WO2010058530A1 - 摺動部材およびその製造方法 - Google Patents

摺動部材およびその製造方法 Download PDFInfo

- Publication number

- WO2010058530A1 WO2010058530A1 PCT/JP2009/005896 JP2009005896W WO2010058530A1 WO 2010058530 A1 WO2010058530 A1 WO 2010058530A1 JP 2009005896 W JP2009005896 W JP 2009005896W WO 2010058530 A1 WO2010058530 A1 WO 2010058530A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- carbon

- lubricating film

- sliding

- sliding member

- fullerene

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/02—Parts of sliding-contact bearings

- F16C33/04—Brasses; Bushes; Linings

- F16C33/043—Sliding surface consisting mainly of ceramics, cermets or hard carbon, e.g. diamond like carbon [DLC]

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/05—Preparation or purification of carbon not covered by groups C01B32/15, C01B32/20, C01B32/25, C01B32/30

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M103/00—Lubricating compositions characterised by the base-material being an inorganic material

- C10M103/02—Carbon; Graphite

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0605—Carbon

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/26—Deposition of carbon only

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/02—Parts of sliding-contact bearings

- F16C33/04—Brasses; Bushes; Linings

- F16C33/06—Sliding surface mainly made of metal

- F16C33/10—Construction relative to lubrication

- F16C33/1095—Construction relative to lubrication with solids as lubricant, e.g. dry coatings, powder

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M2201/00—Inorganic compounds or elements as ingredients in lubricant compositions

- C10M2201/04—Elements

- C10M2201/041—Carbon; Graphite; Carbon black

- C10M2201/0413—Carbon; Graphite; Carbon black used as base material

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/06—Oiliness; Film-strength; Anti-wear; Resistance to extreme pressure

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/12—Inhibition of corrosion, e.g. anti-rust agents or anti-corrosives

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2040/00—Specified use or application for which the lubricating composition is intended

- C10N2040/25—Internal-combustion engines

Definitions

- the present invention relates to a sliding member having a sliding surface that slides on a mating member and a method of manufacturing the same, and more particularly to improvement of the sliding surface for reducing friction with the mating member.

- a lubricating film is formed on the sliding surface that slides with the other member, and the carbon-based molecule having a hollow structure capable of rolling is formed on the lubricating film as a single substance or a group of single substances It is characterized by being contained.

- the sliding member of the present invention when local solid contact occurs at the sliding interface due to the application of high surface pressure between the members, microscopic abrasion occurs on the sliding surface of the sliding member.

- carbon-based molecules having a rollable hollow structure are contained as a single substance or an aggregate of the single substance. Therefore, carbon-based molecules are supplied to the sliding interface by being exposed from the lubricating film by the above-mentioned microscopic wear and part of which is released therefrom. Since such carbon-based molecules have a rollable hollow structure, they act as molecular level ball bearings at the sliding interface.

- the sliding member of the present invention can use various configurations.

- the lubricating film is preferably a DLC film.

- DLC has low friction of its material itself, high hardness (good wear resistance), high chemical stability (good corrosion resistance), weak adhesion (good seizure resistance) Since it is), the sliding characteristic becomes good.

- DLC is composed of harmless carbon and hydrogen as main components, it can satisfy environmental compatibility, and the amount of the raw material (hydrocarbon gas or graphite) is large and stable.

- At least one of fullerene, carbon nanotube, adamantane, a hydrogen compound of fullerene, a hydrogen compound of carbon nanotube, and a hydrogen compound of adamantane can be used.

- fullerene C 60 fullerene can be used.

- the sliding member of the present invention When the sliding member of the present invention is applied to, for example, an engine, it can be used as a sliding member in a cylinder bore or a piston.

- the mating member When a cylinder bore is used as the sliding member, the mating member is a piston, and when using a piston as the sliding member, the mating member is a cylinder bore.

- the lubricating film of the present invention may be applied not only to the sliding member but also to the other member.

