WO2010098388A1 - 顎運動測定システム - Google Patents

顎運動測定システム Download PDFInfo

- Publication number

- WO2010098388A1 WO2010098388A1 PCT/JP2010/052974 JP2010052974W WO2010098388A1 WO 2010098388 A1 WO2010098388 A1 WO 2010098388A1 JP 2010052974 W JP2010052974 W JP 2010052974W WO 2010098388 A1 WO2010098388 A1 WO 2010098388A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- acceleration

- acceleration sensor

- jaw

- axis direction

- jaw movement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/68—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient

- A61B5/6801—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient specially adapted to be attached to or worn on the body surface

- A61B5/6813—Specially adapted to be attached to a specific body part

- A61B5/6814—Head

- A61B5/682—Mouth, e.g., oral cavity; tongue; Lips; Teeth

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/103—Measuring devices for testing the shape, pattern, colour, size or movement of the body or parts thereof, for diagnostic purposes

- A61B5/11—Measuring movement of the entire body or parts thereof, e.g. head or hand tremor or mobility of a limb

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/45—For evaluating or diagnosing the musculoskeletal system or teeth

- A61B5/4538—Evaluating a particular part of the muscoloskeletal system or a particular medical condition

- A61B5/4542—Evaluating the mouth, e.g. the jaw

- A61B5/4557—Evaluating bruxism

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B2562/00—Details of sensors; Constructional details of sensor housings or probes; Accessories for sensors

- A61B2562/02—Details of sensors specially adapted for in-vivo measurements

- A61B2562/0219—Inertial sensors, e.g. accelerometers, gyroscopes, tilt switches

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/45—For evaluating or diagnosing the musculoskeletal system or teeth

- A61B5/4528—Joints

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/68—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient

- A61B5/6801—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient specially adapted to be attached to or worn on the body surface

- A61B5/6813—Specially adapted to be attached to a specific body part

- A61B5/6814—Head

Definitions

- the present invention relates to a jaw movement measuring system.

- Jaw movement is classified into rotational movement of the mandibular head using the mandibular fossa as a bearing and sliding movement in which the mandibular head moves forward.

- a rotational motion mainly occurs.

- the mouth and jaw are greatly opened and closed by yawning or the like, not only rotational motion but also sliding motion occurs.

- jaw movement measuring devices that are widely used among some clinicians include “Nasohexa” manufactured by GC Corporation. Please refer to http://www.gcdental.co.jp/product/pdf/nasohekisa.pdf.

- This device allows a patient to wear a headgear and a device fixed to a dentition to measure three-dimensional movements such as mastication movements and opening / closing movements. That is, the mandibular movement is measured by measuring the relative position of the lower jaw.

- a device called “kinesiograph” is also widely used. In this method, the jaw movement is measured three-dimensionally by fixing the magnet to the dentition of the lower jaw and capturing the magnetism. In the current clinical setting, these two are typical devices for measuring jaw movement.

- JP 2008-18094 A JP200818094A1

- JP200818010A A1 JP200818010A1

- a commercially available jaw movement measuring device has a problem that it is expensive at several million yen and lacks versatility.

- the burden on the patient side is large, such as performing measurement with the headgear attached to the patient.

- the measurement conditions are severe, and it is necessary to prepare a dedicated room for measurement, and the clinics that can be introduced are limited.

- the jaw movement measuring device using the conventional acceleration sensor may pick up vibrations of the skin and the cord, and there is a problem that accurate measurement cannot be performed because there is no reproducibility in the mounting direction.

- an object of the present invention is to provide a jaw movement measuring system capable of accurately measuring jaw movements by attaching a simple detector.

- an object of the present invention is to provide a jaw movement measuring system that is inexpensive and highly versatile as compared with a commercially available jaw movement measuring apparatus.

- the invention according to claim 1 is an acceleration sensor that detects acceleration in three axial directions, a flexible wiring having one end connected to the acceleration sensor, the other end connected to the other end of the flexible wiring, and the Acceleration detector comprising at least an output terminal for outputting acceleration data in three-axis directions and a mounting portion for mounting the acceleration sensor on the chin portion of the lower jaw, and acquiring acceleration data according to jaw movement from the acceleration detector And a jaw motion measuring device that corrects an error caused by the acceleration sensor with respect to the acquired acceleration data and measures a jaw motion represented by an acceleration waveform.

- the acceleration sensor is arranged on the chin portion of the lower jaw so that the X-axis direction corresponds to the left-right direction, the Y-axis direction corresponds to the front-rear direction, and the Z-axis direction corresponds to the up-down direction.

