyl alcohol resin with an average degree of polymerization exceeding 3000. It is also preferable. In this case, the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) may not be 0.65 or more, but is preferably 0.65 or more.

- content of the said plasticizer with respect to 100 weight part of acetal resins is 40 weight part or more. Furthermore, from the viewpoint of further suppressing the generation of foaming and the growth of foaming in the laminated glass, the polyvinyl alcohol obtained by acetalizing a polyvinyl alcohol resin having an average degree of polymerization exceeding 3000 in the first layer 2.

- the hydroxyl group content of the acetal resin is preferably 30 mol% or less.

- the content of the plasticizer with respect to 100 parts by weight of the polyvinyl acetal resin in the first layer 2 is preferably 40 parts by weight or more, more preferably 50 parts by weight. Above, more preferably 55 parts by weight or more, particularly preferably 60 parts by weight or more.

- the content of each hydroxyl group of the polyvinyl acetal resin in the first to third layers is controlled as described above, or the absolute molecular weight is The ratio of the high molecular weight component X of 1 million or more or the ratio of the high molecular weight component Y having the molecular weight y of 1 million or more is controlled, or the ratio (G ′ (Tg + 80) / G ′ (Tg + 30)) is controlled.

- production of foaming and the growth of foaming in a laminated glass can be suppressed much more effectively.

- the polyvinyl acetal resin contained in the first layer (hereinafter sometimes referred to as polyvinyl acetal resin (1)) is not particularly limited as long as the degree of acetylation (acetyl group amount) exceeds 30 mol%.

- the second layer preferably contains a thermoplastic resin, and more preferably contains a polyvinyl acetal resin (hereinafter sometimes referred to as a polyvinyl acetal resin (2)).

- the third layer preferably includes a thermoplastic resin, and more preferably includes a polyvinyl acetal resin (hereinafter sometimes referred to as a polyvinyl acetal resin (3)).

- the adhesive force between the second and third layers and the laminated glass constituent member is sufficient. Get higher.

- thermoplastic resin examples include polyvinyl acetal resin, ethylene-vinyl acetate copolymer resin, ethylene-acrylic copolymer resin, polyurethane resin, and polyvinyl alcohol resin. Thermoplastic resins other than these may be used.

- the degree of acetylation of the polyvinyl acetal resin (1) exceeds 30 mol%, a preferred lower limit is 30.5 mol%, a more preferred lower limit is 32 mol%, a still more preferred lower limit is 35 mol%, and a particularly preferred lower limit is 40 mol. %, A preferred upper limit is 90 mol%, a more preferred upper limit is 80 mol%, a particularly preferred upper limit is 70 mol%, and a most preferred upper limit is 50 mol%.

- the acetylation degree is not less than the above lower limit, the sound insulating properties of the interlayer film and the laminated glass are enhanced. Furthermore, the compatibility of polyvinyl acetal resin (1) and a plasticizer becomes high as the said acetylation degree is more than the said minimum.

- the degree of acetylation of the polyvinyl acetal resins (2) and (3) is preferably lower than the degree of acetylation of the polyvinyl acetal resin (1).

- the degree of acetylation of the polyvinyl acetal resins (2) and (3) is lower than the degree of acetylation of the polyvinyl acetal resin (1), the penetration resistance of the laminated glass can be further enhanced.

- the degree of acetylation of the polyvinyl acetal resins (2) and (3) is preferably 0 mol% or more, more preferably 0.1 mol% or more, still more preferably 0.5 mol% or more, preferably 30 It is not more than mol%, more preferably not more than 20 mol%, still more preferably not more than 10 mol%, particularly preferably not more than 5 mol%, most preferably not more than 3 mol%.

- the acetylation degree is not more than the above upper limit, the penetration resistance of the interlayer film and the laminated glass is increased. Furthermore, when the degree of acetylation is not more than the above upper limit, bleed out of the plasticizer can be suppressed.

- the degree of acetylation of the polyvinyl acetal resins (2) and (3) is 3 mol% or less, the mechanical properties of the interlayer film are further improved. As a result, the penetration resistance of the laminated glass can be further enhanced.

- the degree of acetylation is obtained by subtracting the amount of ethylene groups to which acetal groups are bonded and the amount of ethylene groups to which hydroxyl groups are bonded from the total amount of ethylene groups of the main chain, This is a value expressed as a percentage (mol%) of the mole fraction obtained by dividing by.