- the method of manufacturing a sliding member according to the present invention includes a lubricating film forming step of forming a lubricating film on a sliding surface sliding on a mating member by plasma treatment of a raw material of the lubricating film, and in the lubricating film forming step, A carbon-based molecule gas containing at least one of a carbon-based molecule having a movable hollow structure and a hydrogenated carbon-based molecule is introduced into the raw material plasma to ionize the carbon-based molecule gas, and At the time of deposition of the raw material on the sliding surface, it is characterized in that the ionized carbon-based molecular gas is taken into the lubricating film to be molecularized.

- the manufacturing method of the sliding member of the present invention can obtain the same effect as the sliding member of the present invention.

- carbon-based molecules having a rollable hollow structure are supplied from the lubricating film to the sliding interface due to microscopic wear with the other member, and there Act as a ball bearing.

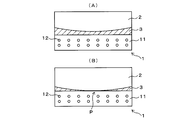

- FIG. 1 represents the state near the sliding interface of the sliding member of FIG. 1 sliding with the other member

- (A) is a fluid lubrication state where lubricating oil intervenes at the sliding interface

- (B) is a local solid at the sliding interface

- FIG. (A) represents the state near the sliding interface of the sliding member of FIG. 1 sliding with the other member

- (A) is a fluid lubrication state where lubricating oil intervenes at the sliding interface

- (B) is a local solid at the sliding interface

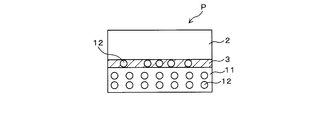

- FIG. 1 is a side sectional view showing a schematic configuration of a sliding member 1 according to an embodiment of the present invention.

- the sliding member 1 includes a main body 10, and a lubricating film 11 is formed on the surface of the main body 10. Inside the lubricating film 11, carbon-based molecules 12 having a rollable hollow structure are contained in a dispersed manner.

- the lubricating film 11 is a DLC film made of, for example, Diamond-Like Carbon (DLC), and its film thickness is, for example, 3 ⁇ m.

- the lubricating film 11 is not limited to the DLC film, and various modifications are possible.

- a dry coating film made of CrN, TiCN, TiAlN or the like, or a plating film of Ni or the like may be used.

- DLC has low friction of the material itself, high hardness (good wear resistance), high chemical stability (good corrosion resistance) and weak adhesion (good seizure resistance). Moreover, since DLC is composed of harmless carbon and hydrogen as main components, it can satisfy environmental compatibility, and the amount of the raw material (hydrocarbon gas or graphite) is large and stable. Specifically, DLC has lower friction than CrN having the same corrosion resistance as compared to the other materials. In addition, DLC is superior to Ni plating in any of the above characteristics.

- DLC is preferable because it has various merits as a lubricating film as compared with the other materials described above.

- fullerene is used as the carbon-based molecule 12

- the DLC film acts as a nanoscale gear (nanogear) at the contact point with the fullerene, Contribute to low friction.

- the carbon-based molecule 12 is released from the lubricating film 11 to the sliding surface at the time of local solid contact with the partner member (not shown) of the lubricating film 11, and acts as a molecular bearing there.

- the carbon-based molecule 12 may be present as a single molecule as shown in FIG. 6 (A), or as shown in FIG. 6 (B), the carbon-based molecule 12 is present as an aggregate composed of plural molecules. It may be In FIG. 6, the molecule of the carbon-based molecule 12 is shown in a simplified manner for the convenience of illustration.

- the carbon-based molecule 12 contained in the lubricating film 11 is an allotrope of carbon synthesized by a large number of carbon atoms, and is a spherical molecule (eg, C-like molecule having no anisotropy in the rolling direction with respect to external load) 60 fullerene) or its hydrogen compound is most desirable.

- it may be a pseudo-spherical body having a closed structure (for example, higher fullerenes such as C 70 , C 74 and C 76 , adamantane (Adamantane, C 10 H 16 ), or a hydrogen compound thereof).

- they may be molecules (for example, carbon nanotubes) having a circular cross section in at least one direction or hydrogen compounds thereof.

- C 60 fullerene is spherical with a diameter of about 0.7 nm and has high hardness, so the spherical shape is maintained even under high load conditions. Further, since the liberation of the carbon-based molecule 12 is due to a part of the surface of the lubricating film 11, the deposition in the lubricating oil between the lubricating film 11 and the other member is prevented, and As the lubricating oil passes through the filter, its clogging by the carbon-based molecules 12 is prevented.