- the jaw movement measuring apparatus is mounted, and the first correction for rotating the orthogonal coordinates of the acceleration sensor around the Z axis and the acceleration data in the Z axis direction are minimized so that the acceleration data in the X axis direction is minimized. So that the orthogonal coordinates of the acceleration sensor are rotated around the X axis so that the error caused by the displacement of the mounting position of the acceleration sensor is corrected with respect to the acquired acceleration data.

- the jaw movement measuring system according to claim 1, comprising a unit.

- the jaw movement measuring device further includes a display device and a display control device for controlling the display device, and the display control device includes acceleration data acquired from the acceleration detector, and the acceleration sensor.

- An axis selection unit that selects any one of the three axes and an angle setting unit that sets a rotation angle around the selected axis are displayed on the display device, and the misalignment correction unit is selected by the axis selection unit

- the first correction to minimize the acceleration data in the X-axis direction is performed by rotating the Cartesian coordinates of the acceleration sensor around the Z axis set by the angle set by the angle setting unit, and the selection by the axis selection unit

- the second correction for minimizing the acceleration data in the Z-axis direction is performed by rotating the orthogonal coordinates of the acceleration sensor around the set X-axis by an angle set by the angle setting unit.

- the acceleration data acquired from the acceleration detector so that a velocity waveform obtained by integrating the voltage signal in the Y-axis direction varies within a certain amplitude range.

- the jaw movement measuring system according to any one of claims 1 to 3, further comprising a base line setting unit that sets a base line to determine a zero point of an acceleration waveform.

- the display control device sets a baseline for the acceleration data in the Y-axis direction acquired from the acceleration detector and the acquired acceleration data.

- a second step in which the base line setting unit integrates acceleration data in the Y-axis direction based on the base line set by the base line setting unit, and the display control

- the apparatus repeatedly performs the third step of displaying the velocity waveform obtained by integrating the acceleration data in the Y-axis direction on the display device until the baseline is determined, and sets the baseline for the acceleration data.

- the invention according to claim 6 is the jaw movement measurement according to any one of claims 1 to 5, wherein the acceleration sensor is reduced in size and weight so as not to hang down the skin of the chin portion of the lower jaw. System.

- the flexibility is imparted and the weight is reduced to such an extent that the acceleration detected by the acceleration sensor is not changed. It is a jaw movement measuring system as described in.

- the invention of claim 8 is characterized in that the mounting portion holds the acceleration sensor and absorbs vibration of the skin, and an adhesive member that bonds the acceleration sensor to the chin portion of the lower jaw via the buffer member;

- the jaw movement measuring system according to any one of claims 1 to 7, further comprising:

- the zero point of the acceleration waveform can be determined by setting the base line in real time while viewing the display screen.

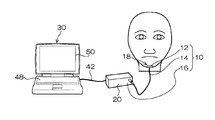

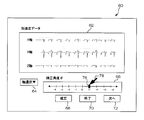

- FIG. 1 is a schematic diagram showing the configuration of a jaw movement measuring system according to an embodiment of the present invention.

- the jaw movement measuring system is connected to the acceleration detector 10, an interface device 20 that performs analog / digital conversion on the output of the acceleration detector 10, and the acceleration detector 10 via the interface device 20.

- a jaw movement measuring device 30 a jaw movement measuring device 30.

- the acceleration detector 10 includes an acceleration sensor 12 that detects acceleration in three axial directions, a flexible wiring 14 having one end connected to the acceleration sensor 12, and a connector 16 connected to the other end of the flexible wiring 14.

- the connector 16 is connected to the interface device 20.

- the acceleration sensor 12 is attached to the chin portion 18 of the lower jaw using an attachment member described later.

- the acceleration detector 10 detects a voltage signal (hereinafter, appropriately referred to as acceleration or acceleration data) corresponding to the acceleration in the three-axis directions by the acceleration sensor 12.

- the detected voltage signal is input to the interface device 20 via the flexible wiring 14 and the connector 16 and converted from an analog signal to a digital signal.

- the acceleration data converted into the digital signal is input to the jaw movement measuring device 30.

- the jaw movement measuring device 30 acquires acceleration data corresponding to the jaw movement from the acceleration detector 10, corrects an error caused by the acceleration sensor 12 with respect to the acquired acceleration data, and moves the jaw movement represented by an acceleration waveform. Measure.

- FIG. 2 is a schematic diagram showing the configuration of the peripheral portion of the acceleration sensor.

- the acceleration sensor 12 a small and lightweight three-axis acceleration sensor having a size of about 5 mm ⁇ 5 mm is preferably used.

- the small and lightweight acceleration sensor 12 does not hang down the skin of the lower chin portion 18, thereby suppressing the generation of noise due to vibration of the acceleration sensor 12.