- the amount of ethylene group to which the acetal group is bonded can be measured, for example, according to JIS K6728 “Testing method for polyvinyl butyral”.

- the difference is preferably 10 mol% or more, more preferably 20 mol% or more, preferably 50 mol% or less, more preferably 30 mol% or less.

- the difference in the degree of acetylation between the polyvinyl acetal resin (1) and the polyvinyl acetal resin (2), (3) is not less than the above lower limit and not more than the above upper limit, the sound insulation and penetration resistance of the interlayer film and the laminated glass are more It gets even higher.

- the polyvinyl acetal resins (1) to (3) can be produced, for example, by acetalizing polyvinyl alcohol with an aldehyde.

- the polyvinyl alcohol can be obtained, for example, by saponifying polyvinyl acetate.

- the saponification degree of the polyvinyl alcohol is generally in the range of 70 to 99.9 mol%, preferably in the range of 75 to 99.8 mol%, and preferably in the range of 80 to 99.8 mol%. It is more preferable.

- the average degree of polymerization of the polyvinyl alcohol for obtaining the polyvinyl acetal resins (1) to (3) is preferably 200 or more, more preferably 500 or more, still more preferably 1600 or more, particularly preferably 2600 or more, and most preferably. It is 2700 or more, preferably 5000 or less, more preferably 4000 or less, and further preferably 3500 or less.

- the average degree of polymerization is not less than the above lower limit, the penetration resistance of the laminated glass is further enhanced.

- the average degree of polymerization is not more than the above upper limit, the intermediate film can be easily molded.

- the average degree of polymerization of the polyvinyl alcohol is particularly preferably 2700 or more and 5000 or less.

- the preferred lower limit of the average degree of polymerization of the polyvinyl alcohol resin used to obtain the polyvinyl acetal resin (1) in the first layer is 3010, preferred lower limit is 3050, preferred lower limit is 3500, preferred lower limit is 3600, preferred lower limit is 4000, preferred lower limit is 4050, preferred upper limit is 7000, preferred upper limit is 6000, preferred upper limit is 5000, preferred upper limit is 4900, preferred upper limit is 4500.

- the occurrence of foaming and the growth of foaming in the laminated glass are further suppressed, the sound insulation of the laminated glass is sufficiently enhanced, and the intermediate film can be easily formed.

- the polyvinyl acetal resin (1 The average degree of polymerization of the polyvinyl alcohol resin used to obtain a) is preferably 3010 or more, more preferably 3020 or more, preferably 4000 or less, more preferably less than 4000, It is more preferably 3800 or less, particularly preferably 3600 or less, and most preferably 3500 or less.

- the polyvinyl acetal resins (2) and (3) in the second and third layers can be produced by acetalizing a polyvinyl alcohol resin.

- the preferable lower limit of the average degree of polymerization of the polyvinyl alcohol resin for obtaining the polyvinyl acetal resins (2) and (3) in the second and third layers is 200, the more preferable lower limit is 500, and the still more preferable lower limit is 1000, particularly preferable.

- the lower limit is 1500, the preferred upper limit is 4000, the more preferred upper limit is 3500, the still more preferred upper limit is 3000, and the particularly preferred upper limit is 2500.

- the average degree of polymerization satisfies the preferable lower limit, the penetration resistance of the laminated glass can be further enhanced.

- the average degree of polymerization satisfies the preferable upper limit the intermediate film can be easily formed.

- the average degree of polymerization of the polyvinyl alcohol resin used to obtain the polyvinyl acetal resin (1) in the first layer is such that the polyvinyl acetal resins (2) and (3) in the second and third layers are obtained. It is preferably higher than the average degree of polymerization of the polyvinyl alcohol resin to be used, preferably 500 or higher, preferably 800 or higher, more preferably 1000 or higher, still more preferably 1300 or higher, more preferably 1800 or higher. Particularly preferred.

- the average degree of polymerization of the polyvinyl alcohol is determined by a method based on JIS K6726 “Testing method for polyvinyl alcohol”.

- the carbon number of the acetal group contained in the polyvinyl acetal resin is not particularly limited.

- the aldehyde used when manufacturing the said polyvinyl acetal resin is not specifically limited.