- the carbon-based molecule 12 preferably has a spherical shape like C 60 fullerene as described above from the viewpoint of ease of rolling, but higher-order fullerenes such as C 70 fullerene, carbon nanotubes, adamantane (Adamantane)

- C 70 fullerene fullerene

- carbon nanotubes carbon nanotubes

- adamantane Adamantane

- the diameter in the rolling direction is larger than the above value, the rolling operation becomes difficult.

- adamantane since adamantane is smaller than fullerene, it can enter into the clearance of the sliding interface where it is difficult for fullerenes to enter, whereby the sliding characteristics are improved.

- the carbon-based molecules 12 do not form a spherical shape (for example, when forming a cylindrical shape like a carbon nanotube), the carbon nanotube rolls in the sliding direction when released from the surface (sliding surface) of the lubricating film 11 It is desirable to be easy. In order to realize this, it is preferable to orient carbon nanotubes in advance when the lubricating film 11 is formed.

- the carbon-based molecule 12 When configured as described above, it is important for the carbon-based molecule 12 to have rollability and a nanoscale size in order to function as a molecular bearing.

- a carbon-based molecule gas containing at least one of a carbon-based molecule and a hydrogenated carbon-based molecule is introduced into the plasma of the raw material, the carbon-based molecule gas is dehydrogenated Ionize.

- the raw material plasma collides with the surface of the main body 10, it is deposited there to form the lubricating film 11.

- the ionized carbon-based molecular gas also collides with the surface of the main body 10, it is taken into the lubricating film 11, and carbon is received therein to be molecularized.

- the ionized carbon-based molecule in the high-speed collision to the main body 10 to which the voltage is applied, the ionized carbon-based molecule rapidly loses energy by the collision. At this time, since the ionized carbon-based molecules and hydrogen ions are to be stabilized, the ionized carbon-based molecules receive hydrogen ions, and as a result, some of the carbon-based molecules exist as hydrogenated fullerenes. is there.

- the lubricating film 11 is formed on the surface of the main body 10 of the sliding member 1, and the carbon-based molecules 12 are dispersed in the lubricating film 11.

- CVD method CVD method or PVD method.

- the main body 10 of the sliding member 1 is set in the vacuum furnace of the CVD apparatus.

- DC pulse voltage is applied to the main body 10.

- a reducing gas for example, argon gas

- a raw material gas of the lubricating film 11 in the case of DLC film formation, a hydrocarbon gas (for example, butane, acetylene or the like) and a carbon molecule ball partially hydrogenated (for example, fullerene) are introduced into a vacuum furnace.

- a hydrocarbon gas for example, butane, acetylene or the like

- a carbon molecule ball partially hydrogenated for example, fullerene

- the amount of gas inflow, pressure, temperature, voltage value of bias, pulse duty value (ratio of one cycle of rectangular wave to the width of high pulse side) are always adjusted within a range where the optimum plasma state can be continued.

- the lubricating film 11 is formed on the surface of the main body 10, and the carbon-based molecules 12 are dispersed in the lubricating film 11.

- the main body 10 of the sliding member 1 is set in the vacuum furnace of the PVD apparatus.

- a DC pulse voltage is applied to the main body 10.

- a reducing gas for example, argon gas

- argon gas for example, argon gas

- the cleanliness of the surface of the main body 10 is improved by the ion bombardment effect.

- a solid material for example, graphite

- a carbon-based molecule for example, fullerene

- FIG. 2 shows the state in the vicinity of the sliding interface of the sliding member 1 sliding with the mating member 2

- A shows a fluid lubrication state in which the lubricating oil 3 intervenes in the sliding interface

- FIG. 6 is a side sectional view showing a schematic configuration of boundary lubrication state in which local solid contact has occurred.

- FIG. 3 is a partially enlarged view of a portion (indicated by a point P) where the local solid contact has occurred in FIG. 2 (B).

- the lubricating oil 3 is interposed between the members 1 and 2, and the carbon-based molecules 12 present in the lubricating film 11 cause the sliding member 1 to slide. Does not contribute.