- a chip removed from the sensor board of a commercially available acceleration sensor (3-axis acceleration sensor “AS-3ACC” manufactured by Asakusa Giken Co., Ltd.) is used as the acceleration sensor 12.

- the flexible wiring 14 a flexible wiring that is so flexible that it can be bent and is lightweight is preferably used.

- the flexible wiring 14 having high flexibility and light weight does not fluctuate the voltage signal detected by the acceleration sensor 12.

- the flexible wiring 14 in which a plurality of thin wires 14A are bundled is used according to the number of lead terminals of the acceleration sensor 12. In FIG. 2, six thin wires 14A are bundled.

- Each of the thin wires 14 ⁇ / b> A is an electric wire covered with an insulating coating, and the coating at the end is removed and soldered directly to the lead terminal of the acceleration sensor 12.

- a 0.05 mm diameter electric wire covered with expanded PTFE made by Junko Co., Ltd. is used as the fine wire 14A.

- PTFE is a tetrafluoroethylene resin, so-called Teflon (registered trademark).

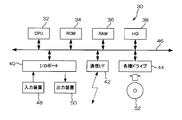

- FIG. 3 is a block diagram showing the configuration of the jaw movement measuring apparatus.

- the jaw movement measuring device 30 is composed of, for example, a computer in which a jaw movement measuring program is installed and its peripheral devices.

- the jaw movement measuring device 30 is a ROM (Read CPU) that stores various programs such as a CPU (Central Processing Unit) 32 and an OS (Operating Systems) that control the entire device and perform various operations. Only Memory) 34, RAM (Random Access Memory) 36 used as a work area when executing the program, hard disk (HD) 38 for storing various information, input / output (I / O) port 40, communication interface (I / F) ) 42 and various drives 44. These units are connected to each other by a bus 46.

- ROM Read CPU

- RAM Random Access Memory

- An input device 48 such as a keyboard and a mouse and a display device 50 such as a display are connected to the I / O port 40.

- the communication I / F 42 exchanges various information with the outside through a wired or wireless communication line.

- the communication I / F 42 is wired to the interface device 20 via a cable, and a digital signal (acceleration data) corresponding to the voltage signal output from the acceleration detector 10 is input.

- the various drives 44 are devices that read data from and write data to a computer-readable portable recording medium 52 such as a flexible disk, a magneto-optical disk, and a CD-ROM.

- the jaw movement measurement program is read from the portable recording medium 52 and stored in the ROM 34 or the hard disk 38. Alternatively, it is transmitted via the Internet, received by the communication I / F 42, and stored in the ROM 34 or the hard disk 38.

- the hard disk 38 has a database area (not shown) for storing various databases, and stores various medical databases.

- the CPU 32 reads the program from the ROM 34 or the hard disk 38 and loads it into the RAM 36.

- the RAM 36 is used as a work area, and the loaded program is executed while interacting with the user using the input device 48 and the display device 50.

- the processing routine of the jaw movement measurement program will be described later.

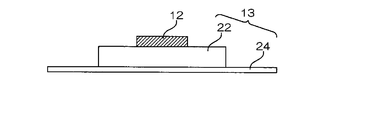

- FIG. 4A is a laminated cross-sectional view showing the structure of the mounting member.

- FIG. 4B is a schematic diagram illustrating a state in which the acceleration sensor is mounted on the chin portion 18 by the mounting member. Here, illustration of the flexible wiring 14 and the like is omitted.

- the acceleration detector 10 includes an attachment member 13 for attaching the acceleration sensor 12 to the chin portion 18 of the lower jaw.

- the mounting member 13 includes a buffer member 22 that holds the acceleration sensor 12 and absorbs vibrations of the skin, and an adhesive member 24 that bonds the acceleration sensor 12 to the lower jaw portion 18 via the buffer member 22.

- the sheet-like adhesive member 24 has a surface opposite to the surface on which the buffer member 22 is provided as an adhesive surface.

- a double-sided adhesive tape or the like having a thickness of about 1 mm can be used.

- the adhesive member 24 for example, a medical adhesive tape that is excellent in adhesion to the skin, such as used for electrocardiogram measurement, can be used.

- the mounting member 13 is mounted such that the adhesive surface of the adhesive member 24 adheres to the skin on the surface of the chin portion 18.

- the chin portion 18 is the tip of the lower jaw and has a curved shape, but the vibration of the skin is absorbed by interposing the thick buffer member 22 between the acceleration sensor 12 and the adhesive member 24. In addition, the bending of the acceleration sensor 12 is prevented.