- the acetal group in the polyvinyl acetal resin preferably has 3 to 5 carbon atoms, more preferably 3 or 4. When the carbon number of the acetal group in the polyvinyl acetal resin is 3 or more, the glass transition temperature of the intermediate film is sufficiently low, and the sound insulation of solid sound at a low temperature is further enhanced.

- the aldehyde is not particularly limited. In general, an aldehyde having 1 to 10 carbon atoms is preferably used as the aldehyde.

- Examples of the aldehyde having 1 to 10 carbon atoms include propionaldehyde, n-butyraldehyde, isobutyraldehyde, n-valeraldehyde, 2-ethylbutyraldehyde, n-hexylaldehyde, n-octylaldehyde, and n-nonylaldehyde.

- propionaldehyde, n-butyraldehyde, isobutyraldehyde, n-hexylaldehyde or n-valeraldehyde is preferable, propionaldehyde, n-butyraldehyde or isobutyraldehyde is more preferable, and n-butyraldehyde is further preferable.

- the said aldehyde only 1 type may be used and 2 or more types may be used together.

- the polyvinyl acetal resin is preferably a polyvinyl butyral resin.

- the interlayer film for laminated glass according to the present invention preferably contains a polyvinyl butyral resin as the polyvinyl acetal resin contained in the first to third layers. Synthesis of polyvinyl butyral resin is easy. Furthermore, the use of the polyvinyl butyral resin allows the intermediate film to have a more appropriate adhesive force with respect to the laminated glass component. Furthermore, light resistance, weather resistance, etc. can be further improved.

- the hydroxyl group content (hydroxyl content) of the polyvinyl acetal resin (1) is preferably 45 mol% or less, more preferably 35 mol% or less, still more preferably 30 mol% or less, still more preferably 25 mol% or less, Especially preferably, it is 20 mol% or less, Most preferably, it is 15 mol% or less.

- the content of the hydroxyl group is not more than the above upper limit, the sound insulating property of the laminated glass is further enhanced. Furthermore, the flexibility of the interlayer film is increased, and the handling of the interlayer film is facilitated. From the viewpoint of further improving the sound insulation in the high frequency region of the laminated glass, the lower the hydroxyl group content of the polyvinyl acetal resin (1), the better.

- the hydroxyl group content of the polyvinyl acetal resin (1) may be 0 mol%.

- the hydroxyl group content (hydroxyl content) of the polyvinyl acetal resins (2) and (3) is preferably higher than the hydroxyl group content of the polyvinyl acetal resin (1).

- the content of hydroxyl groups (hydroxyl group amount) in the polyvinyl acetal resins (2) and (3) is preferably 20 mol% or more, more preferably 25 mol% or more, still more preferably 30 mol% or more, preferably 50 mol%. Below, more preferably 45 mol% or less, still more preferably 40 mol% or less, and particularly preferably 35 mol% or less.

- the penetration resistance of a laminated glass becomes still higher that the content rate of the said hydroxyl group is more than the said minimum. Further, when the content of the hydroxyl group is not more than the upper limit, bleeding out of the plasticizer is difficult to occur. Furthermore, the flexibility of the interlayer film is increased, and the handling of the interlayer film is facilitated.

- the content of hydroxyl groups in the polyvinyl acetal resins (1) to (3) is a percentage (mol%) obtained by dividing the amount of ethylene groups to which hydroxyl groups are bonded by the total amount of ethylene groups in the main chain. ).

- the amount of the ethylene group to which the hydroxyl group is bonded can be determined, for example, by measuring the amount of ethylene group to which the hydroxyl group of polyvinyl alcohol as a raw material is bonded in accordance with JIS K6726 “Testing method for polyvinyl alcohol”. it can.

- the degree of acetalization of the polyvinyl acetal resin (1) is preferably 20 mol% or more, more preferably 25 mol% or more, still more preferably 30 mol% or more, preferably 65 The mol% or less, more preferably 60 mol% or less, still more preferably 55 mol% or less.

- the degree of acetalization is not less than the above lower limit, the compatibility between the polyvinyl acetal resin (1) and the plasticizer is increased, and bleeding out of the plasticizer can be suppressed.

- the degree of acetalization is less than or equal to the above upper limit, the reaction time required for producing a polyvinyl acetal resin is shortened.