- the boundary lubrication state shown in FIG. 2 (B) is brought about by the application of high surface pressure between the members 1 and 2, local solid contact occurs at the sliding interface and the sliding surface of the sliding member There is microscopic wear.

- carbon-based molecules 12 having a rollable hollow structure are contained as a single substance or an aggregate of the single substance. Therefore, the carbon-based molecules 12 are exposed from the lubricating film 11 by the microscopic abrasion, and part of the carbon-based molecules 12 are supplied therefrom to the sliding interface. Since such carbon-based molecules 12 have a rollable hollow structure, they act as molecular level ball bearings at the sliding interface, as shown in FIG. In this case, when at least one carbon-based molecule 12 is present, local friction can be reduced compared to when it is not present. In particular, in this case, since the carbon-based molecule 12 can move in the lubricating oil 3, it can enter a necessary place, whereby the reduction effect can be effectively obtained.

- the friction can be significantly reduced at the sliding interface, the energy loss due to the friction can be reduced.

- Fuel consumption of an internal combustion engine such as an engine can be improved.

- the above effect can be obtained by the simple configuration in which the lubricating film 11 of the sliding member 1 contains the carbon-based molecule 12 having a hollow structure capable of rolling, mass production becomes possible, and the manufacturing cost Can be reduced.

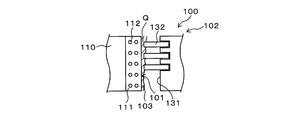

- FIG. 4 is a view showing a part of a schematic configuration of an internal combustion engine 100 (for example, an engine) using a cylinder bore 101 as a specific application example of the sliding member 1.

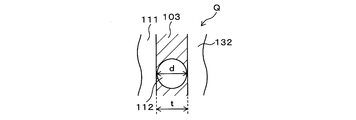

- FIG. 5 is a partially enlarged view of a point (indicated by point Q) at which local solid contact has occurred in internal combustion engine 100.

- the piston 102 slides along the inner circumferential surface (sliding surface) inside the cylinder bore 101.

- the piston 102 has a skirt portion (not shown) formed at the lower portion, a land portion 131 formed at the upper portion, and a ring portion 132 provided in a groove between the lands 131.

- the cylinder bore 101 corresponds to the sliding member 1

- a part of the cylinder block 110 corresponds to the main body 10

- the piston ring 132 corresponds to the mating member.

- a lubricating film 111 is formed on the inner peripheral surface of the cylinder bore 101, and carbon-based molecules 112 having a rollable structure are dispersedly contained in the lubricating film 111.

- the lubricant film 111 and the carbon-based molecule 112 correspond to the lubricant film 11 and the carbon-based molecule 12 and have the same configuration as them.

- the diameter d of the carbon-based molecule 112 (for example, the diameter of a spherical shape such as fullerene, for example, the diameter of the circular bottom of a cylindrical shape such as a nanotube) has a lubricating oil

- the aspect set smaller than the minimum oil film thickness t of 103 is preferable from the viewpoint of air tightness.

- the piston 102 rotates when sliding in the vertical direction with respect to the cylinder bore 101, in the embodiment using the carbon nanotube, the orientation direction of the carbon nanotube is aligned in the sliding direction according to the sliding.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Inorganic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Physical Vapour Deposition (AREA)

- Lubricants (AREA)

- Carbon And Carbon Compounds (AREA)

- Chemical Vapour Deposition (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/127,689 US20110249920A1 (en) | 2008-11-19 | 2009-11-06 | Sliding member and process for producing the same |

| EP09827311A EP2361881A4 (en) | 2008-11-19 | 2009-11-06 | SLIDING ELEMENT AND MANUFACTURING METHOD THEREFOR |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008295399A JP2010120806A (ja) | 2008-11-19 | 2008-11-19 | 摺動部材およびその製造方法 |

| JP2008-295399 | 2008-11-19 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2010058530A1 true WO2010058530A1 (ja) | 2010-05-27 |