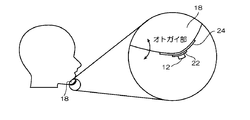

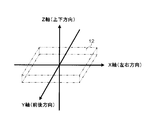

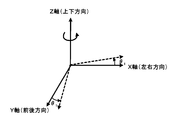

- FIG. 5 is a diagram showing the relationship between the orthogonal coordinate system of the acceleration sensor and the direction of jaw movement.

- the acceleration sensor 12 is a three-axis acceleration sensor that detects acceleration in the three-axis directions of the X-axis, Y-axis, and Z-axis of the orthogonal coordinate system.

- the lower jaw portion 18 constituting a part of the human body has a distinction between the left-right direction, the front-rear direction, and the up-down direction.

- the acceleration sensor 12 is attached to the lower jaw portion 18 so that the X-axis direction corresponds to the left-right direction, the Y-axis direction corresponds to the front-rear direction, and the Z-axis direction corresponds to the up-down direction. More specifically, as will be described later with reference to the drawings, the Y-axis direction corresponds to the tangential direction (front-rear direction) of the rotational movement around the rotational axis of the mandibular head, and the Z-axis direction corresponds to the rotational axis, the acceleration sensor 12, Corresponds to the extending direction (vertical direction) of the straight line connecting the two (see FIG. 12).

- FIG. 6A, FIG. 6B, and FIG. 6C are diagrams showing the left-right direction, the front-rear direction, and the up-down direction with respect to the chin portion of the lower jaw.

- the acceleration sensor 12 is mounted along the tangent line of the chin portion 18. When viewed from the side, the acceleration sensor 12 is disposed obliquely. Each of the directions indicated by the arrows corresponds to the left-right direction, the front-rear direction, and the up-down direction with respect to the chin portion of the lower jaw. If this is the correct mounting position and the acceleration sensor 12 is mounted at a position shifted from this position, as described below, “position shift correction” for correcting an error due to the mounting position shift is necessary.

- FIG. 16 is a flowchart showing the processing routine of the jaw movement measurement program.

- step 100 the jaw movement measuring device 30 acquires acceleration data at the time of tapping.

- step 102 the correction angle setting screen 60 shown in FIG. 7 is displayed on the display device 50 of the jaw movement measuring device 30.

- the correction angle setting screen 60 includes an acceleration data display unit 62, an axis selection unit 64, and an angle setting unit 66 that display acceleration data in the X-axis direction, the Y-axis direction, and the Z-axis direction. It is displayed.

- the axis selection unit 64 is configured to be able to select any of the X axis, the Y axis, and the Z axis.

- the angle setting unit 66 is configured to be able to set the correction angle ⁇ by moving the cursor 76 with a pointer 78 on, for example, a scale from ⁇ 4 to +4.

- a confirmation button 68, an end button 70, and a “next” button 72 for instructing selection of the next axis are displayed.

- the operator looks at the acceleration data display unit 62 and first confirms acceleration data in the X-axis direction. If it is determined that the amplitude of the acceleration data in the X-axis direction is large, the Z-axis is selected by operating the axis selector 64 so that the amplitude of the acceleration data in the X-axis direction is minimized (substantially zero) and setting the correction angle theta 1 about the Z-axis, to select the enter button 68.

- the jaw motion measuring device 30 confirms the X axis direction, Y based on the set correction angle in the next step 108.

- a correction value of acceleration data in the axial direction and the Z-axis direction is calculated.

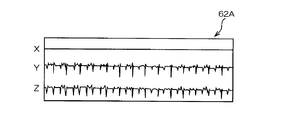

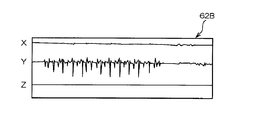

- the corrected acceleration data is displayed on the acceleration data display unit 62 of the correction angle setting screen 60. As shown in FIG. 8, the data screen 62A is displayed in which the amplitude of acceleration data in the X-axis direction is substantially zero and the amplitude of acceleration data in the Y-axis direction and the Z-axis direction is increased.

- FIG. 9A and 9B are diagrams for explaining the significance of the first correction.

- the first correction when viewed from the acceleration sensor 12 side, the first correction is the acceleration sensor 12 that is mounted obliquely with respect to the left-right direction in the chin portion 18, and the X-axis direction is the left-right direction. It corresponds to the state rotated so that it may become parallel to.

- the first correction corresponds to a state in which the orthogonal coordinates are rotated around the Z axis by an angle ⁇ 1 when viewed from the orthogonal coordinates side.

- the jaw movement measuring device 30 returns to step 102 and displays the correction angle setting screen 60 shown in FIG. 7 on the display device 50 of the jaw movement measuring device 30. To display.