- the degree of acetalization of the polyvinyl acetal resins (2) and (3) is preferably 55 mol% or more, more preferably 60 mol% or more, still more preferably 63 mol% or more. , Preferably 85 mol% or less, more preferably 75 mol% or less, and still more preferably 70 mol% or less.

- the degree of acetalization is not less than the above lower limit, the compatibility between the polyvinyl acetal resins (2) and (3) and the plasticizer is increased.

- the degree of acetalization is less than or equal to the above upper limit, the reaction time required for producing a polyvinyl acetal resin is shortened.

- the degree of acetalization is a value obtained by dividing a mole fraction obtained by dividing the amount of ethylene groups to which acetal groups are bonded by the total amount of ethylene groups in the main chain, as a percentage (mol%).

- the degree of acetalization was determined by measuring the acetylation degree (acetylation degree) and the hydroxyl group content (vinyl alcohol content) by a method based on JIS K6728 “Testing methods for polyvinyl butyral”. It can be calculated by calculating the fraction and then subtracting the degree of acetylation and the hydroxyl content from 100 mol%.

- the degree of acetalization was determined by measuring the acetylation degree (acetylation degree) and the hydroxyl group content (vinyl alcohol content) by a method based on JIS K6728 “Testing methods for polyvinyl butyral”. It can be calculated by calculating the fraction and then subtracting the degree of acetylation and the hydroxyl content from 100 mol%.

- the degree of acetalization (degree of butyralization) and the degree of acetylation are measured by a method based on JIS K6728 “Testing method for polyvinyl butyral” or ASTM D1396-92. Can be calculated from the results. Measurement by a method based on ASTM D1396-92 is preferred.

- the preferred lower limit of the weight average molecular weight of the polyvinyl acetal resins (1) to (3) is 100,000, the more preferred lower limit is 300,000, the preferred upper limit is 10,000,000, and the more preferred upper limit is 5,000,000. is there.

- the weight average molecular weight of the polyvinyl acetal resin is not more than the preferable lower limit, the strength of the interlayer film may be lowered.

- the weight average molecular weight of the polyvinyl acetal resin exceeds the preferable upper limit, the strength of the obtained interlayer film may be too strong.

- the said weight average molecular weight shows the weight average molecular weight in polystyrene conversion by gel permeation chromatography (GPC) measurement.

- the said weight average molecular weight and the said number average molecular weight show the weight average molecular weight and number average molecular weight in polystyrene conversion by a gel permeation chromatography (GPC) measurement.

- GPC gel permeation chromatography

- An approximate straight line obtained by plotting the molecular weight against the elution time indicated by the peak top of each standard sample peak is used as a calibration curve.

- the surface layer (the second and third layers) and the intermediate layer (the first layer) And the peeled first layer (intermediate layer) is dissolved in tetrahydrofuran (THF) to prepare a 0.1 wt% solution.

- the obtained solution can be analyzed by a GPC apparatus, and a weight average molecular weight and a number average molecular weight can be measured.

- a GPC apparatus As a GPC apparatus, a GPC apparatus (Hitachi High-Tech "RI: L2490, autosampler: L-2200, pump: L-2130, GPC apparatus to which a GPC light scattering detector (" Model 270 (RALS + VISCO) "manufactured by VISCOTEK)" is connected. Column oven: L-2350, column: GL-A120-S and GL-A100MX-S in series ”) can be used to analyze the weight average molecular weight and the number average molecular weight.

- Method for producing a polyvinyl acetal resin containing a high molecular weight component X having an absolute molecular weight of 1 million or more or a high molecular weight component Y having a molecular weight y of 1 million or more A specific method for producing a polyvinyl acetal resin containing a high molecular weight component X having an absolute molecular weight of 1 million or more or a high molecular weight component Y having a molecular weight y of 1 million or more will be described below.

- the polyvinyl alcohol can be obtained, for example, by saponifying polyvinyl acetate.

- the saponification degree of the polyvinyl alcohol is generally in the range of 70 to 99.9 mol%, preferably in the range of 75 to 99.8 mol%, and preferably in the range of 80 to 99.8 mol%. It is more preferable.

- the preferred lower limit of the degree of polymerization of the polyvinyl alcohol is 200, the more preferred lower limit is 500, the still more preferred lower limit is 1,000, the particularly preferred lower limit is 1,500, the preferred upper limit is 3,000, the more preferred upper limit is 2,900, and further A preferred upper limit is 2,800, and a particularly preferred upper limit is 2,700.