Family

ID=42197973

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2009/005896 Ceased WO2010058530A1 (ja) | 2008-11-19 | 2009-11-06 | 摺動部材およびその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20110249920A1 (enExample) |

| EP (1) | EP2361881A4 (enExample) |

| JP (1) | JP2010120806A (enExample) |

| WO (1) | WO2010058530A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103982548A (zh) * | 2014-05-19 | 2014-08-13 | 金迪荣 | 双金属平衡轴承 |

| CN104061231A (zh) * | 2014-05-18 | 2014-09-24 | 金迪荣 | 汽车双金属平衡轴承 |

| US9926968B2 (en) * | 2013-08-21 | 2018-03-27 | Mag Ias Gmbh | Sliding surface |

| CN112940824A (zh) * | 2021-02-06 | 2021-06-11 | 中国科学院兰州化学物理研究所 | 一种润滑油添加剂的应用及制备方法、高温润滑油及制备方法和应用 |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5669042B2 (ja) * | 2011-02-10 | 2015-02-12 | 勝義 近藤 | 摺動部材およびその製造方法 |

| FR2985739B1 (fr) * | 2012-01-12 | 2014-02-28 | Centre Nat Rech Scient | Renforcement de l'adhesion ou de la fixation de nanotubes de carbone a la surface d'un materiau par une couche de carbone |

| DE102013202121A1 (de) * | 2013-02-08 | 2014-08-14 | Ks Gleitlager Gmbh | Metall/Kunststoff-Gleitlagerverbundwerkstoff und hieraus hergestelltes Gleitlagerelement |

| GB2513867A (en) * | 2013-05-07 | 2014-11-12 | Mahle Int Gmbh | Sliding engine component |

| CN103982549A (zh) * | 2014-05-19 | 2014-08-13 | 金迪荣 | 多层耐磨平衡轴承 |

| CN103982546A (zh) * | 2014-05-20 | 2014-08-13 | 金迪荣 | 多层耐磨汽车平衡轴承 |

| CN113151785B (zh) * | 2020-01-22 | 2022-02-08 | 中国工程物理研究院激光聚变研究中心 | 一种薄膜制备组件、薄膜制备方法及其应用 |

| US20250229464A1 (en) * | 2021-10-13 | 2025-07-17 | Mitsubishi Corporation | Structure, sliding material, and manufacturing method thereof |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001261318A (ja) * | 2000-03-23 | 2001-09-26 | Kobe Steel Ltd | ダイヤモンドライクカーボン硬質多層膜および耐摩耗性、耐摺動性に優れた部材 |

| JP2003062799A (ja) | 2001-08-27 | 2003-03-05 | Japan Science & Technology Corp | 炭素ボール分子または炭素チューブ分子による潤滑システム |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5374463A (en) * | 1991-10-22 | 1994-12-20 | International Business Machines Corporation | Magnetic recording disk having a contiguous fullerene film and a protective overcoat |

| US7132936B1 (en) * | 1999-04-20 | 2006-11-07 | Peter Norton | Angular rate sensor |

| JP5168744B2 (ja) * | 2000-07-31 | 2013-03-27 | オイレス工業株式会社 | 潤滑被覆用組成物および該組成物を被覆してなる摺動部材 |

| DE10254368B3 (de) * | 2002-11-21 | 2004-06-17 | Daimlerchrysler Ag | Geschmiertes Gleitsystem und Verfahren zur Verminderung der Reibung |

| WO2005100465A1 (en) * | 2004-04-15 | 2005-10-27 | Showa Denko K. K. | Carbon-based electrically conducting filler, composition and use thereof |

| US20070249507A1 (en) * | 2006-04-24 | 2007-10-25 | Nissan Motor Co., Ltd. | Hard carbon film and hard carbon film sliding member |

| JP2009133408A (ja) * | 2007-11-30 | 2009-06-18 | Nsk Ltd | 転がり摺動部材およびこれを用いた転動装置ならびにプーリ装置 |

| JP2009167512A (ja) * | 2008-01-21 | 2009-07-30 | Kobe Steel Ltd | 摺動部品用ダイヤモンドライクカーボン皮膜およびその製造方法 |