- the operator operates the axis selection unit 64 to select the X axis so that the amplitude of the acceleration data in the Z axis direction is minimized (substantially zero), sets the correction angle ⁇ 2 around the X axis,

- the confirm button 68 is selected.

- the Y-axis direction corresponds to the tangential direction (front-rear direction) of the rotational motion around the rotational axis of the mandibular head

- the Z-axis direction is the extending direction of the straight line connecting the rotational axis and the acceleration sensor 12. (Vertical direction) (see FIG. 12).

- the jaw movement measuring device 30 calculates the correction value of the acceleration data in the X-axis direction, the Y-axis direction, and the Z-axis direction based on the set correction angle in the same manner as in steps 104 to 110, and after the correction.

- the acceleration data is displayed on the acceleration data display unit 62 of the correction angle setting screen 60. As shown in FIG. 10, a data screen 62B is displayed in which the amplitude of the acceleration data in the Z-axis direction is reduced and the amplitude of the acceleration data in the Y-axis direction is increased.

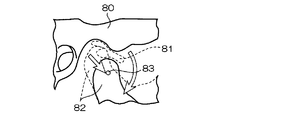

- FIG. 12A and FIG. 12B are explanatory diagrams for explaining the relationship between the jaw movement and the mounting position of the acceleration sensor.

- the jaw movement is “rotation movement” around the rotation axis 83 of the mandibular head 82 with the mandible 80 as a bearing, and the mandibular head 82 moves forward relative to the mandible 80. It is classified as “sliding movement”.

- a cartilage 81 is interposed between the mandibular fossa 80 and the mandibular head 82.

- the Y-axis direction corresponds to the tangential direction (front-rear direction) of the rotational movement around the rotation axis of the mandibular head

- the Z-axis direction corresponds to the rotation axis and the acceleration sensor. 12 is attached to the chin portion 18 of the lower jaw so as to correspond to the extending direction (vertical direction) of the straight line connecting 12.

- the “tapping motion” that opens and closes the mouth and jaws at a substantially constant interval is basically the rotational motion shown in FIG. 12A, and has the most back-and-forth movement (corresponding to the Y-axis direction) with respect to the chin portion of the lower jaw. (See FIG. 6B). Therefore, in the present embodiment, the tapping motion is measured, and the amplitude of the acceleration data in the X-axis direction and the Z-axis direction is decreased (in other words, the amplitude of the acceleration data in the Y-axis direction is increased). ) Correction is performed.

- FIG. 11A and 11B are diagrams for explaining the significance of the second correction.

- the second correction when viewed from the acceleration sensor 12 side, the second correction is the acceleration sensor 12 mounted in the chin portion 18 with the Z-axis direction being inclined with respect to the vertical direction. It is equivalent to the state rotated about the X-axis direction (left-right direction) so that it may become parallel to.

- the second correction corresponds to a state in which the orthogonal coordinates are rotated around the X axis by an angle ⁇ 2 when viewed from the orthogonal coordinates side.

- the operator looks at the acceleration data display unit 62 on which the corrected data screen 62B is displayed, and confirms the acceleration data in the X-axis direction, the Y-axis direction, and the Z-axis direction.

- the end button 70 is operated to end the positional deviation correction.

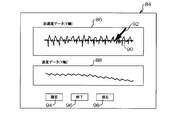

- step 114 the jaw movement measuring device 30 proceeds to step 116 and displays the baseline setting screen 84 shown in FIG. 13 on the display device 50 of the jaw movement measuring device 30.

- the baseline setting screen 84 displays an acceleration data display unit 86 that displays acceleration data in the Y-axis direction, and a speed data display unit 88 that displays speed data obtained by integrating the acceleration data in the Y-axis direction. Yes.

- a base line setting line 90 for setting the position of the base line is displayed as shown by a dotted line.

- the base line setting line 90 is configured to be moved up and down by a pointer 92 so that the position of the base line can be set.

- the base line setting screen 84 includes a confirmation button 94, an end button 96, and a “return” button 98 for instructing to return to the setting of the base line.

- the operator moves the baseline setting line 90 to set it at a predetermined position, and selects the confirm button 94.

- the jaw movement measuring device 30 integrates the acceleration data in the Y-axis direction based on the set baseline in the next step 120, and the velocity in the Y-axis direction. Calculate the data.

- the speed data after setting the base line is displayed on the speed data display unit 88 of the base line setting screen 84.

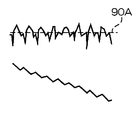

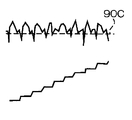

- FIG. 14A, 14B, and 14C are diagrams showing the relationship between the position of the base line and the velocity waveform.

- the acceleration data is obtained as a voltage signal proportional to the acceleration, and the zero point is not fixed. Therefore, even if this is integrated to obtain the speed, a correct value cannot be obtained.

- FIG. 14A when the position of the base line is high, the velocity waveform falls to the right.

- FIG. 14C when the position of the base line is low, the velocity waveform is at the upper right. This indicates that the base line position (that is, the zero point of the acceleration waveform) is inappropriate.

- FIG. 14B if the velocity waveform becomes flat so as to fluctuate within a certain amplitude range, the position of the base line is set appropriately.

- the operator looks at the display of the speed data display section 88, selects the “return” button 98 until the position of the base line becomes appropriate, and repeatedly sets the base line.

- the “end” button 96 is selected to fix the base line.

- step 124 When the input of the “return” instruction is confirmed in step 124, the jaw movement measuring apparatus 30 returns to step 116 and displays the baseline setting screen 84, and the set baseline is the same as in steps 118 to 122. Based on the above, the velocity data in the Y-axis direction is calculated, and the velocity data after setting the baseline is displayed. On the other hand, when the input of the end instruction is confirmed in step 126, the process proceeds to step 128.

- step 128 as shown in FIG. 15, the jaw movement measurement screen 100 including the acceleration data 102 displayed based on the last set baseline is displayed. That is, the acceleration waveforms in the X-axis direction, the Y-axis direction, and the Z-axis direction are displayed together with the zero point (base line) of the acceleration waveform.

- This is a screen showing accurate measurement results of jaw movement.

- the jaw movement measurement screen 100 is displayed and the jaw movement measurement program processing routine is terminated.

- a simple detector equipped with a three-axis acceleration sensor is attached, and at the same time, a “misalignment correction” or an acceleration waveform for correcting an error caused by a misalignment of the mounting position of the acceleration sensor. It is possible to accurately measure jaw movements by performing “baseline setting” to determine the zero point of the jaw.

- a detector including a three-axis acceleration sensor is used as a small and lightweight acceleration sensor, a flexible and lightweight flexible wiring, the acceleration sensor is held and the vibration of the skin is absorbed.

- the buffer member or the like it is possible to suppress the generation of noise due to the vibration of the acceleration sensor.

- the acceleration sensor is wired to the jaw movement measuring device configured by a computer or the like.

- the acceleration sensor can perform wireless communication. Can also be used. In this case, a radio signal from the acceleration sensor is input to the communication I / F of the jaw movement measuring device.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Medical Informatics (AREA)

- Animal Behavior & Ethology (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Biophysics (AREA)

- Pathology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Dentistry (AREA)

- Molecular Biology (AREA)

- Surgery (AREA)

- Physics & Mathematics (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Physiology (AREA)

- Physical Education & Sports Medicine (AREA)

- Orthopedic Medicine & Surgery (AREA)

- Rheumatology (AREA)

- Measurement Of The Respiration, Hearing Ability, Form, And Blood Characteristics Of Living Organisms (AREA)

- Dental Tools And Instruments Or Auxiliary Dental Instruments (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/203,272 US8544322B2 (en) | 2009-02-27 | 2010-02-25 | Jaw motion measuring system |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009047257A JP5350016B2 (ja) | 2009-02-27 | 2009-02-27 | 顎運動測定システム |

| JP2009-047257 | 2009-02-27 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2010098388A1 true WO2010098388A1 (ja) | 2010-09-02 |

Family

ID=42665592

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2010/052974 Ceased WO2010098388A1 (ja) | 2009-02-27 | 2010-02-25 | 顎運動測定システム |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US8544322B2 (enExample) |

| JP (1) | JP5350016B2 (enExample) |

| WO (1) | WO2010098388A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20230130056A1 (en) * | 2021-10-27 | 2023-04-27 | Bussert Medical, Inc | Anti-clenching training device |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6298145B2 (ja) | 2013-03-15 | 2018-03-20 | アルフレッド イー. マン ファウンデーション フォー サイエンティフィック リサーチ | 高速のターンオン時間をもつ電流検出複数出力電流刺激装置 |

| US9780596B2 (en) | 2013-07-29 | 2017-10-03 | Alfred E. Mann Foundation For Scientific Research | Microprocessor controlled class E driver |

| US9855423B2 (en) | 2014-08-15 | 2018-01-02 | Axonics Modulation Technologies, Inc. | Systems and methods for neurostimulation electrode configurations based on neural localization |

| JP6795490B2 (ja) | 2014-08-15 | 2020-12-02 | アクソニクス モジュレーション テクノロジーズ インコーポレイテッド | 試験的神経刺激のための外部パルス発生器デバイスおよび関連方法 |

| WO2016025910A1 (en) | 2014-08-15 | 2016-02-18 | Axonics Modulation Technologies, Inc. | Implantable lead affixation structure for nerve stimulation to alleviate bladder dysfunction and other indications |

| AU2015301401B2 (en) | 2014-08-15 | 2020-01-16 | Axonics Modulation Technologies, Inc. | Electromyographic lead positioning and stimulation titration in a nerve stimulation system for treatment of overactive bladder |

| JP6779860B2 (ja) | 2014-08-15 | 2020-11-04 | アクソニクス モジュレーション テクノロジーズ インコーポレイテッド | 埋込可能神経刺激装置と共に用いるための統合型筋電図臨床医用プログラム装置 |

| BR112017005246B1 (pt) * | 2014-09-15 | 2023-12-12 | 3M Innovative Properties Company | Dispositivo para monitorar indicadores de disfunção |

| AU2015342962A1 (en) | 2014-11-06 | 2017-06-29 | Shane MATT | Three dimensional imaging of the motion of teeth and jaws |

| JP6775951B2 (ja) * | 2014-12-27 | 2020-10-28 | 三栄源エフ・エフ・アイ株式会社 | 飲食物の嚥下感覚の評価方法 |

| EP3242721B1 (en) | 2015-01-09 | 2019-09-18 | Axonics Modulation Technologies, Inc. | Attachment devices and associated methods of use with a nerve stimulation charging device |

| CA2973192C (en) | 2015-01-09 | 2023-04-04 | Axonics Modulation Technologies, Inc. | Improved antenna and methods of use for an implantable nerve stimulator |

| CA2973190A1 (en) | 2015-01-09 | 2016-07-14 | Axonics Modulation Technologies, Inc. | Patient remote and associated methods of use with a nerve stimulation system |

| EP3319683A4 (en) | 2015-07-10 | 2018-12-26 | Axonics Modulation Technologies, Inc. | Implantable nerve stimulator having internal electronics without asic and methods of use |

| CA3012828C (en) | 2016-01-29 | 2024-04-30 | Axonics Modulation Technologies, Inc. | Methods and systems for frequency adjustment to optimize charging of implantable neurostimulator |

| CA3241636A1 (en) | 2016-02-12 | 2017-08-17 | Axonics, Inc. | External pulse generator device and associated methods for trial nerve stimulation |

| US20170265801A1 (en) * | 2016-03-15 | 2017-09-21 | Aalok Nital Patwa | Bruxism Detection System With Chin-Mounted Accelerometer Sensor |

| CN111741789B (zh) | 2018-02-22 | 2024-07-05 | 艾克索尼克斯股份有限公司 | 用于试验神经刺激的神经刺激引线和使用方法 |

| US11642537B2 (en) | 2019-03-11 | 2023-05-09 | Axonics, Inc. | Charging device with off-center coil |

| US11848090B2 (en) | 2019-05-24 | 2023-12-19 | Axonics, Inc. | Trainer for a neurostimulator programmer and associated methods of use with a neurostimulation system |

| US11439829B2 (en) | 2019-05-24 | 2022-09-13 | Axonics, Inc. | Clinician programmer methods and systems for maintaining target operating temperatures |

| TWI702941B (zh) * | 2019-11-28 | 2020-09-01 | 長庚醫療財團法人林口長庚紀念醫院 | 下頜張合力量與施力穩定狀態檢測裝置 |

| US12420103B1 (en) | 2020-08-20 | 2025-09-23 | Axonics, Inc. | Neurostimulation leads with reduced current leakage |

| CN114287361B (zh) * | 2022-01-20 | 2022-12-23 | 中国农业科学院农业信息研究所 | 一种牲畜行为监测分析系统及方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6361121A (ja) * | 1986-09-01 | 1988-03-17 | Canon Inc | 振動検出装置用出力補正装置 |

| JPH10124245A (ja) * | 1996-10-18 | 1998-05-15 | Ricoh Co Ltd | ペン型入力装置 |

| JP2008307207A (ja) * | 2007-06-14 | 2008-12-25 | Advanced Telecommunication Research Institute International | 動作計測装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10124254A (ja) | 1996-10-21 | 1998-05-15 | Nisshin Koki Kk | 光学式マウスシステム |

| JP5077522B2 (ja) | 2006-07-12 | 2012-11-21 | 株式会社東京技研 | 摂食機能測定装置 |

| JP5082127B2 (ja) | 2006-07-13 | 2012-11-28 | 株式会社東京技研 | 口腔運動測定装置 |

-

2009

- 2009-02-27 JP JP2009047257A patent/JP5350016B2/ja not_active Expired - Fee Related

-

2010

- 2010-02-25 US US13/203,272 patent/US8544322B2/en not_active Expired - Fee Related

- 2010-02-25 WO PCT/JP2010/052974 patent/WO2010098388A1/ja not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6361121A (ja) * | 1986-09-01 | 1988-03-17 | Canon Inc | 振動検出装置用出力補正装置 |

| JPH10124245A (ja) * | 1996-10-18 | 1998-05-15 | Ricoh Co Ltd | ペン型入力装置 |

| JP2008307207A (ja) * | 2007-06-14 | 2008-12-25 | Advanced Telecommunication Research Institute International | 動作計測装置 |

Non-Patent Citations (2)

| Title |

|---|

| IVICA PELIVAN ET AL.: "Tri-axial Accelerometric Analysis of Dynamic Patterns of Mandibular Movements", INTERNATIONAL POSTER JOURNAL OF DENTISTRY AND ORAL MEDICINE, vol. 2, no. 2, 2007, Retrieved from the Internet <URL:http://ipj.quintessenz.de/index.php?content=awards&doc=poster&select=360> [retrieved on 20100527] * |

| KUNITAKA ISAJI ET AL.: "Shika Ryoiki ni Okeru Kasokudo Sensor no Oyo", CHIIKI IRYO, 2002, pages 604 - 606 * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20230130056A1 (en) * | 2021-10-27 | 2023-04-27 | Bussert Medical, Inc | Anti-clenching training device |

Also Published As

| Publication number | Publication date |

|---|---|

| US20120048013A1 (en) | 2012-03-01 |

| JP2010200856A (ja) | 2010-09-16 |

| JP5350016B2 (ja) | 2013-11-27 |

| US8544322B2 (en) | 2013-10-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5350016B2 (ja) | 顎運動測定システム | |

| JP6112300B2 (ja) | マスタースレーブロボットの制御装置及び制御方法、マスタースレーブロボット、並びに、制御プログラム | |

| Barlow et al. | A new head-mounted lip-jaw movement transduction system for the study of motor speech disorders | |

| JP2010200856A5 (enExample) | ||

| JP2018196580A (ja) | 歯列矯正支援方法および歯列矯正支援システム | |

| WO2007021007A1 (ja) | 歯の咬み合わせ修正支援装置、プログラム、及び記録媒体 | |

| CN102188291A (zh) | 牙科诊断系统和牙科治疗系统 | |

| KR20170004401A (ko) | 치아 부착용 웨어러블 장치 및 치아 고정용 감지장치 | |

| CN108066034B (zh) | 牙齿受力测量装置及方法 | |

| Mostashiri et al. | A novel spatial mandibular motion-capture system based on planar fiducial markers | |

| CN117119997A (zh) | 用于口腔护理设备的口腔用具 | |

| Shenoy et al. | Design and validation of an IMU based full hand kinematic measurement system | |

| WO2015122466A1 (ja) | コンピュータ、コンピュータで実行される方法、及びコンピュータプログラム、並びにフェイスボウ | |

| JP5273432B2 (ja) | コントローラ | |

| CN112790888B (zh) | 下颌运动捕捉系统、捕捉方法以及模拟方法 | |

| JP2016041176A (ja) | 筋トーヌス計測装置 | |

| JP3855038B2 (ja) | 剛体運動測定方法、剛体運動測定装置、剛体運動測定プログラム、顎運動測定方法、顎運動測定装置および顎運動測定プログラム | |

| EP3682847A1 (en) | Occlusal pressure analysis device, occlusal pressure analysis program, and occlusal pressure analysis method | |

| CN214511395U (zh) | 下颌运动捕捉系统 | |

| Farook et al. | A 3D printed electronic wearable device to generate vertical, horizontal and phono-articulatory jaw movement parameters: A concept implementation | |

| TWI616193B (zh) | 口腔咬合路徑量測裝置、用於感測一口腔咬合運動的方法、以及用於感測一口腔運動的裝置 | |

| JP5363181B2 (ja) | 歯牙模型、歯列模型、顎模型、頭部模型、医療用実習装置 | |

| Hayashi et al. | Comparison of the finite helical axis and the rectangular coordinate system in representing orthodontic tooth movement | |

| WO2022176943A1 (ja) | 口腔内カメラシステム及び画像表示方法 | |

| JP2022041340A (ja) | 歯科用下顎運動測定器用生体標点測定指示具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 10746267 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE1 | Request for preliminary examination filed after expiration of 19th month from priority date (pct application filed from 20040101) | ||

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13203272 Country of ref document: US |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 10746267 Country of ref document: EP Kind code of ref document: A1 |