- the said polymerization degree is too low, there exists a tendency for the penetration resistance of a laminated glass to fall. If the polymerization degree is too high, it may be difficult to mold the intermediate film.

- the polyvinyl alcohol and aldehyde are reacted using a catalyst to acetalize the polyvinyl alcohol.

- a solution containing the polyvinyl alcohol may be used. Water etc. are mentioned as a solvent used for the solution containing this polyvinyl alcohol.

- the method for producing the polyvinyl acetal resin contained in the first layer is a method for producing a polyvinyl acetal resin by reacting polyvinyl alcohol with an aldehyde using a catalyst to acetalize the polyvinyl alcohol. Is preferred.

- the manufacturing method of the said 1st layer is the process of obtaining polyvinyl acetal resin by making polyvinyl alcohol and an aldehyde react using a catalyst, and acetalizing polyvinyl alcohol, and the obtained polyvinyl acetal resin and a plasticizer, It is preferable to provide the process of obtaining the said 1st layer using the mixture which mixed.

- a second layer is laminated on the first layer, and a third layer is further laminated as necessary.

- a multilayer interlayer film can be obtained.

- a multilayer intermediate film may be produced by coextrusion of the first layer and the second layer, and the multilayer may be produced by coextrusion of the first layer, the second layer, and the third layer.

- An intermediate film may be manufactured.

- the aldehyde is not particularly limited. In general, an aldehyde having 1 to 10 carbon atoms is preferably used as the aldehyde.

- Examples of the aldehyde having 1 to 10 carbon atoms include propionaldehyde, n-butyraldehyde, isobutyraldehyde, n-valeraldehyde, 2-ethylbutyraldehyde, n-hexylaldehyde, n-octylaldehyde, and n-nonylaldehyde.

- n-butyraldehyde n-hexylaldehyde or n-valeraldehyde is preferable, and n-butyraldehyde is more preferable.

- the said aldehyde only 1 type may be used and 2 or more types may be used together.

- a method of adding a crosslinking agent such as dialdehyde, a method of promoting an acetalization reaction between molecules by adding an excess of aldehyde, and a high degree of polymerization examples include a method of adding polyvinyl alcohol. Moreover, these methods may be used independently and 2 or more types may be used together.

- the catalyst is preferably an acid catalyst.

- the acid catalyst include nitric acid, hydrochloric acid, sulfuric acid, phosphoric acid, and paratoluenesulfonic acid.

- the above molecular weight in terms of polystyrene indicates the molecular weight in terms of polystyrene as measured by gel permeation chromatography (GPC).

- the proportion (%) of the high molecular weight component Y having a molecular weight y of 1 million or more in the polyvinyl acetal resin is a peak area detected by an RI detector when measuring the polystyrene-equivalent molecular weight by GPC of the polyvinyl acetal resin.

- the molecular weight y is calculated from the ratio of the area corresponding to the region of 1 million or more.

- the peak area means the area between the peak of the component to be measured and the baseline.

- the molecular weight in terms of polystyrene is measured, for example, as follows.

- GPC measurement of a polystyrene standard sample with a known molecular weight is performed.

- polystyrene standard samples (“Shodex Standard SM-105”, “Shodex Standard SH-75” manufactured by Showa Denko KK)

- An approximate straight line obtained by plotting the weight average molecular weight against the elution time indicated by the peak top of each standard sample peak is used as a calibration curve.

- the surface layer and the intermediate layer are peeled from the multi-layered intermediate film left for one month in a constant temperature and humidity chamber (humidity 30% ( ⁇ 3%), temperature 23 ° C.).

- the peeled intermediate layer is dissolved in tetrahydrofuran (THF) to prepare a 0.1% by weight solution.

- THF tetrahydrofuran

- an area corresponding to a region where the polystyrene-equivalent molecular weight of the polyvinyl acetal resin in the intermediate layer is 1 million or more is calculated.

- the value obtained by dividing the area corresponding to the region where the polystyrene conversion molecular weight of the polyvinyl acetal resin in the intermediate layer is 1 million or more by the peak area of the polyvinyl acetal resin in the intermediate layer as a percentage (%) the above polyvinyl acetal The ratio (%) of the high molecular weight component Y in which the molecular weight y is 1 million or more can be calculated.

- GPC Gel Permeation Chromatography

- the first layer contains a plasticizer (hereinafter sometimes referred to as plasticizer (1)).

- the second layer preferably contains a plasticizer (hereinafter sometimes referred to as a plasticizer (2)).

- the third layer preferably contains a plasticizer (hereinafter sometimes referred to as a plasticizer (3)).

- the plasticizers (1) to (3) contained in the first to third layers are not particularly limited. Conventionally known plasticizers can be used as the plasticizers (1) to (3). As the plasticizers (1) to (3), only one type may be used, or two or more types may be used in combination.

- plasticizers (1) to (3) examples include organic ester plasticizers such as monobasic organic acid esters and polybasic organic acid esters, and organic phosphate plasticizers and organic phosphorous acid plasticizers. A phosphoric acid plasticizer etc. are mentioned. Of these, organic ester plasticizers are preferred.

- the plasticizer is preferably a liquid plasticizer.

- the monobasic organic acid ester is not particularly limited.

- examples include esters.

- Examples of the glycol include triethylene glycol, tetraethylene glycol, and tripropylene glycol.

- Examples of the monobasic organic acid include butyric acid, isobutyric acid, caproic acid, 2-ethylbutyric acid, heptylic acid, n-octylic acid, 2-ethylhexylic acid, n-nonylic acid, and decylic acid.

- the polybasic organic acid ester is not particularly limited, and examples thereof include an ester compound of a polybasic organic acid and an alcohol having a linear or branched structure having 4 to 8 carbon atoms.

- Examples of the polybasic organic acid include adipic acid, sebacic acid, and azelaic acid.

- the organic ester plasticizer is not particularly limited, and triethylene glycol di-2-ethylbutyrate, triethylene glycol di-2-ethylhexanoate, triethylene glycol dicaprylate, triethylene glycol di-n- Octanoate, triethylene glycol di-n-heptanoate, tetraethylene glycol di-n-heptanoate, dibutyl sebacate, dioctyl azelate, dibutyl carbitol adipate, ethylene glycol di-2-ethylbutyrate, 1,3-propylene glycol di -2-Ethyl butyrate, 1,4-butylene glycol di-2-ethyl butyrate, diethylene glycol di-2-ethyl butyrate, diethylene glycol di-2-ethyl hexanoate, dipropylene glycol Rudi-2-ethylbutyrate, triethylene glycol di-2-ethylpentanoate, te

- the organic phosphate plasticizer is not particularly limited, and examples thereof include tributoxyethyl phosphate, isodecylphenyl phosphate, triisopropyl phosphate, and the like.

- the plasticizers (1) to (3) are preferably diester plasticizers represented by the following formula (1).

- R1 and R2 each represent an organic group having 3 to 10 carbon atoms

- R3 represents an ethylene group, an isopropylene group or an n-propylene group

- p represents an integer of 3 to 10

- R1 and R2 are each preferably an alkyl group having 5 to 10 carbon atoms.

- the plasticizer includes at least one of triethylene glycol di-2-ethylhexanoate (3GO), triethylene glycol dibutyrate (3GB), dibutyl adipate and triethylene glycol di-2-ethylbutyrate (3GH).

- One type is preferably included, and more preferably triethylene glycol di-2-ethylhexanoate or triethylene glycol dibutyrate.

- the content of the plasticizer (1) is preferably 25 to 60 parts by weight with respect to 100 parts by weight of the polyvinyl acetal resin (1).

- the content of the plasticizer (1) is more preferably 30 parts by weight or more, further preferably 40 parts by weight or more, more preferably 55 parts by weight or less, with respect to 100 parts by weight of the polyvinyl acetal resin (1). Preferably it is 50 weight part or less.

- the content of the plasticizer (1) is not less than the above lower limit, the flexibility of the interlayer film is increased and the handling of the interlayer film is facilitated.

- the content of the plasticizer (1) is not more than the above upper limit, the transparency of the interlayer film is further increased.

- the content of the plasticizer (2) is preferably 15 to 45 parts by weight with respect to 100 parts by weight of the polyvinyl acetal resin (2).

- the content of the plasticizer (3) is preferably 15 to 45 parts by weight with respect to 100 parts by weight of the polyvinyl acetal resin (3).

- the content of the plasticizers (2) and (3) is more preferably 20 parts by weight or more and more preferably 40 parts by weight or less with respect to 100 parts by weight of the polyvinyl acetal resins (2) and (3). .

- the content of the plasticizers (2) and (3) is not less than the above lower limit, the flexibility of the interlayer film is increased and the handling of the interlayer film is facilitated.

- the content of the plasticizers (2) and (3) is not more than the above upper limit, the penetration resistance of the interlayer film is further enhanced.

- the content of the plasticizer (2) with respect to 100 parts by weight of the polyvinyl acetal resin (2) in the second layer (hereinafter sometimes referred to as content (2)) is the same as that in the first layer.

- the content of the plasticizer (1) is preferably less than 100 parts by weight of the polyvinyl acetal resin (1) (hereinafter sometimes referred to as content (1)).

- the content of the plasticizer (3) (hereinafter sometimes referred to as content (3)) relative to 100 parts by weight of the polyvinyl acetal resin (3) in the third layer is the first layer.

- the content of the plasticizer (1) relative to 100 parts by weight of the polyvinyl acetal resin (1) is preferably less than the content of the plasticizer (1).

- a preferable lower limit of the difference between the content (1) and the contents (2) and (3) is 1 part by weight, a more preferable lower limit is 5 parts by weight, a still more preferable lower limit is 10 parts by weight, and a particularly preferable lower limit is 15 parts by weight. Weight parts, the most preferred lower limit is 20 parts by weight, the preferred upper limit is 40 parts by weight, the more preferred upper limit is 35 parts by weight, the still more preferred upper limit is 30 parts by weight, and the particularly preferred upper limit is 25 parts by weight.

- the difference between the content (1) and the contents (2) and (3) is not less than the above lower limit, the sound insulating property of the laminated glass is further enhanced, and if it is not more than the above upper limit, The penetration resistance is further increased.

- the difference between the content (1) and the contents (2) and (3) is a value obtained by subtracting the contents (2) and (3) from the content (1).

- the interlayer film for laminated glass according to the present invention includes an ultraviolet absorber, an antioxidant, a light stabilizer, a flame retardant, an antistatic agent, a pigment, a dye, an adhesive force adjusting agent, a moisture resistant agent, and a fluorescent whitening as necessary.

- Additives such as an agent and an infrared absorber may be included. As for these additives, only 1 type may be used and 2 or more types may be used together.

- the thickness of the first layer is preferably in the range of 0.02 to 1.8 mm.

- the thickness of the first layer is more preferably 0.05 mm or more, further preferably 0.08 mm or more, more preferably 0.5 mm or less, and still more preferably 0.15 mm or less.

- the thicknesses of the second and third layers are each preferably in the range of 0.1 mm to 1 mm.

- the thickness of the second and third layers is more preferably 0.2 mm or more, further preferably 0.3 mm or more, more preferably 0.5 mm or less, and further preferably 0.4 mm or less.

- the thickness of the second and third layers is not less than the above lower limit and not more than the above upper limit, the thickness of the intermediate film does not become too thick, and the sound insulating properties of the intermediate film and the laminated glass are further increased, and the plasticizer Bleed-out can be suppressed.

- the ratio of the thickness of the first layer to the thickness of the intermediate film ((thickness of the first layer) / (thickness of the intermediate film)) is small.

- the ratio in the intermediate film is 0.05 or more and 0.35 or less, even if the content of the plasticizer with respect to 100 parts by weight of the polyvinyl acetal resin in the first layer is large, it is combined.

- production of foaming in glass and the growth of foam are fully suppressed, and the sound-insulating property of a laminated glass can be improved further.

- the ratio ((the thickness of the first layer) / (the thickness of the intermediate film)) is preferably 0.06 or more, more preferably 0.07 or more, still more preferably 0.08 or more, and particularly preferably 0.1 or more. , Preferably 0.3 or less, more preferably 0.25 or less, still more preferably 0.2 or less, particularly preferably 0.15 or less.

- the thickness of the interlayer film for laminated glass according to the present invention is preferably in the range of 0.1 to 3 mm.

- the thickness of the intermediate film is more preferably 0.25 mm or more, and more preferably 1.5 mm or less.

- the thickness of the intermediate film is not less than the above lower limit, the penetration resistance of the intermediate film and the laminated glass is sufficiently high.

- the thickness of the interlayer film is not more than the above upper limit, the transparency of the interlayer film is further improved.

- the method for producing the interlayer film for laminated glass according to the present invention is not particularly limited.

- a conventionally known method can be used as a method for producing the intermediate film.

- the manufacturing method etc. which knead

- the method of kneading is not particularly limited. Examples of this method include a method using an extruder, a plastograph, a kneader, a Banbury mixer, a calendar roll, or the like. Especially, since it is suitable for continuous production, a method using an extruder is preferable, and a method using a twin screw extruder is more preferable.

- the interlayer film for laminated glass according to the present invention the first layer and the second and third layers are separately manufactured, and then the first layer and the second and third layers are laminated. A multilayer interlayer film may be obtained, or the interlayer may be obtained by laminating the first layer and the second and third layers by coextrusion.

- the second and third layers contain the same polyvinyl acetal resin, and the second and third layers contain the same polyvinyl acetal resin and It is more preferable that the same plasticizer is contained, and it is further preferable that the second and third layers are formed of the same resin composition.

- FIG. 2 An example of the laminated glass using the intermediate film for laminated glasses which concerns on one Embodiment of this invention is shown with sectional drawing.

- a laminated glass 11 shown in FIG. 2 includes an intermediate film 1 and first and second laminated glass constituent members 21 and 22.

- the intermediate film 1 is sandwiched between the first and second laminated glass constituent members 21 and 22.

- a first laminated glass constituting member 21 is laminated on the first surface 1 a of the intermediate film 1.

- a second laminated glass constituting member 22 is laminated on a second surface 1b opposite to the first surface 1a of the intermediate film 1.

- a first laminated glass constituting member 21 is laminated on the outer surface 3 a of the second layer 3.

- a second laminated glass constituent member 22 is laminated on the outer surface 4 a of the third layer 4.

- the laminated glass according to the present invention includes a first laminated glass constituent member, a second laminated glass constituent member, and an intermediate film sandwiched between the first and second laminated glass constituent members.

- the interlayer film for laminated glass of the present invention is used as the interlayer film.

- first and second laminated glass constituent members include glass plates and PET (polyethylene terephthalate) films.

- the laminated glass includes not only laminated glass in which an intermediate film is sandwiched between two glass plates, but also laminated glass in which an intermediate film is sandwiched between a glass plate and a PET film or the like.

- Laminated glass is a laminated body provided with a glass plate, and preferably at least one glass plate is used.

- the glass plate examples include inorganic glass and organic glass.

- the inorganic glass examples include float plate glass, heat ray absorbing plate glass, heat ray reflecting plate glass, polished plate glass, mold plate glass, mesh plate glass, wire plate glass, and green glass.

- the organic glass is a synthetic resin glass substituted for inorganic glass.

- the organic glass examples include polycarbonate plates and poly (meth) acrylic resin plates.

- the poly (meth) acrylic resin plate include a polymethyl (meth) acrylate plate.

- the thickness of the first and second laminated glass constituent members is not particularly limited, but is preferably in the range of 1 to 5 mm.

- the thickness of the glass plate is preferably in the range of 1 to 5 mm.

- the thickness of the PET film is preferably in the range of 0.03 to 0.5 mm.

- the method for producing the laminated glass is not particularly limited.

- the first and second laminated glass constituent members are sandwiched between the first and second laminated glass members, passed through a pressing roll, or put in a rubber bag and sucked under reduced pressure.

- the air remaining between the glass component and the intermediate film is degassed. Thereafter, it is pre-adhered at about 70 to 110 ° C. to obtain a laminate.

- the laminate is put in an autoclave or pressed and pressed at about 120 to 150 ° C. and a pressure of 1 to 1.5 MPa. In this way, a laminated glass can be obtained.

- the laminated glass can be used for automobiles, railway vehicles, aircraft, ships, buildings, and the like. Laminated glass can be used for other purposes.

- the intermediate film is preferably an architectural or vehicle intermediate film, and more preferably a vehicle intermediate film.

- the laminated glass is preferably laminated glass for buildings or vehicles, and more preferably laminated glass for vehicles.

- the interlayer film and the laminated glass are suitably used for an electric vehicle using an electric motor and a hybrid electric vehicle using an internal combustion engine and an electric motor.

- the laminated glass can be used for an automobile windshield, side glass, rear glass, roof glass, or the like.

- polyvinyl butyral resin polyvinyl acetal resin

- degree of butyralization degree of acetalization