-

2008

- 2008-11-19 JP JP2008295399A patent/JP2010120806A/ja active Pending

-

2009

- 2009-11-06 EP EP09827311A patent/EP2361881A4/en not_active Withdrawn

- 2009-11-06 US US13/127,689 patent/US20110249920A1/en not_active Abandoned

- 2009-11-06 WO PCT/JP2009/005896 patent/WO2010058530A1/ja not_active Ceased

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001261318A (ja) * | 2000-03-23 | 2001-09-26 | Kobe Steel Ltd | ダイヤモンドライクカーボン硬質多層膜および耐摩耗性、耐摺動性に優れた部材 |

| JP2003062799A (ja) | 2001-08-27 | 2003-03-05 | Japan Science & Technology Corp | 炭素ボール分子または炭素チューブ分子による潤滑システム |

Non-Patent Citations (3)

| Title |

|---|

| MASATO BAN: "Nano Kozoka ni yoru DLC-maku no Taikyusei Kojo", THE JOURNAL OF THE SURFACE FINISHING SOCIETY OF JAPAN, vol. 58, no. 1, 1 January 2007 (2007-01-01), pages 23 - 27, XP008164380 * |

| S. SHIMIZU ET AL.: "Development of nanoparticle dispersive diamond- like carbon film", SYNOPSES OF THE INTERNATIONAL TRIBOLOGY CONFERENCE KOBE, 2 June 2005 (2005-06-02), pages 379 * |

| See also references of EP2361881A4 |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9926968B2 (en) * | 2013-08-21 | 2018-03-27 | Mag Ias Gmbh | Sliding surface |

| CN104061231A (zh) * | 2014-05-18 | 2014-09-24 | 金迪荣 | 汽车双金属平衡轴承 |

| CN103982548A (zh) * | 2014-05-19 | 2014-08-13 | 金迪荣 | 双金属平衡轴承 |

| CN112940824A (zh) * | 2021-02-06 | 2021-06-11 | 中国科学院兰州化学物理研究所 | 一种润滑油添加剂的应用及制备方法、高温润滑油及制备方法和应用 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2361881A4 (en) | 2012-05-09 |

| US20110249920A1 (en) | 2011-10-13 |

| EP2361881A1 (en) | 2011-08-31 |

| JP2010120806A (ja) | 2010-06-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2010058530A1 (ja) | 摺動部材およびその製造方法 | |

| Wu et al. | Carbon solid lubricants: role of different dimensions | |

| Yin et al. | A new pathway for superlubricity in a multilayered MoS2–Ag film under cryogenic environment | |

| Wang et al. | Nanocomposite microstructure and environment self-adapted tribological properties of highly hard graphite-like film | |

| Jang et al. | Friction properties of thick tetrahedral amorphous carbon coating with different surface defects under dry contact conditions | |

| JP2010120806A5 (enExample) | ||

| US11047478B2 (en) | Piston ring and method of manufacture | |

| JP2024506966A (ja) | 低摩擦コーティング | |

| Mandal et al. | Lubricated sliding wear mechanism of chromium-doped graphite-like carbon coating | |

| Shi et al. | Tribological properties and bearing application of Mo-based films in space environment | |

| CN1967000A (zh) | 摩擦系统及具有这种摩擦系统的用于控制流体的阀 | |

| Oohira | Characteristics and Applications of DLC films | |

| CN106605043B (zh) | 滚子式摇臂 | |

| JP2018053307A (ja) | 摺動部材およびその製造方法 | |

| Piazzoni et al. | Tribological coatings for complex mechanical elements produced by supersonic cluster beam deposition of metal dichalcogenide nanoparticles | |

| Ma et al. | The low-temperature ion sulfurizing technology and its applications | |

| JP5077629B2 (ja) | 硬質炭素被膜 | |

| CN104727876A (zh) | 凸轮从动辊装置 | |

| JP4816940B2 (ja) | 硬質炭素被膜 | |

| KR101285724B1 (ko) | 마이크로 및 나노 표면구조를 가진 내마모 박막 및 이의 형성 방법 | |

| JP4968619B2 (ja) | 硬質炭素被膜 | |

| US20250051682A1 (en) | System for generating high-lubricity substances for lubrication of a mechanical device | |

| Haider | MoSx Coatings by Closed-Field Magnetron Sputtering | |

| Erdemir | Low-friction materials and coatings | |

| JP4997404B2 (ja) | トライボマイクロプラズマコーティング方法及び同コーティング装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 09827311 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13127689 Country of ref document: US |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2009827311 Country of ref document: EP |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |